Ultrafine particle mixing device

A technology of ultra-fine particles and mixing device, which is applied in the directions of mixer, mixing method, transportation and packaging, etc., can solve the problems of uneven mixing, difficult to mix evenly in a fluidized bed, and difficult to fluidize ultra-fine particles, and achieve good mixing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

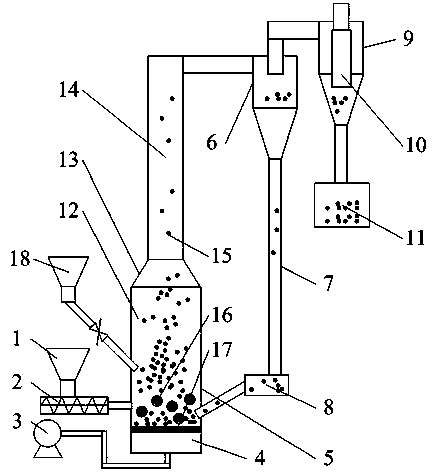

[0016] The mixing device of ultrafine particles of the present invention comprises a hopper 1, a screw feeder 2, a Roots blower 3, an air chamber 4, a circulating fluidized bed 5, a primary cyclone dust collector 6, a standpipe 7, a feeder 8, Secondary cyclone separator 9, bag dust collector 10 and material collector 11; wherein, circulating fluidized bed 5 is composed of low-velocity bed 12, transition section 13, and high-speed bed 14, and a dense-porous plate is arranged at the lower part of low-velocity bed 12 As the air distribution plate 17, the lower part of the air distribution plate 17 is an air chamber 4, the top of the low-speed bed 12 is connected with a transition section 13, the top of the transition section 13 is connected with a high-speed bed 14, and the top of the high-speed bed 14 is connected to the first-stage cyclone. The dust collector 6 is connected, and the bottom of the primary cyclone dust collector 6 is connected to the riser 7, and the bottom of the...

Embodiment 2

[0019] A mixing device for different ultrafine particles, such as attached figure 1 1. As shown in Example 1, a certain amount of auxiliary fluidized particles 16 (such as hollow alumina) with a particle size of 100 μm-100 mm is first added to the low-velocity bed 12 through the auxiliary fluidized particle silo 18 (with a valve on it). Then, manganese dioxide and lithium carbonate, which are materials for preparing lithium manganate with a particle size of less than 100 μm, are transported into the low-speed bed 12 through the screw feeder 2 . At the same time, fluidized nitrogen is supplied to the low-velocity bed 12 at the bottom of the circulating fluidized bed 5, and the manganese dioxide and lithium carbonate entering the circulating fluidized bed 5 are carried out in the low-velocity bed 12 under the action of the auxiliary fluidized particles 16 (hollow alumina). Steady-state fluidization and mixing under gas velocity to achieve primary mixing of manganese dioxide and...

Embodiment 3

[0021] A mixing device for different ultrafine particles, such as attached figure 1 1. As shown in Example 1, a certain amount of auxiliary fluidized particles 16 (such as solid alumina) with a particle size of 100 μm-100 mm is first added to the low-velocity bed 12 through the auxiliary fluidized particle silo 18 (with a valve on it). Keep the static bed height of auxiliary material 500-1000mm. Then, manganese dioxide and lithium carbonate, which are materials for preparing lithium manganate with a particle size of less than 100 μm, are transported into the low-speed bed 12 through the screw feeder 2 . Fluidizing nitrogen gas is supplied to the low velocity bed 12 at the bottom of the circulating fluidized bed 5, and the manganese dioxide and lithium carbonate entering the lower part of the circulating fluidized bed 5 pass through the gaps of the auxiliary fluidized particles 16 (solid alumina). The gas velocity of the fluidized gas is controlled to be greater than the term...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com