A color-tunable amorphous alloy color film and its preparation method

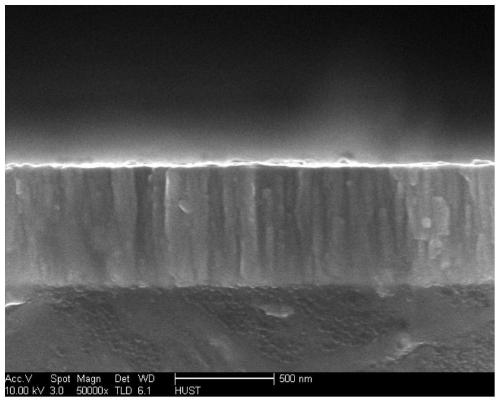

An amorphous alloy thin film, amorphous alloy technology, applied in metal material coating process, vacuum evaporation coating, coating and other directions, can solve the problem of difficult to prepare environment-friendly, high hardness, color-tunable color thin film materials and so on , to achieve the effect of excellent scratch resistance, tight bonding and strong process operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

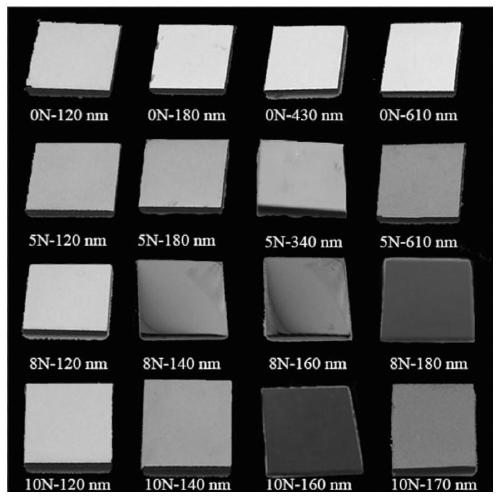

Embodiment 1

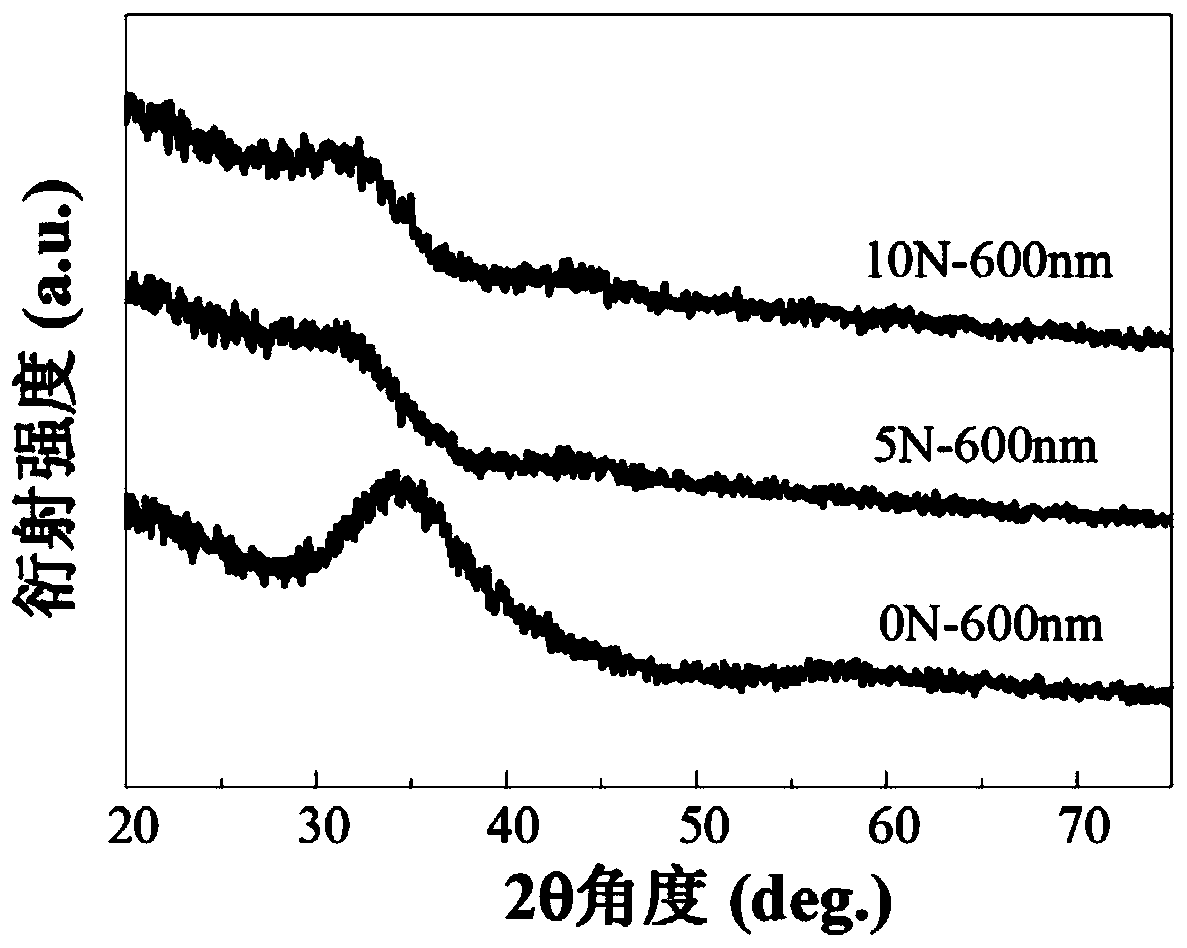

[0038] The main components of the iron-based amorphous film in this embodiment are Ni, Cu, Fe, Al, Ag, N and Zr, and the atomic percentage (at.%) contents of each element are respectively:

[0039] Ni 0%

[0040] Cu 16.1%

[0041] Fe 3.6%

[0042] Al 7.0%

[0043] Ag 2.2%

[0044] N 25.0%

[0045] Zr balance

[0046] Its preparation method is:

[0047] S1: Prepare the target material, pre-smelt the alloy of Zr, Cu, Fe, Al and Ag elements with a purity of 99.98% into a block according to the atomic ratio of Zr60.14Cu22.31Fe4.85Al9.7Ag3 (at%) The ingot is prepared into a single Zr-based alloy target with a target specification of Φ60mm x 3mm, and the prepared alloy target is placed in the target position of the sputtering table as a target for sputtering;

[0048] S2: Select and process the substrate, choose 304 stainless steel as the substrate material, wipe the stainless steel substrate to make its surface smooth, then put it into acetone solution for ultrasonic cleanin...

Embodiment 2

[0052] The composition of the film in this example is the same as in Example 1. In the preparation method, only the sputtering time is different from Example 1, and the others are the same. The sputtering time in this example is 12 minutes, and the gray amorphous alloy film is obtained. , the thickness of the film is 140 nm.

Embodiment 3

[0054] The composition of the film in this example is the same as in Example 1. In the preparation method, only the sputtering time is different from Example 1, and the others are the same. The sputtering time in this example is 23 minutes, and the gray amorphous alloy film is obtained. , the thickness of the film is 340 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com