High-temperature circular-heating fluidized bed pyrolysis gas producing system

A high-temperature cycle and cyclic heating technology, applied in the manufacture of combustible gas, granular/powder fuel gasification, energy input, etc., can solve the problems of small processing capacity, low calorific value, increase operating cost, etc., and reduce the content of carbon monoxide. , the effect of reducing the amount of residual carbon and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

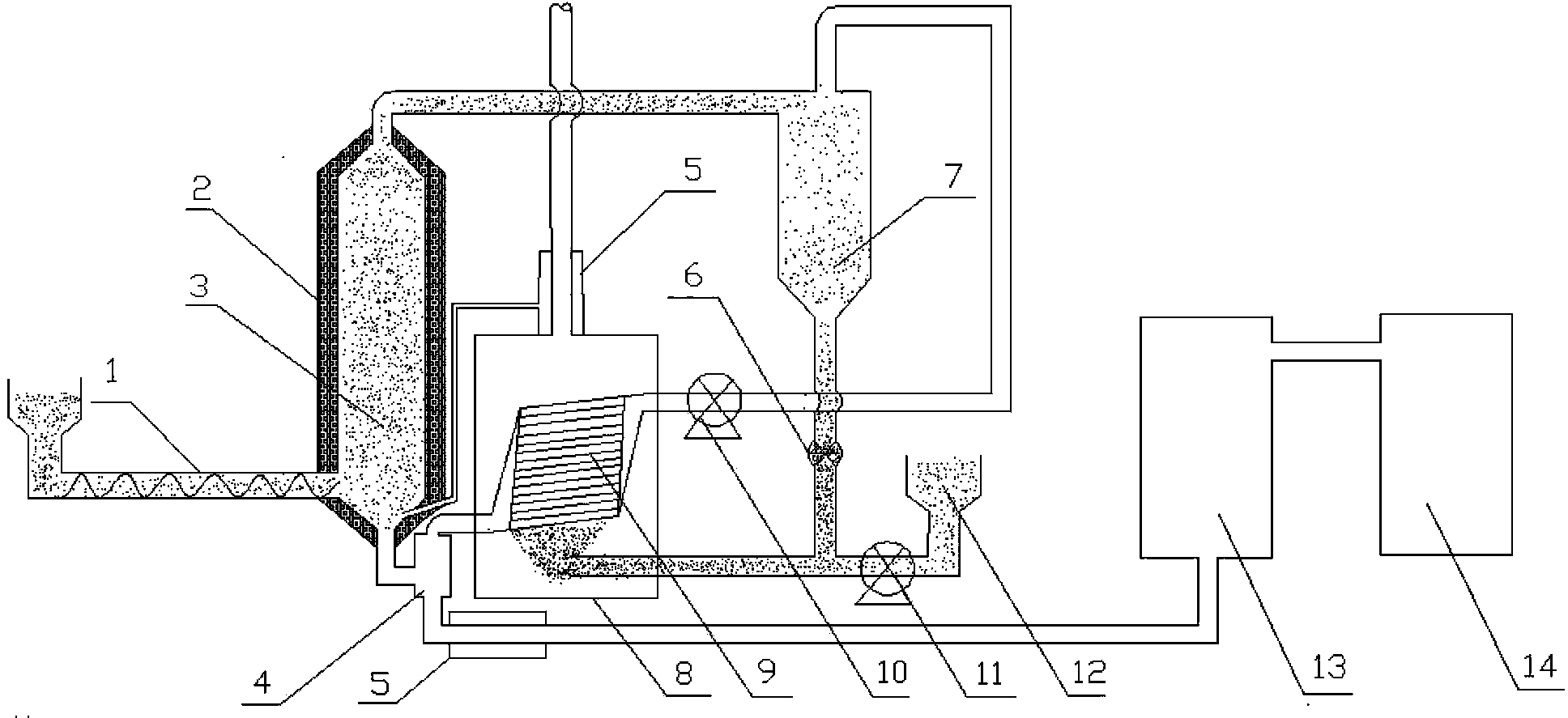

[0025] The high temperature circulating heating fluidized bed pyrolysis gas production system includes gasification material feeding system 1, insulation jacket 2, fluidized bed 3, gas distributor 4, waste heat boiler 5, format feeder 6, cyclone dust collector 7 , Circulating heating furnace 8, inclined tubes 9, high-temperature circulating fan 10, ordinary fan 11, supplementary fuel system 12, ash removal and purification device 13, and gas storage device 14. When producing gas, first add granular biomass to the gasification material feeding system 1, start the high-temperature fan 9, and then gradually heat the gas in the inclined tubes 9 in the circulating heating furnace 8 to 1000°C through the supplementary combustion system 12, Become a high-temperature gas; the high-temperature gas enters the fluidized bed 3, fluidizes and gasifies the granular biomass in it at the same time, controls the flow rate of the gas, and stabilizes the temperature difference between the gas out...

Embodiment 2

[0028] The high temperature circulating heating fluidized bed pyrolysis gas production system includes gasification material feeding system 1, insulation jacket 2, fluidized bed 3, gas distributor 4, waste heat boiler 5, format feeder 6, cyclone dust collector 7 , Circulating heating furnace 8, inclined tubes 9, high temperature fan 10, common fan 11, supplementary fuel system 12, ash removal and purification device 13, gas storage device 14. When producing gas, first add powdery biomass raw materials to the gasification material feeding system 1, then add gas to the inclined tubes 9 in the circulating heating furnace 8 through the supplementary combustion system 12, start the high-temperature fan 9, and make the circulating heating furnace 8 The gas in the middle inclined tube 9 is gradually heated to 1100°C and becomes a high-temperature gas; the high-temperature gas enters the fluidized bed 3, fluidizes and vaporizes the gasified material in it at the same time, controls the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com