Continuous production device and method of orientation nanometer fiber yarns

A technology for nanofibers, manufacturing devices, for fiber processing, filament/thread forming, textiles and papermaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

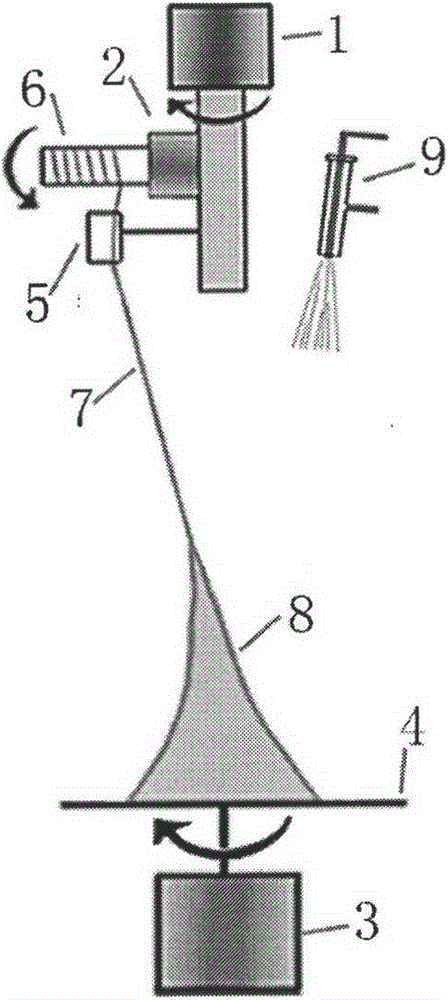

Method used

Image

Examples

Embodiment 1

[0025] The polyacrylonitrile spinning solution with a mass fraction of 12% (the solvent is N,N-dimethylformamide) is spun into nano Fiber, when spinning, the included angle of spinneret head (9) and motor 1 central axis is 30 degrees, and opposite direction draws yarn (7), makes the nanofiber that generates draw yarn (7) and the receiver of rotation ( 4) connect, the rotating speed of receiver (4) is 20r / min; Nanofiber forms an orientated funnel-shaped nanofiber net (8) at drawing yarn (7) and the receiver (4) of rotation gradually, then Under the rotation of the yarn guide tube (5), the yarn guide (7) is driven to continuously bundle the nanofibrous web (8) into yarns, and the rotating speed of the yarn guide tube (5) is 100r / min; 6) Wind the bundled yarn at a speed of 7.8r / min.

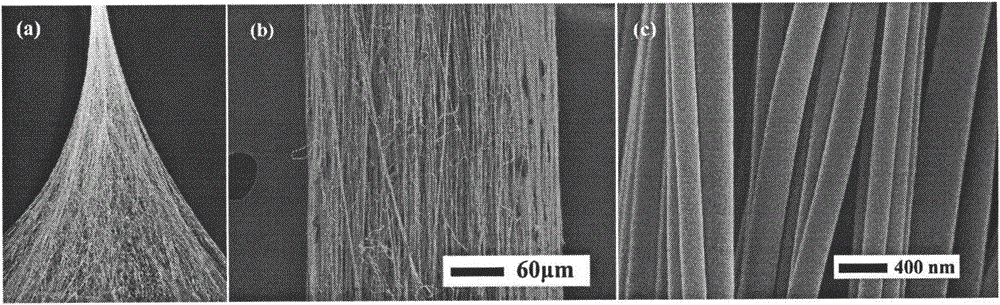

[0026] The whole process of adopting the present invention to prepare polyacrylonitrile nanofiber yarn is as follows: figure 2 shown. (a) is a photo of a funnel-shaped nanofiber web; (b) and (c)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com