Plasticity machining method for metal composite pipe

A metal composite pipe and plastic processing technology, applied in the field of metal composite spinning, can solve the problems of easy stress release failure of metal composite pipe, long metallurgical composite production cycle, high operation requirements, etc., achieve high bonding strength, low production cost, Good process flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

[0044] Specific examples: (1) Select copper pipe and steel pipe, wherein the inner diameter of the copper pipe is Φ100mm, the wall thickness of the copper pipe is 0.6mm, the inner diameter of the steel pipe is Φ101.2mm, the wall thickness of the steel pipe is 1.8mm, and the copper pipe is 5mm longer than the steel pipe. The hole and the outer circle of the copper tube form an H8 / g7 fit.

[0045] (2) Carry out surface treatment: adopt the hydrochloric acid of mass percentage 10% to clean the inner surface of steel pipe and the outer surface of copper pipe, clean with clear water, then blow dry;

[0046](3) Use a steel wire throwing plate to roughen the outer surface of the copper pipe and the inner surface of the steel pipe respectively, then clean with acetone, and blow dry;

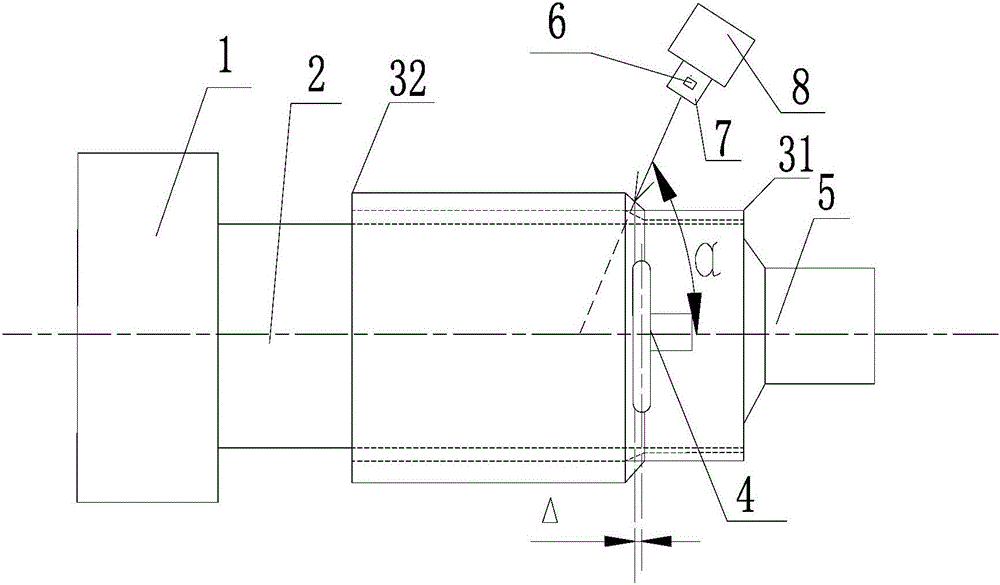

[0047] (4) The copper pipe penetrates into the steel pipe to form a composite pipe blank and is sleeved on the mandrel 2, and the bottom of the pipe wall of the copper pipe is used for positioning, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com