Functional biocatalyst for biogas fermentation and method for fermenting using catalyst

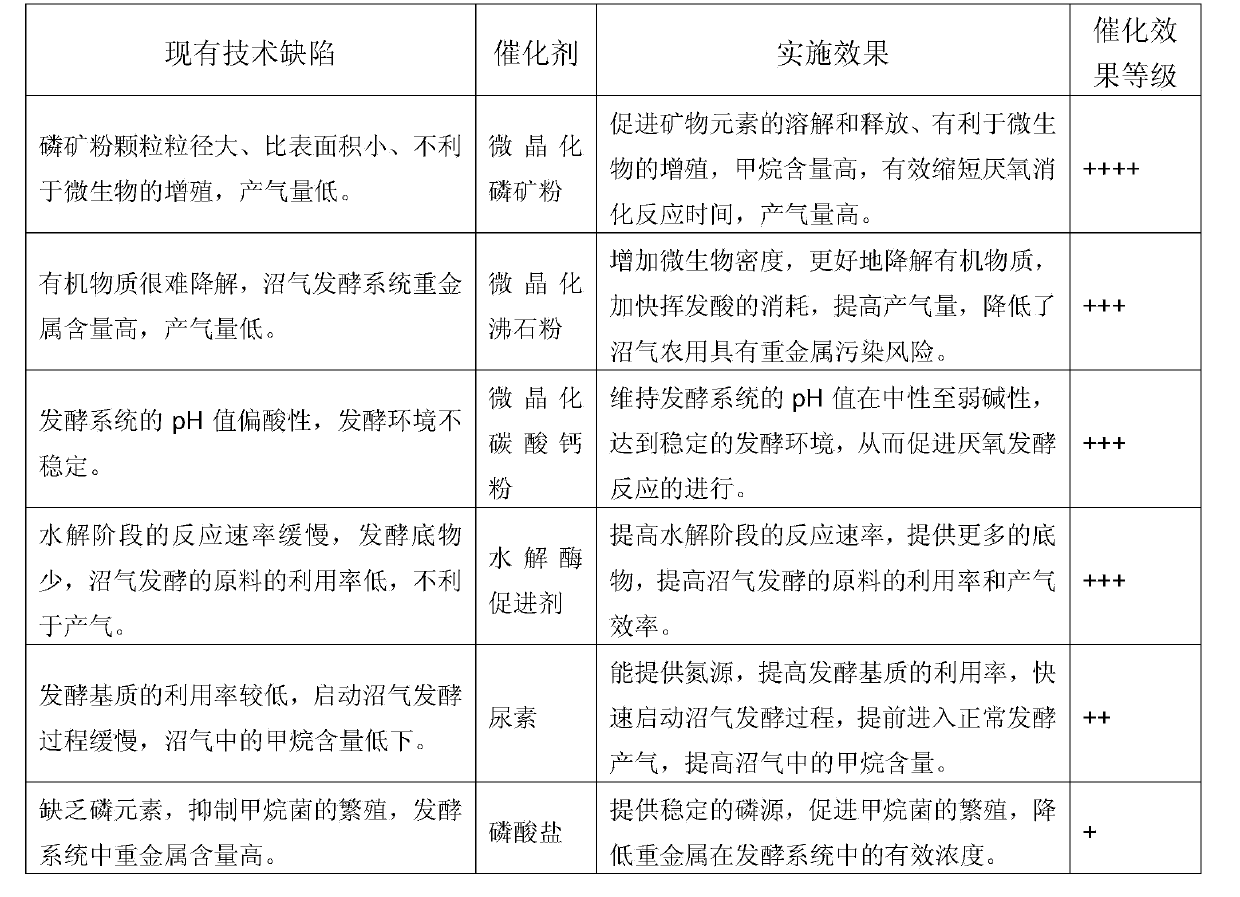

A biocatalyst and biogas fermentation technology, which is applied to the multifunctional biocatalyst containing microcrystalline phosphate rock powder and the field of biogas fermentation using the catalyst, can solve the problem of reduced biogas production, low biogas conversion rate, and lack of biogas fermentation raw materials Fully decompose and utilize problems to achieve the effects of easy operation, good effect, deodorization and inhibition of pathogenic microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

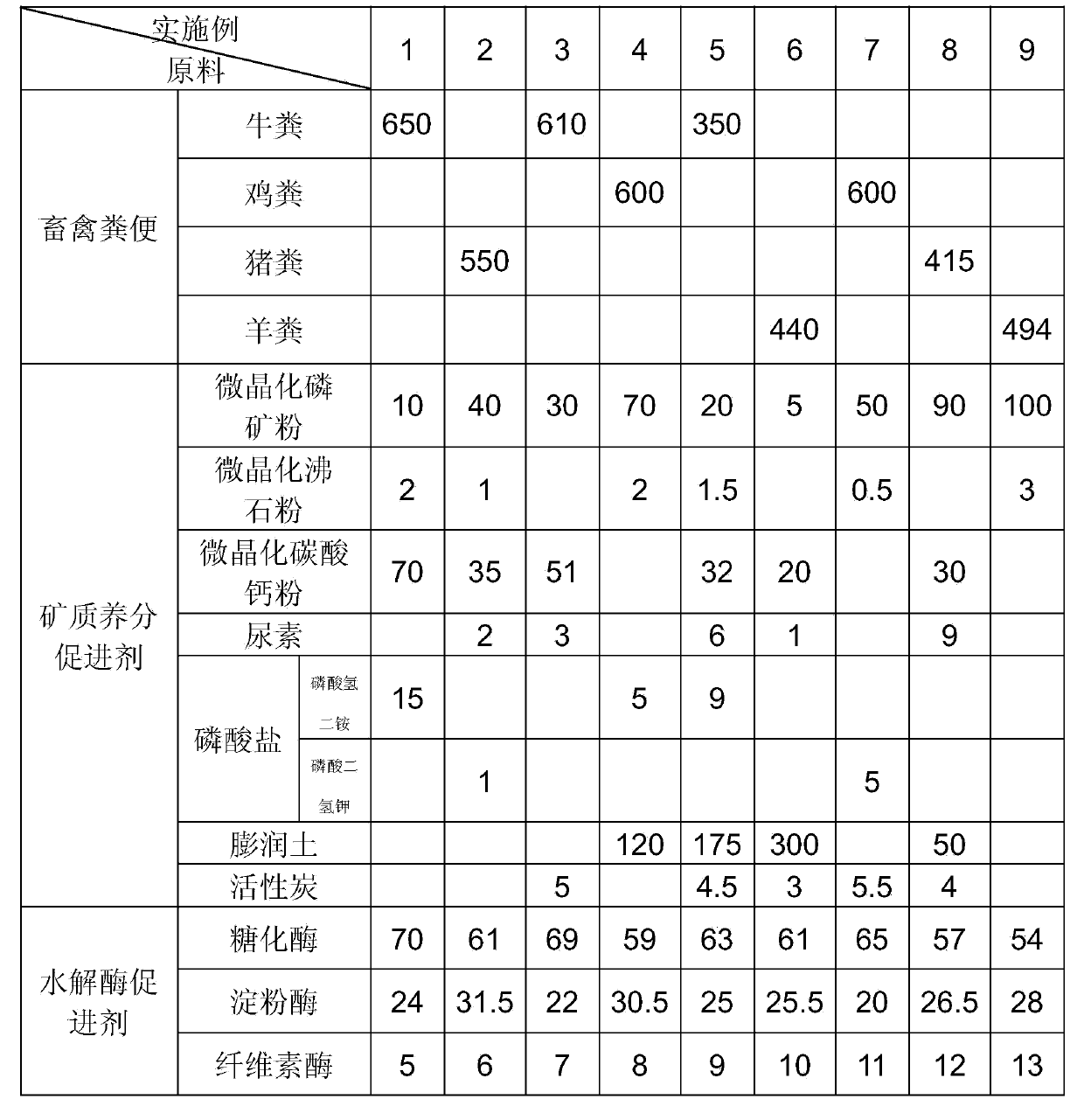

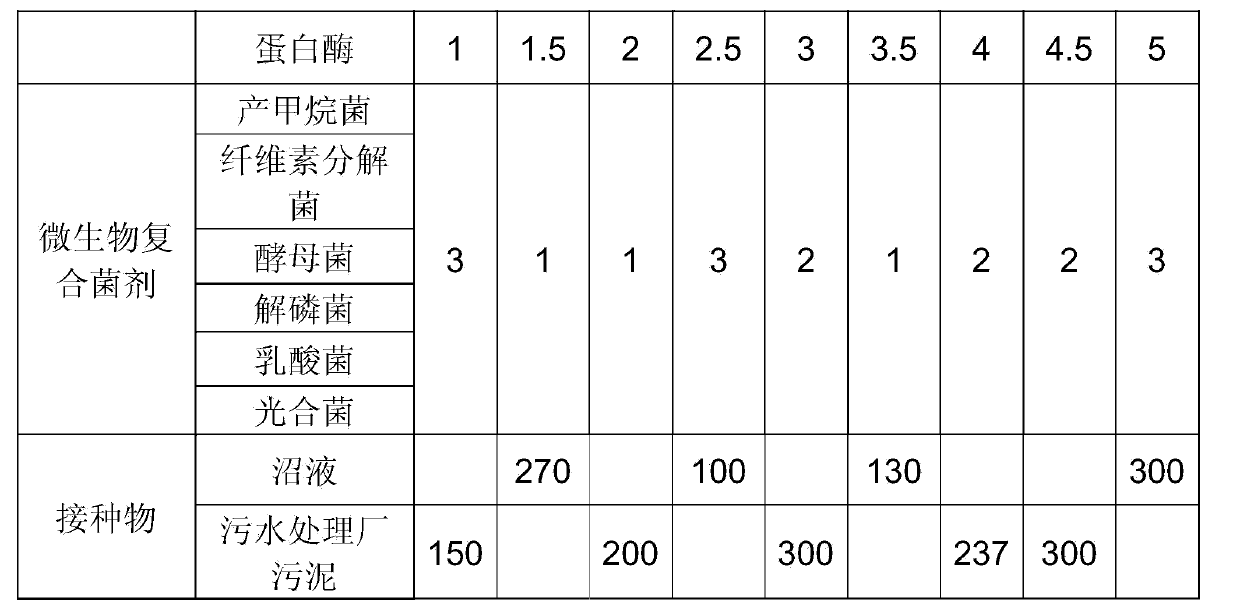

[0047] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention in any way.

[0048] The present invention utilizes the fermentation method of functional biocatalyst for biogas fermentation to carry out according to the following method:

[0049] The first step is to prepare microcrystalline phosphate rock powder:

[0050] Put the phosphorus mineral containing 96%-98% by mass in the crushing equipment, put the pulverized powder in the grinding equipment, and add 2%-4% of the mass percentage of activator in the grinding equipment to carry out ultrafine Processing, using mechanochemical and high-shear mechanical impact to prepare natural minerals into products with an average particle size of more than 400 mesh, and obtain P 2 o 5 Biogas fermented microcrystalline phosphate rock powder with a content between 15% and 25%, and packaged for later use.

[0051] Microcrystalline zeol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com