Fluorine-free nano durable super hydrophobicity finishing method for cellulose fabric

A cellulose fabric, super water-repellent technology, used in fiber processing, plant fibers, textiles and papermaking, etc., can solve problems such as poor production safety, and achieve the effects of low performance requirements, easy industrialization, and excellent water repellency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

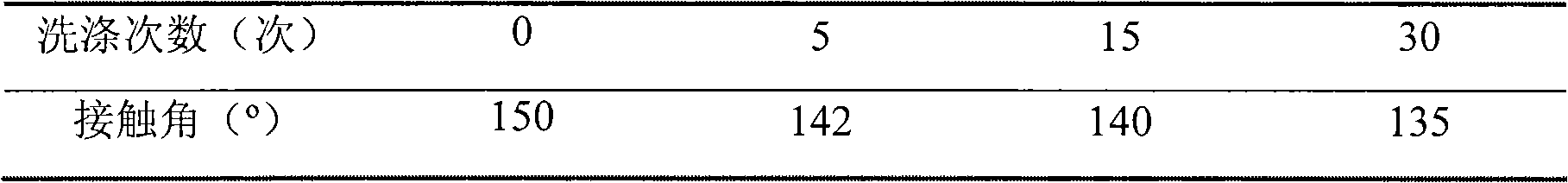

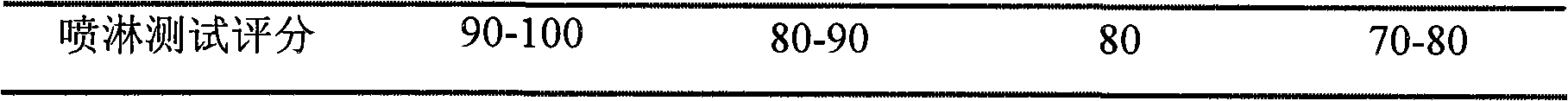

Embodiment 1

[0024] Prepare an aqueous solution containing tetraethyl silicate, butane tetracarboxylic acid and sodium hypophosphite, wherein the concentration of tetraethyl silicate in mass percentage is 5%, the mass percentage concentration of butane tetracarboxylic acid is 6%, and the mass percentage of sodium hypophosphite The concentration is 4%; the solution is ultrasonically oscillated for 30 minutes and stirred for 30 minutes to obtain modified SiO 2 sol; cotton gauze card (20 s ×16 s, 128×60) in the above-mentioned finishing solution obtained by dipping and rolling twice, with a liquid loading rate of 80%, pre-bake at 80°C for 3 minutes, and bake at 170°C for 2 minutes.

[0025] Prepare the ethanol solution of 4% cetyltrimethoxysiloxane in the mass percentage of butane tetracarboxylic acid aqueous solution catalytic hydrolysis, soak the fabric obtained in the previous finishing in this solution for 2 hours, and then pre-dry at 80 ° C for 3 minutes, and baked at 170°C for 2 minut...

Embodiment 2

[0031] Prepare an aqueous solution containing tetraethyl silicate, citric acid and sodium hypophosphite, wherein the tetraethyl silicate mass percentage concentration is 4%, the citric acid mass percentage concentration is 6%, and the sodium hypophosphite mass percentage concentration is 4%; The solution was ultrasonically oscillated for 30 minutes and stirred for 30 minutes to obtain modified SiO 2 sol; cotton gauze card (20 s ×16 s , 128×60) in the above-mentioned finishing solution obtained by dipping and rolling twice, with a liquid loading rate of 80%, pre-bake at 80°C for 3 minutes, and bake at 170°C for 2 minutes.

[0032] Prepare the ethanol solution of 5% cetyltrimethoxysiloxane in which the mass percentage of citric acid aqueous solution is catalyzed and hydrolyzed, soak the fabric obtained in the previous finishing in the solution for 2 hours, then pre-dry at 80°C for 3 minutes, °C for 3 minutes to obtain a fluorine-free nano-durable super water-repellent cotton f...

Embodiment 3

[0034] Prepare an aqueous solution containing tetraethyl silicate, polyethylene glycol 400, citric acid, sodium hypophosphite and sodium phosphate, wherein the concentration of tetraethyl silicate is 5% by mass, and the concentration of polyethylene glycol 400 by mass is 2% , the mass percentage concentration of butane tetracarboxylic acid is 6%, the mass percentage concentration of sodium hypophosphite and sodium phosphate is 3%; the solution is ultrasonically oscillated for 30 minutes and stirred for 30 minutes to obtain modified SiO 2 Sol; linen (14 s ×14 s , 54×52) in the above-mentioned finishing solution obtained by dipping and rolling twice, with a liquid-carrying rate of 80%, pre-bake at 80°C for 3 minutes, and bake at 160°C for 2 minutes.

[0035] Prepare a methanol solution of 5% hexadecyltrimethoxysiloxane in which hydrochloric acid aqueous solution is catalyzed and hydrolyzed, and soak the fabric obtained in the previous finishing in the solution for 2 hours, then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com