Patents

Literature

48results about How to "Strong continuous production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

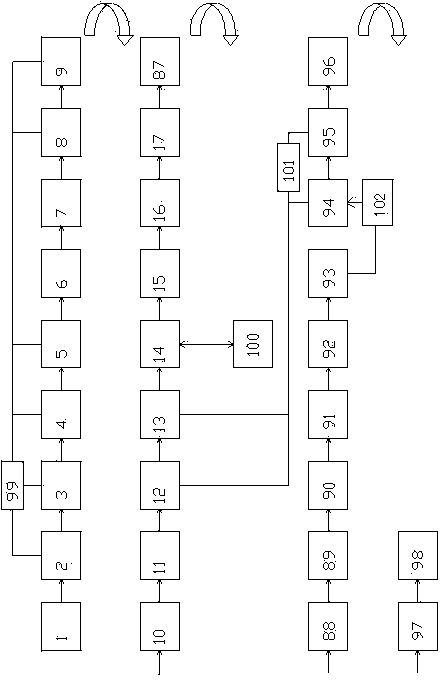

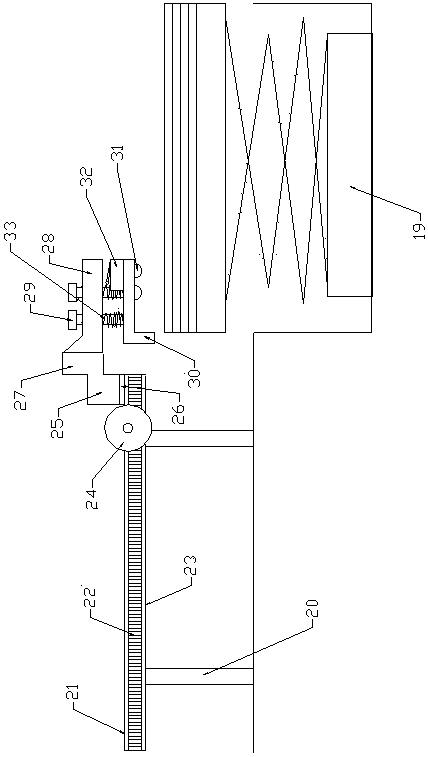

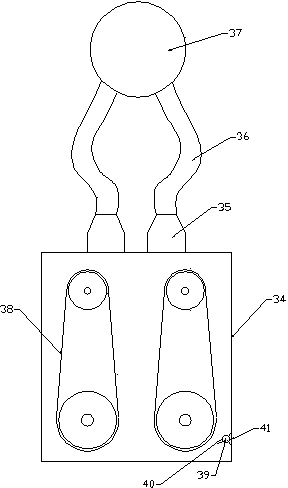

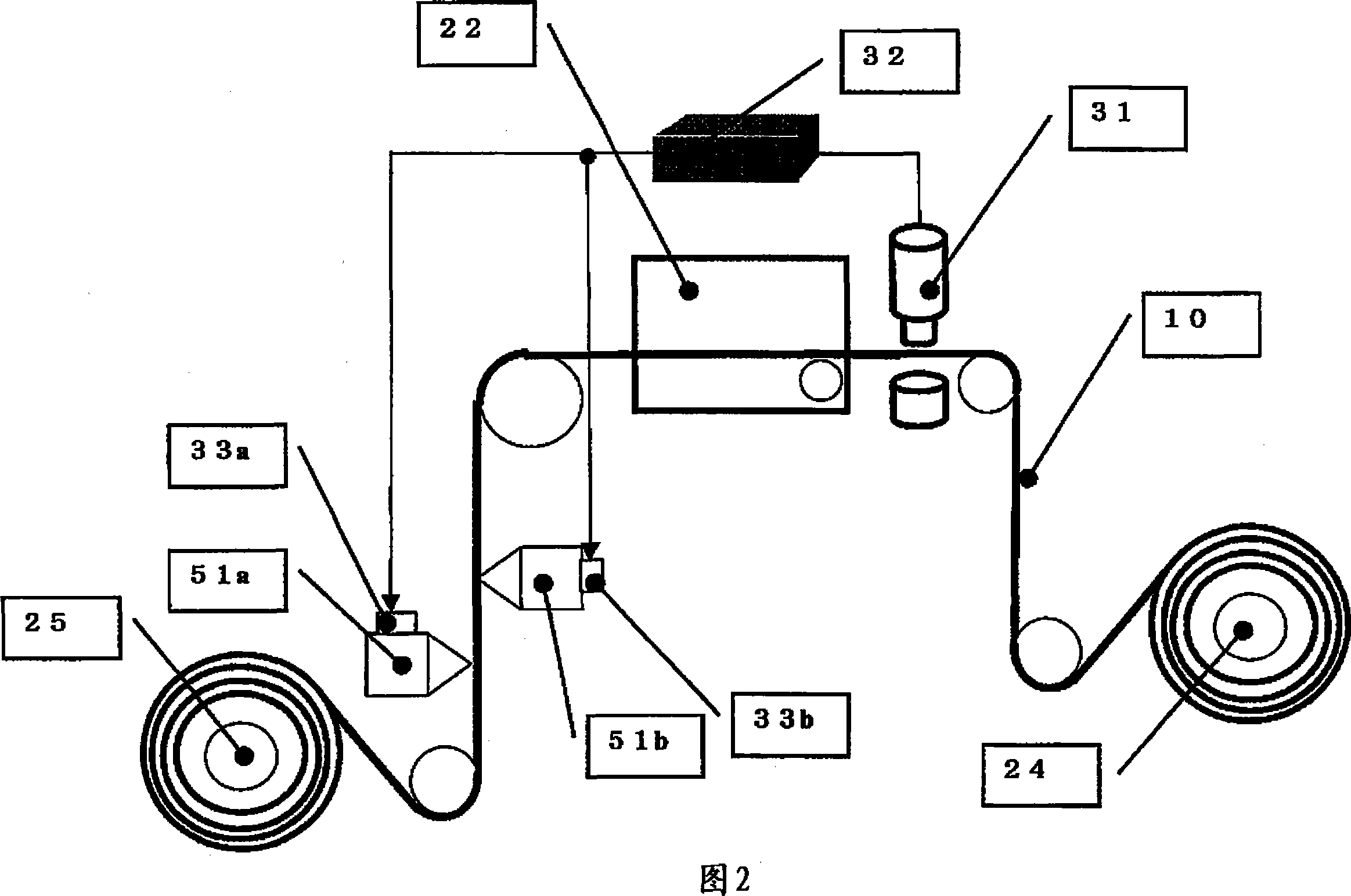

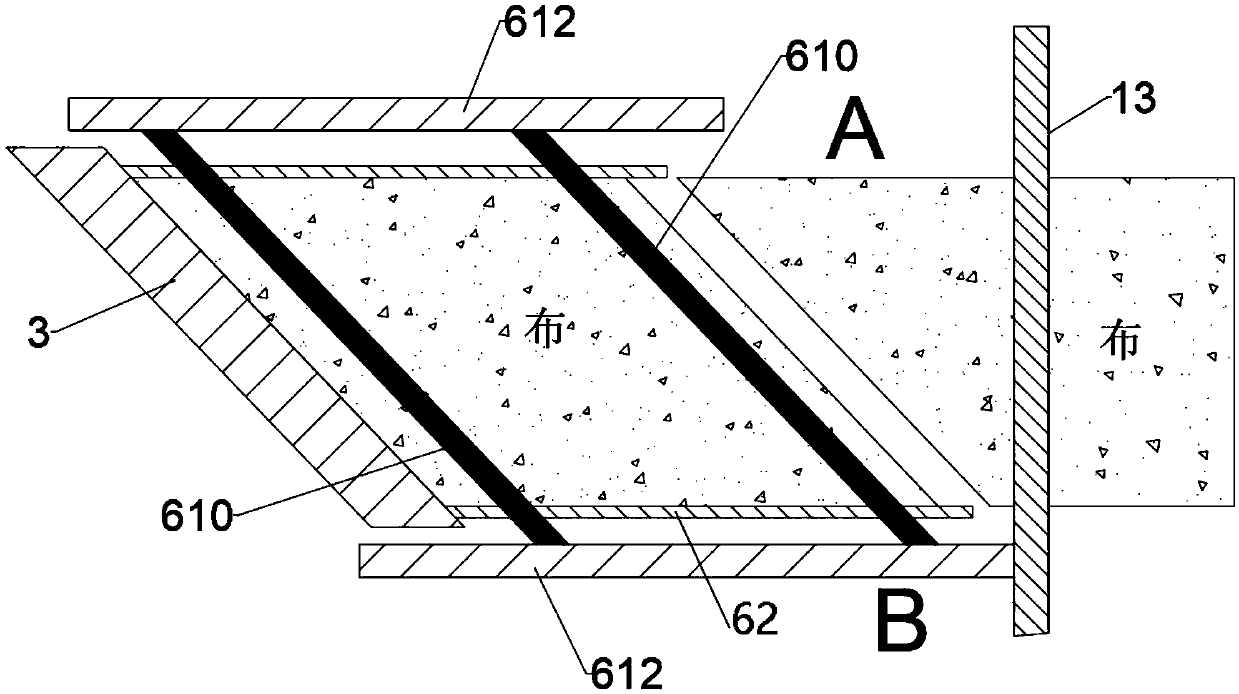

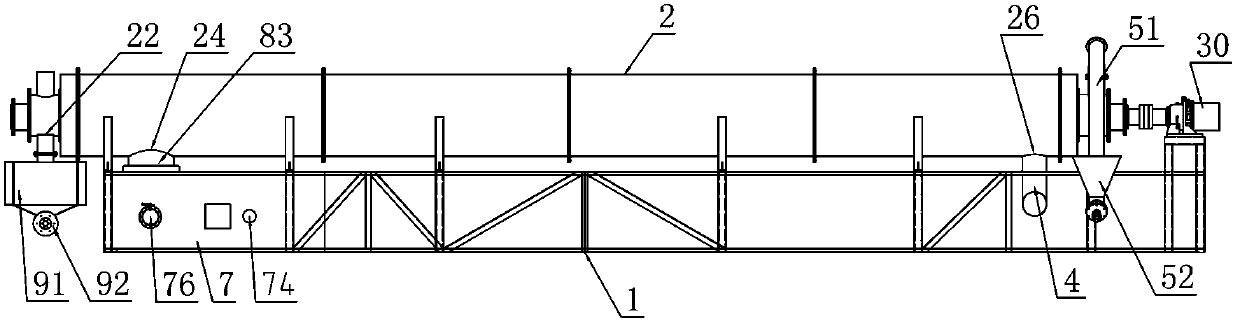

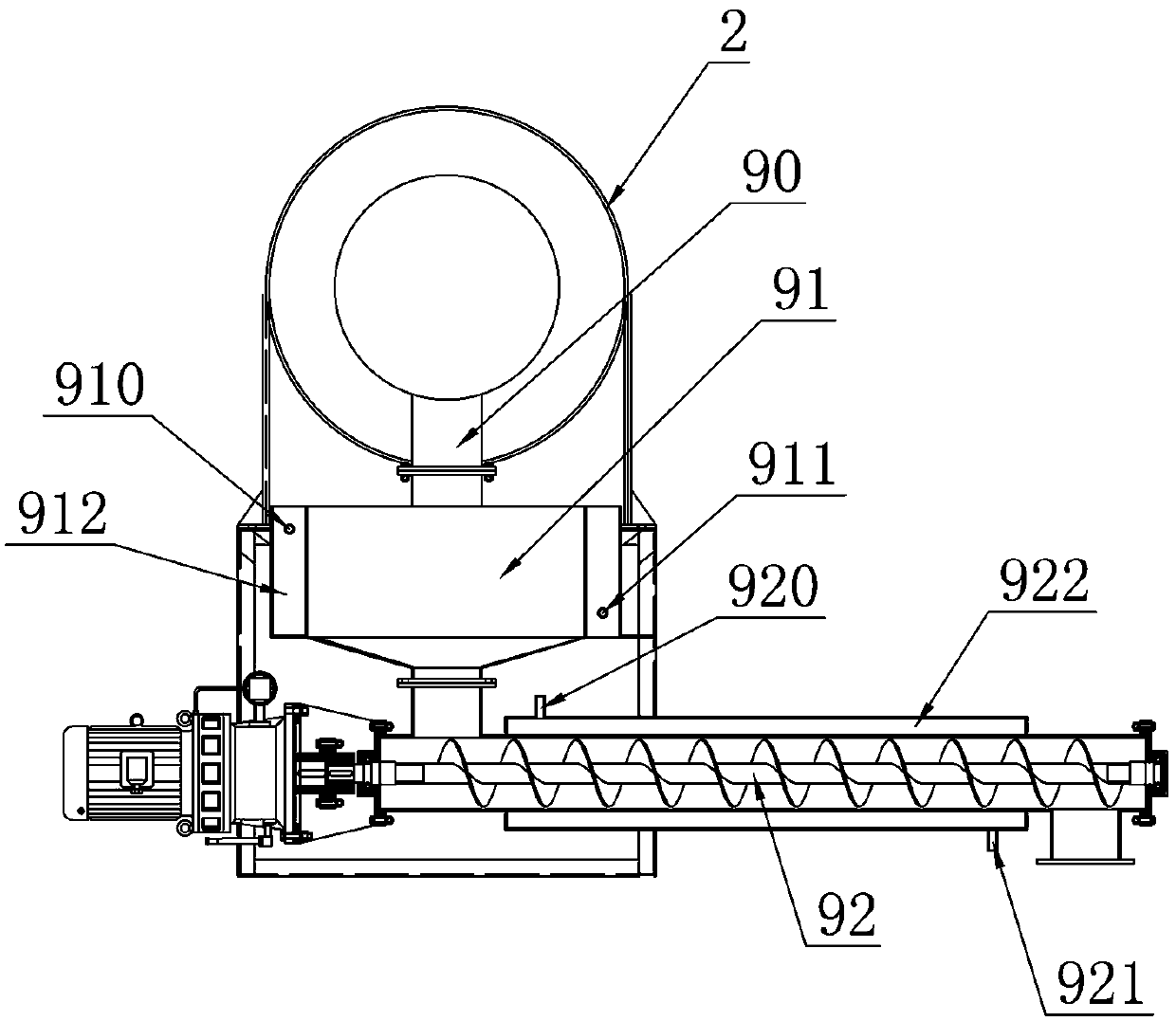

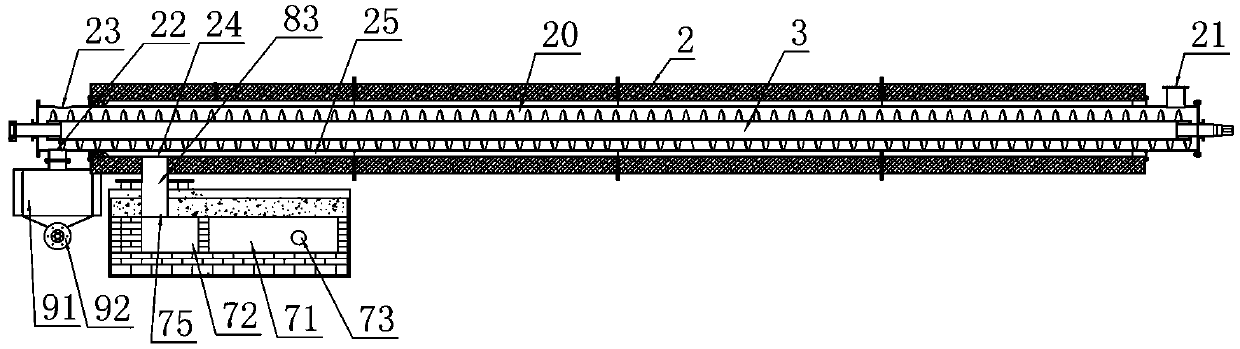

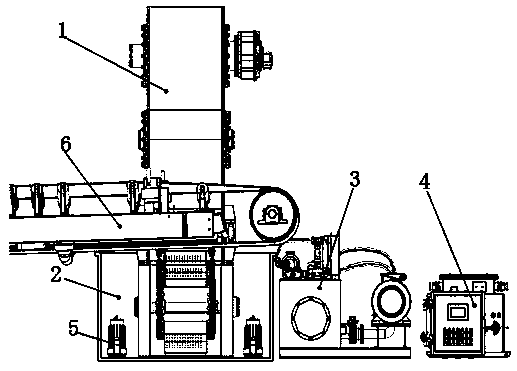

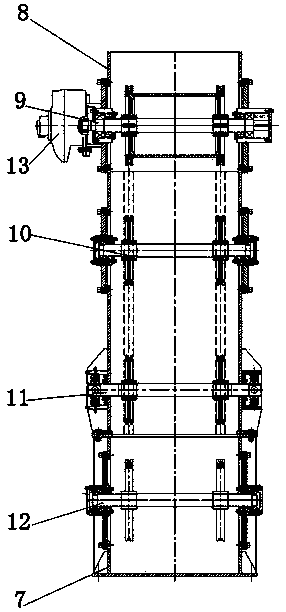

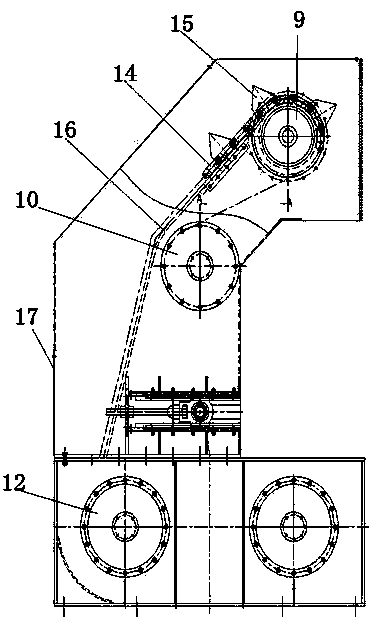

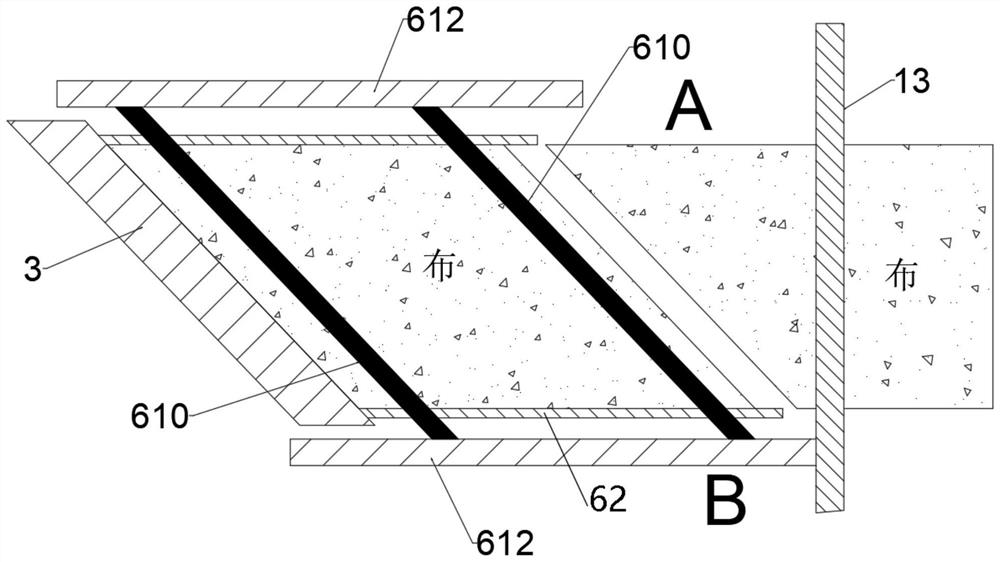

System and technology for producing heat preservation and decoration integrated plate

The invention relates to a system and technology for producing heat preservation and decoration integrated plate. The system is simple in structure, convenient to operate, high in mechanization degree, high in continuous production capacity and high in automation degree; automatic production is carried out in the overall processes of feeding materials, processing the materials and obtaining finished products; equipment production lines are planed uniformly; the full-automatic production from the step of feeding the materials to the step of obtaining the finished products is achieved through four transfer machines; in addition, the operation rate of equipment is high, the quality of the manufactured products is stable, defective products caused by manual misoperation are reduced, raw materials of an enterprises are saved, and benefits are brought to the enterprise; the system is used in combination with different workpieces, all the workpieces are improved creatively, and the system is suitable for production on a large scale; the production technology is simple, technological parameters which are required finally can be directly obtained as long as the products go through the equipment at a time, the overall process is mechanized, the automation degree is high, the technological process is smooth and closely linked, resources are saved, the efficiency of the finished products is improved, and excellent social benefits and economic benefits are achieved.

Owner:HENAN DESHENG ENVIRONMENT ENERGY CONSERVATION TECH LIMITED

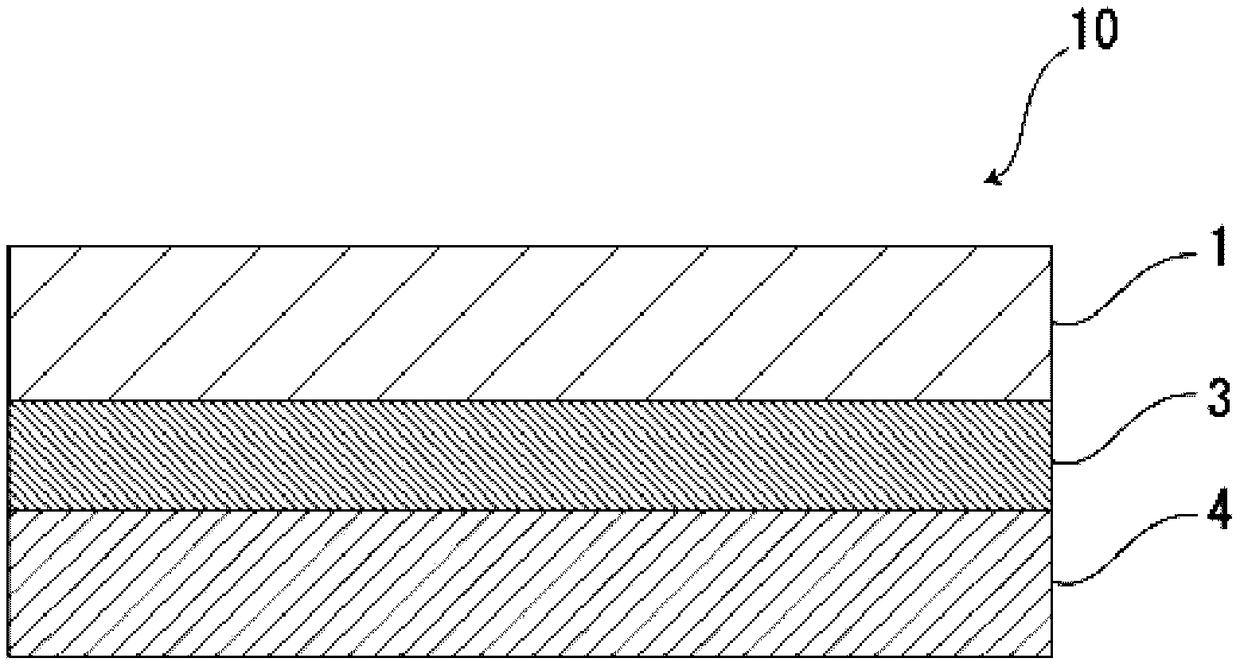

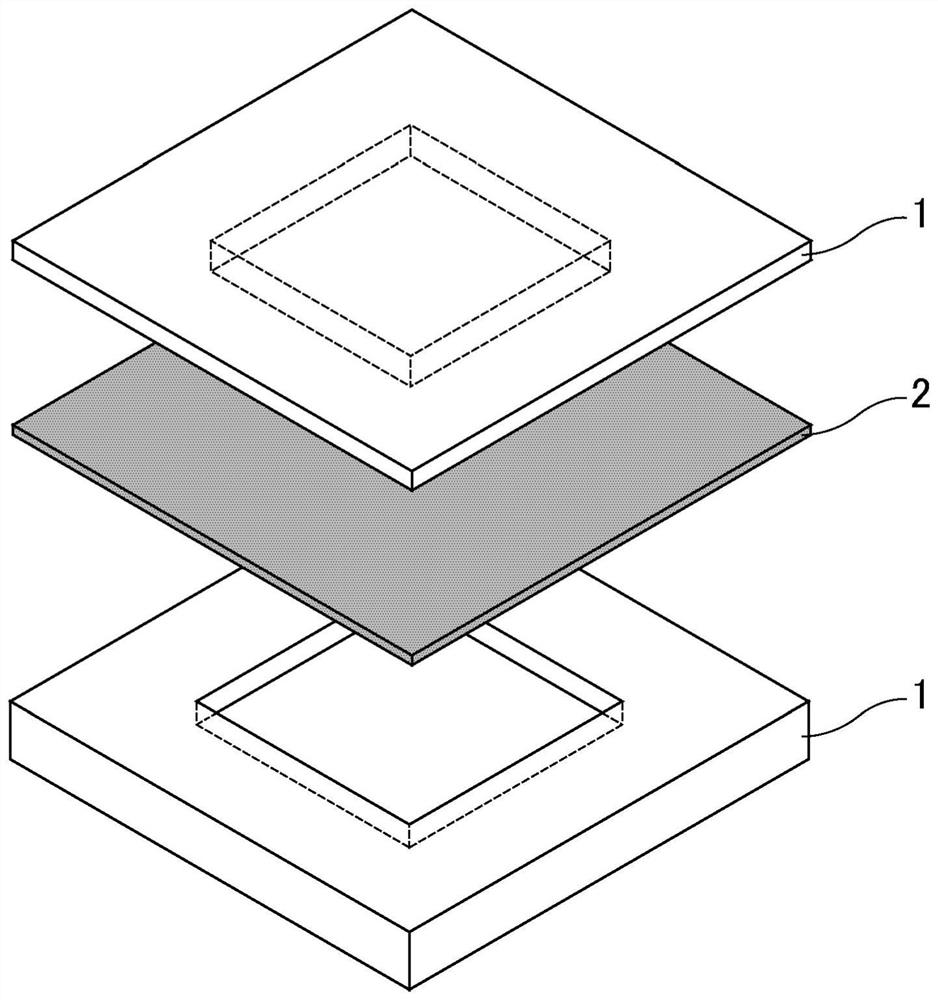

Polyimide multilayered adhesive film and process for producing the same

InactiveCN101080471AMeasure the thickness correctlyUniform film thicknessFilm/foil adhesivesSynthetic resin layered productsInfraredHeat resistance

This invention provides a polyimide multilayered adhesive film, which can accurately measure the thickness of each layer by a infrared absorption method, and a process for producing the same. The adhesive film comprises a highly heat-resistant polyimide layer, and an adhesive layer containing a thermoplastic polyimide and provided on at least one surface of the highly heat-resistant polyimide layer. The adhesive film is produced by a coextrusion-cast coating method and is characterized in that any one of the highly heat-resistant polyimide layer and the adhesive layer is composed mainly of a polyimide resin containing a functional group which exhibits a characteristic infrared absorption wavelength. Thereafter, in the step of measuring the film thickness, the film thickness of each layer is measured with an infrared light absorption-type film thickness measuring meter, and, based on the resultant film thickness measured data, the film thickness of each layer during film formation is controlled and regulated for the production of the polyimide multilayered adhesive film.

Owner:KANEKA CORP

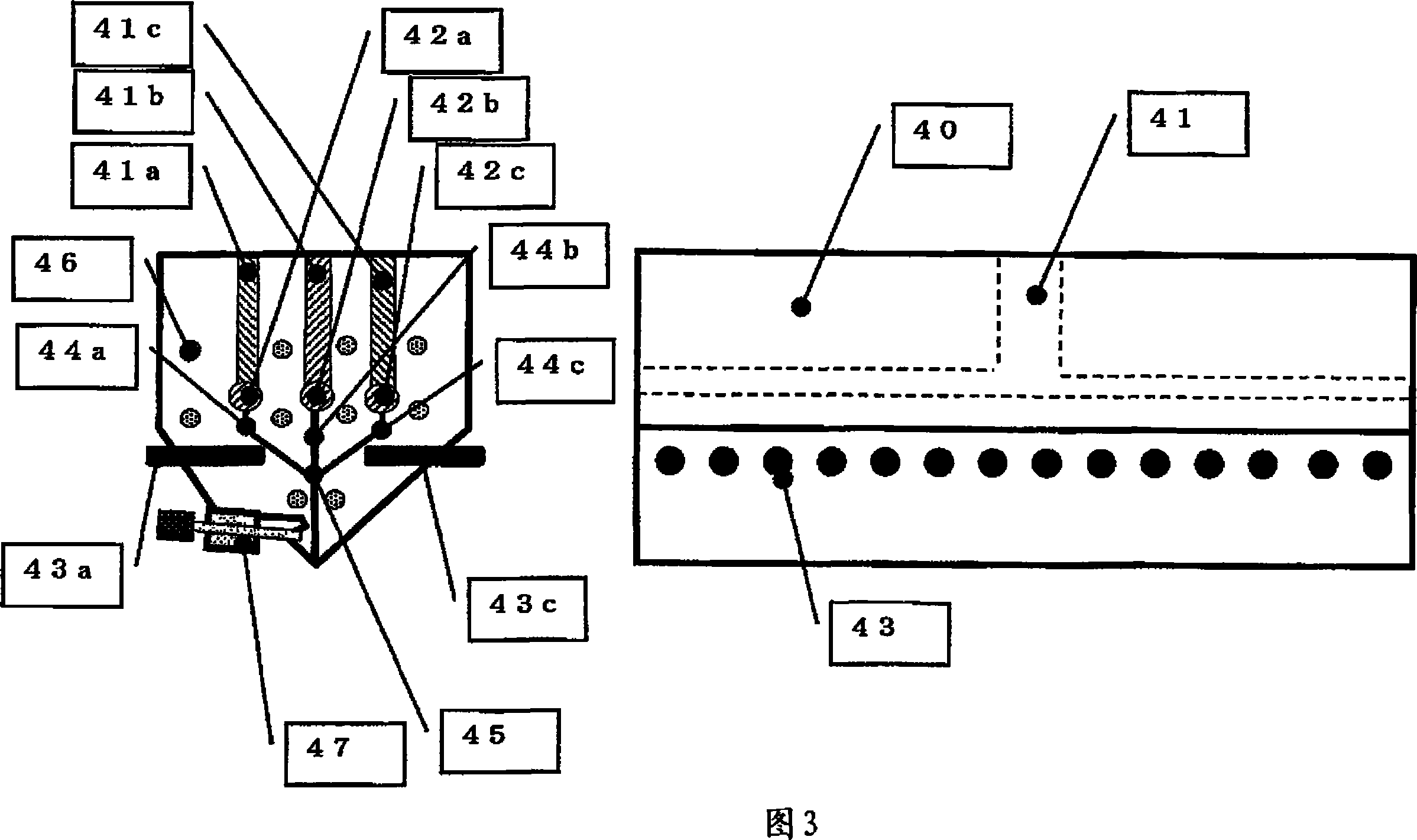

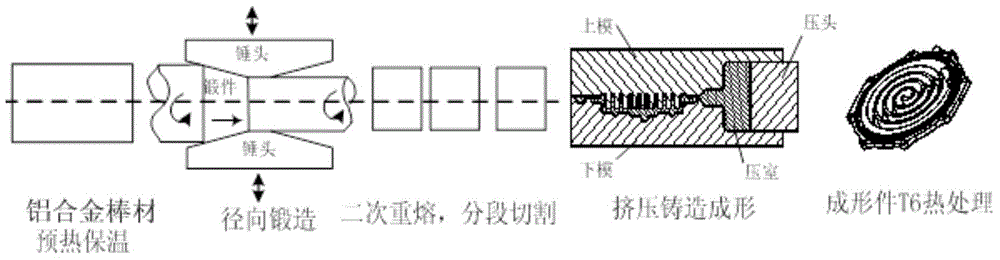

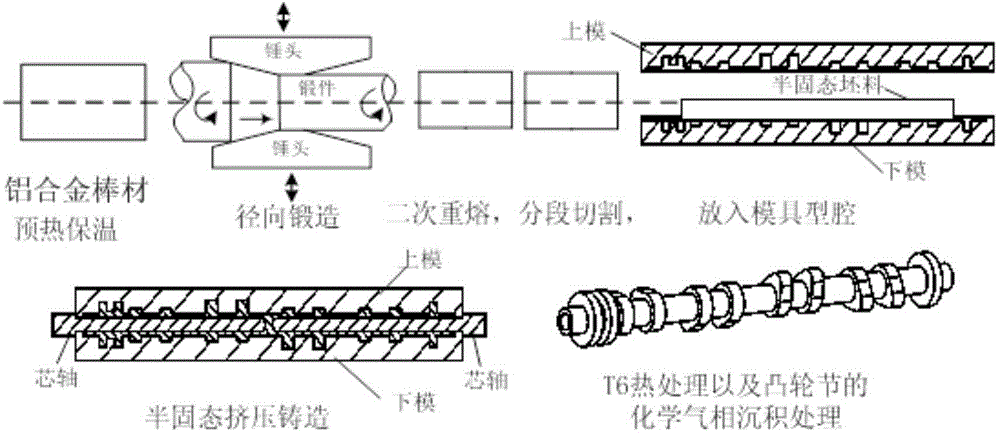

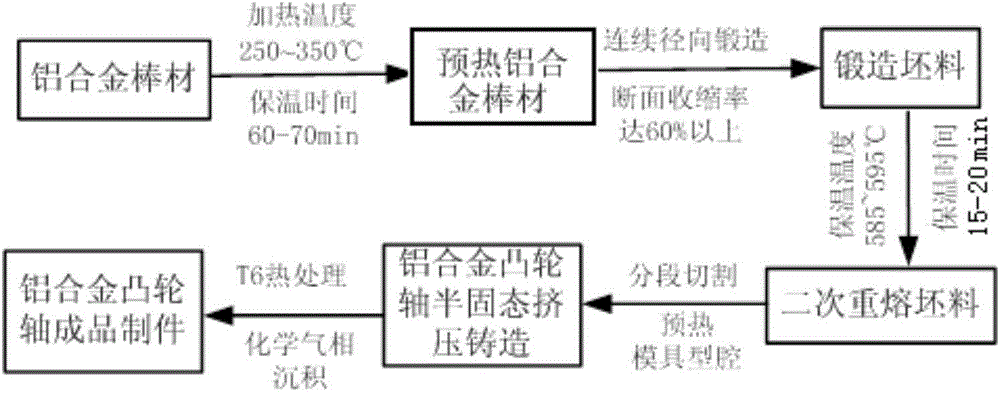

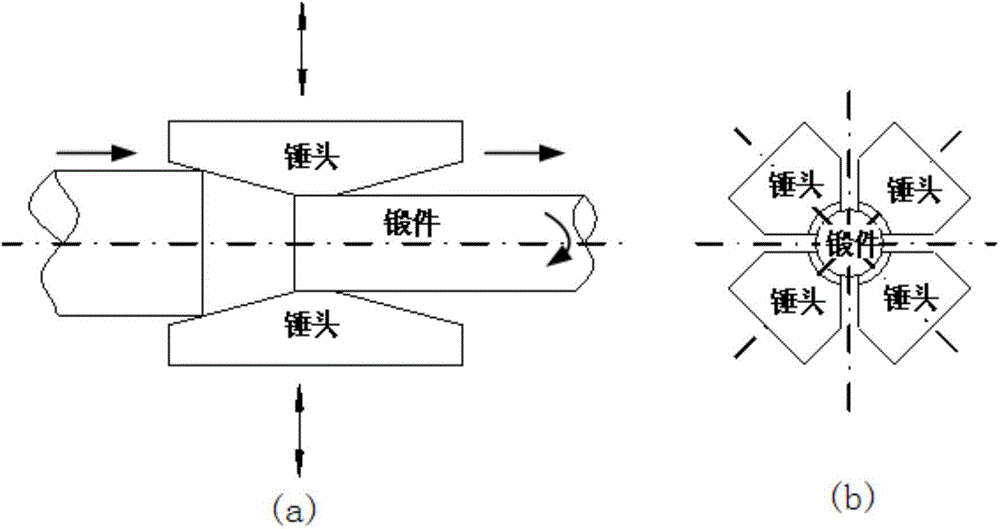

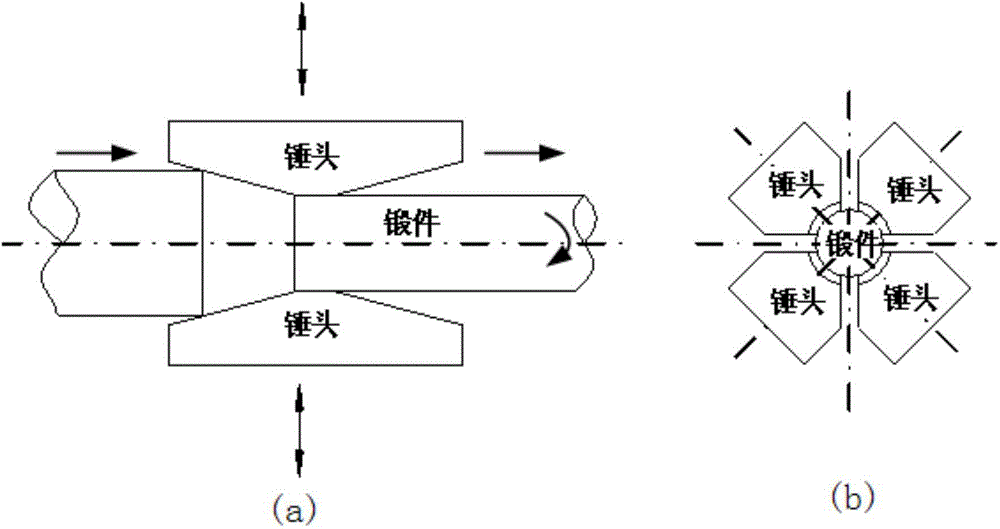

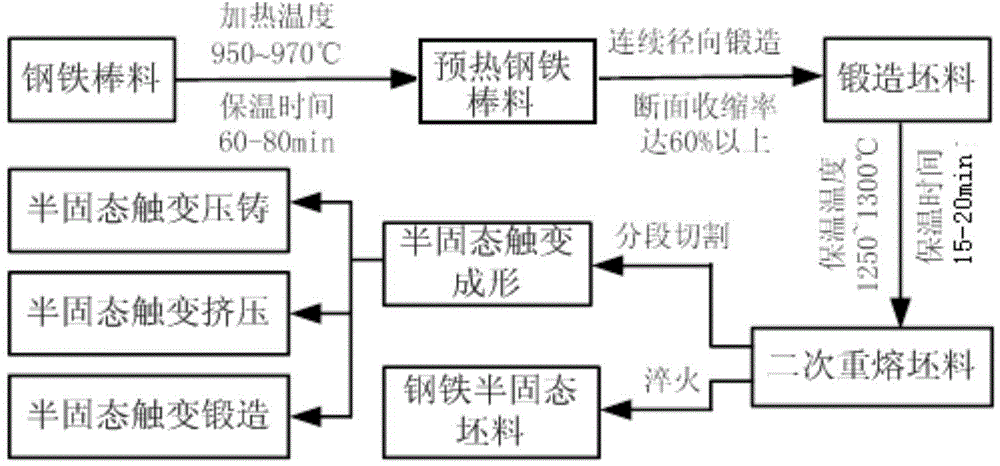

Process for preparing semi-solid state aluminum alloy scroll plate by radial forging strain induction method

InactiveCN104561852AAvoid uneven defectsReduce plastic forming forceIncreasing energy efficiencySemi solidInduction method

The invention discloses a process for preparing a semi-solid state aluminum alloy scroll plate by a radial forging strain induction method. The method comprises the following steps: pre-heating an aluminum alloy rods at first; performing radial forging on the aluminum alloy rods; performing secondary remelting on blanks subjected to radial forging; performing extrusion casting on the aluminum alloy scroll plate; performing T6 heat treatment on the aluminum alloy scroll plate acquired by extrusion casting in a semi-solid state to increase the mechanical property. According to the process, the aluminum alloy semi-solid state blanks which are uniform and free of microdefect are prepared and are subjected to extrusion casting to form a scroll plate workpiece with less microdefects and high mechanical performance, and the process is simple and easy to operate.

Owner:XI AN JIAOTONG UNIV

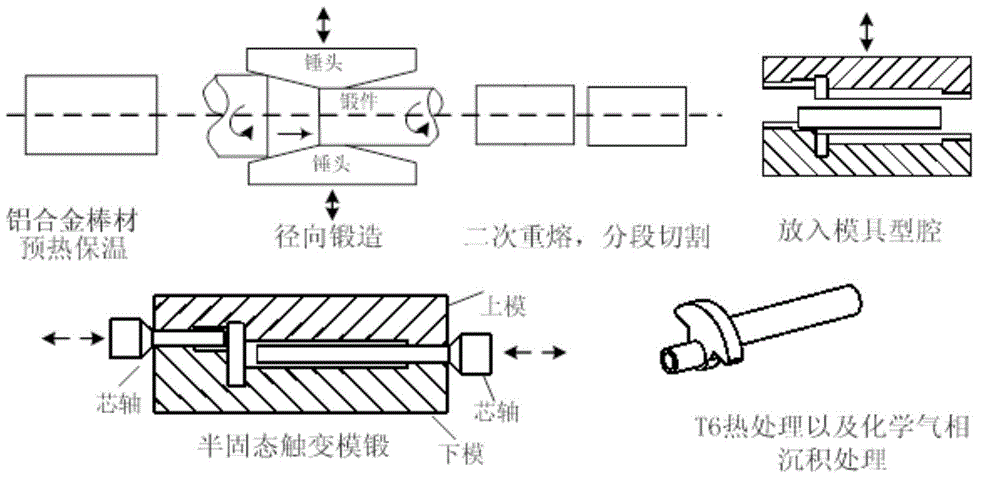

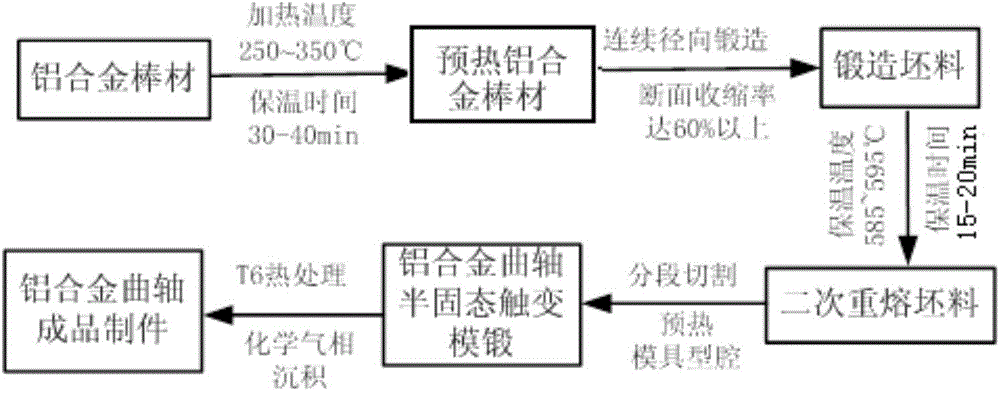

Radial forging strain-induced semi-solid state process for manufacturing aluminum alloy crankshaft of air condition compressor

InactiveCN104525829AGood microstructureGood formabilityMetal-working apparatusEngine componentsCast ironRadial forging

A radial forging strain-induced semi-solid state process for manufacturing an aluminum alloy crankshaft of an air condition compressor comprises the steps that an aluminum alloy bar material is preheated, radial forging is carried out on the aluminum alloy bar material, secondary remelting is carried out on a bank after radial forging, then semi-solid thixotropy forging of the aluminum alloy crankshaft is carried out, and subsequent processing of the aluminum alloy crankshaft is carried out. The uniform aluminum alloy semi-solid blank without mirodefects can be manufactured and the aluminum alloy crankshaft with fewer microstructure defects and good mechanical performance is formed and replaces a cast iron crankshaft through the process, the process is simple, and operation is easy.

Owner:XI AN JIAOTONG UNIV

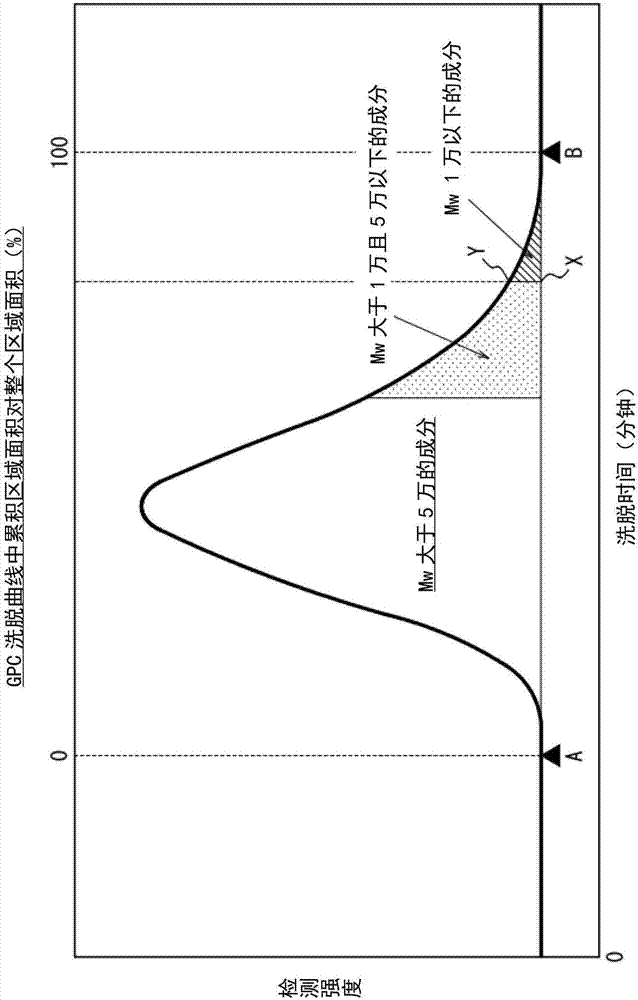

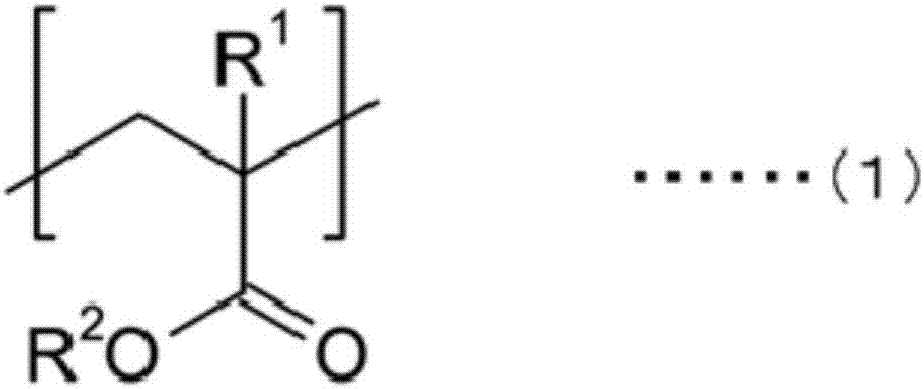

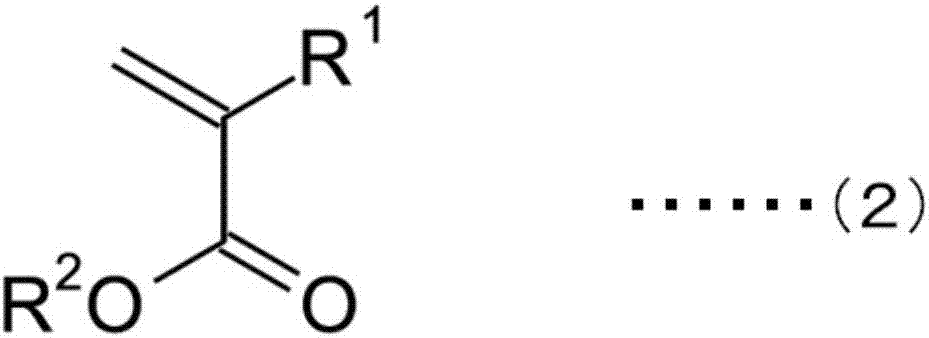

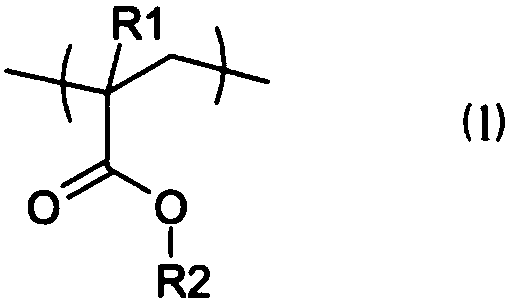

Methacrylic resin composition, preparation method thereof, particles and moulded body

ActiveCN107540779AStrong continuous productionGood physical propertiesOptical elementsMethacrylateForeign matter

The purpose of the invention is to provide a methacrylic resin composition which has excellent continuous productivity and less content of foreign matters and can prepare a moulded body with excellentphysical property and appearance and also provide a preparation method of the methacrylic resin composition, particles and the moulded body. According to the invention, the composition contains methacrylic resin which contains more than 50 mass percent of a methacrylate monomer unit (A) and has ring structure, a glass-transition temperature is 110 DEG C to 160 DEG C, a particle counter is used for measuring, and each 1g contains less than 100 of foreign matters with partical sizes of more than 10[mu]m and less than 20[mu]m; the prepare method comprises: when an extruder runs, delivery volumes(delivery volumes / number of holes) of the methacrylic resin composition from holes of each die is more than 5kg / (hr*number) and less than 30 kg / (hr*number).

Owner:ASAHI KASEI KK

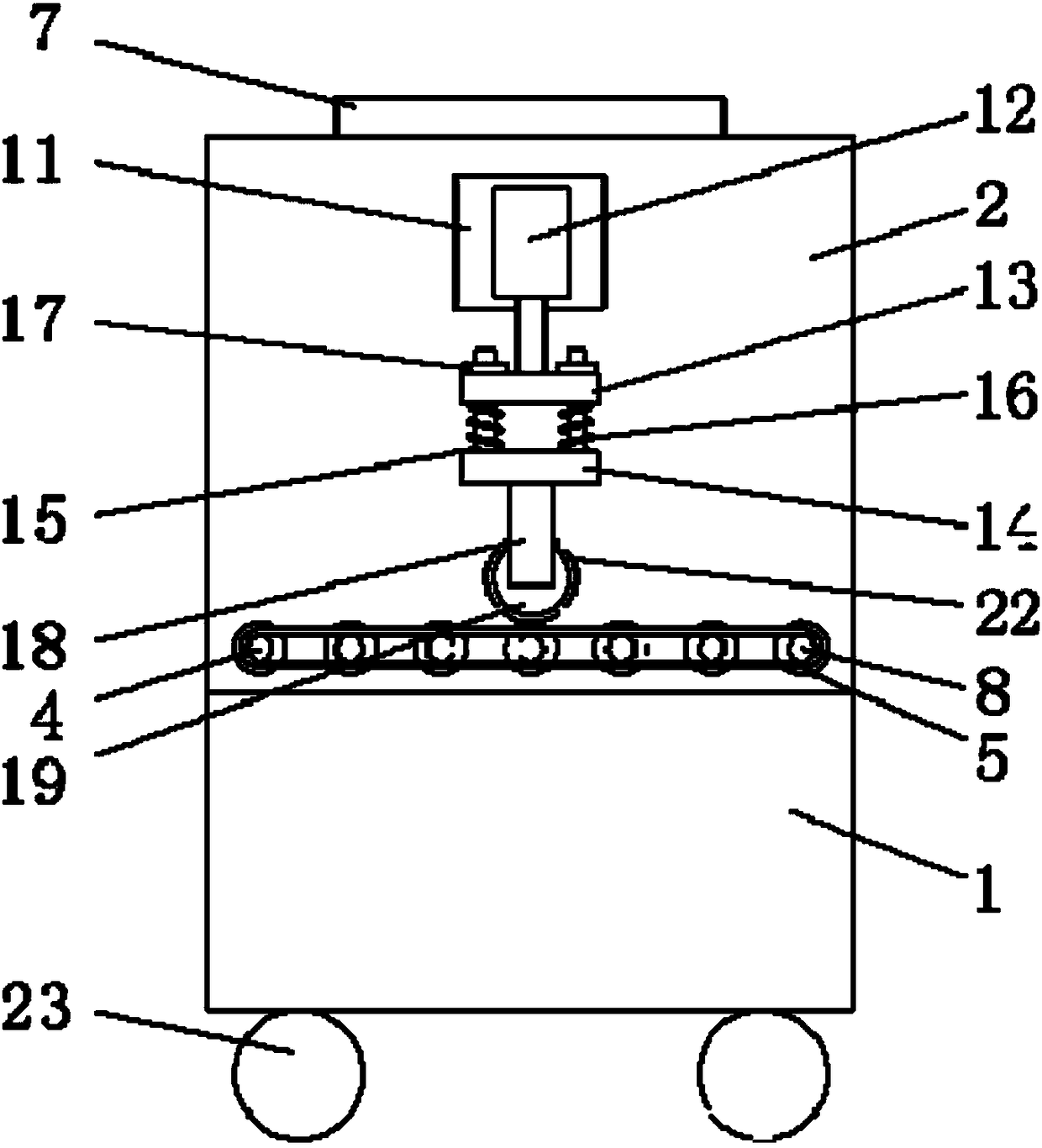

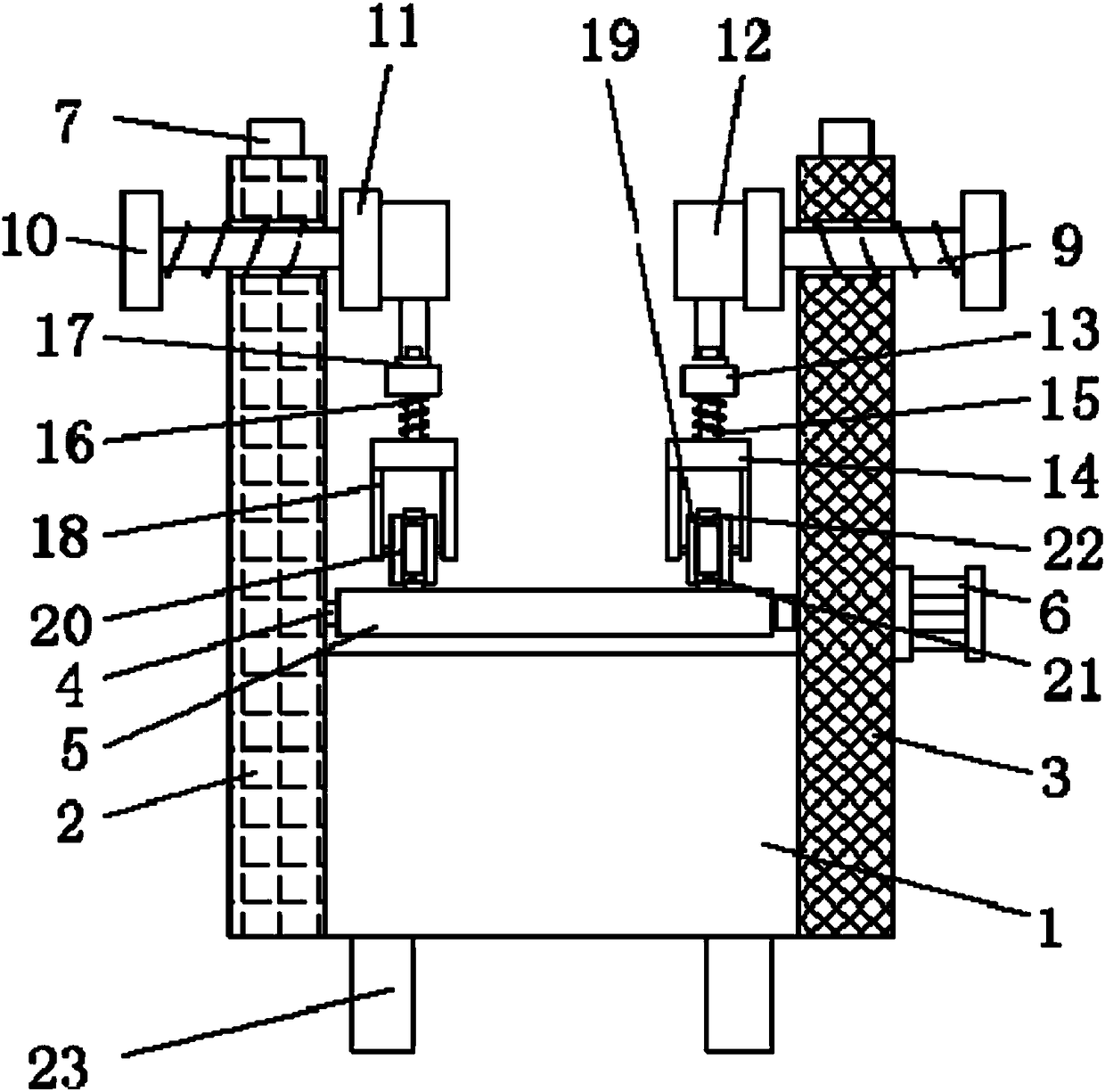

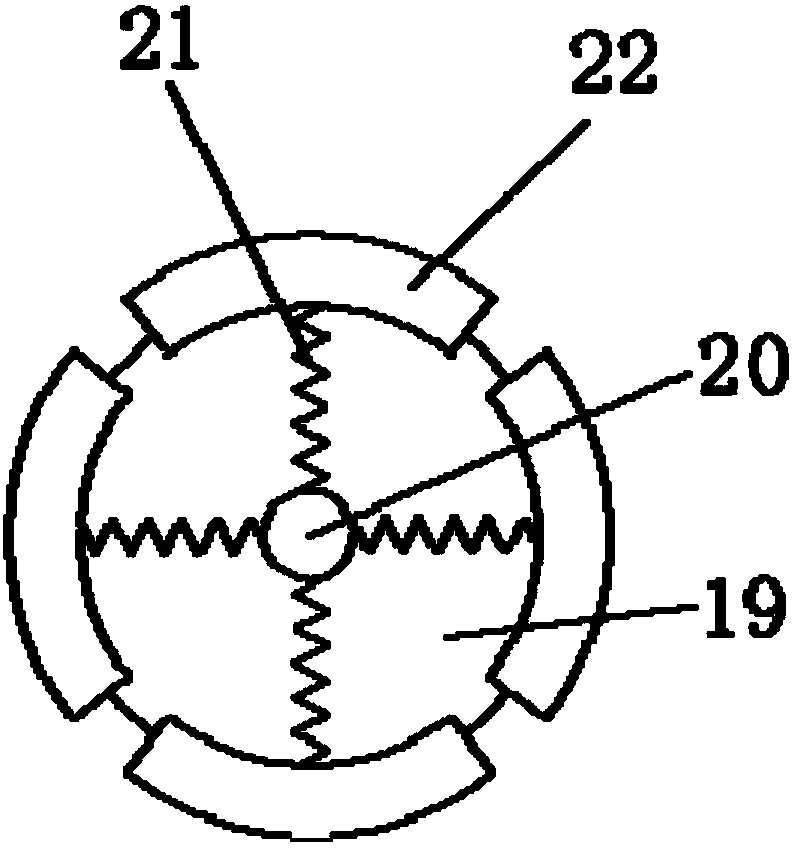

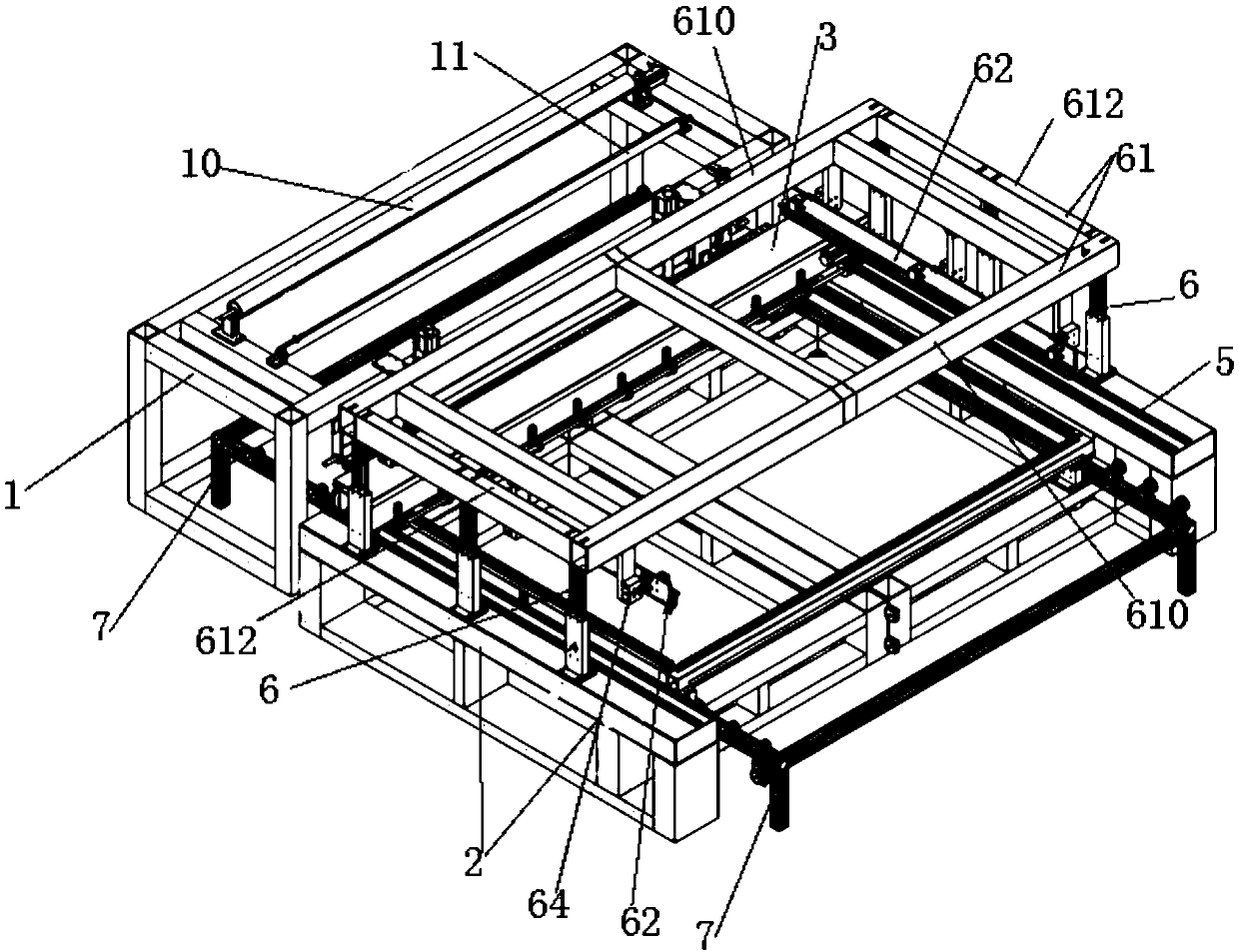

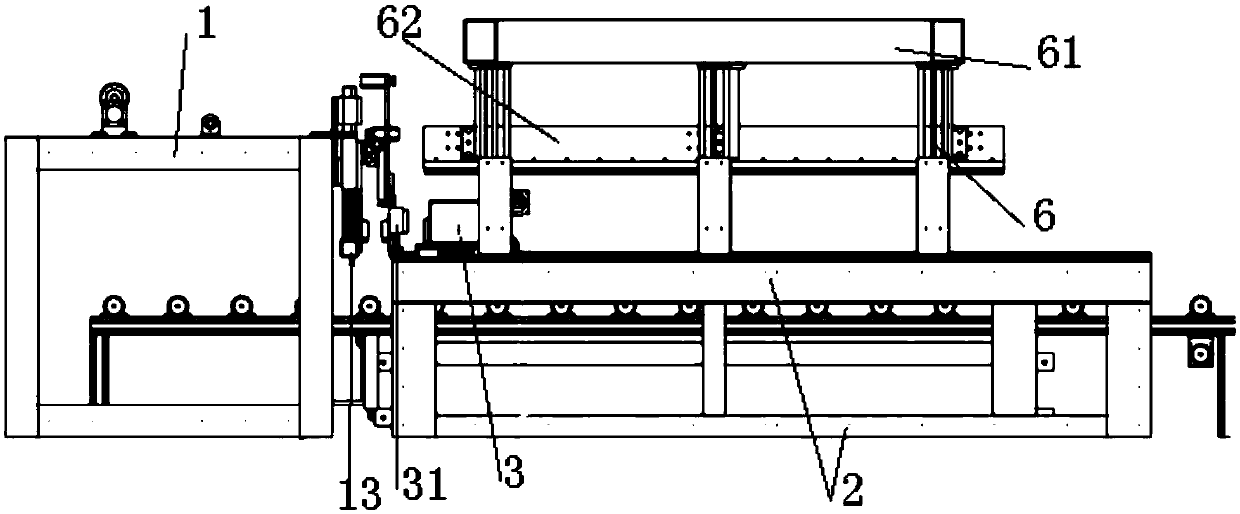

Blank pressing device for processing corrugated cardboard box

InactiveCN108312632AEfficient edge pressingStrong continuous productionBox making operationsPaper-makingMechanical engineeringCardboard box

The invention discloses a blank pressing device for processing a corrugated cardboard box. The blank pressing device comprises a base, wherein a first supporting plate and a second supporting plate are correspondingly connected to the front face and the back face of the base. A first rotating rod is movably connected with the front face of the first supporting plate, a second rotating rod is movably connected between the first supporting plate and the second supporting plate, and rollers are fixedly connected with the surface of the first rotating rod and the surface of the second rotating rod. A motor is fixedly connected with the front face of the second supporting plate. The first rotating rod, the second rotating rod, the rollers, the motor, a screw rod, a movable plate, an electric telescopic rod, a connecting block, a connecting plate, a supporting rod, a first spring, a nut, the supporting plates, a round block, a connecting rod, a second spring and a pressing block are matchedand used, thus the blank pressing device for processing the corrugated cardboard box is efficient in blank pressing, the flattening of the corrugated cardboard box does not need manual pressing operation, the continuous production capacity is strong, and the corrugated cardboard box can be adjusted, the application range is wide and the blank pressing device for processing the corrugated cardboardbox is beneficial for users to use.

Owner:FOSHAN XUNTUOAO TECH CO LTD

Semisolid process for manufacturing engine aluminum alloy cam shaft through radial forging strain provocation method

InactiveCN104624914AAvoid composition segregation and uneven microstructure defectsAvoid uneven defectsMetal-working apparatusEngine componentsMicro structureCam

Disclosed is a semisolid process for manufacturing an engine aluminum alloy cam shaft through a radial forging strain provocation method. Aluminum alloy rod materials are preheated and then forged in the radial direction, a blank is remelted again after radial forging, the aluminum alloy cam shaft is extruded and cast, and finally follow-up treatment is carried out on the aluminum alloy cam shaft in the radial direction. Through the process, the uniform aluminum alloy semisolid blank without micro defects can be manufactured, the aluminum alloy cam shaft which has a few micro structure defects and is good in mechanical performance can be formed, and the process is simple and easy to operate.

Owner:XI AN JIAOTONG UNIV

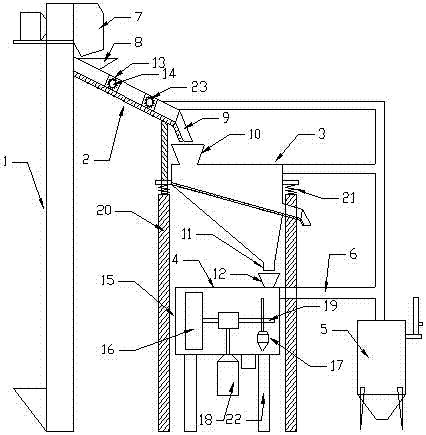

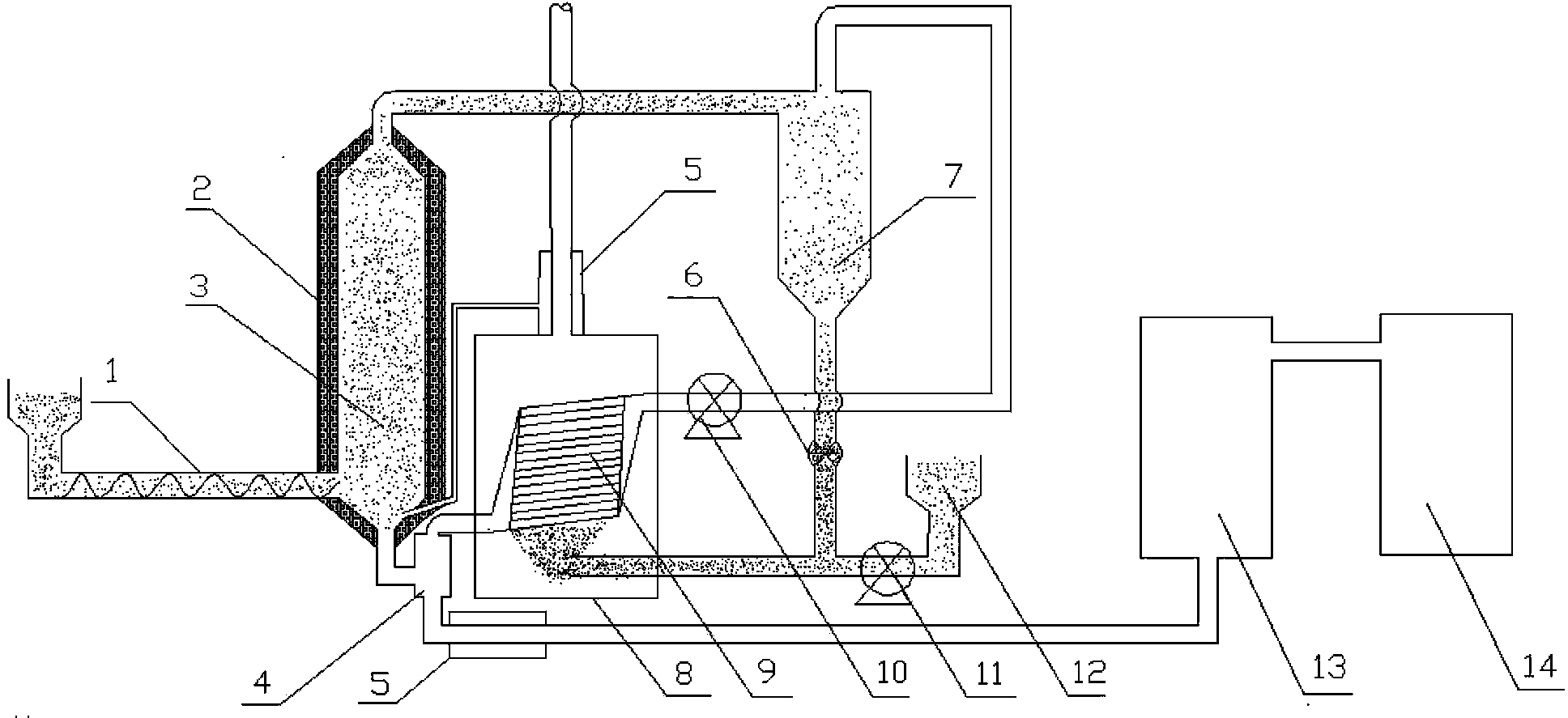

Environment-friendly used casting sand dry recovery and treatment equipment

InactiveCN107052233AQuality improvementImprove efficiencyMould handling/dressing devicesBucket elevatorGrinding wheel

The invention discloses environment-friendly used casting sand dry recovery and treatment equipment. The environment-friendly used casting sand dry recovery and treatment equipment comprises a bucket elevator, a used sand conveying and crushing device, a vibrating screen, a rotary sand rolling device and a dust collection device. The used sand conveying and crushing device, the vibrating screen and the rotary sand rolling device are mounted and fixed from top to bottom in sequence. The dust collection device communicates with the used sand conveying and crushing device, the vibrating screen and the rotary sand rolling device through dust collection pipelines correspondingly. The rotary sand rolling device comprises a sand cylinder, a sand rolling wheel, a sand turning shovel and a rotating motor II. The front end of a rotary shaft of the rotary motor II is provided with a horizontal connecting rod. The two ends of the horizontal connecting rod are provided with the sand rolling wheel and the sand turning shovel correspondingly. The environment-friendly used casting sand dry recovery and treatment equipment can effectively improve the recovery quality and efficiency of used sand by crushing, screening, turning and grinding used casting sand, and is high in continuous production capacity and capable of conducting dust collection in each step and guaranteeing reduction of environmental pollution.

Owner:绵阳易简环保科技有限公司

Method for extracting vanadium from vanadium-containing solution

InactiveCN106222412AOvercoming extractionOvercoming long stripping stagesProcess efficiency improvementPhase splittingEmulsion

The invention relates to a method for extracting vanadium from a vanadium-containing solution. According to the technical scheme, a surfactant, a carrier, liquid paraffin and a membrane solvent are mixed evenly, and an evenly-mixed organic phase is obtained; then a back-extractant is added into the evenly-mixed organic phase, stirring is conducted, and an emulsion is obtained; the vanadium-containing solution and the emulsion are mixed, stirred and subjected to standing and phase splitting, and a vanadium-loaded solution and primary raffinate are obtained; the vanadium-loaded solution is subjected to demulsification and phase splitting, and a lean organic phase and a vanadium-rich solution are obtained; and the lean organic phase and the primary raffinate are mixed, stirred and subjected to standing and phase splitting, a vanadium-loaded organic phase and secondary raffinate are obtained, and the vanadium-loaded organic phase is directly returned to make an emulsion again. The method has the characteristics of being small in extractant usage quantity, short in technological process and high in vanadium recovery rate, production efficiency and continuous productbility.

Owner:WUHAN UNIV OF SCI & TECH +1

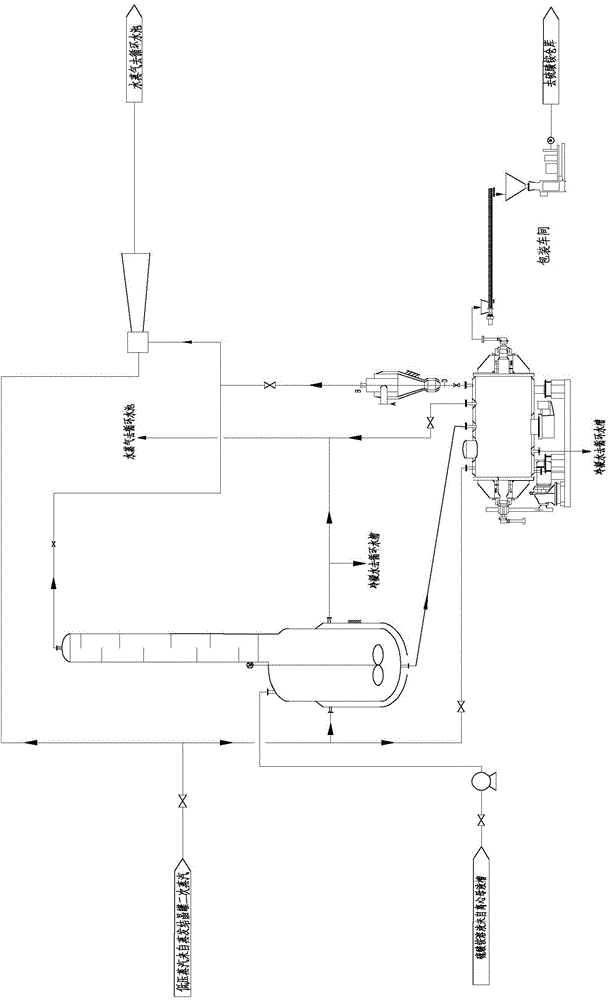

Novel treatment method for mother liquor obtained after centrifugal separation of ammonium sulfate in ammonia-process desulfurization

InactiveCN104310429ASolve the problem of excessive corrosion rateAvoid enrichmentAmmonium sulfatesSludgeNovel treatment method

The invention relates to a novel treatment method for mother liquor obtained after centrifugal separation of ammonium sulfate in ammonia-process desulfurization. The method comprises the following steps: pumping 20-40% ammonium sulfate mother liquor from an ammonium sulfate centrifugal mother liquor tank to a stripping tower for vacuum concentration, introducing 0.2-0.5Mpa steam into a jacket of the stripping tower to heat, connecting a vacuum system inside the stripping tower, and improving the concentration of the ammonium sulfate solution to 60-70% so as to obtain ammonium sulfate slurry; and conveying the ammonium sulfate slurry to a rake type drier by virtue of a sludge pump, drying for 4-6 hours in the rake type drier to obtain an ammonium sulfate finished product with the water content of 5%, and conveying to a packaging workshop by virtue of a screw conveyor to package. Under the premise of not reducing the quality of the ammonium sulfate product, the problem that a crystallizer in ammonium sulfate production is excessively fast corroded is solved, ammonium sulfate wastewater is comprehensively used, the centrifugal waste liquid is treated, the energy is comprehensively utilized, the energy consumption for by-producing ammonium sulfate in ammonia-process desulfurization is reduced, and the economic benefit is improved. Meanwhile, the method provided by the invention can be used for projects such as ammonium chloride, ammonium nitrate and the like and has a wide application prospect and good economic and social benefits.

Owner:WUHAN XINGLIANHE ENG

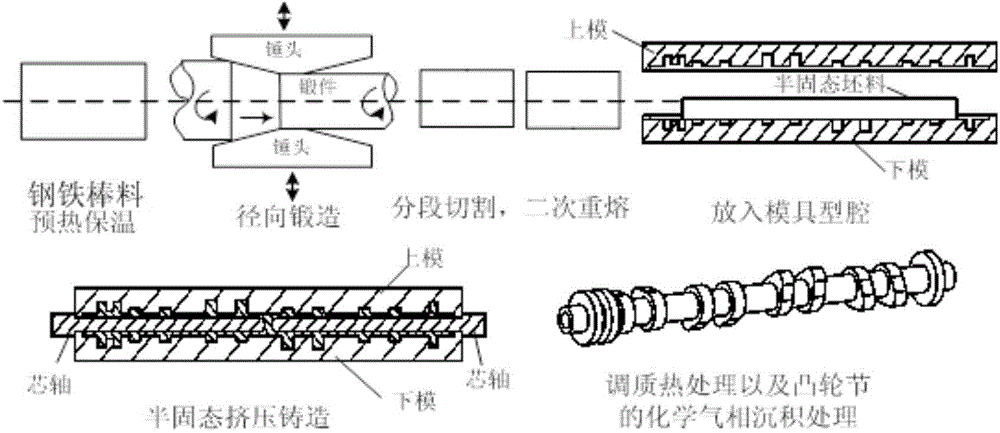

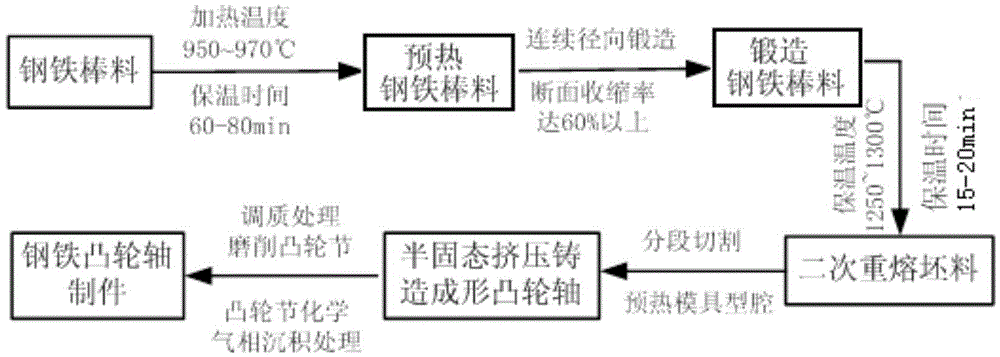

Process for manufacturing semi-solid steel cam shaft through radial forging strain induction method

InactiveCN104550838AUniform compositionFew ingredientsMetal-working apparatusTissue defectSemi solid

The invention discloses a process for manufacturing a semi-solid steel cam shaft through a radial forging strain induction method. The process comprises the following steps: preheating a steel bar material and preserving heat; radially forging the steel bar material; re-melting a radially-forged blank; performing extrusion casting on the steel cam shaft; performing subsequent treatment on the steel cam shaft. By adopting the process, steel semi-solid blanks which are uniform and free from micro-defects can be manufactured in batches, and the steel cam shaft which has less micro tissue defects, high mechanical performance and high wear resistance can be formed. The process flow is simple, and operation is easy.

Owner:XI AN JIAOTONG UNIV

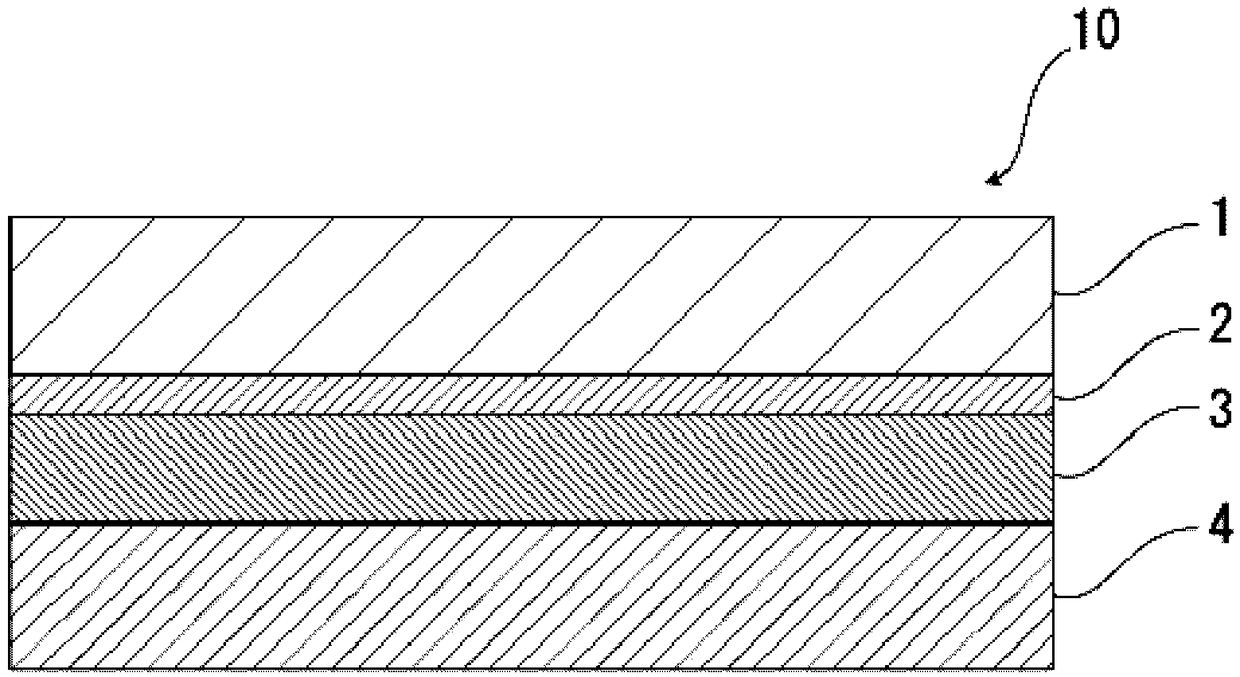

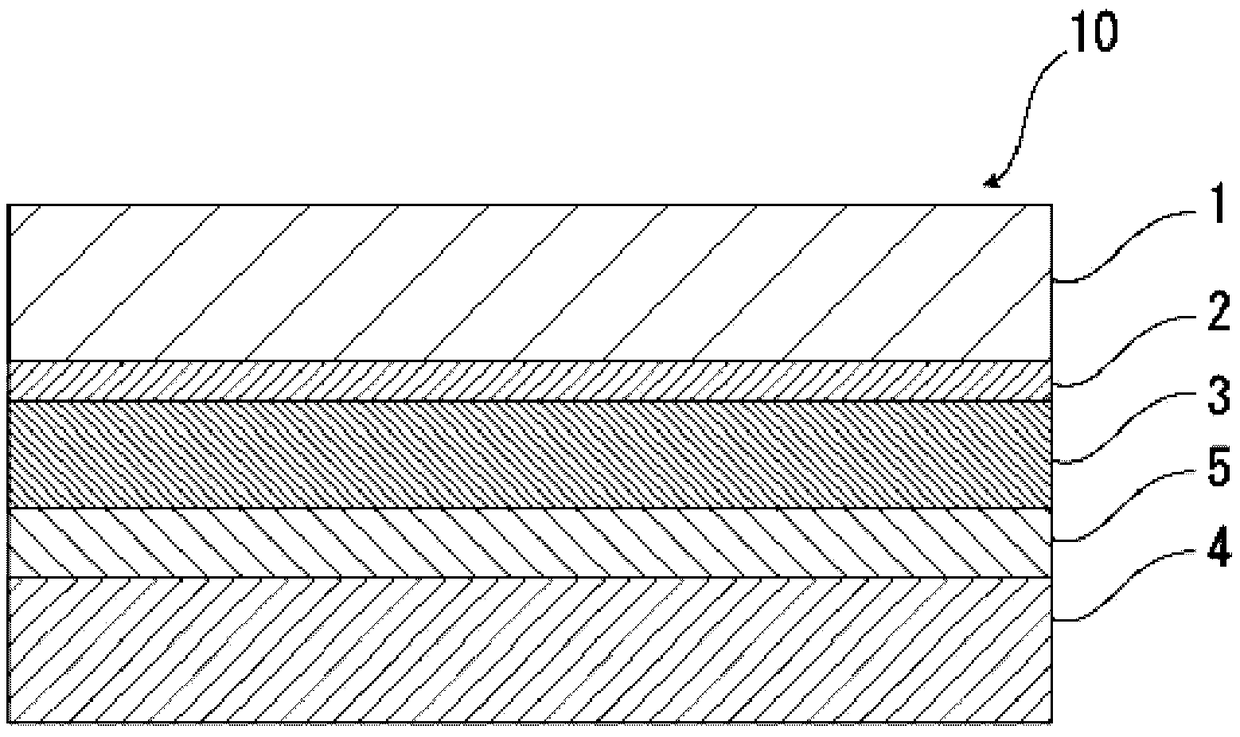

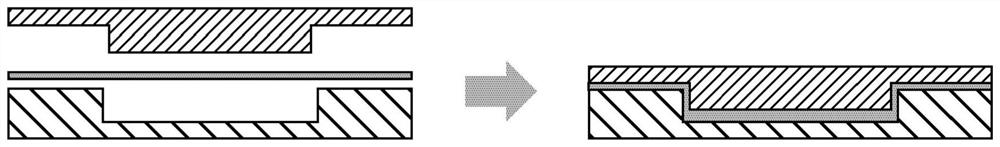

Packaging material for batteries, method for producing same and battery

ActiveCN109196683AGood molding effectStrong continuous productionCell component detailsMetal layered productsInfraredPhysical chemistry

Provided is a packaging material for batteries, which has high formability and enables the achievement of excellent continuous productivity of batteries. A packaging material for batteries, which is configured from a laminate that comprises at least a base layer, a barrier layer and a thermally fusible resin layer in this order, and wherein: the thermally fusible resin layer contains an amide-based lubricant and at least one agent selected from the group consisting of an antioxidant, a light stabilizer and a nucleator; and the absorption spectrum intensity ratio X = A / B as calculated using theabsorption peak intensity A at the wavenumber of 1,650 c<-1> ascribed to C=O expansion / contraction vibration of the amide groups of the amide-based lubricant and the absorption peak intensity B at 1,460 cm-1 ascribed to -CH2- deformation vibration contained in the thermally fusible resin layer, said absorption peak intensity A and absorption peak intensity B being determined from the absorption spectrum obtained by spectrally dividing reflected light when the surface of the thermally fusible resin layer is irradiated with infrared light, is within the range of from 0.05 to 0.80 (inclusive).

Owner:DAI NIPPON PRINTING CO LTD

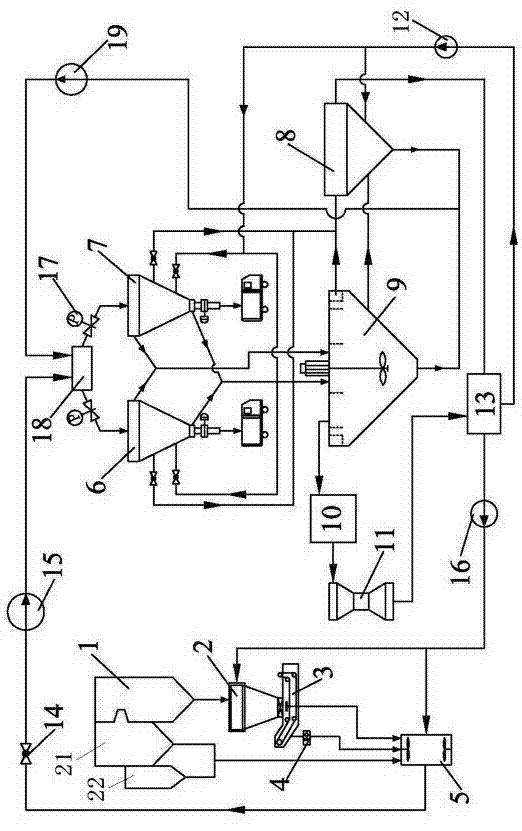

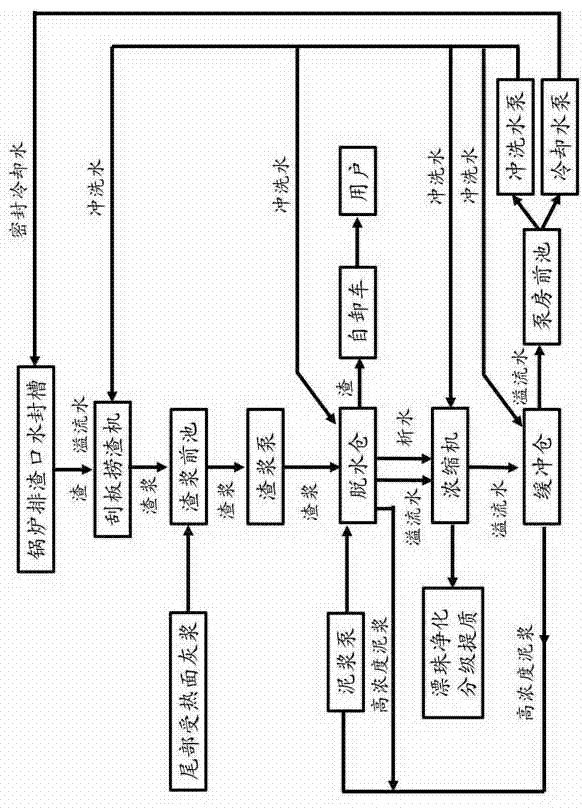

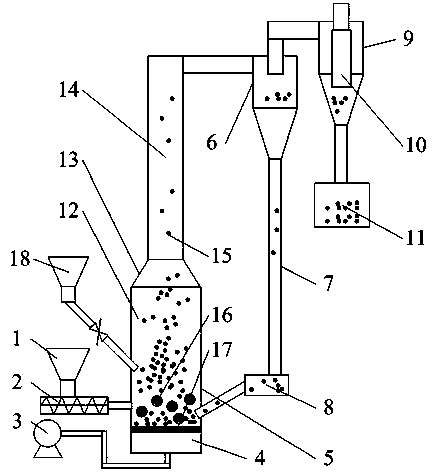

Efficient recycling device and process for hollow particles in ash residues in ash storing yard and storage yard of power station

ActiveCN103752592AThe process is easy to operateLow running costSolid waste disposalSlurry pumpPower station

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Process for preparing semisolid steel blank by using radial forging strain induction method

The invention discloses a process for preparing a semisolid steel blank by using a radial forging strain induction method. The process comprises the following steps: firstly, preheating a steel rod material, performing radial forging on the steel rod material, performing secondary remelting on the blank after radial forging, and finally preparing the semisolid steel blank. By adopting the process, semisolid steel blanks which are uniform in tissue and small in micro defect can be prepared in batch, and the process is simple in procedure and easy to operate.

Owner:XI AN JIAOTONG UNIV

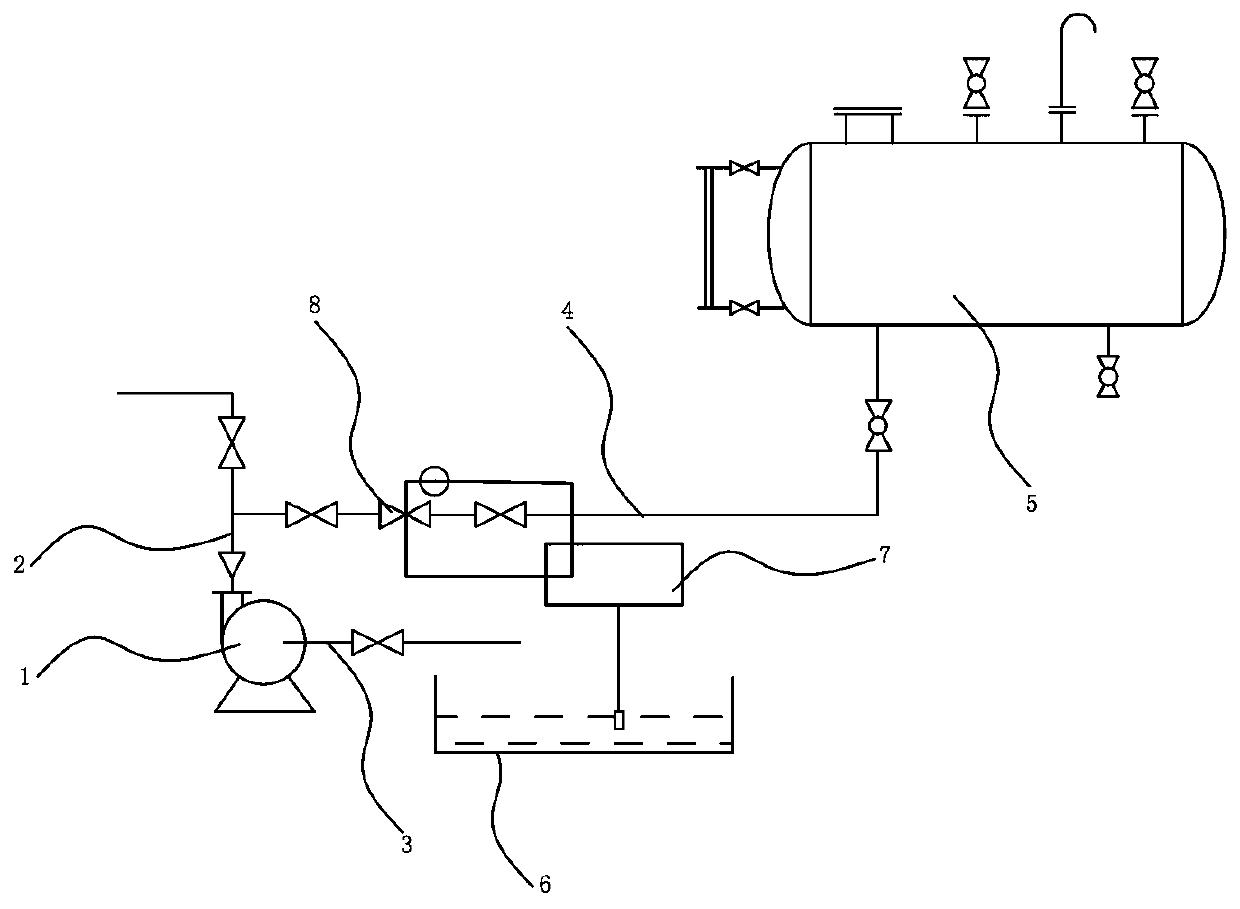

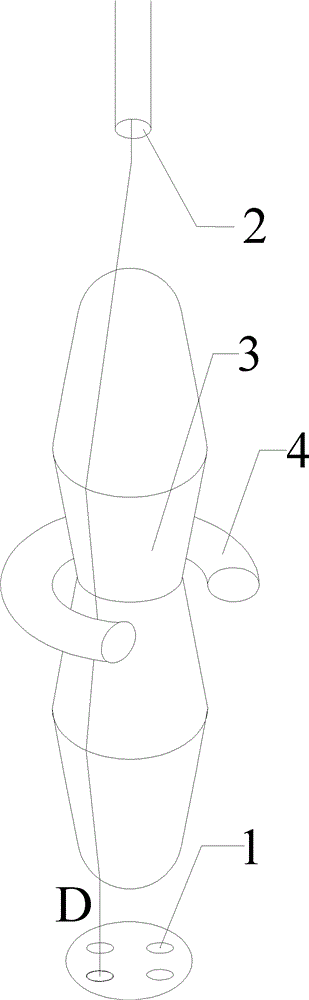

High-temperature circular-heating fluidized bed pyrolysis gas producing system

InactiveCN103254941BAddress unmanageable maladiesAvoid Separation ProcessesEnergy inputGranular/pulverulent flues gasificationFluidized bedThermal insulation

The invention belong to the field of high-efficiency reutilization of biomass solid wastes, and particularly relates to a high-temperature circular-heating fluidized bed pyrolysis gas producing system and a corresponding gas producing method. The system comprises a gasification material feed system, a thermal insulation jacket, a fluidized bed, a gas distributor, a waste heat boiler, a grid feeder, a cyclone dust collector, a circular heating furnace, an inclined tube nest, a high-temperature circulating blower, a common blower, a fuel supplementing system, a dust removal purifier and a gas storage device. The gas producing method with the system comprises the following steps: introducing heated high-temperature gas into the gasification raw material for fluidization and gasification to obtain pyrolysis gas; removing powder carbon from the pyrolysis gas by the cyclone dust collector, and dividing the gas into circular gas and outlet gas by the gas distributor; removing impurities from the outlet gas, and storing; and heating the circular gas to remove tar to obtain high-temperature gas, and recirculating. Compared with the prior art, the fluidizing agent used in the invention is pyrolysis gas of biomass, so no tar is generated after high-temperature circulation and purification.

Owner:BEIJING UNIV OF CHEM TECH

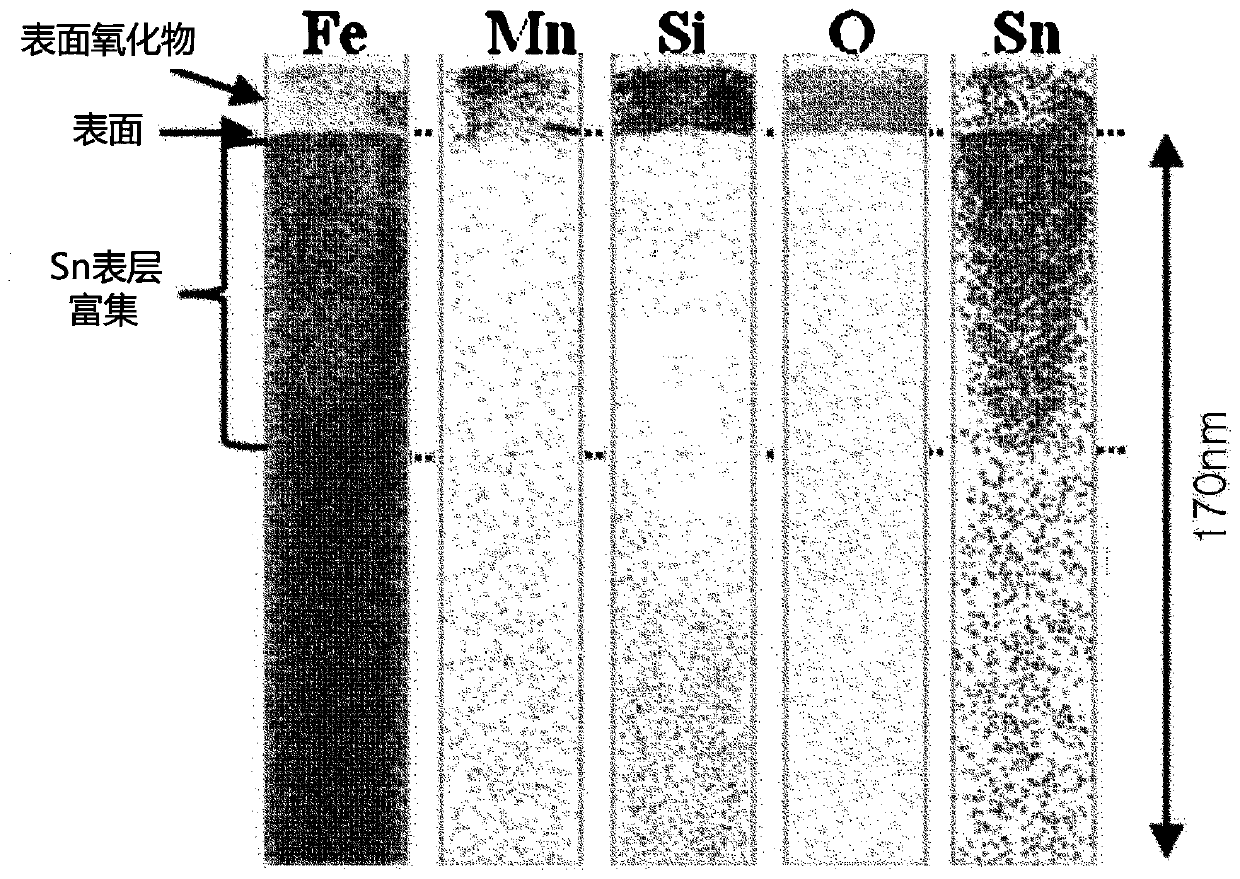

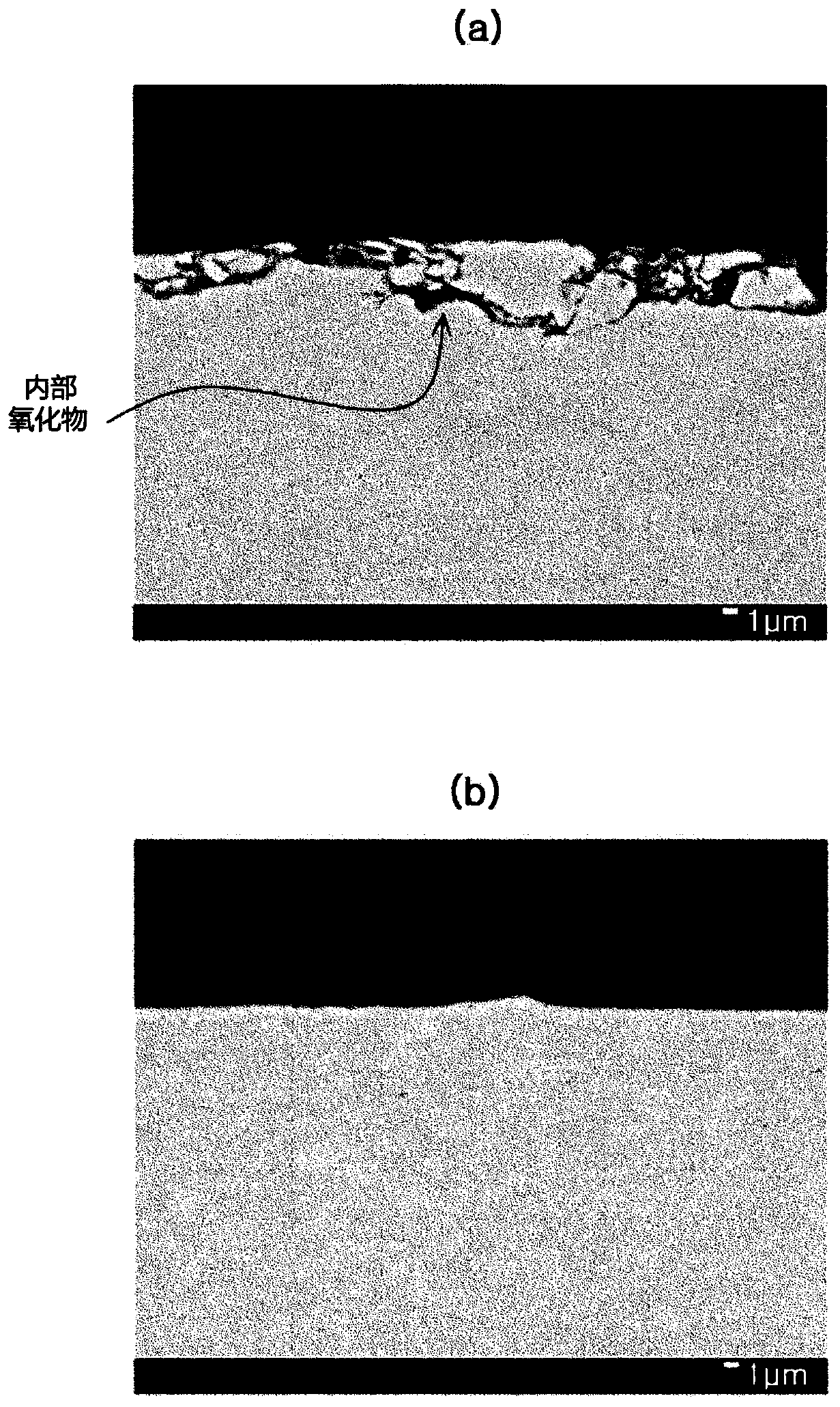

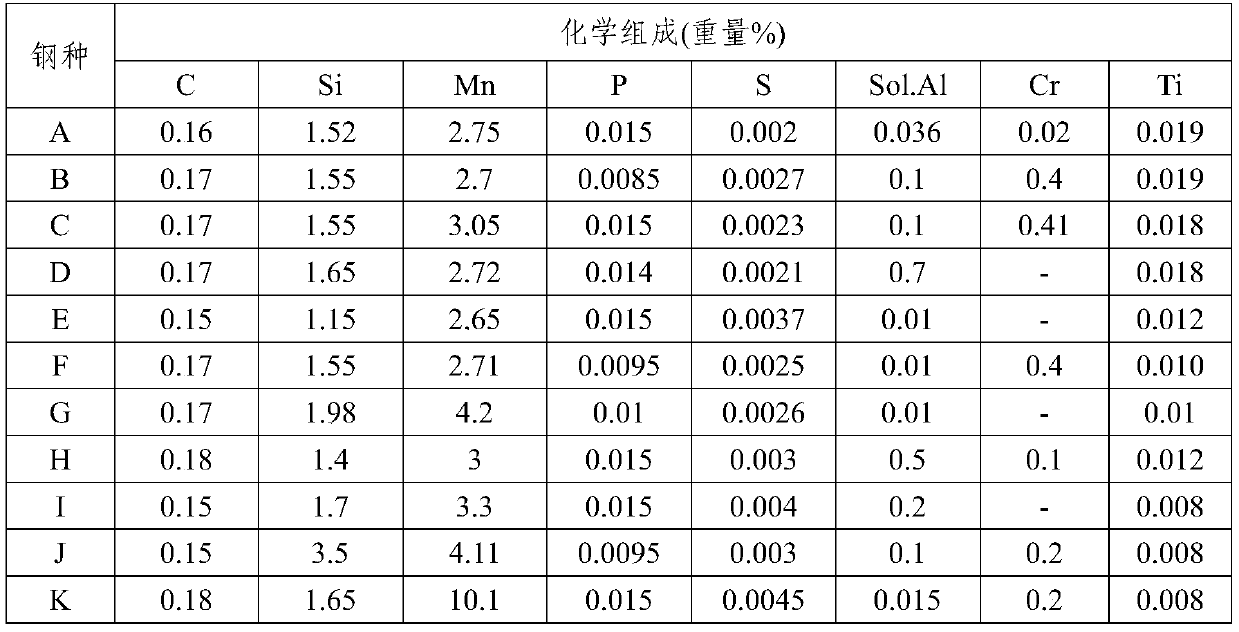

High strength hot rolled steel sheet and cold rolled steel sheet having excellent continuous productivity, high strength hot dip galvanized steel sheet having excellent surface quality and plating adhesion, and manufacturing method therefor

ActiveCN110100031AStrong continuous productionQuality improvementHot-dipping/immersion processesMaximum depthImpurity

Disclosed are a high strength hot rolled steel sheet and the like, the hot rolled steel sheet comprising: by wt%, 0.14-0.3% of C, 1-2.0% of Si, 2.6-5% of Mn, 0.001-2% of sol.Al, (48 / 14)*[N]-0.1% of Ti, 0.04% or less (excluding 0%) of P, 0.015% or less (excluding 0%) of S, 0.02% or less (excluding 0%) of N, 0.08-0.2% of a sum of one or more types among Sb, Bi, Sn, and Zn, and the balance of Fe andinevitable impurities, wherein an internal oxide containing one or more types of elements among Si, Mn, Al, and Fe is present in the surface layer part of the hot rolled steel sheet, and a maximum depth of the internal oxide is 1 mum or less (including 0 mum).

Owner:浦项股份有限公司

Scale removal device for water ring vacuum pump in running

InactiveCN110735802AAvoid foulingDescaling achievedPump componentsRadial flow pumpsAlkaline waterEngineering

The invention discloses a scale removal device for a water ring vacuum pump in running. The scale removal device comprises the water ring vacuum pump, the water ring vacuum pump is provided with an air inlet pipe and an emptying port, a branch pipe is furthermore connected to the air inlet pipe, and the other end of the branch pipe is connected to a hydrochloric acid solution storage tank; an adjusting valve is arranged on the branch pipe, a liquid collection tank is arranged at the emptying port, and a pH online monitor is connected to the interior of the liquid collection tank. The water ring vacuum pump is a negative pressure system in the running process, a hydrochloric acid solution enters the air inlet pipe of the water ring vacuum pump through the branch pipe, and is mixed with alkaline water in an alkaline impurity and a gaseous medium for acid-base neutralization through high-speed rotation of an impeller of the water ring vacuum pump, and the alkaline impurity in the water ring vacuum pump can be removed. By means of the scale removal device, the running period of equipment can be prolonged, the operation is simple, and the practicability is high.

Owner:HUBEI SHANSHUI CHEM

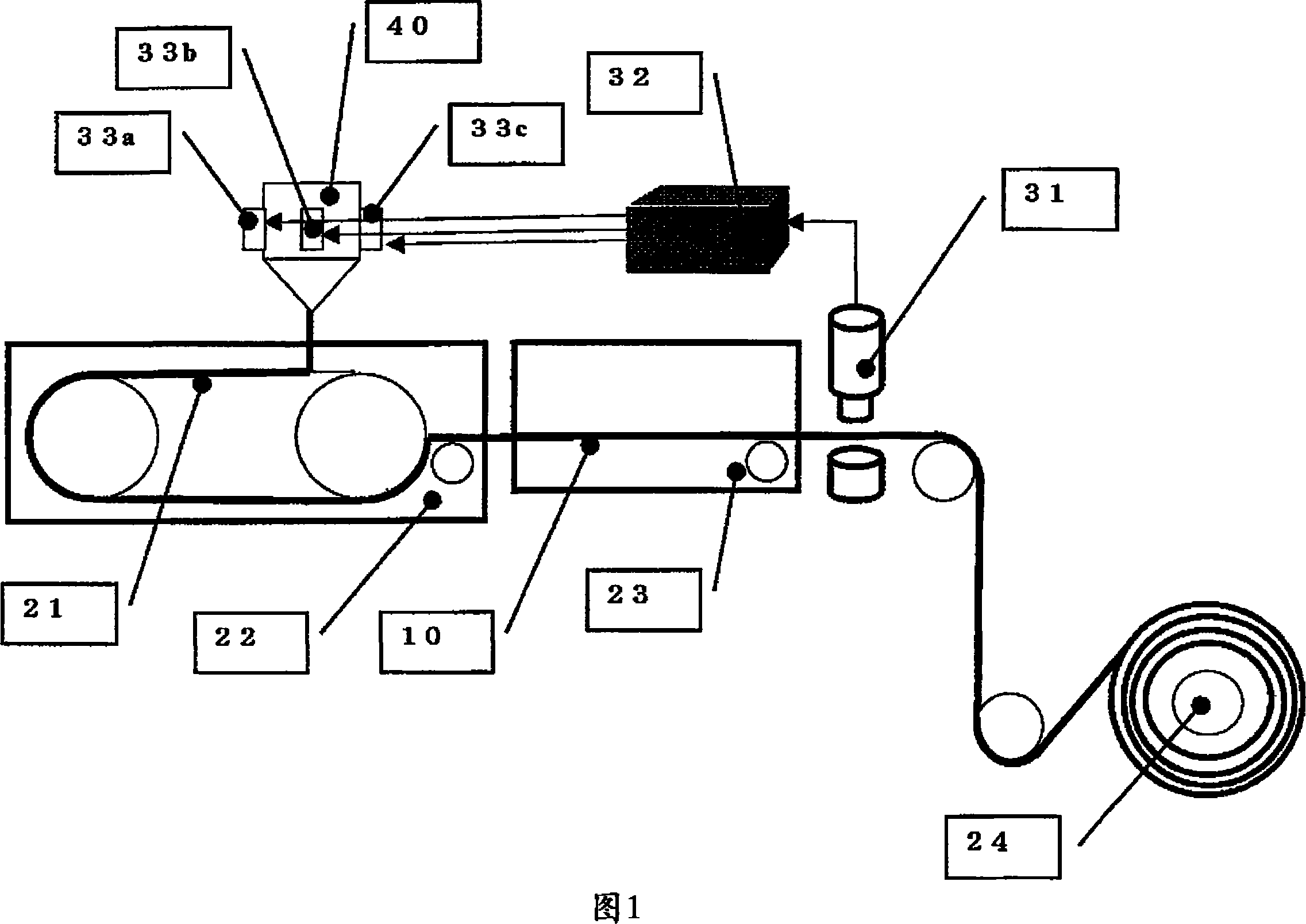

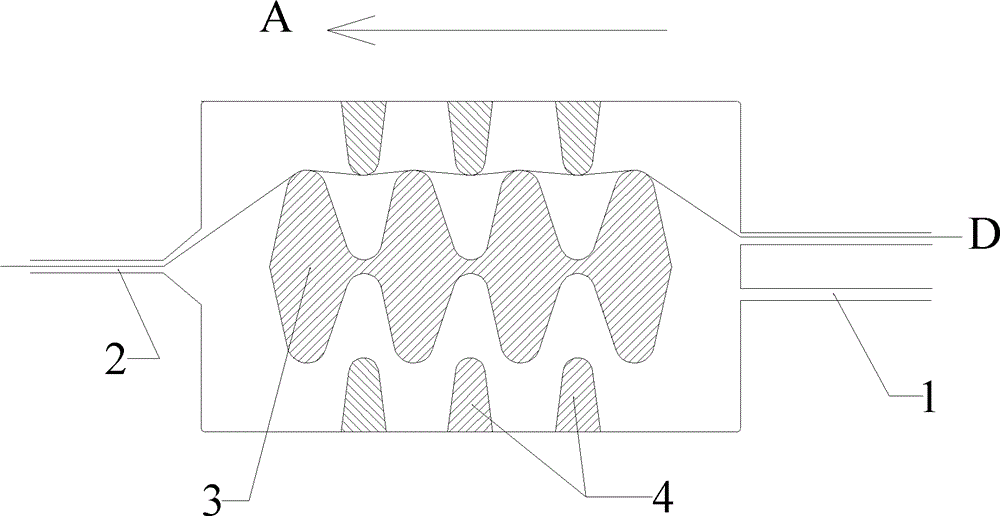

Production equipment and method for long fiber reinforced thermoplastic

ActiveCN102601887BReduce wearImprove dispersion efficiencyCoatingsPolymer scienceLong-fiber-reinforced thermoplastic

The invention discloses a dispersed structure during production of long fiber reinforced thermoplastic when grey yarns are impregnated, an impregnating mould head that uses the dispersed structure and a production method that uses the impregnating mould head. The dispersed structure provided by the invention is provided with a rotary dispersing core that is capable of dispersing the grey yarns effectively, has small abrasion and is not easy to break the mould head. The impregnating mould head that comprises a plurality of impregnating units and uses the structure is convenient to disassemble and has good universality and high efficiency. Compared with prior production method, the production method for long fiber reinforced thermoplastic that uses the impregnating mould head uses multiple strands and units to impregnate so that reinforced fiber is distributed uniformly in the bar (cross section) and ensures that fiber is not exposed so as to improve the production efficiency and quality. Meanwhile, as monofilament is not easy to break the mould head, the continuous production capacity of the production equipment is high.

Owner:JURONG BASTEP COMPOSITE MATERIALS

Method for extracting V2O5 and KAl(SO4)2.12H2O from mica-type stone coal

ActiveCN104789762AEasy to operateStrong continuous productionProcess efficiency improvementLeaching rateProcess engineering

The invention particularly relates to a method for extracting V2O5 and KAl(SO4)2.12H2O from mica-type stone coal. The technical scheme is as follows: the method comprises the following steps: crushing mica-type stone coal raw ore, grinding, and carrying out sulfating roasting to obtain a roasted product; carrying out primary leaching and primary solid-liquid separation on the roasted product to obtain a primary leach solution and a primary leach residue; carrying out secondary leaching on the primary leach residue, carrying out secondary solid-liquid separation to obtain a secondary leach solution and a secondary leach residue, returning the secondary leach solution as a primary leaching agent, and using the secondary leach residue as end tailings; cooling the primary leach solution to crystallize to obtain a crude product and a mother solution, and recrystallizing the crude product to obtain the KAl(SO4)2.12H2O; and extracting the mother solution to obtain an extraction raffinate and a vanadium-rich solution, returning the extraction raffinate as a secondary leaching agent, and precipitating vanadium from the vanadium-rich solution to obtain the product V2O5. The method has the characteristics of high V and K leaching rates, high yield, high production continuity and environment friendliness, and is simple to operate.

Owner:WUHAN UNIV OF SCI & TECH +1

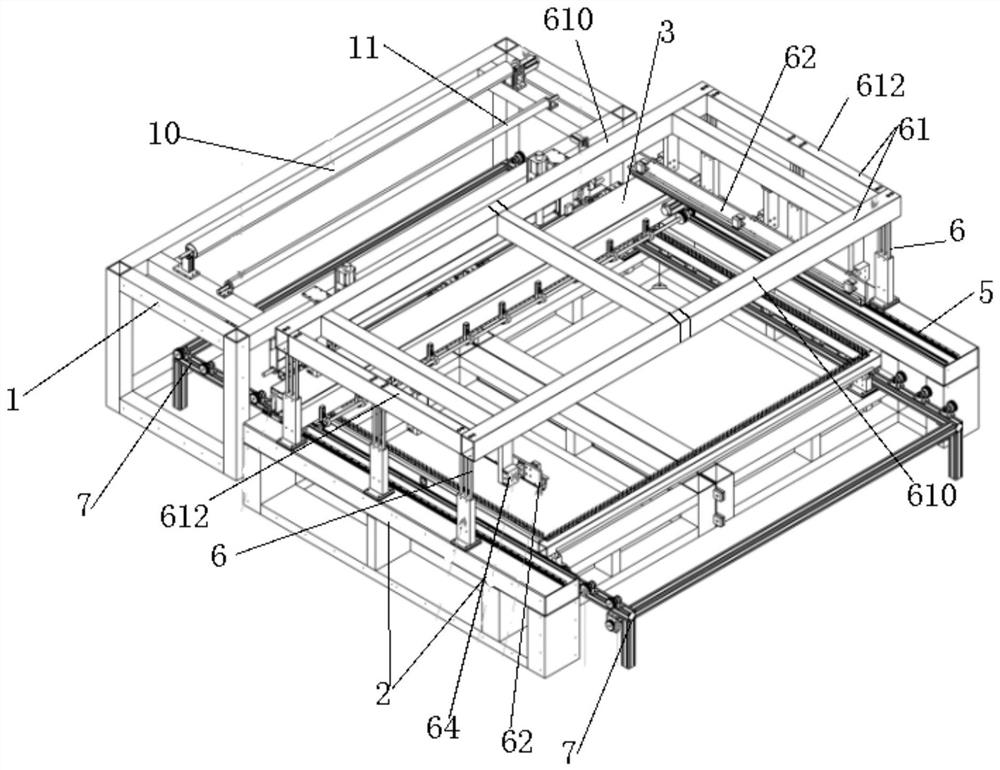

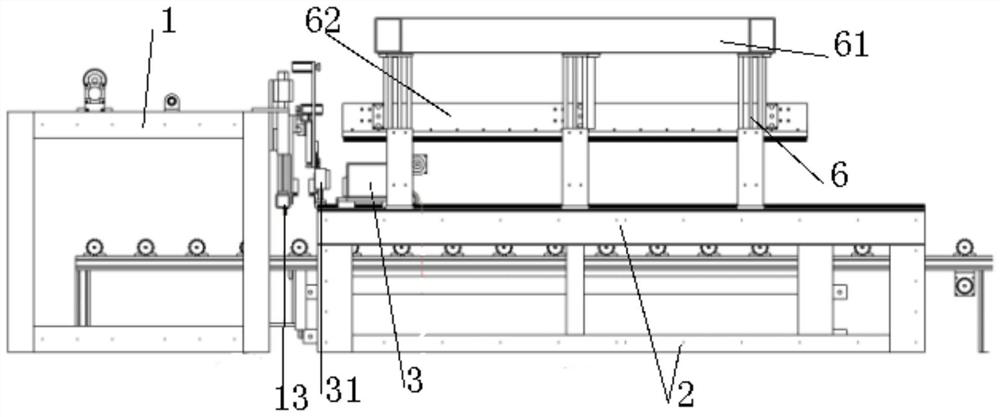

Automatic cloth hanging device

ActiveCN110685100AHigh degree of automationStrong continuous productionTextile treatment machine partsSevering textilesEngineeringMechanical engineering

An automatic cloth hanging device comprises a first base and a second base; a first roller and a second roller parallel to each other are arranged on the first base; a cloth hanging rack is arranged on one side, close to the second base, of the first base, and is parallel to the first roller; a gantry is arranged at the end, close to the first base, of the second base, is parallel to the cloth hanging rack, and is provided with an X-axis cloth hanging rack. The automatic cloth hanging device has the advantages of keeping cloth uniform, flat, tidy and smooth in hanging; cloth can be leveled effectively due to the fact that the cloth can be pulled from different directions by the cloth hanging racks; the automatic cloth hanging device has high level of automation, high continuous productioncapacity and low production cost.

Owner:广东众恒科技有限公司

Continuous chemical solid waste anaerobic carbonizing furnace

PendingCN107841317ANon-stop operationUninterrupted operation, continuous productionGasifier feeding meansGasification processes detailsCycloneCombustion chamber

The invention discloses a continuous chemical solid waste anaerobic carbonizing furnace which comprises: a fixing frame, a feed device, a jacket type double-layer furnace body with a gas mixture outlet, a discharge device, a combustion chamber with a burner nozzle and a third gas inlet and a fourth gas inlet, a mixing chamber with a third gas outlet and a fifth gas inlet, and a jacket pipeline, wherein one end of an inner pipe of the jacket pipeline is communicated with a first gas outlet of the furnace body, and the other end of the inner pipe is sequentially connected with a first cyclone dust collector and a first fan; a second gas outlet and a second gas inlet with a second fan are formed in an outer pipe of the jacket pipeline; the gas mixture outlet is communicated with the third gasinlet sequentially through a first pipeline and a third fan; the second gas outlet is connected with a fourth gas inlet through a second pipeline; the third gas outlet is communicated with a first gas inlet through a third pipeline; the fifth gas inlet is connected with a fourth fan. The carbonizing furnace has the advantages of strong continuous productivity, stable production, low energy consumption and zero exhaust emission in a carbonizing process.

Owner:张家港市天源机械制造有限公司

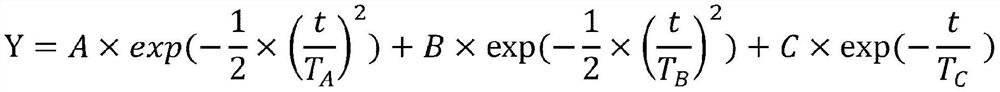

Chlorinated vinyl chloride-based resin

ActiveCN113728017AStrong continuous productionRefractory to pyrolysisCoatingsPolymer scienceChlorinated polyvinyl chloride

The present invention provides a chlorinated vinyl chloride-based resin which is prone to virtually no thermal decomposition, has excellent continuous productivity during a molding process, and can achieve both processability and unevenness preventing properties of a molded article. The present invention relates to a chlorinated vinyl chloride-based resin in which a component ratio of component C150 [component C150 / (component A150 + component B150 + component C150)] is less than 8.0%, as measured through the Solid Echo method at 150 DEG C by using pulse NMR, and as obtained by waveform-separating a free induction decay curve with respect to 1H spin-spin relaxation into three curves derived from the three components of component A150, component B150, and component C150 in order of shorter relaxation time by means of the least-squares method.

Owner:SEKISUI CHEM CO LTD +1

Stretched multilayer thermoplastic resin film

ActiveCN108602335AAdhesiveStretchableSynthetic resin layered productsPolarising elementsRefractive indexGlass transition

This invention can provide a stretched multilayer thermoplastic resin film comprising a layer including a thermoplastic resin (B) layered on at least one surface of a layer including a methacrylate resin (A), said stretched multilayer thermoplastic resin film being characterized in that: methyl methacrylate constitutes at least 90 mol% of all constituent units in the methacrylate resin (A); the intrinsic birefringence of the thermoplastic resin (B) is from -0.005 to 0.005; and the glass transition temperature TgA (DEG C) of the methacrylate resin (A) and the glass transition temperature TgB (DEG C) of the thermoplastic resin (B) satisfy the expression 5DEG C<(TgB-TgA)<50DEG C.

Owner:MITSUBISHI GAS CHEM CO INC

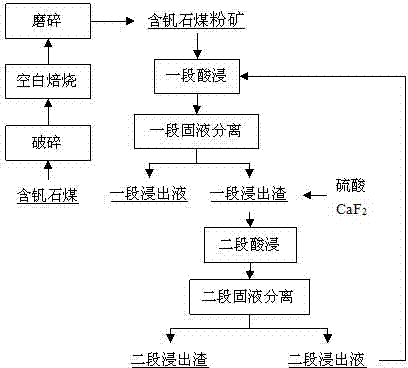

Method for extracting vanadium from stone coal containing vanadium

InactiveCN103421963BImprove leaching rateEliminate the effects ofProcess efficiency improvementPregnant leach solutionEngineering

The invention specifically relates to a method for extracting vanadium from vanadium-containing stone coal. The technical plan is: first crush the vanadium-containing stone coal to a particle size of <3mm, raise the temperature to 700~900°C, roast at a constant temperature for 1~2 hours, cool and grind to obtain vanadium-containing stone coal powder; Stirring and leaching with the vanadium-containing stone coal at a liquid-solid mass ratio of (2.5~5)︰1 at 80~100°C for 1~4h, performing a stage of solid-liquid separation, and the obtained stage leaching solution is used for subsequent purification and enrichment operations , the first-stage leaching residue is used in the second-stage acid leaching process; then prepare H2SO4 with a volume concentration of 10-25% in the stirring leaching tank, and add 1-7wt of the first-stage leaching residue according to the liquid-solid mass ratio (0.8~2)︰1 % CaF2, stirring and leaching at 80-100°C for 4-8 hours, and the second-stage solid-liquid separation, the obtained second-stage leachate is the leaching agent for the first-stage acid leaching, and the second-stage leaching residue is the final tailings. The invention has the advantages of high vanadium leaching rate, low acid consumption, simple process for extracting vanadium from stone coal and strong continuous productivity.

Owner:WUHAN UNIV OF SCI & TECH +1

A kind of mica type stone coal extraction v <base:sub> 2</base:sub> o <base:sub> 5</base:sub> and kal(so <base:sub> 4</base:sub> ) <base:sub> 2</base:sub> 12h <base:sub> 2</base:sub> o's method

ActiveCN104789762BImprove leaching rateControl separation temperatureProcess efficiency improvementRaffinateLeaching rate

The invention particularly relates to a method for extracting V2O5 and KAl(SO4)2.12H2O from mica-type stone coal. The technical scheme is as follows: the method comprises the following steps: crushing mica-type stone coal raw ore, grinding, and carrying out sulfating roasting to obtain a roasted product; carrying out primary leaching and primary solid-liquid separation on the roasted product to obtain a primary leach solution and a primary leach residue; carrying out secondary leaching on the primary leach residue, carrying out secondary solid-liquid separation to obtain a secondary leach solution and a secondary leach residue, returning the secondary leach solution as a primary leaching agent, and using the secondary leach residue as end tailings; cooling the primary leach solution to crystallize to obtain a crude product and a mother solution, and recrystallizing the crude product to obtain the KAl(SO4)2.12H2O; and extracting the mother solution to obtain an extraction raffinate and a vanadium-rich solution, returning the extraction raffinate as a secondary leaching agent, and precipitating vanadium from the vanadium-rich solution to obtain the product V2O5. The method has the characteristics of high V and K leaching rates, high yield, high production continuity and environment friendliness, and is simple to operate.

Owner:WUHAN UNIV OF SCI & TECH +1

Automatic floating coal removal system for mine

InactiveCN109264307AChange trackOptimize coal cleaning pathConveyorsCleaningComputerized maintenance management systemHydraulic pump

The invention discloses an automatic floating coal removal system for a mine. The removal system comprises a chain bucket type coal removal mechanical device, a coal pool, a hydraulic pump station anda control cabinet; the chain bucket type coal removal mechanical device is installed in the coal pool, mud pumps are arranged in the coal pool, the hydraulic pump station is in driving connection with the chain bucket type coal removal mechanical device, and the control cabinet is separately connected with the chain bucket type coal removal mechanical device, the hydraulic pump station and the mud pumps. According to the system, structural parameters can be adjusted according to actual production needs, floating coal can be removed in time, the operation is simple, the labor intensity of workers is reduced, potential safety hazards are eliminated, the work efficiency is improved, the continuous production capacity is good, maintenance and management are easy, and a good application and popularization effect is achieved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

An automatic hanging device

ActiveCN110685100BUniform hanging clothValance levelingTextile treatment machine partsSevering textilesEngineeringMechanical engineering

An automatic cloth hanging device includes a first base and a second base; the first base is provided with a first roller and a second roller that are parallel to each other; The frame is parallel to the first roller; the end of the second base close to the first base is provided with a gantry frame, the gantry frame is parallel to the cloth hanging frame, and the X-axis cloth hanging frame is arranged on the gantry frame; the beneficial effect is that the hanging cloth can be uniform, Flat, tidy and smooth; the cloth can be stretched from different directions through multiple hanging racks to make the cloth more flat; the high degree of automation and the strong continuous production capacity can reduce the production cost.

Owner:广东众恒科技有限公司

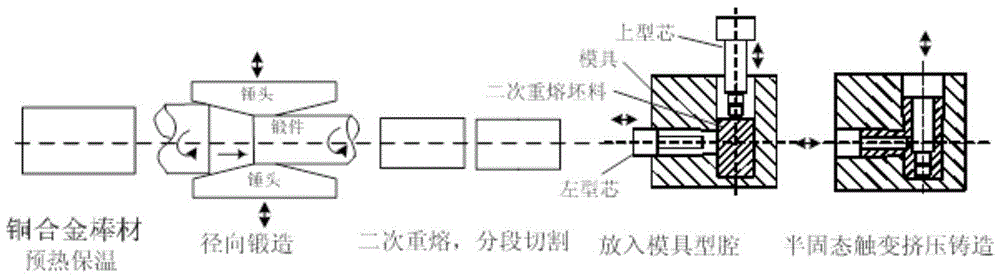

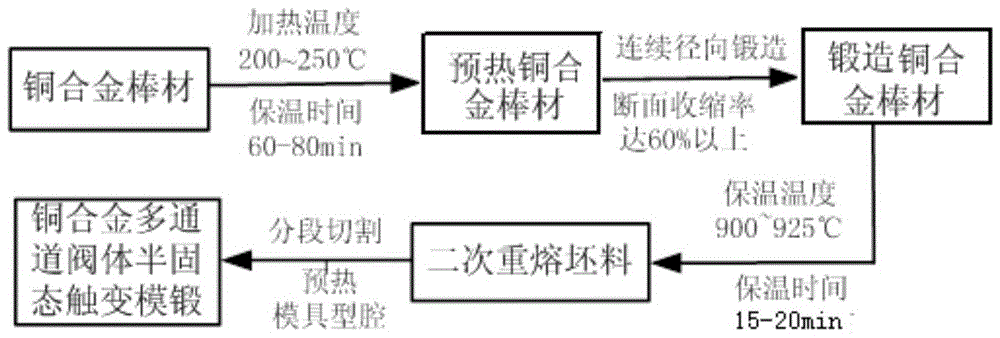

Fabrication process of semi-solid copper alloy multi-channel valve body by radial forging strain induction method

InactiveCN104624917BHigh microscopic defectsGood spherical grainValve arrangementsMetal-working apparatusMicro structureProduction rate

The process of preparing semi-solid copper alloy multi-channel valve body by radial forging strain induction method, first preheating the copper alloy rod, and then radially forging the copper alloy rod, the secondary remelting of the blank after radial forging, and then performing Semi-solid thixotropic die forging of copper alloy multi-channel valve body until the parts are completely solidified. Through this process, uniform copper alloy semi-solid blanks without microscopic defects can be prepared and formed with less microstructure defects, good mechanical properties, and sealing The multi-channel valve body with strong performance has less production process and high productivity.

Owner:XI AN JIAOTONG UNIV

Ultrafine particle mixing device

InactiveCN102614801BWell mixedEfficient mixingTransportation and packagingMixing methodsFluidized bedFine particulate

The invention discloses an ultrafine particle mixing device. An ultrafine particle mixing device system comprises a hopper, a spiral feeder, a Roots blower, an air chamber, a circulating fluidized bed, a cyclone dust collector, a vertical pipe, a material returning device, a bag-type dust collector and a material collector, wherein the circulating fluidized bed comprises a low speed bed, a transitional section and a high speed bed; a porous plate is arranged at the upper part of the air chamber as an air distribution plate; and the bag-type dust collector is connected with the cyclone dust collector. Ultrafine particles and auxiliary fluidized particles are available in the low speed bed. The auxiliary fluidized particles are added to the low speed bed through an auxiliary fluidized particle storage bin. The number of the types of the ultrafine particles is not less than two. The particle sizes of the ultrafine particles are less than 100 microns. The Roots blower supplies inert fluidizing gas which does not react with the ultrafine particles. The particle sizes of the auxiliary fluidized particles are more than 100 microns and less than 100 mm. A feeding device is the spiral feeder.

Owner:SOUTHEAST UNIV

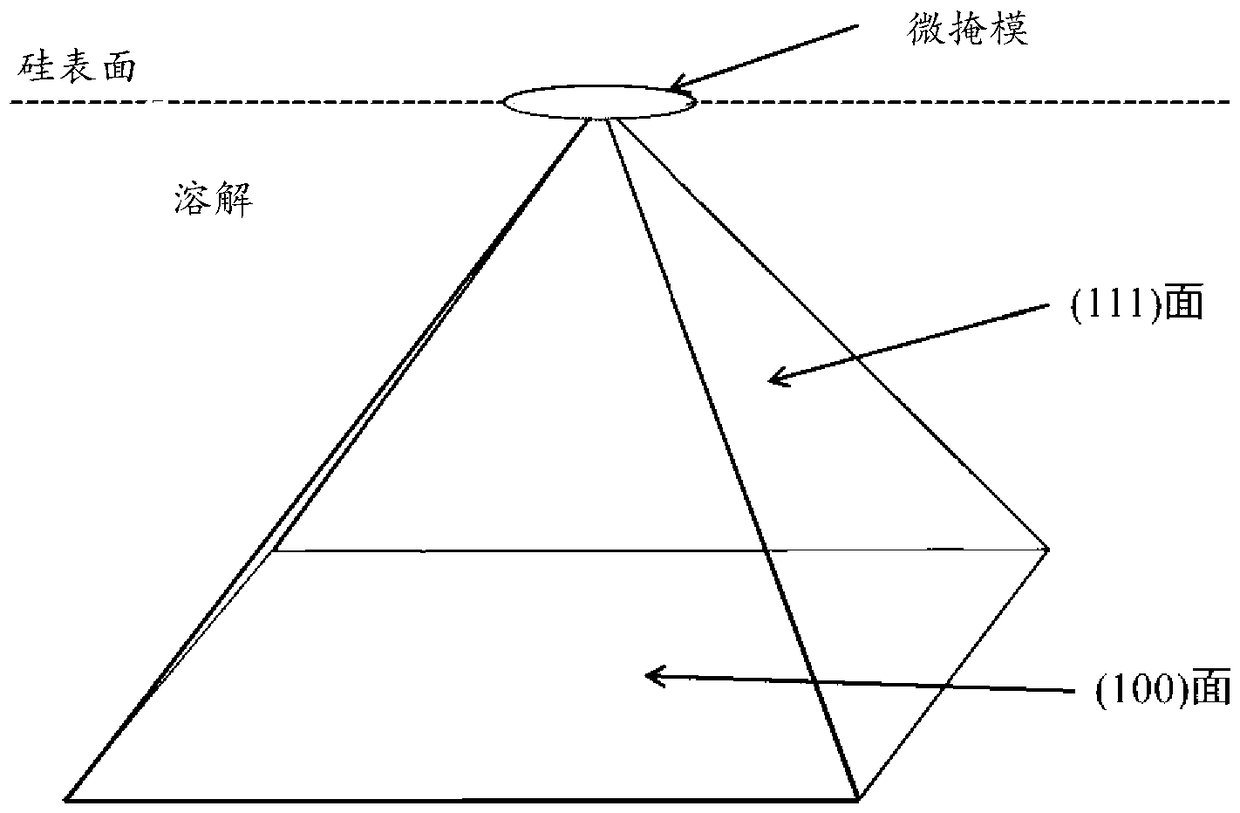

Etching liquid for semiconductor substrate

InactiveCN109314052AReduce processing load and costLow storage stabilityFinal product manufactureSemiconductor/solid-state device manufacturingOligomerSolar battery

The present invention provides an etching liquid, which is an alkaline etching liquid for treating the surface of a semiconductor substrate for solar cells, the alkaline etching liquid contains at least one hydroxystyrene-based polymer represented by general formula (1), the total amount of oligomers and monomers in which n is 1-8 contained in the hydroxystyrene-based polymer is no greater than 3.5% of the hydroxystyrene-based polymer. The present invention exhibits the effect of enabling texture formation on a semiconductor substrate for a solar cell in a shorter time at a relatively low temperature, exhibiting exceptional continuous producibility and product storage stability, and making it possible to stably obtain a surface having and low light reflectance. It is also possible to stably form pyramid-shaped recesses and projections of 3 [mu]m or less on average, and to stably impart surface shapes exhibiting a light reflectivity of 10% or less, which were unobtainable using the prior art, to a semiconductor substrate for a solar cell, without being affected by lot-to-lot fluctuations in the raw materials for the etching liquid.

Owner:SETTSU OIL MILL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com