Antibacterial polyester fiber and fabric

A technology of polyester fiber and fiber, applied in fabric surface trimming, weaving, yarn and other directions, can solve the problems of low fiber bonding, poor washability, poor antibacterial persistence, etc., achieve broad antibacterial spectrum, excellent antibacterial property, and strong adsorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

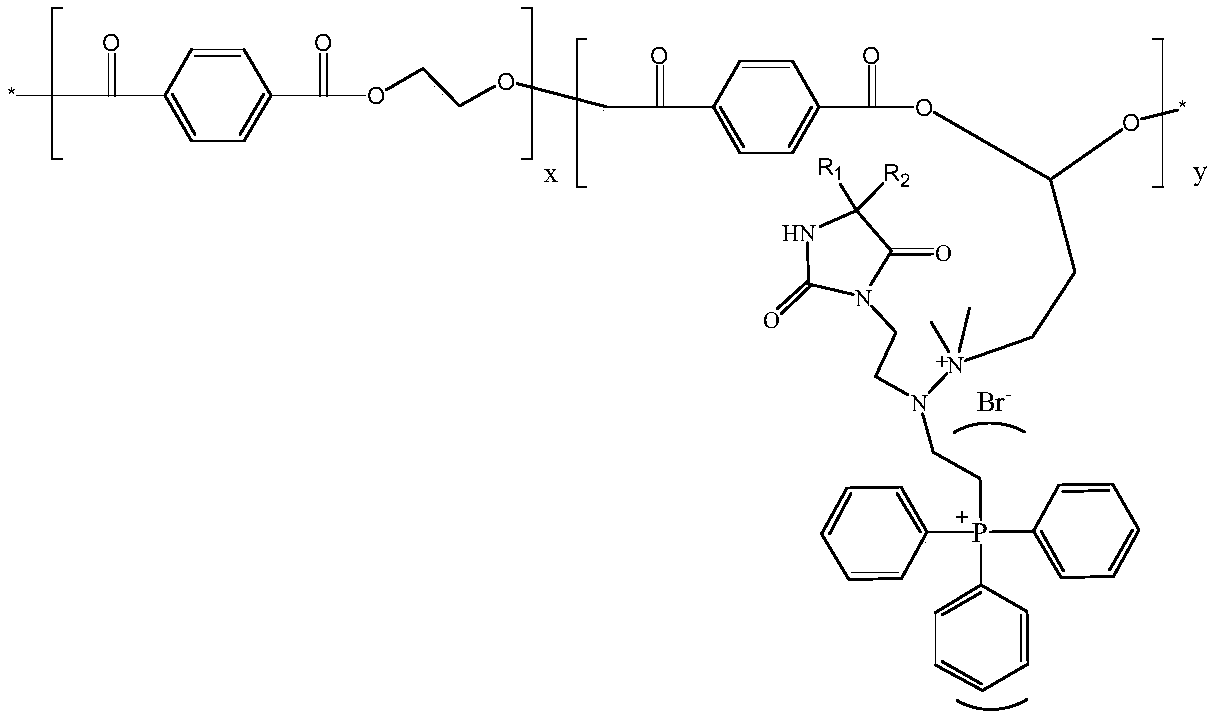

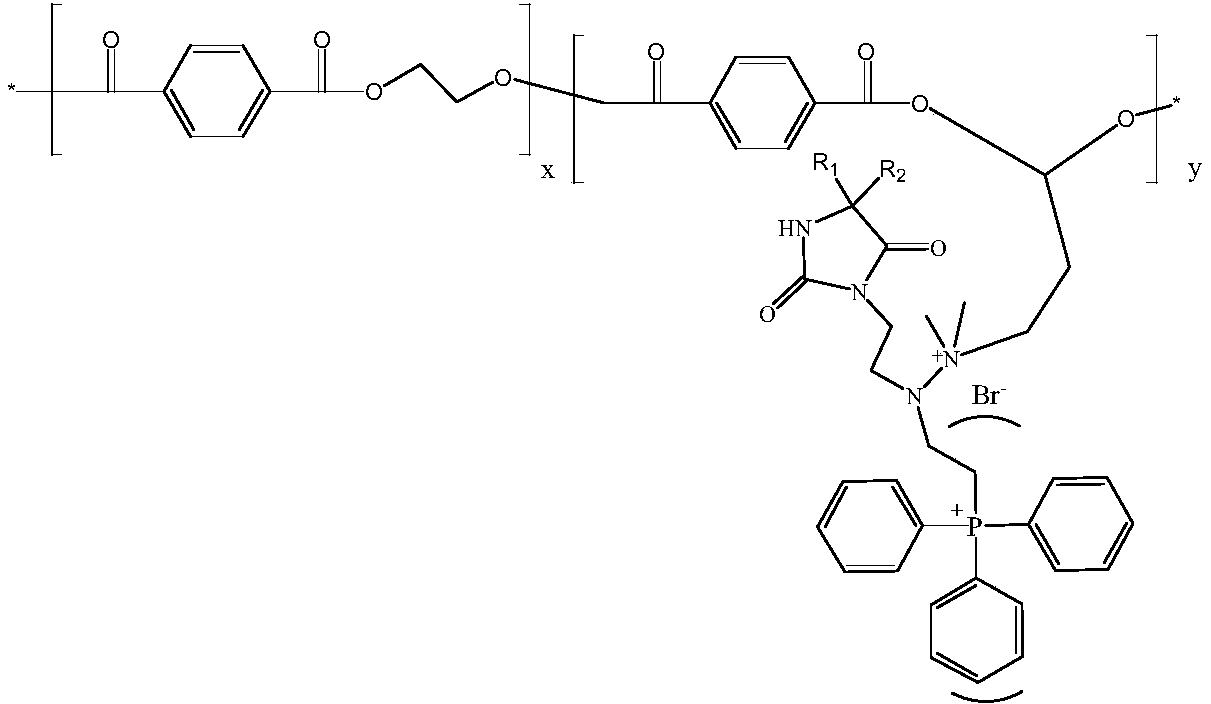

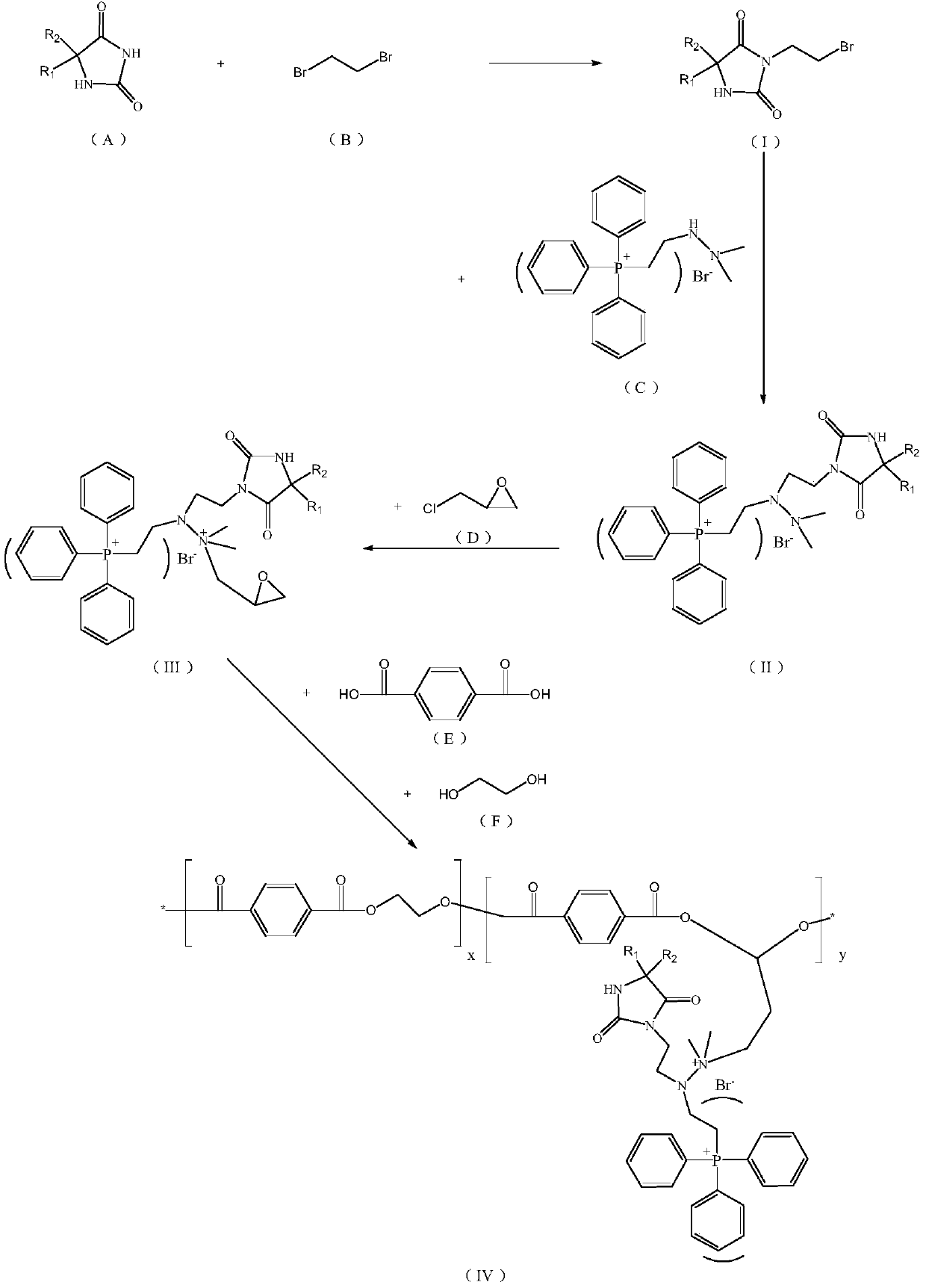

Image

Examples

Embodiment 1

[0048] Antibacterial polyester fiber preparation steps are as follows:

[0049]Step (1) Add 1mol 5,5-dimethylhydantoin (A) and 1.2mol 1,2-dibromoethane (B) into 50mol N,N-dimethylformamide and heat to 80°C , stirred vigorously for 2 hours, cooled, stood still, and concentrated in vacuo; slowly added 50mol of water, stirred for 30min, then added 80mol of chloroform, stirred for 30min, stood to separate layers, took the organic phase and dried it with anhydrous sodium sulfate, filtered, and rotary evaporated , to obtain the intermediate product I (IR: 1051cm -1 : tertiary amine-C-N-generated; 1672cm -1 : Amide-C=O exists; 644cm -1 :-C-Br exists).

[0050] Step (2) Add 1mol I, 1.1mol quaternary phosphonium salt (C) into 50mol N,N-dimethylformamide, heat to 80°C, stir vigorously for 6h, cool, stand still, rotary evaporate, purify, and dry , to obtain the intermediate product II (IR: 644cm -1 :-C-Br disappeared; 1074cm -1 :-N-N-Existence; 1673cm -1 : Amide-C=O exists; 3100cm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com