High-strength composite lithium ion battery diaphragm

A technology for ion batteries and lithium composites, which is applied to battery components, circuits, electrospinning, etc., can solve problems such as poor mechanical properties, thermal stability, and electrochemical properties, and achieve reduced agglomeration, good dispersion, and good affinity liquid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

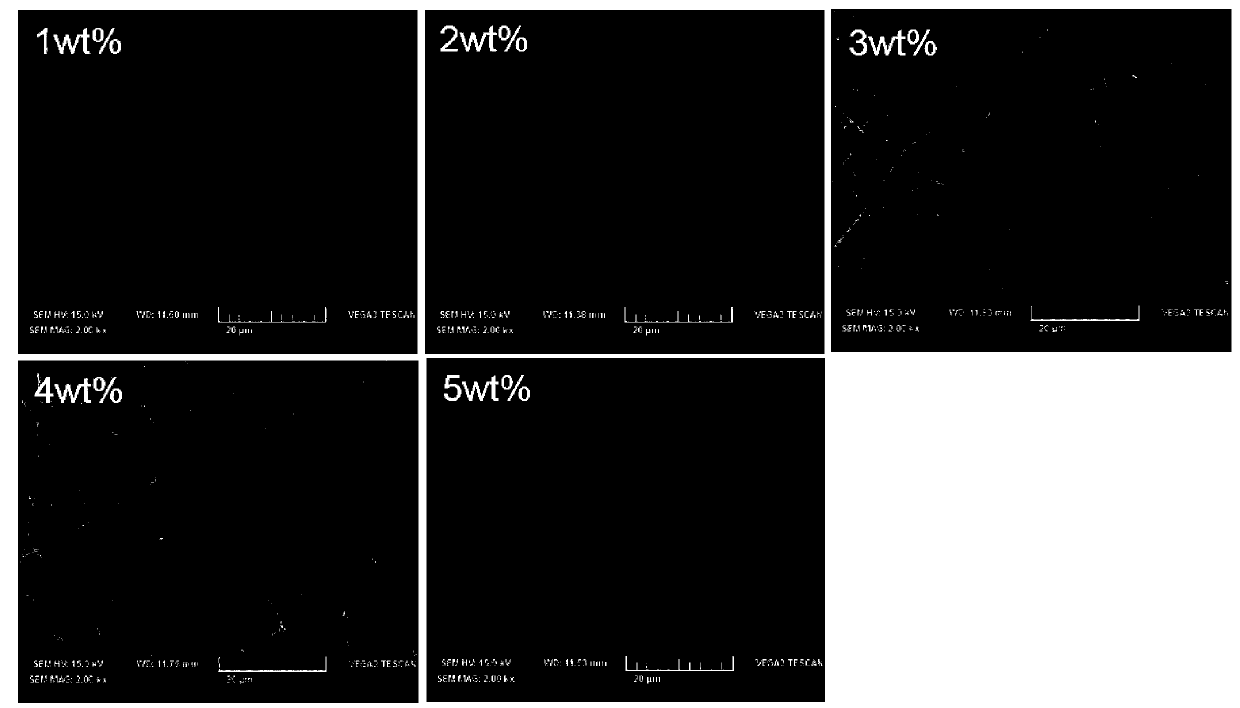

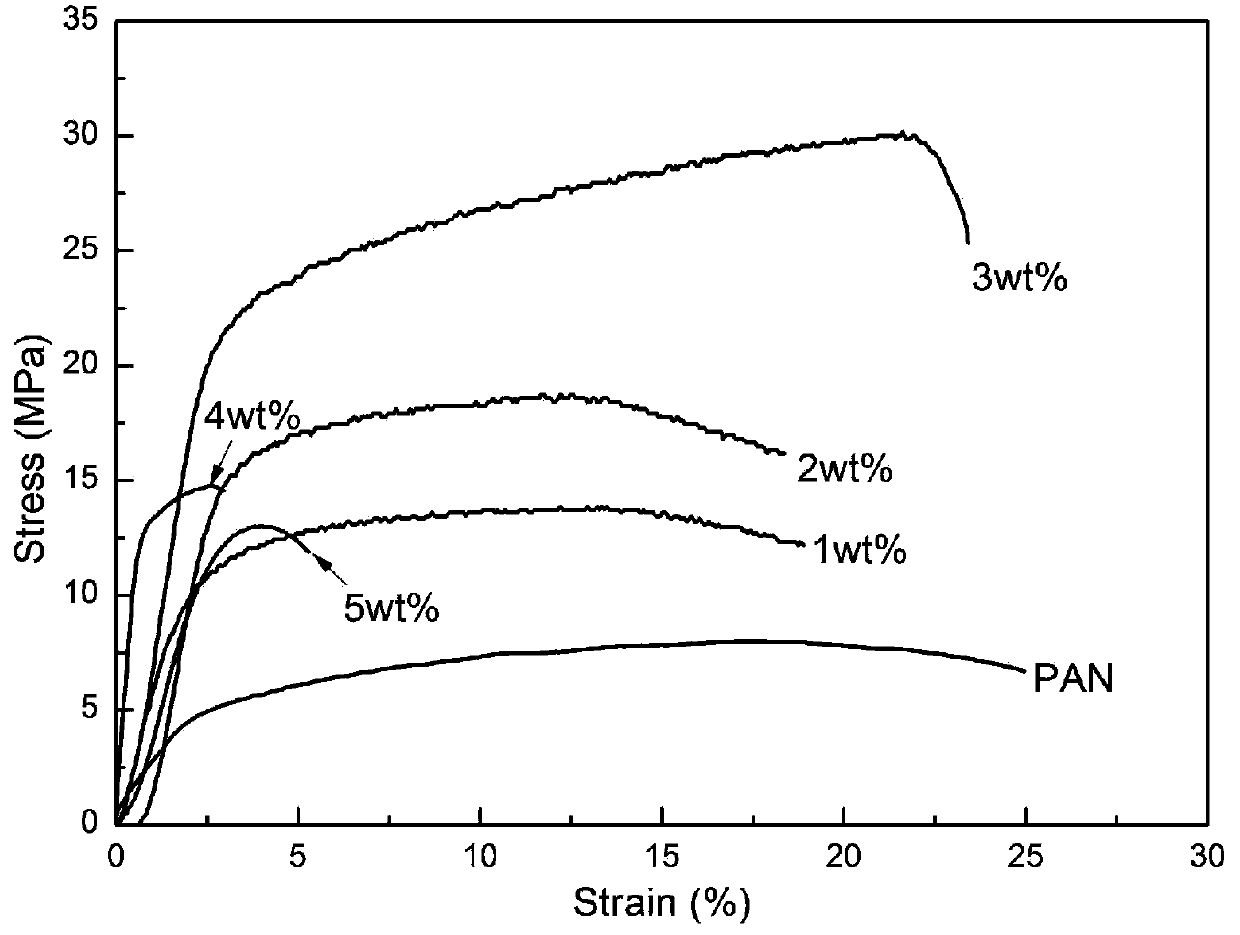

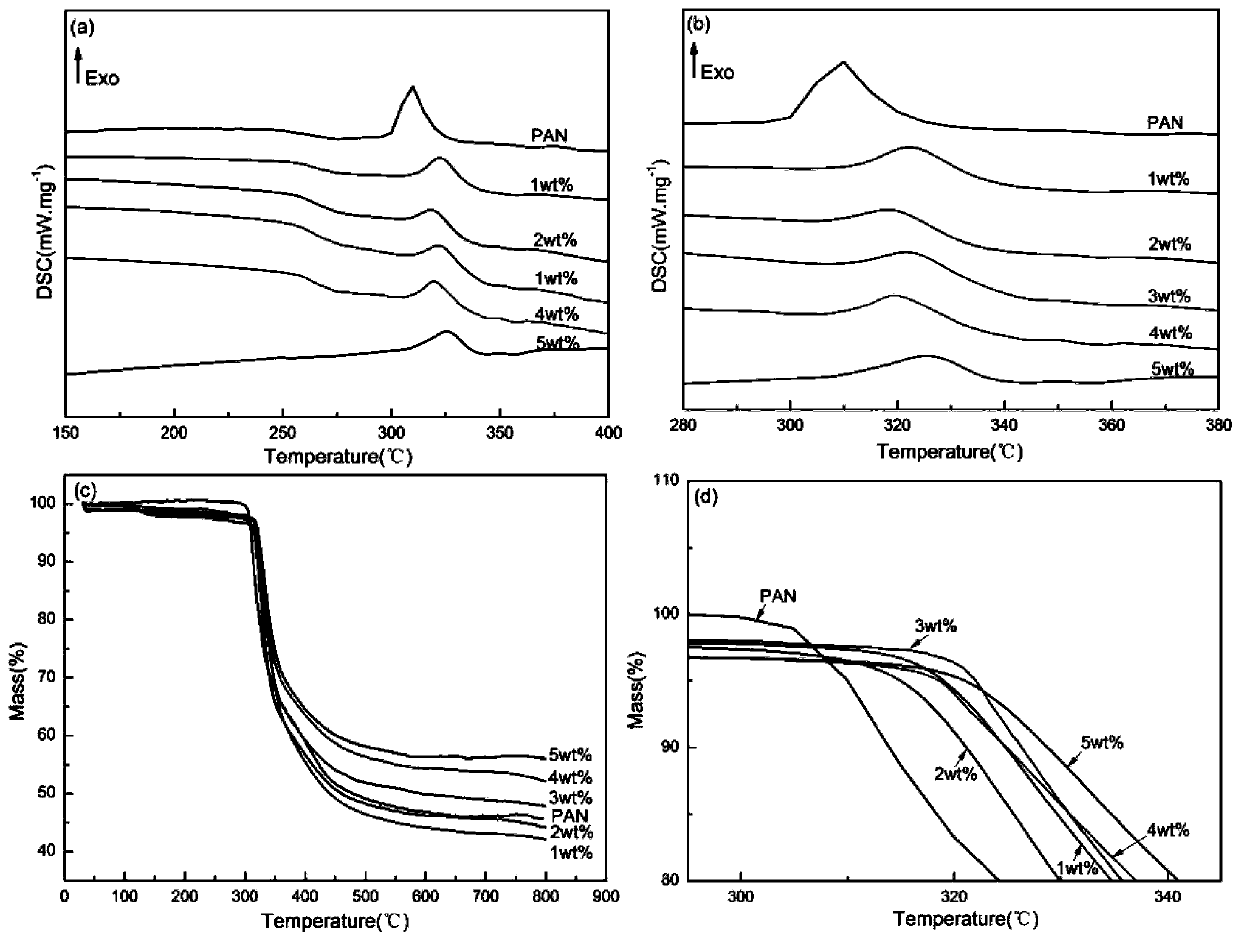

[0033] 1) Accurately weigh 5g TiO 2 Put 5g of KH560 in a beaker, then add 15g of N-N dimethylacetamide and 20g of deionized water, then place the beaker in an ultrasonic machine and heat it to 60°C for 300min. After the ultrasound is finished, filter and dry to obtain the modified TiO 2 .

[0034] 2) Take 0.78g polyacrylonitrile and 0.06g modified TiO prepared in step 1) 2 Add it into 5.16g N-N dimethylacetamide, heat and stir in an oil bath to fully react, and obtain an electrospinning solution with a concentration of 13wt%, wherein TiO 2 The addition amount of 1wt% was then transferred to a syringe and left to stand for several hours to eliminate air bubbles.

[0035] 3) The electrospinning solution prepared in step 2) was spun at a speed of 0.00012 mm / s. After the preparation was completed, the prepared composite fiber was dried in an oven at 60°C for 12 hours, and then it was dried at a temperature of 80°C and The high-strength composite lithium-ion battery diaphragm w...

Embodiment 2

[0037] 1) Accurately weigh 5g TiO 2 Put 5g of KH560 in a beaker, then add 15g of N-N dimethylacetamide and 20g of deionized water, then place the beaker in an ultrasonic machine and heat it to 70°C for 300min. After the ultrasound is finished, filter and dry to obtain the modified TiO 2 .

[0038] 2) Take 0.78g polyacrylonitrile and 0.12g modified TiO prepared in step 1) 2 Add it into 5.16g N-N dimethylacetamide, heat and stir in an oil bath to fully react, and obtain an electrospinning solution with a concentration of 13wt%, wherein TiO 2 The addition amount of 2wt% is then transferred to a syringe and left to stand for several hours to eliminate air bubbles.

[0039] 3) The electrospinning solution prepared in step 2) was spun at a speed of 0.00012 mm / s. After the preparation was completed, the prepared composite fiber was dried in an oven at 60°C for 12 hours, and then it was dried at a temperature of 80°C and The high-strength composite lithium-ion battery diaphragm wa...

Embodiment 3

[0041] 1) Accurately weigh 5g TiO 2 Put 5g of KH560 in a beaker, then add 15g of N-N dimethylacetamide, 20g of deionized water, then place the beaker in an ultrasonic machine and heat it to 60°C for 300min. After the ultrasound is finished, filter and dry to obtain the modified TiO 2 .

[0042] 2) Take 0.78g polyacrylonitrile and 0.18g modified TiO prepared in step 1) 2 Add it into 5.16g N-N dimethylacetamide, heat and stir in an oil bath to fully react, and obtain an electrospinning solution with a concentration of 13wt%, wherein TiO 2 The addition amount of 3wt% was then transferred to a syringe and left to stand for several hours to eliminate air bubbles.

[0043] 3) The electrospinning solution prepared in step 2) was spun at a speed of 0.00012 mm / s. After the preparation was completed, the prepared composite fiber was dried in an oven at 60°C for 12 hours, and then it was dried at a temperature of 80°C and The high-strength composite lithium-ion battery diaphragm was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com