Novel treatment method for mother liquor obtained after centrifugal separation of ammonium sulfate in ammonia-process desulfurization

A technology of centrifugal separation and ammonia desulfurization, applied in ammonium sulfate and other directions, can solve problems such as equipment corrosion, unfavorable project social benefits, and reduced project economic benefits, etc., and achieves extensive use value and promotion prospects. Reasonable process and the effect of reducing project investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

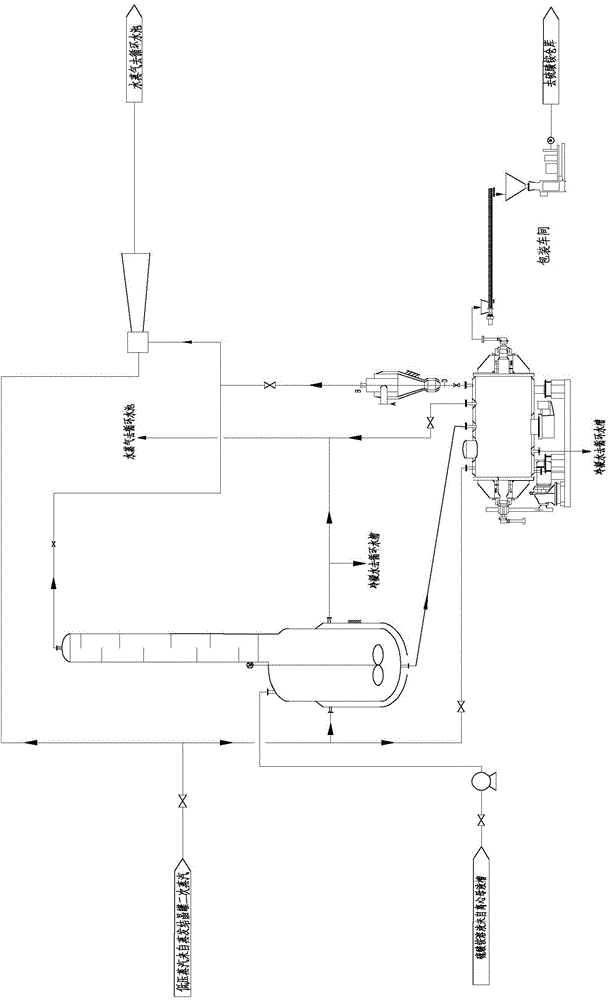

Image

Examples

example 1

[0047] 1. The ammonium sulfate mother liquor with a mass concentration of 20% from the ammonium sulfate centrifuge liquid tank material port is transported in the stripping tower through a pump, with a flow rate of 4t / h, a density of 1.15g / mL, and normal temperature.

[0048] 2. The control process parameters of this example are: the operating temperature in the stripper tank is 70-90°C, the pressure is 0.05MpaG, the speed of the agitator is 100r / min, the flow rate of ammonium sulfate solution into the equipment is 4t / h, and the feed is at room temperature. The steam temperature in the jacket is 120-150°C, and the pressure is 0.2-0.5Mpa.

[0049] 3. The material is evaporated and concentrated by steam heating in the stripping tower with stirring. The water circulation vacuum injection system inside the tower has a pressure of 0.05MpaG. The concentration time is controlled by field instruments or DCS control system.

[0050] 4. When the concentrated ammonium sulfate slurry obta...

example 2

[0053] 1. The ammonium sulfate mother liquor with a mass concentration of 25% from the ammonium sulfate centrifuge liquid tank material port is transported in the stripping tower through a pump, with a flow rate of 4t / h, a density of 1.15g / mL, and normal temperature.

[0054] 2. The control process parameters of this example are: the operating temperature in the stripper tank is 70-90°C, the pressure is 0.05MpaG, the speed of the agitator is 100r / min, the flow rate of ammonium sulfate solution into the equipment is 4t / h, and the feed is at room temperature. The steam temperature in the jacket is 120-150°C, and the pressure is 0.2-0.5Mpa.

[0055] 3. The material is evaporated and concentrated by steam heating in the stripping tower with stirring. The water circulation vacuum injection system inside the tower has a pressure of 0.05MpaG. The concentration time is controlled by field instruments or DCS control system.

[0056] 4. When the concentrated ammonium sulfate slurry obta...

example 3

[0059] 1. The ammonium sulfate mother liquor with a mass concentration of 30% from the ammonium sulfate centrifuge liquid tank material port is transported in the stripping tower through a pump, with a flow rate of 4t / h, a density of 1.16g / mL, and normal temperature.

[0060] 2. The control process parameters of this example are: the operating temperature in the stripper tank is 70-90°C, the pressure is 0.05MpaG, the speed of the agitator is 100r / min, the flow rate of ammonium sulfate solution into the equipment is 4t / h, and the feed is at room temperature. The steam temperature in the jacket is 120-150°C, and the pressure is 0.2-0.5Mpa.

[0061] 3. The material is evaporated and concentrated by steam heating in the stripping tower with stirring. The water circulation vacuum injection system inside the tower has a pressure of 0.05MpaG. The concentration time is controlled by field instruments or DCS control system.

[0062] 4. When the concentrated ammonium sulfate slurry obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com