A 500MPa-level low-Cu Mg-free aluminum alloy and a preparation method thereof

An aluminum alloy, C-460 technology, applied in the field of alloying design and heat treatment of 500MPa low-Cu and Mg-free aluminum alloys, can solve problems such as increasing production costs, reduce usage, ensure performance requirements, and have excellent tensile strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

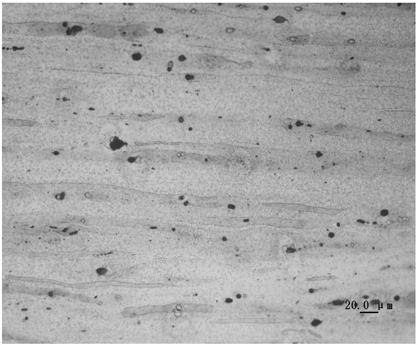

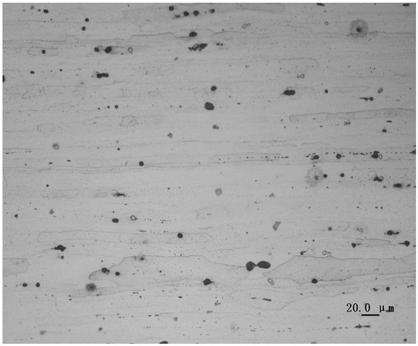

[0036] The composition of the aluminum alloys of Examples 1-3 is the same, and the smelting, casting, forging billet heating and rolling processes are the same, the difference lies in the subsequent heat treatment process system, the specific process is as follows:

[0037] (1) Smelting: A furnace of aluminum alloy was smelted, and its actual chemical composition (% by weight) is Cu: 3.62%, Mn: 0.73%, Fe: 0.41%, Si: 0.38%, Zn: 0.30%, Ti: 0.15%, Ni: 0.08%, and the balance is Al. The cast slab has undergone heat inspection and stack cooling for 48 hours. The surface quality of the slab before entering the furnace is good, and there is no grinding of the slab.

[0038] (2) Slab heating and rolling: hot-roll the homogenized annealed 30±2mm thick plate at 460-480℃ to 6.5±0.5mm at 440-460℃, and then solid solution at 480-500℃ for 1-2h Quenching immediately after that, and then cold rolling to 1.5±0.5mm thin plate at room temperature.

[0039] (3) Heat treatment process and equipme...

Embodiment 4-6

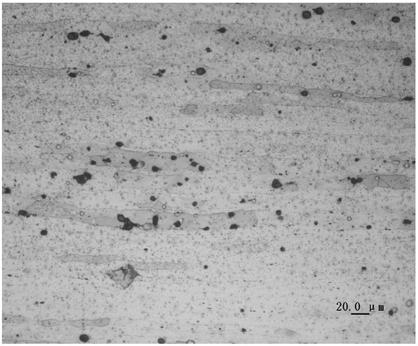

[0046] The composition of the aluminum alloys of Examples 4-6 is the same, and the smelting, casting, forging billet heating and rolling processes are the same, the difference lies in the subsequent heat treatment process system, the specific process is as follows:

[0047] (4) Smelting: A furnace of aluminum alloy was smelted, and its actual chemical composition (% by weight) is Cu: 3.82%, Mn: 0.61%, Fe: 0.31%, Si: 0.14%, Zn: 0.12%, Ti: 0.07%, Ni: 0.5%, and the balance is Al. The cast slab has undergone heat inspection and stack cooling for 48 hours. The surface quality of the slab before entering the furnace is good, and there is no grinding of the slab.

[0048] (5) Slab heating and rolling: the casting slab heating temperature is selected as 430°C, the holding time is 1.5h, and the cooling method is cooled to 250°C with the furnace at a cooling rate of less than 30°C / h and then air-cooled to room temperature; at 450°C The homogenized annealed thick plate is hot rolled fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com