Plasma Spray Welding Composite Roll and Manufacturing Method of Composite Roll Ring

A compound roll and manufacturing method technology, which is applied in the steel rolling field of the steel industry, can solve the problems of difficult-to-work layer roll rings, limited alloy content, complex equipment, etc., and achieve beautiful appearance, high material utilization rate, and reduced material consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

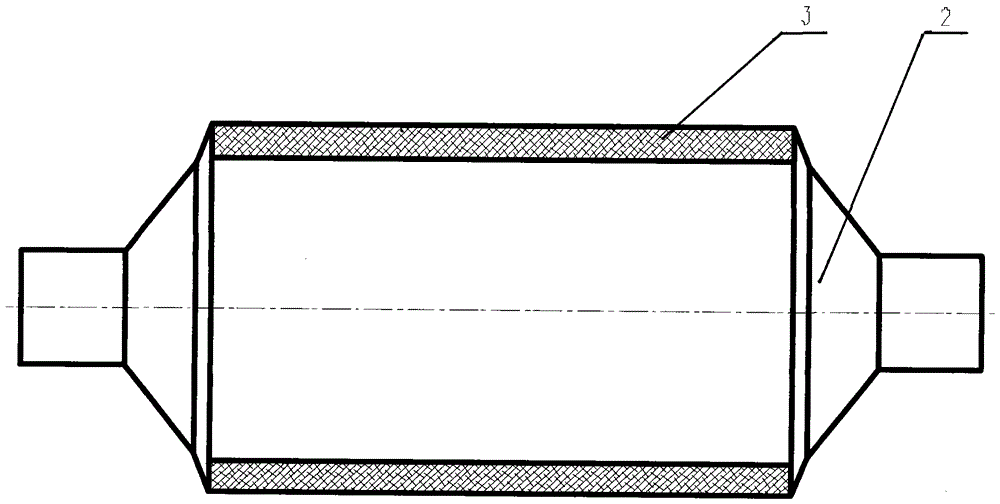

[0034] Example 1: see figure 1 , a plasma spray welded composite roll, comprising a roll base shaft and an alloy working layer, characterized in that: the roll base shaft is a revolving body, the alloy working layer covers the outer surface of the revolving body, and the alloy The working layer is a plasma spray welding composite layer. The base shaft of the roll is a cylinder, and its material is a common alloy steel.

Embodiment 2

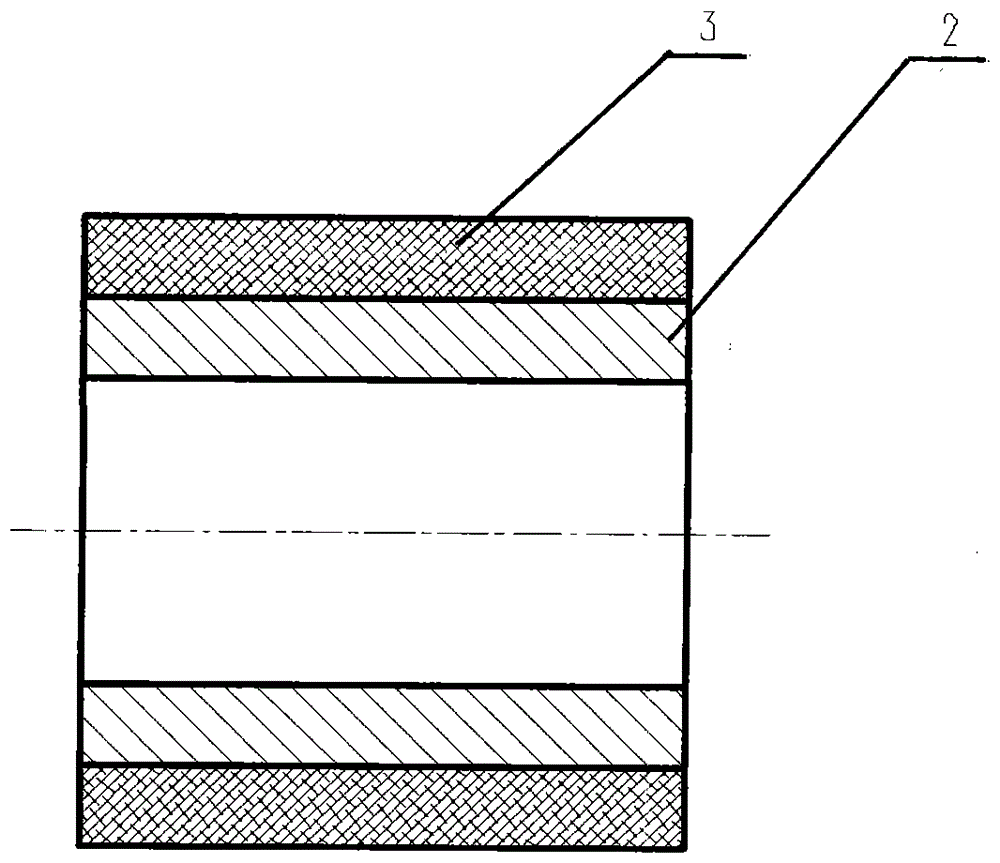

[0035] Example 2: see figure 2 , a plasma spray welding composite roll ring, comprising a base ring of the roll ring and an alloy working layer, characterized in that: the base ring is a revolving body, the alloy working layer covers the outer surface of the revolving body, and the The alloy working layer is a plasma spray welding composite layer. The base ring is an annular body, and its material is commonly used alloy steel.

Embodiment 3

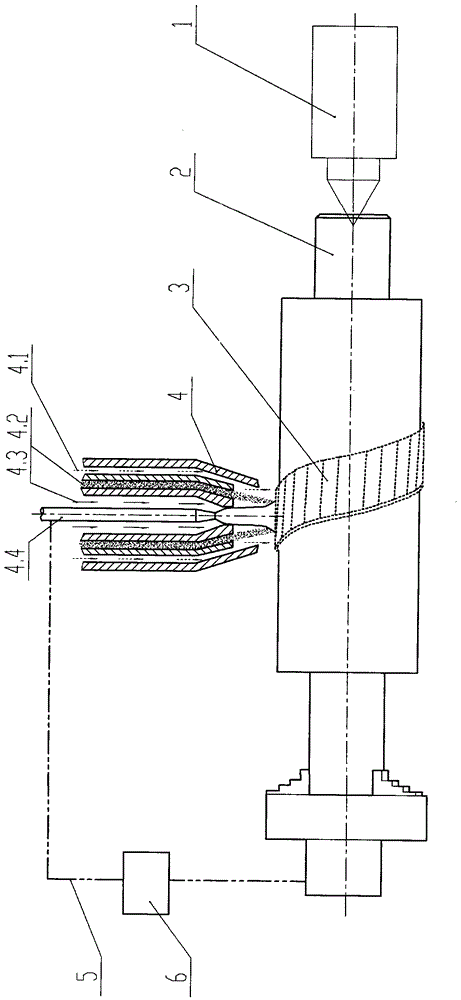

[0036] Example 3: see image 3 , a manufacturing method of a plasma spray-welded composite roll and a composite roll ring, which specifically includes the following steps:

[0037] a: The base shaft or base ring of the roll is machined by machine tools, and the outer surface of the base shaft or base ring is machined to remove surface impurities and dimensions and ensure smoothness;

[0038] b: formulating alloy powder composition for spray welding,

[0039] c: Preheat the base shaft or base ring to 400-450℃ in the heating furnace, and then install it on the rotatable machine tool fixture;

[0040] d: put the alloy powder composition dried in step b into the material box of the plasma spray welding machine; adjust the appropriate process parameters, adjust the nozzle to be about 10mm away from the surface of the base shaft or base ring, and start the spray welding machine to spray and weld to form an alloy Working layer; and keep the base shaft or base ring temperature 280-3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com