Heat treatment method for cast aluminium alloy

A technology of casting aluminum alloy and heat treatment method, which is applied in the field of heat treatment of metal materials and heat treatment process of cast aluminum alloy, can solve problems such as increasing economic cost, and achieve the effects of high production efficiency, low cost and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

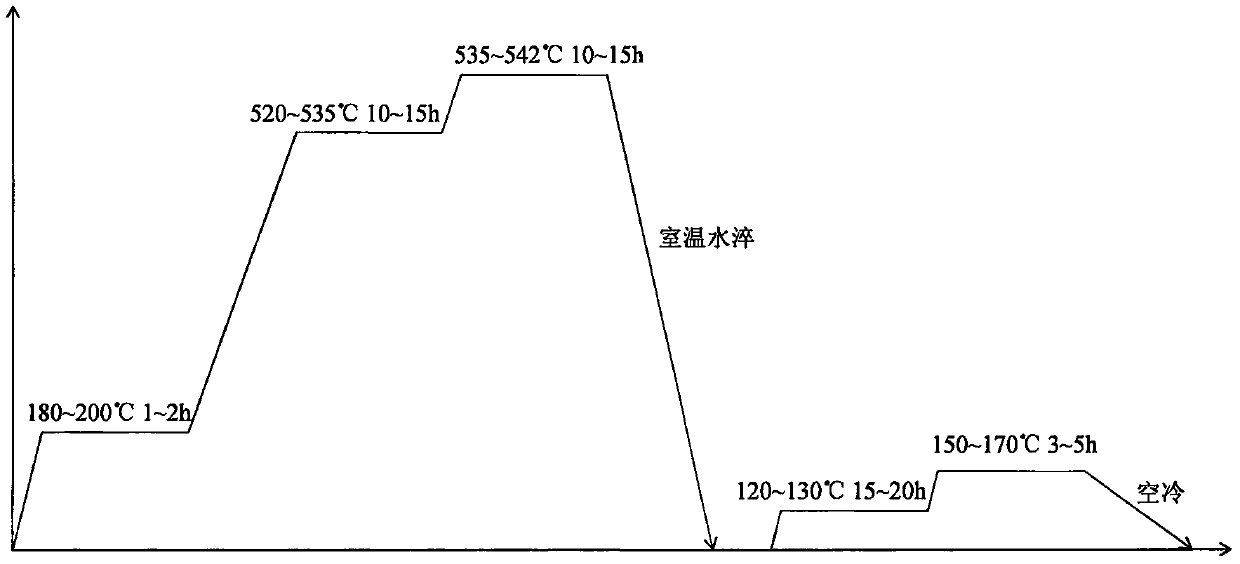

[0018] The technical solution of the present invention will be further introduced in detail below in conjunction with the accompanying drawings of the description.

[0019] The invention discloses a heat treatment method for cast aluminum alloy, wherein, the mass percentage of the components of the cast aluminum alloy is Cu: 2.2-2.9%; Mn: 0.3-0.4%; Cd: 0.15-0.19%; Ti: 0.1-0.15%; Zr: 0.10-0.15%; Ag: 0.05-0.15%, the total impurity content is not more than 0.1%, and the balance is aluminum.

[0020] The aluminum alloy of the above components is melted and poured, and the casting is heat treated.

[0021] as attached figure 1 As shown, a heat treatment method for cast aluminum alloy disclosed in the present invention comprises the following steps:

[0022] The first step is to heat-preserve the casting at 190°C for 1 hour;

[0023] In the second step, the casting is subjected to heat preservation treatment at 525°C, and the heat preservation time is 15h;

[0024] The third ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com