ABC superfine dry powder extinguishing agent and preparation method thereof

A technology of ultra-fine dry powder and fire extinguishing agent, which is applied in the direction of fire prevention equipment, etc. It can solve the problems of unsatisfactory submerged fire extinguishing effect, easy moisture absorption and agglomeration, failure of fire extinguishing agent, etc., and achieves excellent effect, good water repellency and good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

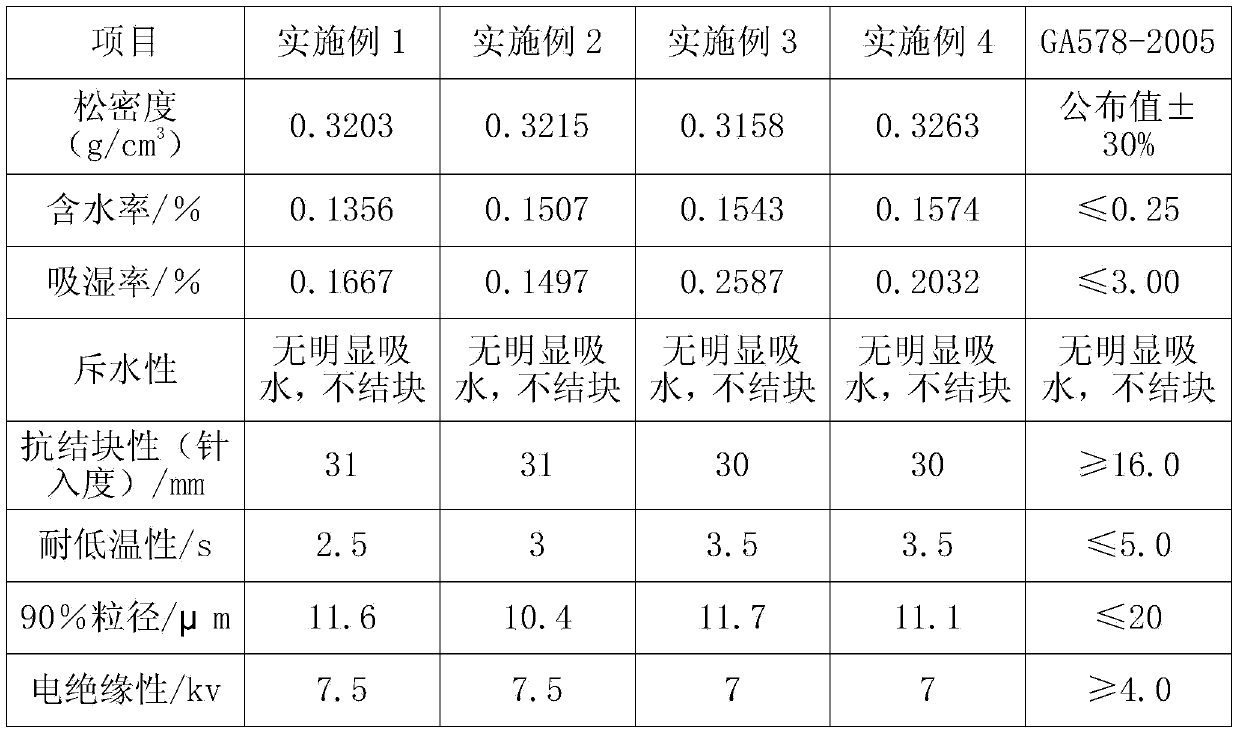

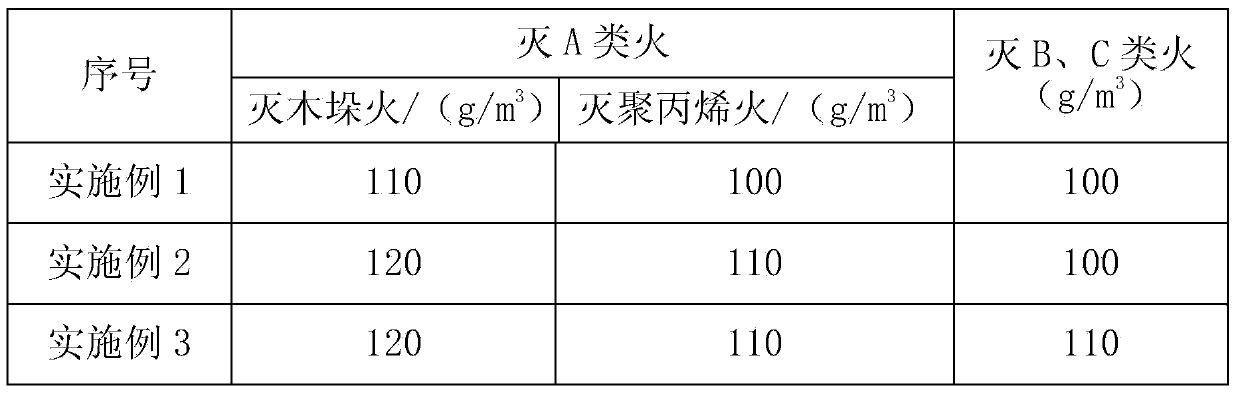

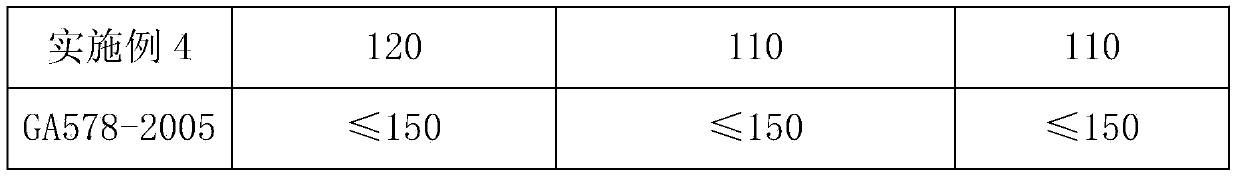

Examples

Embodiment 1

[0020] The preparation of ABC superfine dry powder fire extinguishing agent specifically comprises the following steps:

[0021] Step 1, each raw material component is taken by weighing 1 ton of total raw material: 30kg of mica powder (90% particle diameter is less than or equal to 10 μm), 35kg of hydrophobic fumed silica, 10kg of high boiling silicone oil, 8kg of water, 11kg of gasoline, the rest is ethylenediamine phosphate (90% particle size is less than or equal to 10μm).

[0022] In step 2, the mica powder and ethylenediamine phosphate are dried separately, mixed and stirred evenly to obtain intermediate material A.

[0023] Step 3: Mix high-boiling silicone oil with water and stir, then add gasoline and stir to obtain emulsion B.

[0024] Step 4: spray emulsion B into the stirred intermediate material A after atomization, mix and stir at 95°C, perform surface coating treatment, and evaporate excess gasoline, water and other volatile components to obtain intermediate mat...

Embodiment 2

[0027] The preparation of ABC superfine dry powder fire extinguishing agent specifically comprises the following steps:

[0028] Step 1, each raw material component is taken by weighing 1 ton of total raw material: 35kg of mica powder (90% particle diameter is less than or equal to 10 μm), 40kg of hydrophobic fumed silica, 12kg of high boiling silicone oil, 11kg of water, 13kg gasoline, the rest is ethylenediamine phosphate (90% particle size is less than or equal to 10μm).

[0029] In step 2, the mica powder and ethylenediamine phosphate are dried separately, mixed and stirred evenly to obtain intermediate material A.

[0030] Step 3: Mix high-boiling silicone oil with water and stir, then add gasoline and stir to obtain emulsion B.

[0031] Step 4: spray emulsion B into the stirred intermediate material A after atomization, mix and stir at 100°C, perform surface coating treatment, and evaporate excess gasoline, water and other volatile components to obtain intermediate mate...

Embodiment 3

[0034] The preparation of ABC superfine dry powder fire extinguishing agent specifically comprises the following steps:

[0035] Step 1, each raw material component is taken by weighing 1 ton of total raw material: 40kg of mica powder (90% particle diameter is less than or equal to 10 μm), 45kg of hydrophobic fumed silica, 13kg of high boiling silicone oil, 12kg of water, 14kg of gasoline, the rest is ethylenediamine phosphate (90% particle size is less than or equal to 10μm).

[0036] In step 2, the mica powder and ethylenediamine phosphate are dried separately, mixed and stirred evenly to obtain intermediate material A.

[0037] Step 3: Mix high-boiling silicone oil with water and stir, then add gasoline and stir to obtain emulsion B.

[0038] Step 4: Spray emulsion B into the stirred intermediate material A after atomization, mix and stir at 110°C, perform surface coating treatment, and evaporate excess gasoline, water and other volatile components to obtain intermediate m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com