Non-electric welding agent applicable to emergency welding repair of low-carbon steel thin-walled sheet parts below 5mm and welding pen containing same

A welding powder and field technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve problems such as bronchitis or bronchial pneumonia, endanger the health of operators, and lung irritation symptoms, etc. Strong performance, avoid slag inclusion defects, and easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

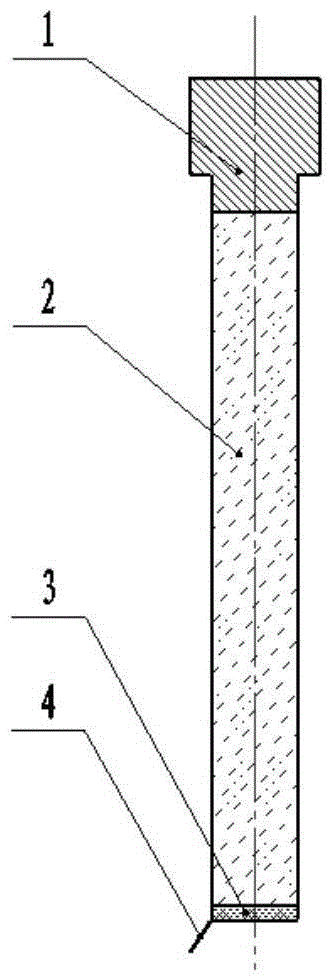

Image

Examples

Embodiment 1

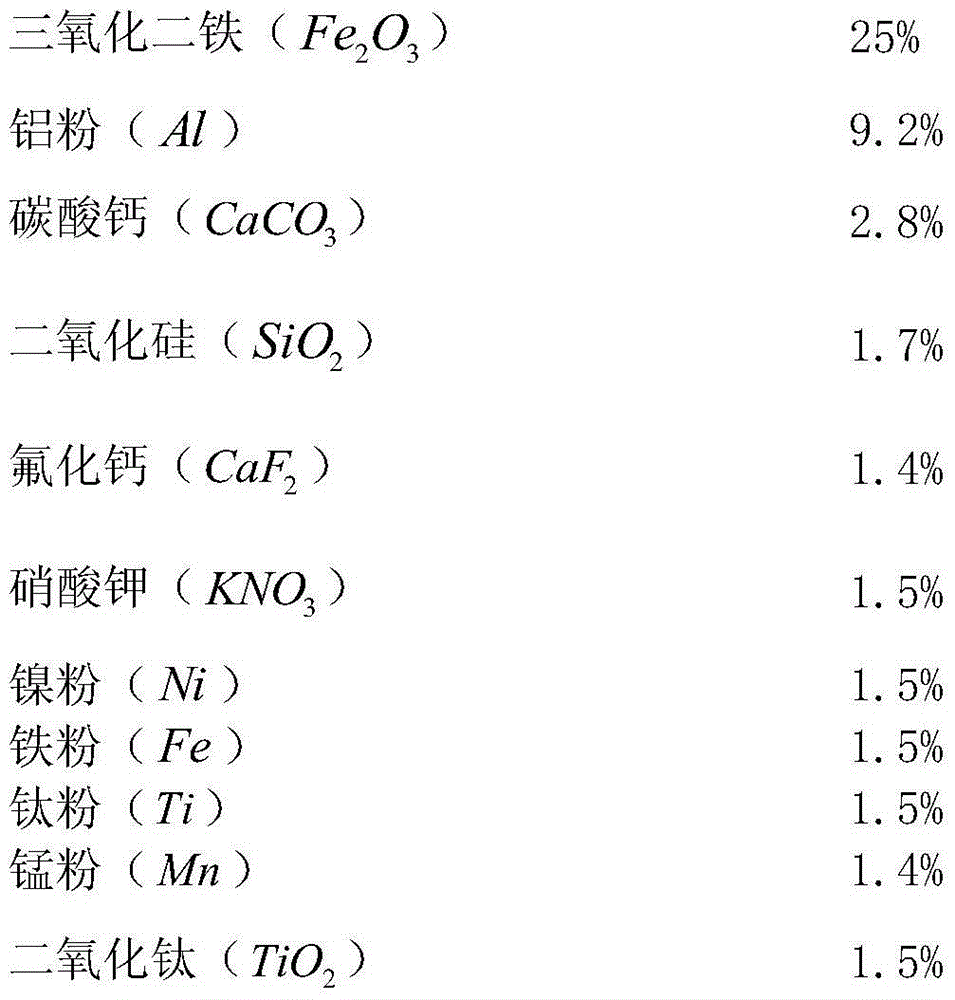

[0024] An electroless welding flux suitable for emergency welding maintenance of low-carbon steel sheet parts below 5mm, the components and their weight percentages are:

[0025]

[0026]

Embodiment 2

[0028] An electroless welding flux suitable for emergency welding maintenance of low-carbon steel sheet parts below 5mm, the components and their weight percentages are:

[0029]

Embodiment 3

[0031] An electroless welding flux suitable for emergency welding maintenance of low-carbon steel sheet parts below 5mm, the components and their weight percentages are:

[0032]

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com