Pressure-torsion die, pressure-torsion machining equipment and pressure-torsion machining method of difficult-to-deform metal materials

A technology for metal materials and processing equipment, applied in metal processing equipment, forging/pressing/hammering machinery, forming tools, etc., can solve the problems of difficult application of torsional motion, high cost, complicated maintenance, etc. The effect of cost reduction and microstructure stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

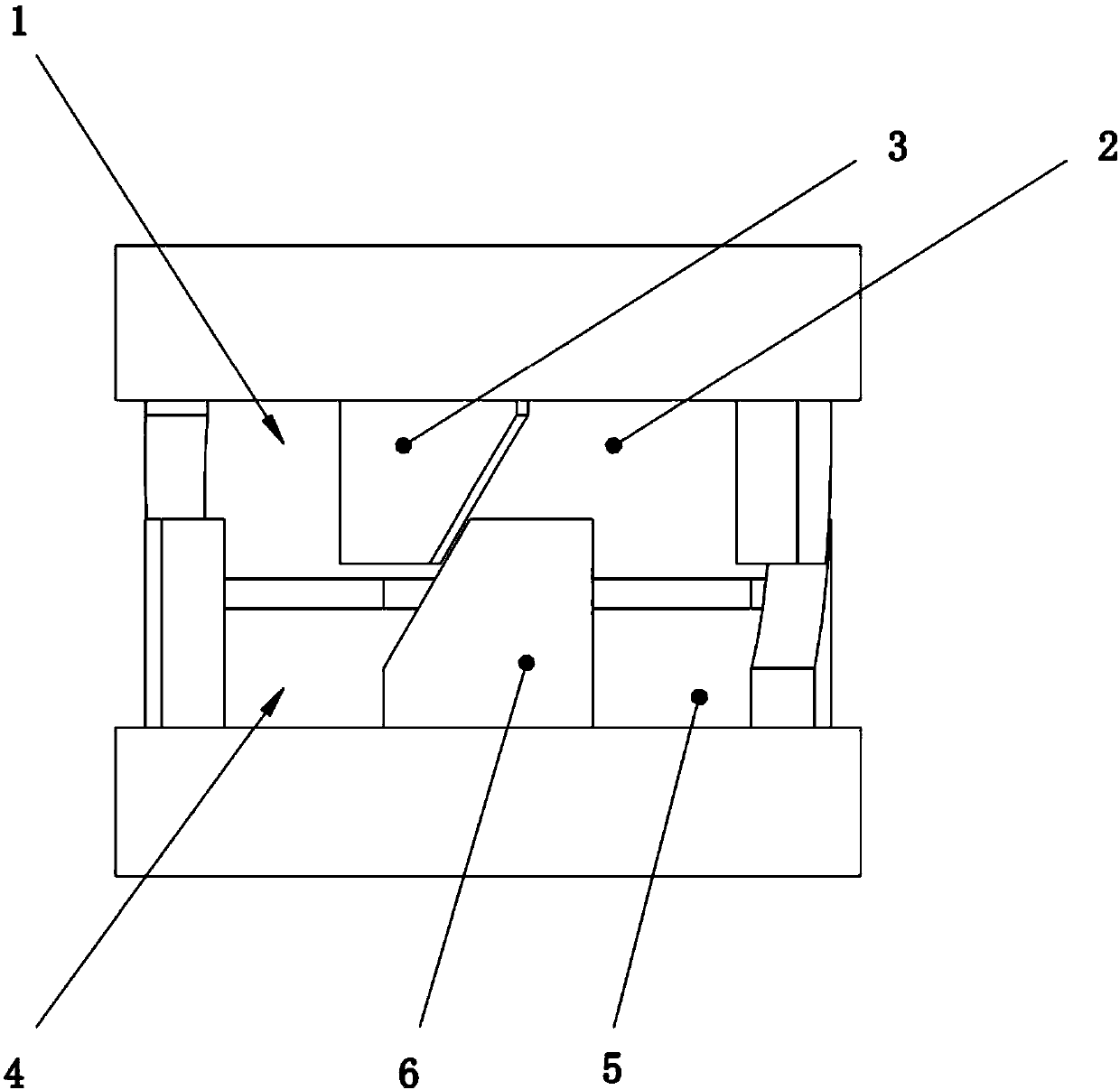

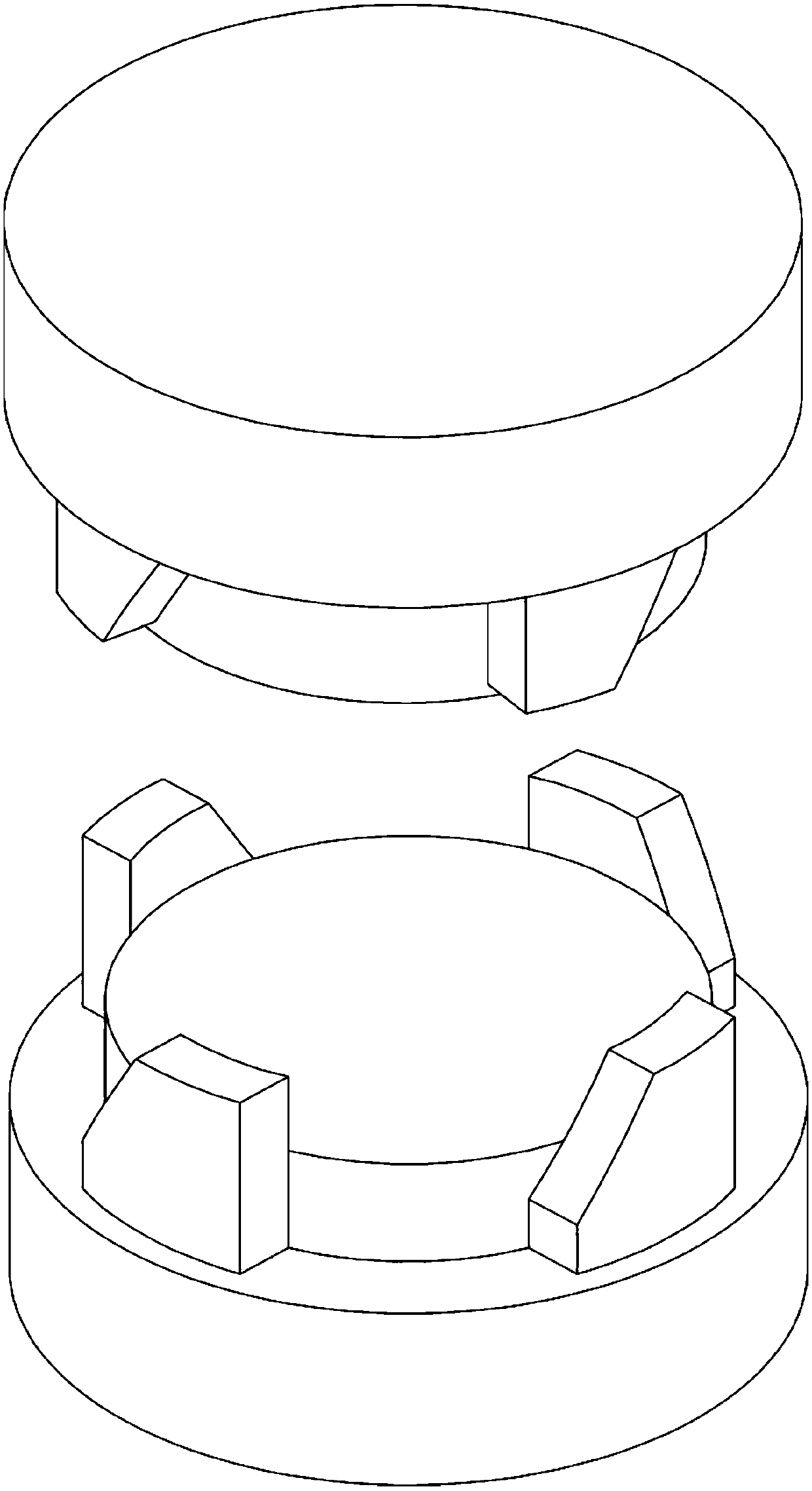

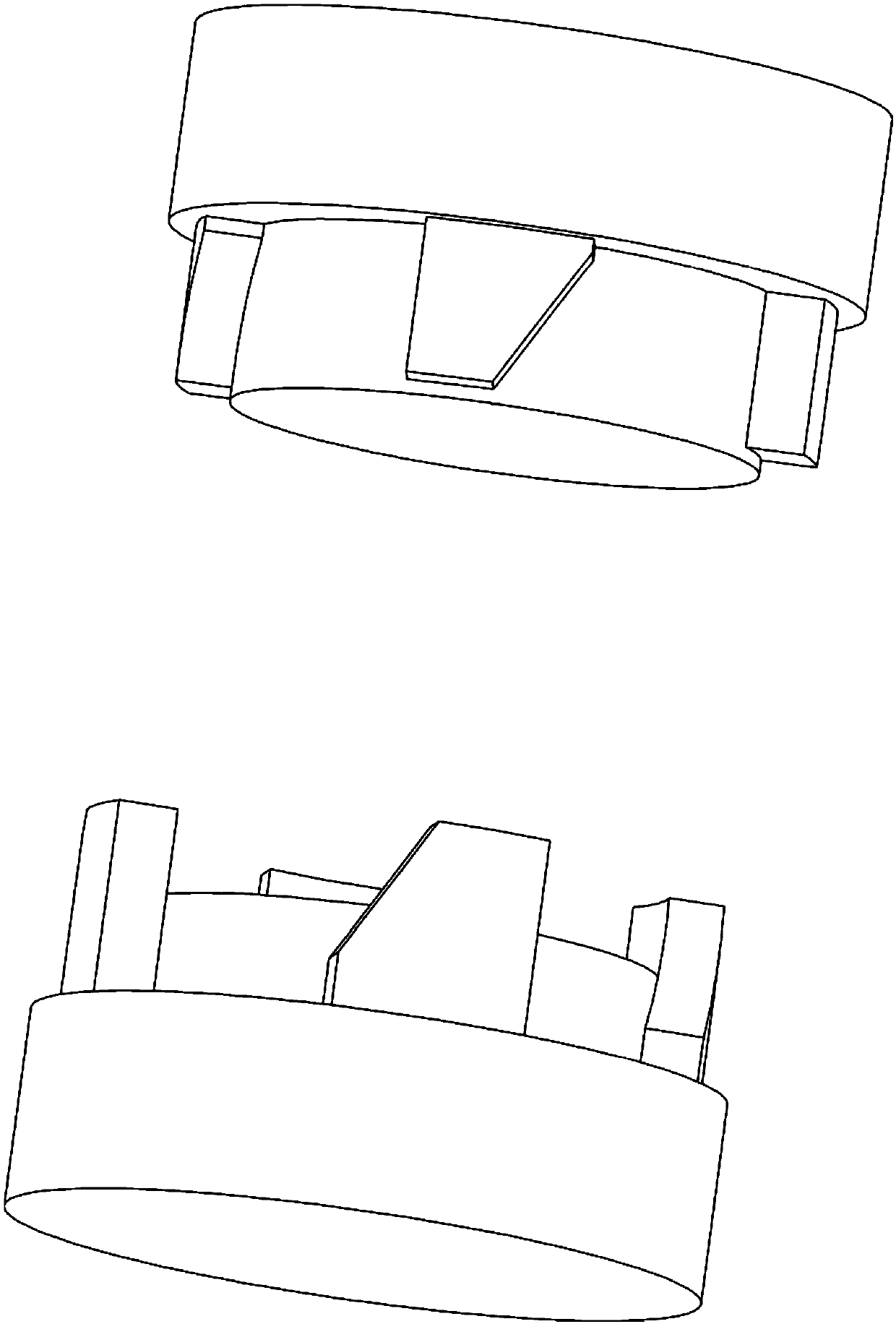

[0036] A 7075 aluminum alloy cylinder with a diameter of 100 mm and a height of 100 mm is selected as the initial material, and the molding die is figure 1 In the compression torsion die with the structure shown, the inclination angle between the driving surface and the driven surface is 45°, and the friction coefficient between the pushing surface and the driven surface is about 0.2. First place the aluminum alloy block in the torsion mold, and then fix the mold on a 500-ton hydraulic press. Start the hydraulic press, the upper pressing block of the hydraulic press goes down and pushes the upper die 1 down through the upper template 9 of the mold until the upper die 1 is in close contact with the aluminum alloy to be processed; at the same time, adjust the initial action position of the spring so that the upper die 1 is in contact with the material When contacting, the pushing surface and driven surface between the upper and lower dies 4 are also in close contact; the hydraul...

Embodiment 2

[0038] A pure molybdenum column with a diameter of 90mm and a height of 50mm is selected as the initial material, and the molding mold is figure 1 In the compression torsion die with the structure shown, the inclination angle between the driving surface and the driven surface is 63°, and the friction coefficient between the pushing surface and the driven surface is about 0.2. First place the pure molybdenum column in the torsion mold, and then fix the mold on the 315-ton hydraulic press. Start the hydraulic press, the upper pressing block of the hydraulic press goes down and pushes the upper die 1 down through the upper template 9 of the mold until the upper die 1 is close to the pure molybdenum column to be processed; at the same time, adjust the initial action position of the spring so that the upper die 1 and the When the material is in contact, the pushing part 3 and the driven part 6 are also in close contact; the hydraulic press continues to push the upper die 1 down by ...

Embodiment 3

[0040] A sintered TZM cylinder with a diameter of 80 mm and a height of 16 mm is selected as the initial material, and the molding die is figure 1 In the compression torsion die with the structure shown, the inclination angle between the driving surface and the driven surface is 70°, and the friction coefficient between the pushing surface and the driven surface is about 0.15. First place the TZM cylinder in the torsion mold, and then fix the mold on the 315-ton hydraulic press. Start the hydraulic press, the upper pressing block of the hydraulic press goes down and pushes the upper die 1 down through the upper template 9 of the mold until the upper die 1 is in close contact with the TZM cylinder to be processed; at the same time, adjust the initial action position of the spring so that the upper die 1 is in contact with the material When in contact, the pushing part 3 and the driven part 6 are also in close contact; the hydraulic press continues to push the upper die 1 down b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com