Preparation method of sucrose-6-benzoate

A technology of benzoate and methyl benzoate, applied in the field of preparation of intermediates, can solve the problems of difficult recovery, high toxicity and the like, and achieve the effects of high economy, improved yield and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

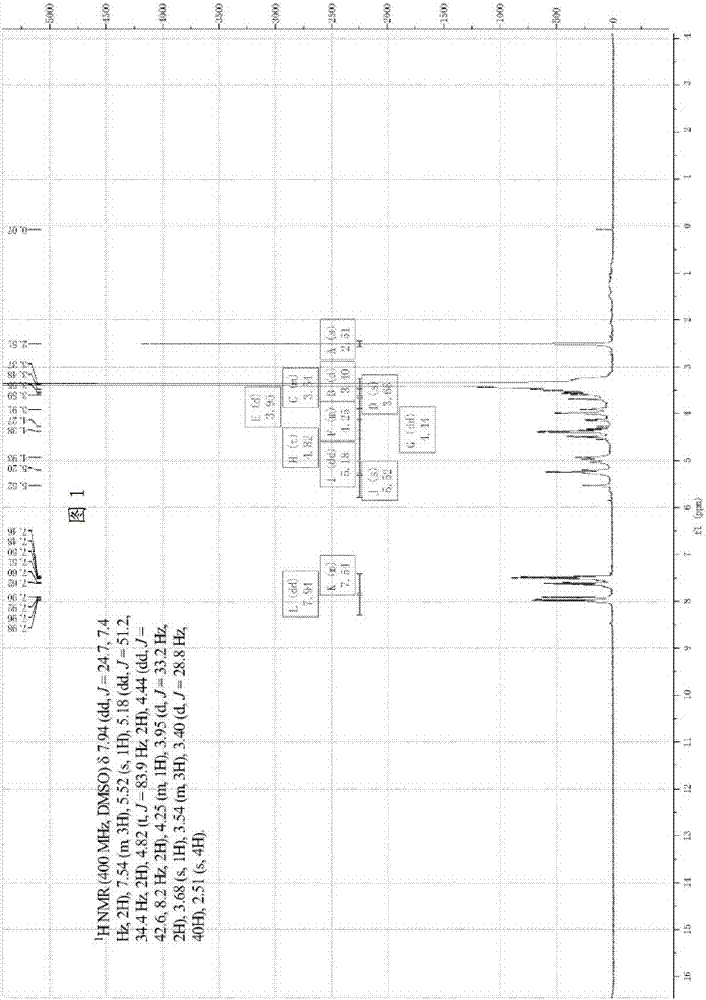

Image

Examples

Embodiment 1

[0026] A kind of preparation method of sucrose-6-benzoate, concrete steps are:

[0027] (1) Add 5g of sucrose into a 100ml three-necked round-bottomed flask at a heating temperature of 75°C, dissolve the sucrose in DMF (N,N-dimethylformamide), cool down to room temperature, and obtain a sucrose solution for use , the mass ratio of sucrose to DMF is 1:5 (ie DMF 25g);

[0028] (2) In the reactive distillation device, add cesium carbonate and methyl benzoate to the sucrose solution obtained in step (1), adjust the vacuum degree to 0.05MPa, maintain 55°C, and react for 5h. The amount of cesium carbonate used is sucrose 1% of the mass (i.e. cesium carbonate 0.05g), the molar ratio of sucrose to methyl benzoate is 1:3 (i.e. methyl benzoate 6ml);

[0029] (3) Cool the reaction solution in step (2) to room temperature, add 50ml of dichloromethane to precipitate unreacted sucrose, filter, recover unreacted sucrose, evaporate the solvent in the filtrate under reduced pressure, and obta...

Embodiment 2

[0031] A kind of preparation method of sucrose-6-benzoate, concrete steps are:

[0032] (1) Add 5g of sucrose to a 250ml three-necked round-bottomed flask at a heating temperature of 120°C, dissolve the sucrose in DMSO, cool down to room temperature, and obtain a sucrose solution for use. The mass ratio of sucrose to DMSO is 1 :3;

[0033] (2) In the reactive distillation device, add rubidium carbonate and methyl benzoate to the sucrose solution obtained in step (1), adjust the vacuum degree to 0.05MPa, maintain 60°C, and react for 4 hours. The amount of rubidium carbonate used is sucrose 0.05% of mass, the mol ratio of described sucrose and methyl benzoate is 1:1;

[0034] (3) Cool the reaction solution in step (2) to room temperature, add 50ml of chloroform to precipitate unreacted sucrose, filter, recover unreacted sucrose, evaporate the solvent in the filtrate under reduced pressure, and obtain sucrose-6-benzoic acid The ester crude product is 3.6g, the yield is 72%. The...

Embodiment 3

[0036] A kind of preparation method of sucrose-6-benzoate, concrete steps are:

[0037](1) Add 5g of sucrose to a 100ml three-necked round-bottomed flask at a heating temperature of 40°C, dissolve the sucrose in DMF, cool down to room temperature, and obtain a sucrose solution for use. The mass ratio of sucrose to DMF is 1 :4;

[0038] (2) In the reactive distillation device, add sodium carbonate and methyl benzoate to the sucrose solution obtained in step (1), adjust the vacuum degree to 0.05MPa, maintain 50°C, and react for 5h. The amount of sodium carbonate used is sucrose 2% of mass, the mol ratio of described sucrose and methyl benzoate is 1:2;

[0039] (3) Cool the reaction solution in step (2) to room temperature, add 50ml of 1,2-dichloroethane to precipitate unreacted sucrose, filter to recover unreacted sucrose, evaporate the solvent in the filtrate under reduced pressure, and obtain The crude product of sucrose-6-benzoate was 3.8g, and the yield was 76%. The crude ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com