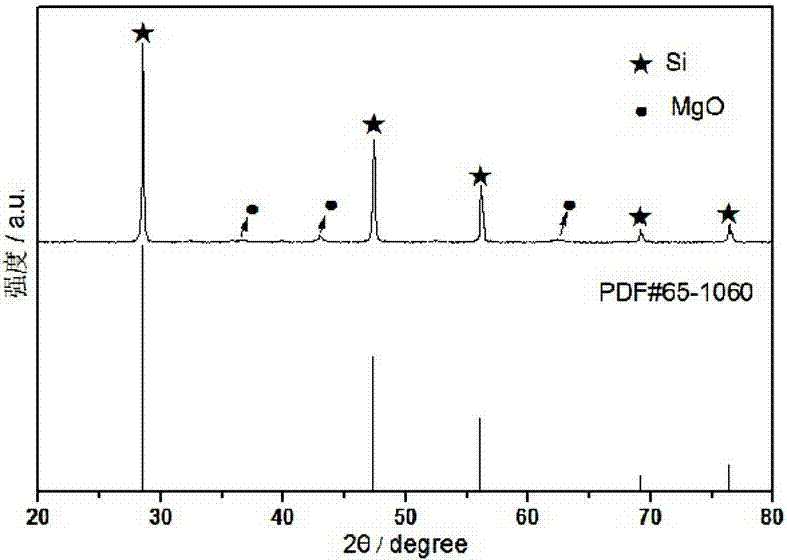

Fluorine-free preparation method for three-dimensional porous silica powder anode material of lithium ion battery

A technology of lithium-ion batteries and negative electrode materials, which is applied in the field of electrochemical power sources, can solve the problems of hydrofluoric acid toxicity and strong corrosion, improve the specific capacity and cycle stability of materials, reduce the cost of material preparation, and avoid environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

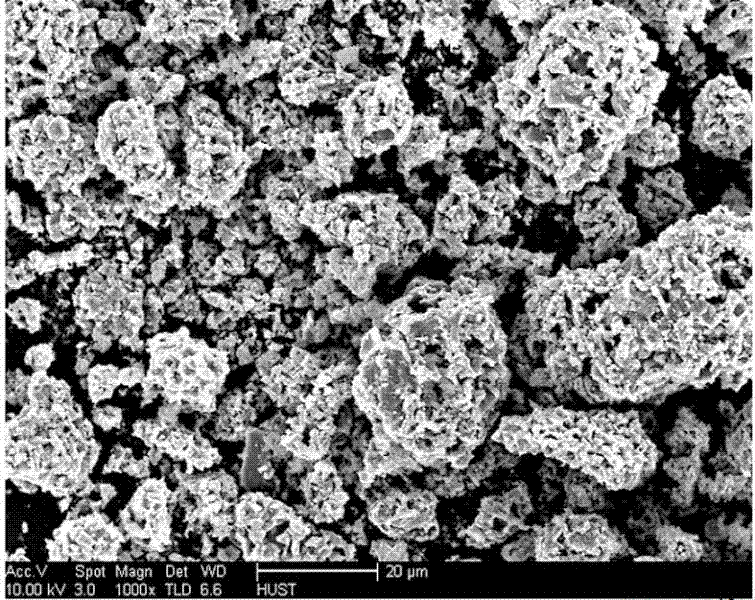

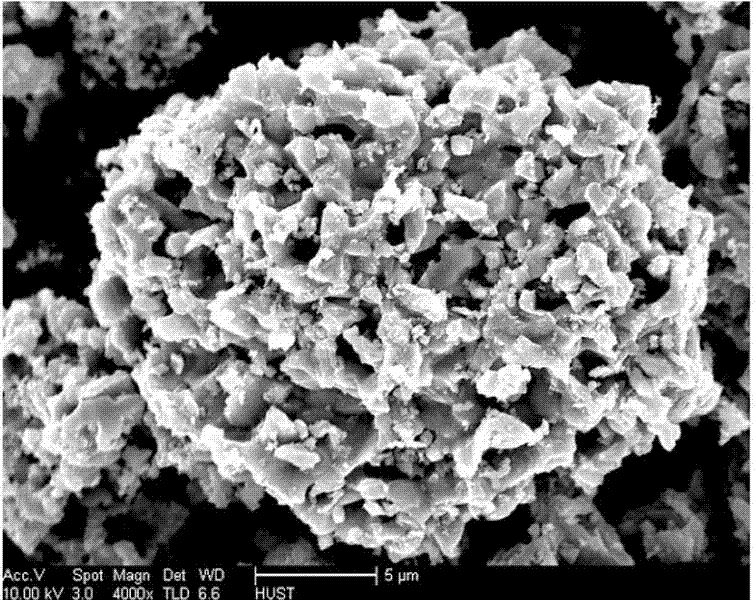

Method used

Image

Examples

Embodiment 1

[0042] Example 1. The three-dimensional porous silicon powder negative electrode material of lithium ion battery was prepared according to the method of the preparation example. During the preparation, the decomposition temperature of magnesium silicide was set at 800° C., and other conditions were according to the scheme of the preparation example. The obtained porous silicon material was prepared as electrode for electrochemical test. The electrode preparation method, battery assembly and test conditions are the same as in Comparative Example 1. The lithium intercalation capacity of the material for the first time is 2883.3mAh / g, the lithium delithiation capacity is 1821.0mAh / g, and the coulombic efficiency is 63.2%. The lithium insertion capacity of the 10th cycle is 123.0mAh / g, and the lithium removal capacity is 119.0mAh / g. The capacity retention rate is 6.53%, and the capacity decay is large. Pure nano-silicon electrode material has poor electrochemical performance. At...

Embodiment 2

[0043] Example 2. The three-dimensional porous silicon powder negative electrode material for lithium-ion batteries was prepared according to the method of the preparation example. During the preparation, the decomposition temperature of magnesium silicide was set at 900° C., and other conditions were according to the scheme of the preparation example. The obtained porous silicon material was prepared as electrode for electrochemical test. The electrode preparation method, battery assembly and test conditions are the same as in Comparative Example 1. The first lithium intercalation capacity of the material is 2007.8mAh / g, the lithium delithiation capacity is 1185.0mAh / g, and the coulombic efficiency is 59.0%. The lithium insertion capacity of the 10th cycle is 529.6mAh / g, the lithium removal capacity is 507.8mAh / g, and the capacity retention rate is 42.85%. After 70 cycles, its lithium intercalation capacity was 211.7mAh / g, its delithiation capacity was 214.0 mAh / g, and its c...

Embodiment 3

[0044] Example 3. The three-dimensional porous silicon powder negative electrode material of lithium ion battery was prepared according to the method of the preparation example. During the preparation, the decomposition temperature of magnesium silicide was set to 1000° C., and other conditions were according to the scheme of the preparation example. The obtained porous silicon material was prepared as electrode for electrochemical test. The electrode preparation method, battery assembly and test conditions are the same as in Comparative Example 1. The first lithium intercalation capacity of the material is 2184.1mAh / g, the first delithiation capacity is 1296.8mAh / g, and the Coulombic efficiency is 59.4%. After 10 cycles, the material can still release a reversible capacity of 596.8mAh / g stably, with a capacity retention rate of 46.02%. After 70 cycles, its lithium intercalation capacity was 261.0mAh / g, its delithiation capacity was 258.2 mAh / g, and its capacity retention rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com