Casting forming method for alloy casting

A casting molding and alloy casting technology, which is applied to casting molding equipment, casting molds, casting mold components, etc., can solve the problems of difficult heat dissipation, slag inclusion defects in castings, and difficult connection between heat sinks and mold shells. Reliable and stable, resulting in improved molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

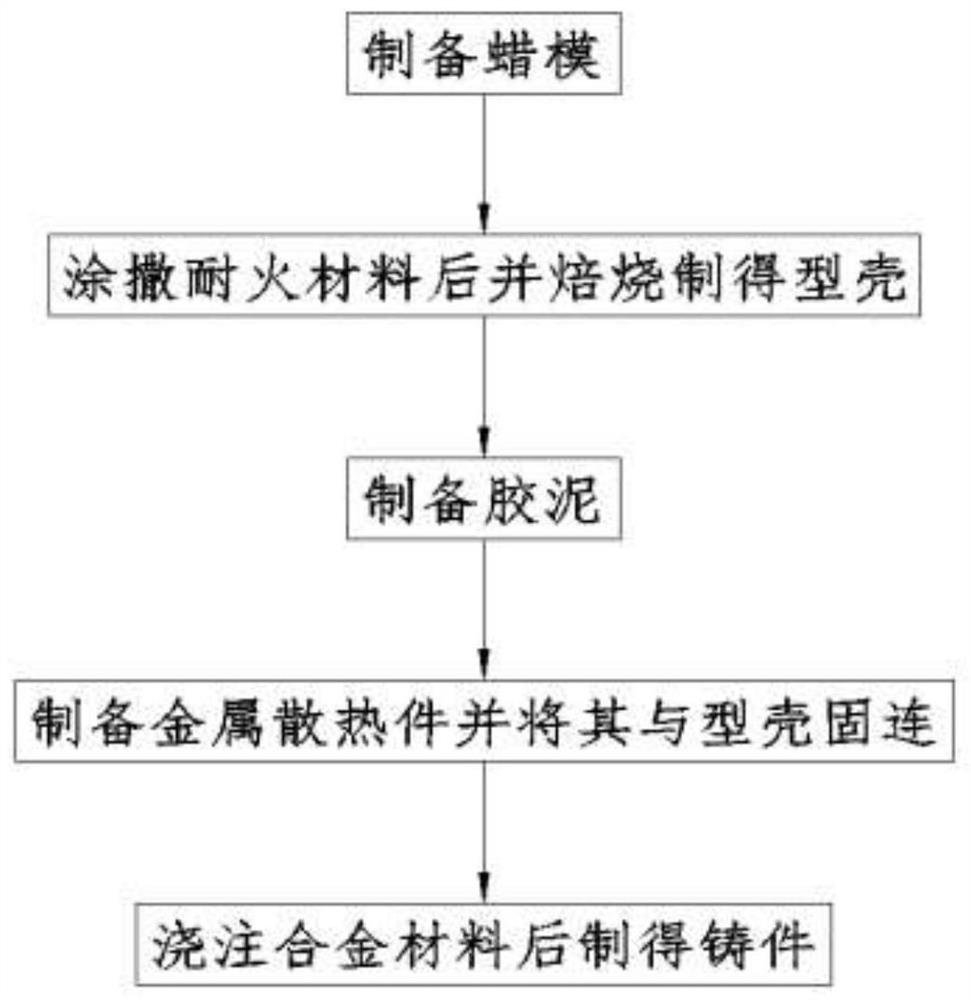

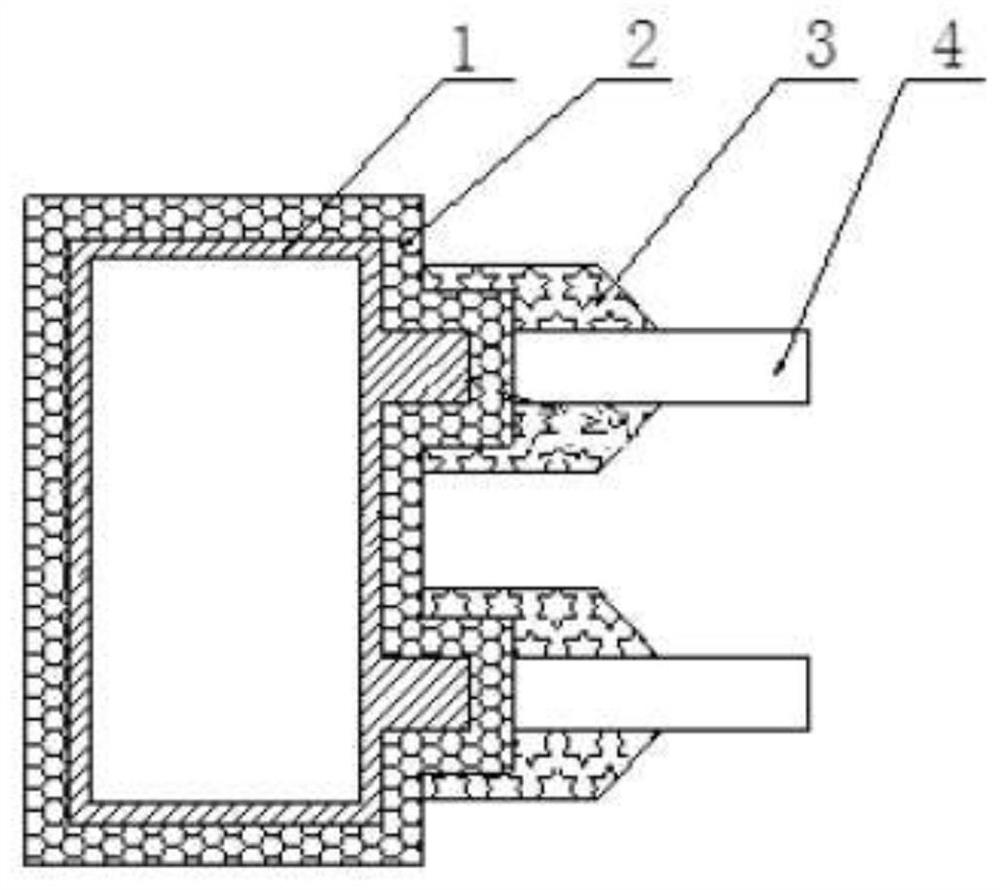

[0024] like figure 1 , figure 2 As shown, the present invention provides a kind of alloy casting casting molding method, comprises the following steps:

[0025] Step 1: Prepare a wax model 1 according to the design drawings;

[0026] Step 2: In step 1, spread a layer of refractory material on the surface of the wax mold 1 and then roast it, so that the wax mold 1 is melted and removed to obtain the mold shell 2; further, in step 2, the wax mold 1 and the refractory material are roasted The temperature is 1050°C.

[0027] Step 3: Evenly mix the bauxite with a fine particle size of 100#, the bauxite with a fine particle size of 60# and silica sol according to the mass ratio of 10:4:1 to prepare the cement 3; in addition, the cement in step 3 3 The service life is 24 hours, that is, the cement 3 must be used within 24 hours after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com