Efficient recycling device and process for hollow particles in ash residues in ash storing yard and storage yard of power station

A recovery device and technology for ash storage yards, applied in the field of high-efficiency recovery devices and recovery technology for ash and slag hollow particles in ash storage yards in power stations, can solve the problems of high-efficiency recovery of ash and slag hollow particles in difficult storage yards, and ash hardening, etc., to achieve The effect of short payback time, continuous production capacity, and wear-resistant electrical insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0024] Example.

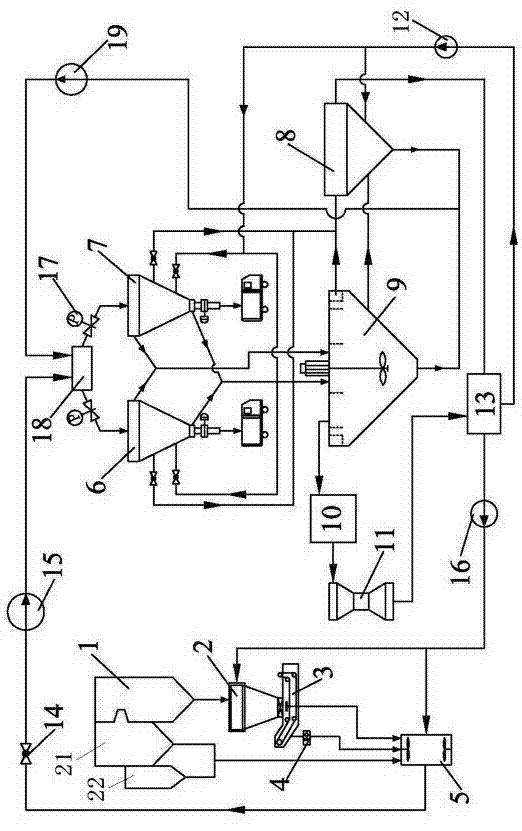

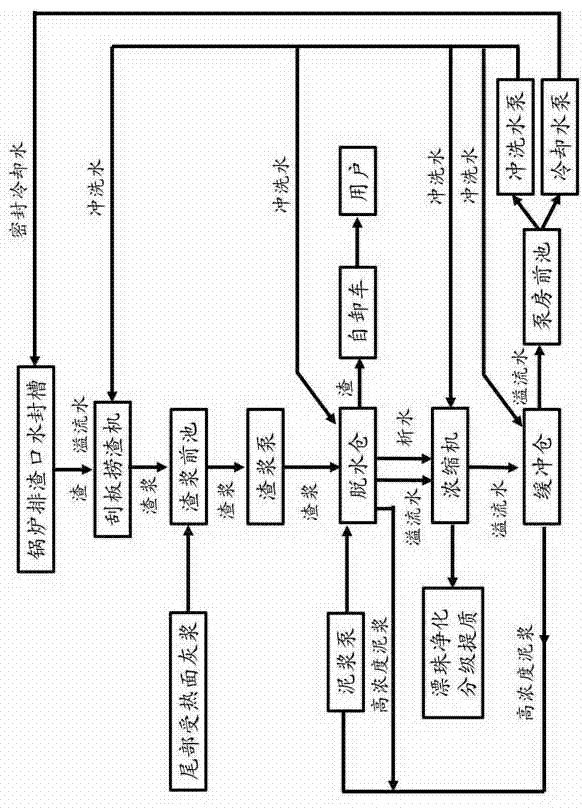

[0025] see Figure 1 to Figure 2 , the high-efficiency recovery device for ash and slag hollow particles in the ash storage yard of the power station in this embodiment includes a crusher 1, a screw feeder 2, a belt conveyor 3, an electric mixer 4, a mortar mixing tank 5, and water-cement ratio monitoring feedback Control system 6, electric control valve 7, slurry pump 8, manual control valve 9, dehydration bin 10, dehydration bin 11, concentrator 12, buffer pool 13, pneumatic gate valve 14, distribution header 15, collection pool 16, Purification and classification quality improvement device 17, return pool 18, No. 1 mud pump 19, No. 2 mud pump 20, circulating water pump 21 and ash yard return wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com