Deprotonated dopamine-coated film and preparation method and application thereof

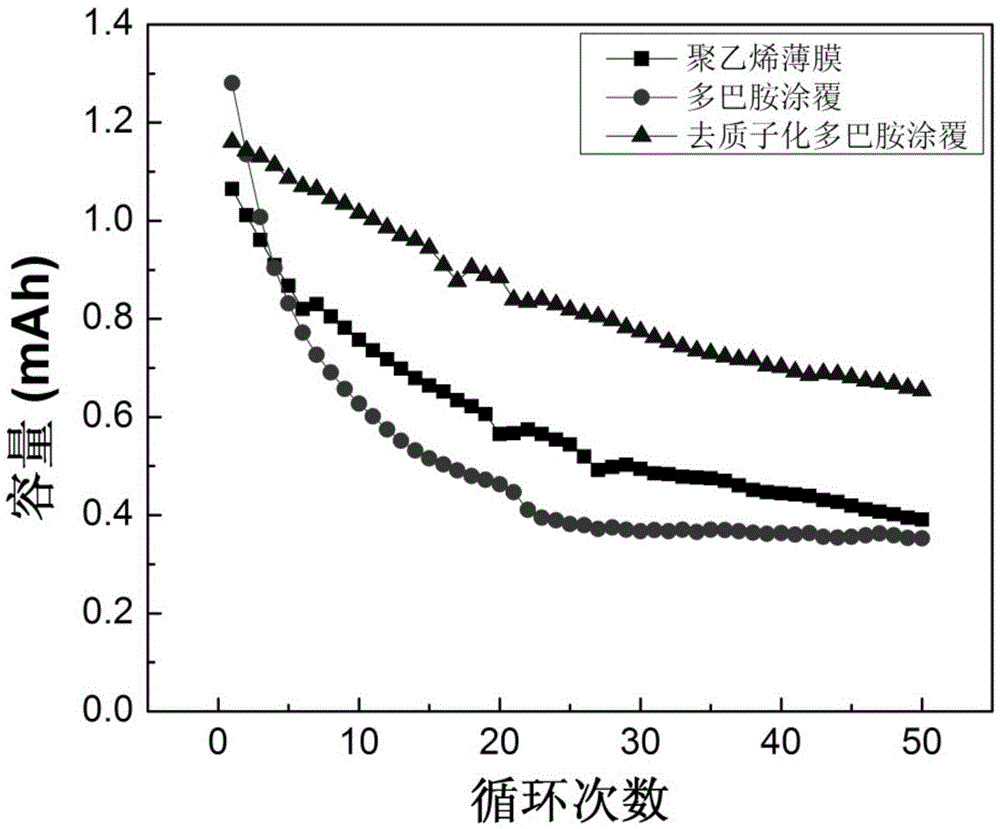

A deprotonation and dopamine technology, applied in the direction of separators/films/diaphragms/spacers, electrochemical generators, structural parts, etc. The effect of enhanced battery cycle performance, improved selective permeability, and improved rate capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

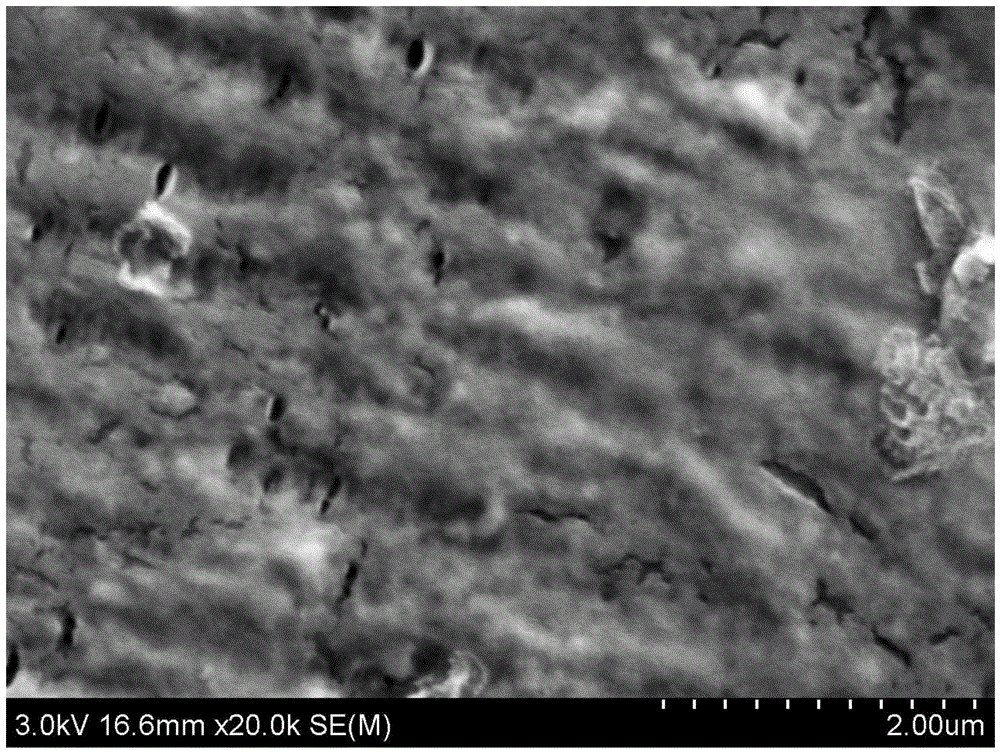

[0030] First, take 0.9g of Tris (Tris) and dissolve it in a mixed solvent of methanol and water (volume 150ml, volume ratio 1:1), then add a certain concentration of hydrochloric acid dropwise until the pH of the mixture is 8.5, and then add 0.3 g of dopamine hydrochloride, stirred and dissolved. Finally, several pieces of polyethylene film prewashed with deionized water were immersed in the mixed solution for 24h. The resulting treated diaphragm was rinsed with deionized water several times, and dried in a vacuum oven at 60° C. for 6 hours to obtain a dopamine-coated modified polyethylene film. Its scanning electron microscope image is figure 1 As shown, it can be seen that there is a uniform coating of dopamine on the surface of the polyethylene film.

Embodiment 2

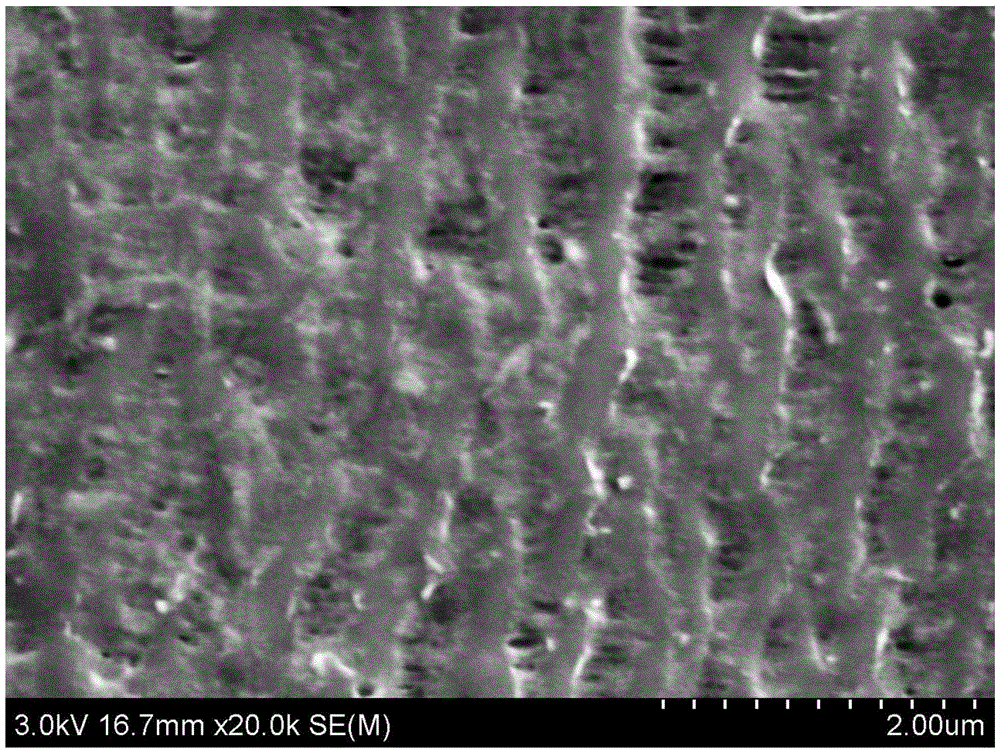

[0032] The method described in Example 1 was used to prepare a dopamine-coated modified polyethylene film. A lithium hydroxide solution with a pH of 13 was prepared, and the dopamine-coated polyethylene film was soaked in it for 0.5 hours, then taken out, rinsed with deionized water several times, and dried in a vacuum oven at 60°C for 6 hours. Its scanning electron microscope image is figure 2 As shown, it can be seen that after the deprotonation treatment, the dopamine coating is slightly peeled off, but the whole remains intact.

Embodiment 3

[0034] The method described in Example 1 was used to prepare a dopamine-coated modified polypropylene film. A sodium hydroxide solution with a pH of 12 was prepared, and the dopamine-coated polypropylene film was soaked in it for 1 hour, then taken out, rinsed with deionized water several times, and dried in a vacuum oven at 60°C for 6 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com