720mpa grade high-strength corrosion-resistant titanium alloy drill pipe and manufacturing method

A manufacturing method and high-strength technology, applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of difficult processing, expensive alloying elements, high production costs, increase the difficulty of extrusion, increase the surface Aggregated thickness and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

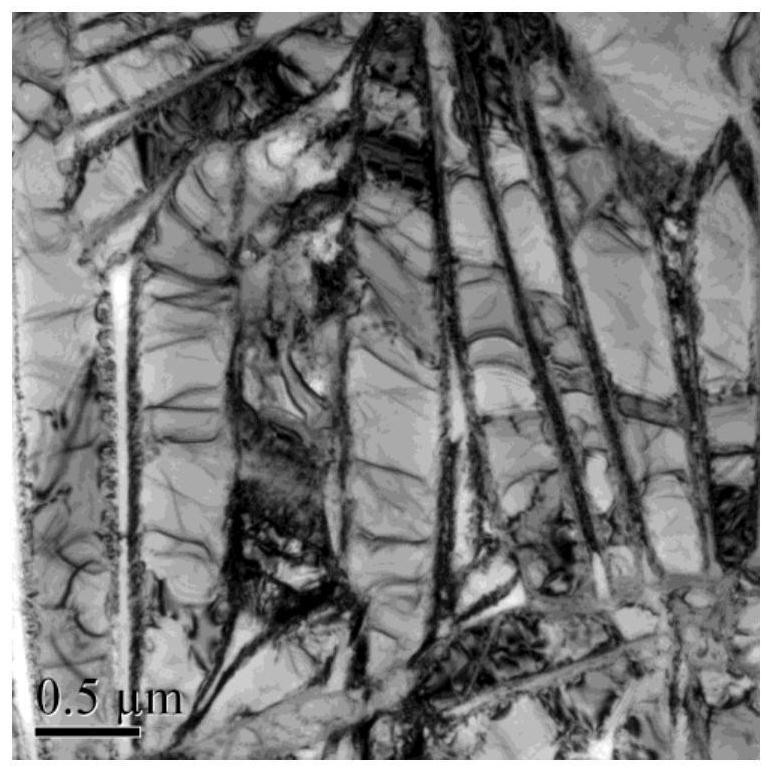

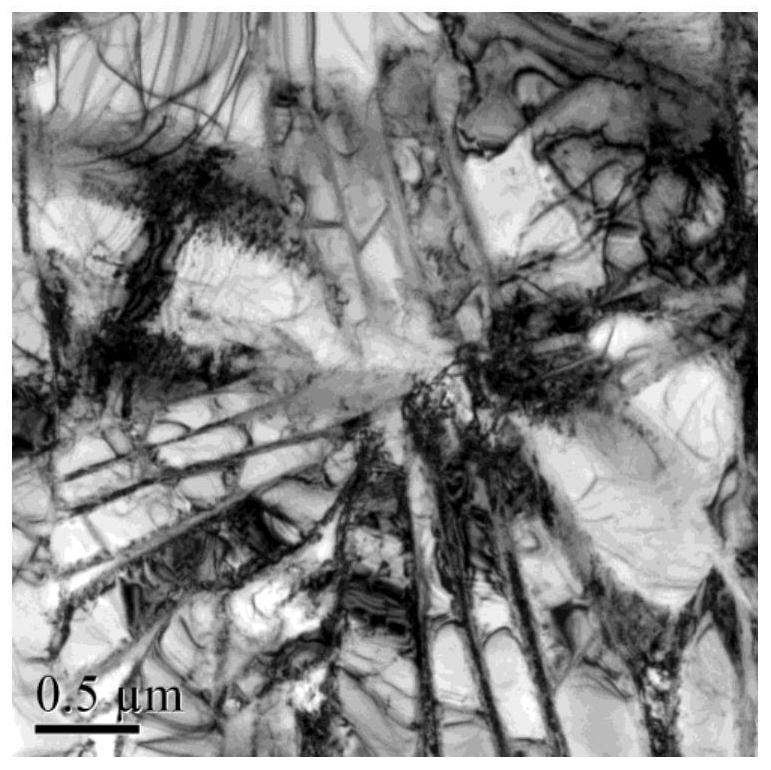

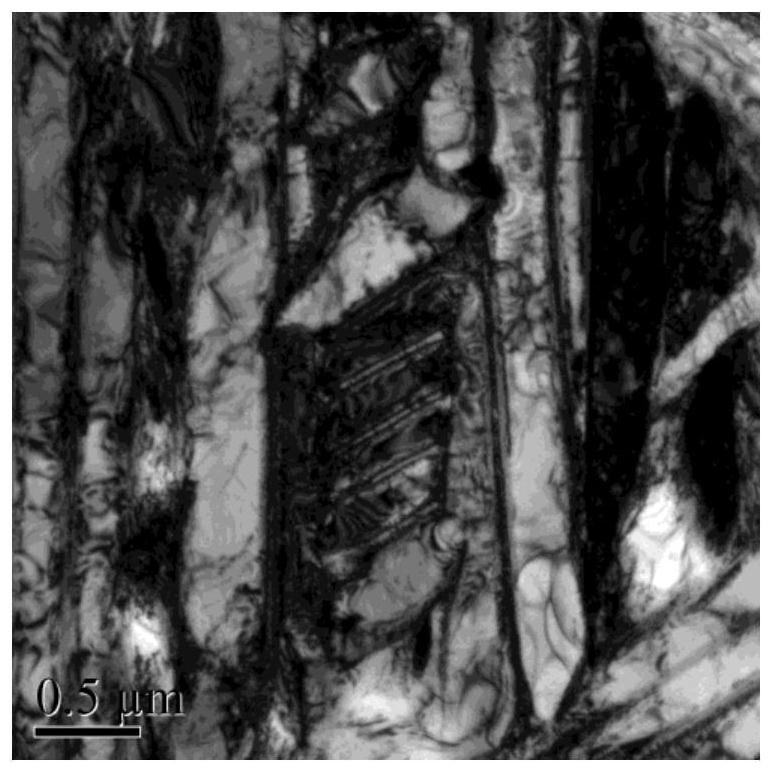

Image

Examples

Embodiment 1

[0057] The invention relates to a method for manufacturing a pipe body for a 720MPa grade high-strength corrosion-resistant titanium alloy drill pipe.

[0058] Step 1, prepare raw materials according to the components of the pipe, and sequentially smelt, cast and forge to obtain a round ingot. The composition of the pipe is calculated as: Al 5.75%, V 1.85%, Ru 0.2%, C≤0.05%, N≤0.03%, H≤0.0125%, O≤0.1%, the balance is Ti;

[0059] Step 2, heating the above-mentioned round ingot to 1000° C., holding it for 1 hour and then extruding and deforming, the extrusion ratio of extrusion is 18, and the extrusion speed is 95m / s to obtain a pipe;

[0060] Step 3, after rolling the pipe at 470°C, keep it at 800°C for 1 hour for annealing treatment;

[0061] Step 4, heating the annealed pipe to 960°C, holding for 1 hour, cooling to 935°C with the furnace, holding for 1 hour, and cooling to room temperature naturally;

[0062] Step 5, after applying 1.5% pre-stretching deformation to the tr...

Embodiment 2

[0065] The invention relates to a method for manufacturing a pipe body for a 720MPa grade high-strength corrosion-resistant titanium alloy drill pipe.

[0066] Step 1, prepare raw materials according to the components of the pipe, smelt and cast in sequence to obtain a round ingot, and the components of the pipe are calculated as: Al 5.8%, V 1.9%, Ru 0.25%, C≤0.05%, N≤ 0.03%, H≤0.0125%, O≤0.1%, the balance is Ti;

[0067] In step 2, the above-mentioned round ingot is heated to 1000° C., held for 1 hour, and then extruded and deformed. The extrusion ratio of extrusion is 23, and the extrusion speed is 110 m / s to obtain a pipe;

[0068] Step 3, after rolling the pipe at 470°C, keep it at 800°C for 1 hour for annealing treatment;

[0069] Step 4, heating the annealed pipe to 965°C, holding for 1 hour, cooling to 935°C with the furnace, holding for 1 hour, and naturally cooling to room temperature;

[0070] Step 5, after applying a pre-stretching deformation of 1.8% to the treat...

Embodiment 3

[0077] The invention relates to a method for manufacturing a pipe body for a 720MPa grade high-strength corrosion-resistant titanium alloy drill pipe.

[0078] Step 1, prepare raw materials according to the components of the pipe, and sequentially smelt, cast and forge to obtain a round ingot. The components of the pipe are calculated as: Al 6%, V 1.5%, Ru 0.3%, C≤0.05%, N≤0.03%, H≤0.0125%, O≤0.1%, the balance is Ti;

[0079] Step 2, heating the above-mentioned round ingot to 980°C, extruding and deforming after 0.8h heat preservation, the extrusion ratio of extrusion is 16, and the extrusion speed is 85m / s to obtain a pipe;

[0080] Step 3, after rolling the pipe at 450°C, keep it at 830°C for 0.8h for annealing treatment;

[0081] Step 4, the annealed pipe is heated to 950°C, kept for 1.2h, cooled to 930°C with the furnace, kept for 1.2h, and naturally cooled to room temperature;

[0082] Step 5, after applying 1% pre-stretching deformation to the treated pipe, heating to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion potential | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com