Fluoride-free waterproof agent, preparation method and textile

A fluorine-free water repellent and fluorine-free technology, applied in the field of textile auxiliaries, can solve the problems of water repellent and washing resistance limitations of water repellents, and achieve high melting point, good water resistance and washing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Take 4 grams behenyl acrylate, 4 grams behenyl methacrylate, 1 gram styrene, 5 grams dipropylene glycol, 10 grams Ethoqual C / 25 (ethoxylated quaternary ammonium salt), 10 grams polyethylene wax , 10 grams of oxidized polyethylene wax, 0.1 gram of acetic acid, heated to 130 degrees to melt and stir evenly, added 64 grams of water to emulsify for 1 hour to obtain a pre-emulsion. Adjust the temperature of the pre-emulsion to 62°C, add 0.5 g of glycidyl acrylate, and stir with nitrogen gas for 30 minutes. Add 0.1 gram of azobisisobutylamidine hydrochloride and 0.5 gram of vinyl chloride, and keep the reaction for 8 hours. Finally, lower the temperature of the system to room temperature, and filter through a 300-mesh filter cloth to obtain a fluorine-free waterproofing agent.

Embodiment 2

[0038] Take 10 grams of Ethoqual C / 25 (ethoxylated quaternary ammonium salt), 10 grams of polyethylene wax, and 10 grams of oxidized polyethylene wax, melt at 130 degrees and stir evenly, add 64 grams of water to emulsify for 1 hour. Add 4 grams of behenyl acrylate, 4 grams of behenyl methacrylate, 1 gram of styrene, 5 grams of dipropylene glycol, and 0.1 gram of acetic acid, and emulsify at high speed for 30 minutes to obtain a pre-emulsion. Adjust the temperature of the pre-emulsion to 62 degrees, add 0.5 g of glycidyl acrylate, and feed nitrogen for 30 minutes at the same time. Add 0.1 gram of azobisisobutylamidine hydrochloride and 0.5 gram of vinyl chloride, and keep the reaction for 8 hours. Finally, lower the temperature of the system to room temperature, and filter through a 300-mesh filter cloth to obtain a fluorine-free waterproofing agent.

Embodiment 3

[0040] Take 4 grams of behenyl acrylate, 4 grams of behenyl methacrylate, 1 gram of styrene, 5 grams of dipropylene glycol, 10 grams of Ethoqual C / 25 (ethoxylated quaternary ammonium salt), melt at 85 degrees and Stir well, add 64 grams of water to emulsify for 1 hour. Then put the emulsion into a 130-degree wax liquid, the wax liquid is composed of 10 grams of polyethylene wax and 10 grams of oxidized polyethylene wax, emulsified at a high speed for 30 minutes to obtain a pre-emulsion. Adjust the temperature of the pre-emulsion to 62°C, add 0.5 g of glycidyl acrylate and 0.1 g of acetic acid, and feed nitrogen gas for 30 minutes at the same time. Add 0.1 gram of azobisisobutylamidine hydrochloride and 0.5 gram of vinyl chloride, and keep the reaction for 8 hours. Finally, lower the temperature of the system to room temperature, and filter through a 300-mesh filter cloth to obtain a fluorine-free waterproofing agent.

[0041] other embodiments

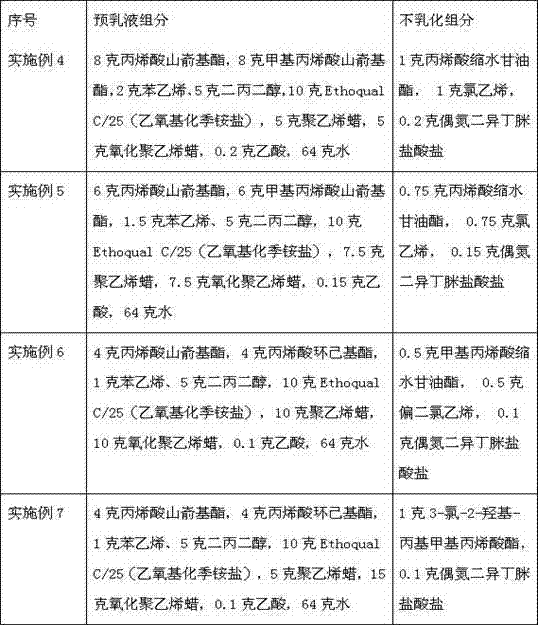

[0042] Each component in oth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com