Production method of spring flat steel

A production method and flat steel technology, applied in the field of iron and steel production, can solve the problems of large equipment wear, large loss of processing tools, high hardness, etc., and achieve the effects of heat treatment process optimization, composition design optimization, and low hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The chemical composition of the steel is C: 0.36%, Si: 1.2%, Mn: 0.3%, Cr: 0.60%, Ni: 0.50%, V: 0.20%, Nb: 0.030%, Al: 0.020%, P: 0.003 %, S: 0.005%, Cu: 0.02%, O: 0.0011%, N: 0.0150%, and the rest are Fe and inevitable impurities. Key process steps include:

[0032] (1) Smelting: During smelting, the converter adopts double-slag carbon-preserving smelting, and the control end point is C=0.17%; the refining adopts high-basicity slag-making and deoxidation process, and Al is adjusted in place at one time in the early stage, and it is strictly forbidden to adjust aluminum in the later stage.

[0033] (2) Continuous casting: The molten steel after smelting is continuously cast to obtain a slab. During continuous casting, the superheat degree of the tundish is 15~25℃, the weak cooling is adopted, the specific water volume is 0.16L / kg, with electromagnetic stirring and light pressing at the end. 24h.

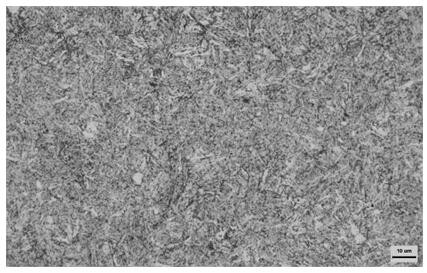

[0034] (3) Rolling: The continuous casting billet is hot rolled into s...

Embodiment 2

[0038]The chemical composition of the steel is C: 0.38%, Si: 1.3%, Mn: 0.3%, Cr: 0.80%, Ni: 0.50%, V: 0.25%, Nb: 0.030%, Al: 0.025%, P: 0.005 %, S: 0.004%, Cu: 0.03%, O: 0.0009%, N: 0.0160%, and the rest are Fe and inevitable impurities. Key process steps include:

[0039] (1) During smelting, the converter adopts double-slag carbon-preserving smelting, and the end-point carbon is controlled at 0.16%; the refining adopts a high-basicity slag-forming and deoxidizing process, and the Al is adjusted in place at one time in the early stage, and it is strictly forbidden to adjust the aluminum in the later stage.

[0040] (2) Continuous casting: The molten steel after smelting is continuously cast to obtain a slab. During continuous casting, the superheat degree of the tundish is 15~25℃, the weak cooling is adopted, the specific water volume is 0.16L / kg, with electromagnetic stirring and light pressing at the end. 24h.

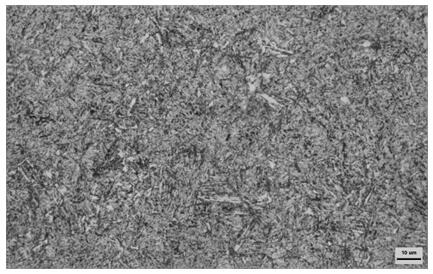

[0041] (3) Rolling: The continuous casting billet is hot ro...

Embodiment 3

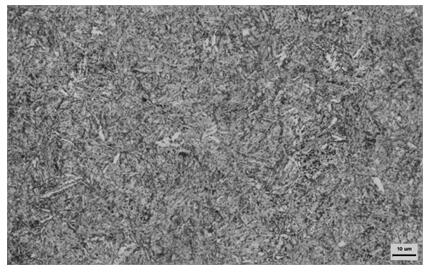

[0045] The chemical composition weight percentage and process steps of the steel are basically the same as those in Example 1. The difference is: in step (4), the spring flat steel is heated to 880°C, kept for 60min, oil-cooled to room temperature, and then tempered. The tempering temperature is 410°C, and the water is cooled to room temperature after 120min of heat preservation.

[0046] Use metallographic microscope to observe the microstructure of the spring flat steel obtained in this example, such as image 3 The microstructure shown is tempered troostite. The room temperature tensile test was carried out according to GB / T 228.1-2021, and the mechanical properties were measured. The obtained mechanical properties test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com