Processing method of sprouted half-polished and obtained sprouted half-polished rice

A technology of germinated brown rice and processing method, which is applied in food preparation, cultivation, food science, etc., can solve the problems of different processing conditions, etc., and achieve the effect of short processing process, good medicine and health care effect, and easy cooking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

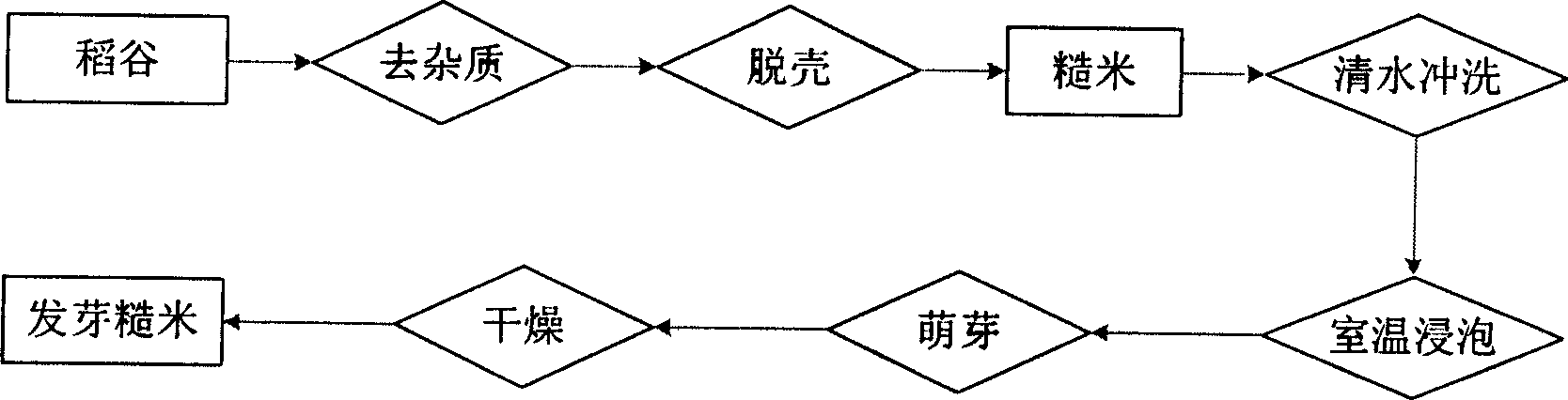

Method used

Image

Examples

Embodiment 1

[0032] Remove impurities from the rice, shell it and make it into brown rice, then wash it with clean water (ordinary tap water), soak it in water at 18°C for 4 hours; then germinate the rice grains at 35°C for 25 hours, and change it every 8 hours Clear water. The germinated rice grains are put into a circulating ventilated drying box, and dried at 40° C. for 8 hours to obtain germinated brown rice with a water weight content of 13%, which can be packaged in separate bags to obtain the finished product of germinated brown rice. The finished product of germinated brown rice has plump grains and is light beige in color, with obvious germination at the end of the rice and no peculiar smell.

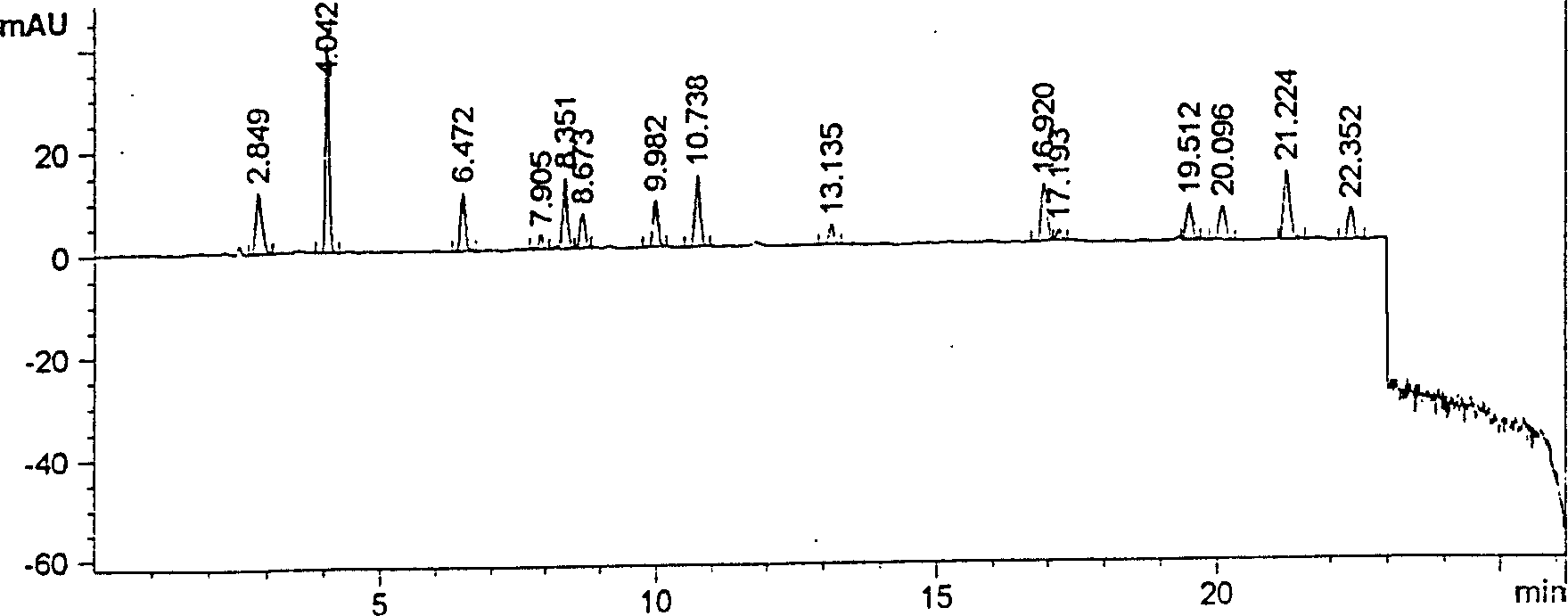

[0033] Amino acid determination, get the germinated brown rice that 100 milligrams make as sample, use the hydrochloric acid (wherein contain the phenol of 1Wt%) acid hydrolysis of 2 milliliters of 5.7 equivalents, then use high-performance liquid chromatography (HPLC) to analyze the vari...

Embodiment 2

[0036] Remove impurities from the rice, shell it and make it into brown rice, then wash it with clean water (ordinary tap water), soak it in water at 24°C for 2 hours; then germinate the rice grains at 40°C for 11 hours, and change the water every 6 hours . The germinated rice grains are put into a circulating ventilated drying oven, and dried at 48° C. for 10 hours to obtain germinated brown rice with a water weight content of 12%, which can be packaged in separate bags to obtain the finished product of germinated brown rice. The finished product of germinated brown rice has plump grains and is light beige in color, with obvious germination at the end of the rice and no peculiar smell.

[0037] Get the germinated brown rice that 100 milligrams make as sample, analyze with the method identical with embodiment one, calculate and handle and get the various amino acid contents in every 100 grams of germinated brown rice respectively: 1240 milligrams of aspartic acid, 2030 milligr...

Embodiment 3

[0039] Remove impurities from the rice, shell it and make it into brown rice, then wash it with clean water (ordinary tap water), soak it in clean water for 2 hours at 20°C; then germinate the rice grains at 40°C for 24 hours, and change it every 8 hours Clear water. The germinated rice grains are put into a circulating ventilated drying oven, and dried at 48° C. for 10 hours to obtain germinated brown rice with a water weight content of 12%, which can be packaged in separate bags to obtain the finished product of germinated brown rice. The finished product of germinated brown rice has plump grains and is light beige in color, with obvious germination at the end of the rice and no peculiar smell.

[0040] Get the germinated brown rice that 100 milligrams make as sample, analyze with the method identical with embodiment one, calculate and handle and get the various amino acid contents in every 100 grams of germinated brown rice to be respectively: 1170 milligrams of aspartic ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com