Fabrication process of semi-solid aluminum alloy scroll disk by radial forging strain induction method

A radial forging and strain-induced technology, which is applied in the field of semi-solid aluminum alloy scrolls prepared by radial forging strain-induced method, can solve the problem that large-scale semi-solid billets cannot be produced in large quantities, large plastic deformation and large forming force. , corrosion of mechanical stirrers, etc., to achieve the effects of good microstructure, reduced plastic forming force, and strong continuous production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below by taking an aluminum alloy rod of Φ150 mm as an example in conjunction with the accompanying drawings.

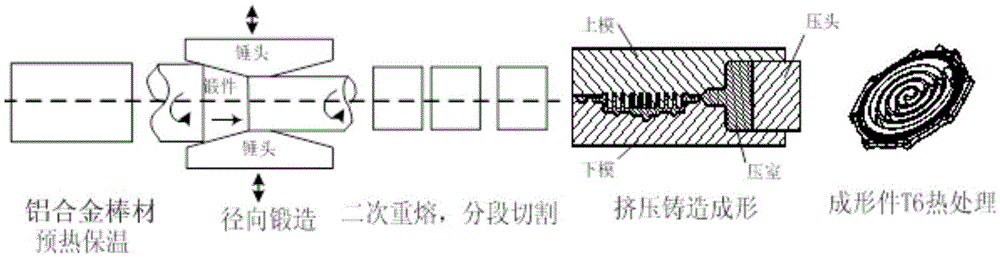

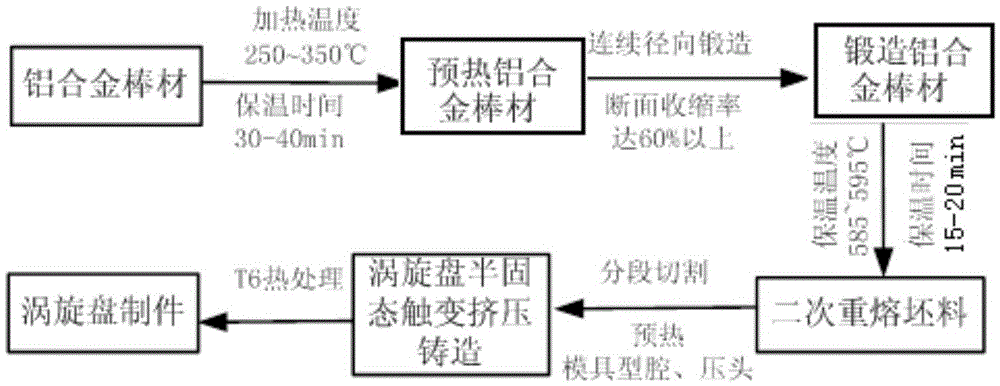

[0019] refer to figure 1 and figure 2 , a radial forging strain-induced method for preparing a semi-solid aluminum alloy scroll, comprising the following steps:

[0020] 1) Preheat the Φ150 aluminum alloy bar, heat the aluminum alloy bar to 250-350°C with the furnace, and then carry out heat preservation treatment for 60-80 minutes to ensure that the entire billet is heated through;

[0021] 2) Carry out radial forging on the aluminum alloy bar, take out the preheated aluminum alloy bar through the manipulator of the radial forging machine and feed it in the axial direction by clamping and rotating, and the four hammers of the radial forging machine are symmetrically distributed around the blank Head, carry out high-frequency reciprocating forging on the blank in the radial direction, so that the bla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com