A high-strength and high-plastic annealed steel strip for pipe making and its production method

A production method and high plasticity technology, applied in the field of metallurgy, can solve the problems of easily warped skin, slag inclusions, elongation less than 28%, and many non-metallic inclusions on the surface, so as to eliminate corner defects and improve the cleanliness of molten steel , Improving the effect of billet quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

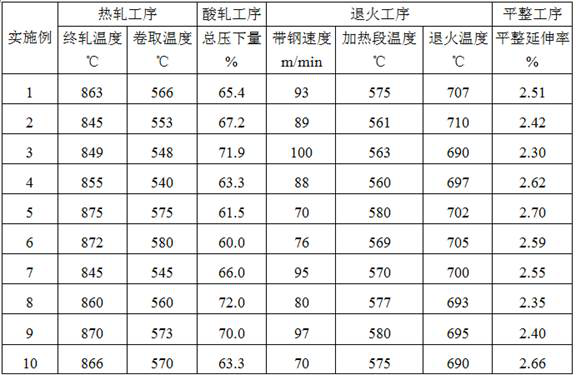

[0017] Example 1-10: A high strength and high plasticity and annealed strip for pipe production process as described below.

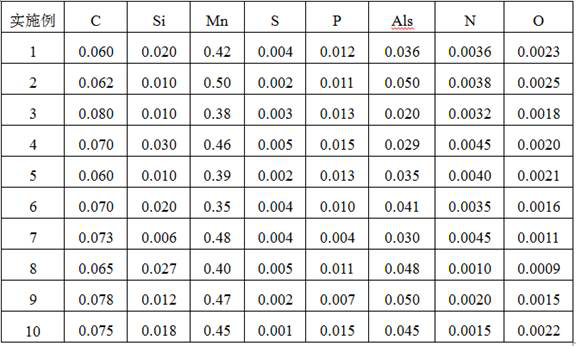

[0018] 1, steel chemical composition: Weight% Example embodiments each of the chemical composition of the steel shown in Table 1.

[0019] Table 1: Chemical composition of the steel strip in each Example (wt%)

[0020]

[0021] In Table 1 the balance being iron and unavoidable impurities.

[0022] 2, production methods: steelmaking, casting, heating, hot rolling, cold rolling, annealing and the formation step, the process of each step is as follows:

[0023] (1) the steelmaking process: hot metal desulfurization includes, smelting, refining the LF, RH vacuum treatment. Smelting process, carbon pull converter, a bottom blown directly after tapping, tapping time ≥3min; after adjusting component into the LF refining by the RH vacuum treatment step, the pure degassing time ≥8min, the molten steel after RH treatment was allowed to stand ≥ 20min;

[0024] (2) c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com