Patents

Literature

38results about How to "Improve battery cycle performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

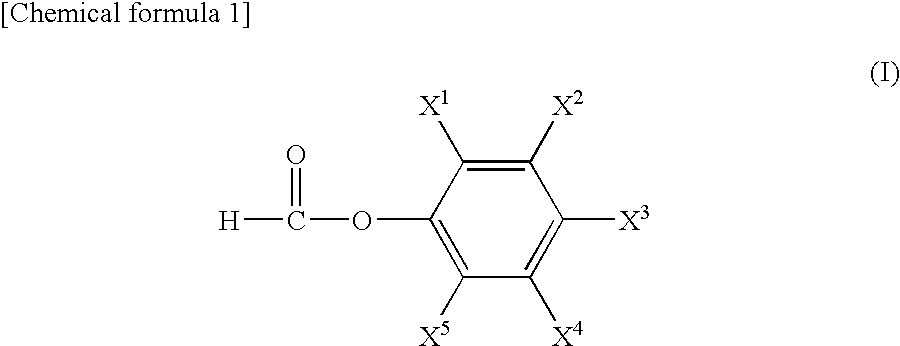

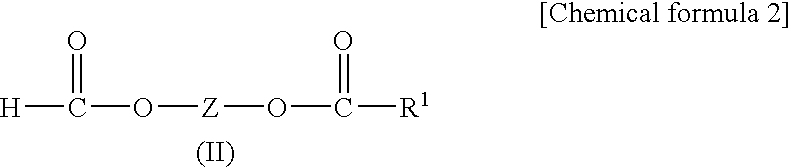

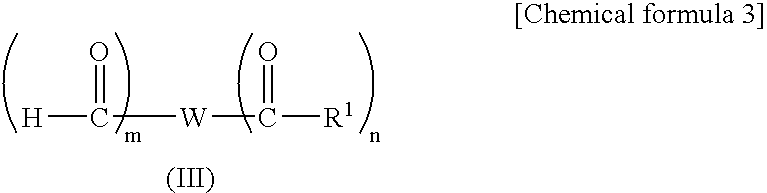

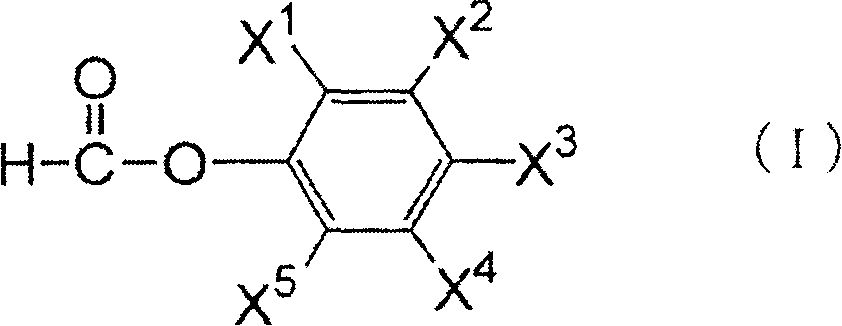

Nonaqueous electrolyte solution and lithium secondary battery using same

InactiveUS7985502B2Improve battery cycle performanceImprove featuresOrganic electrolyte cellsNon-aqueous electrolyte accumulator electrodesLithiumPhysical chemistry

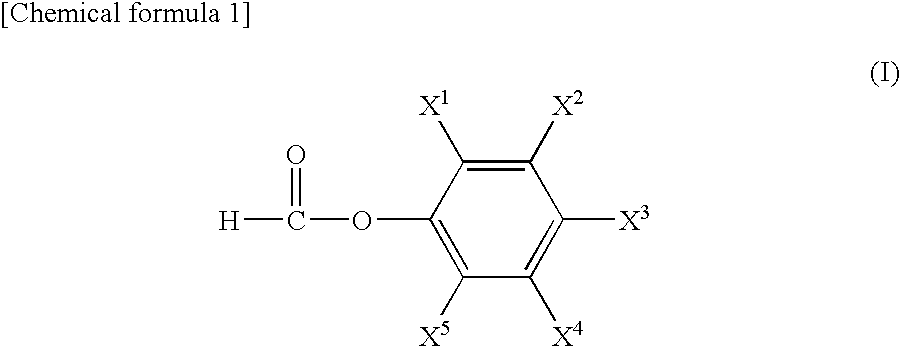

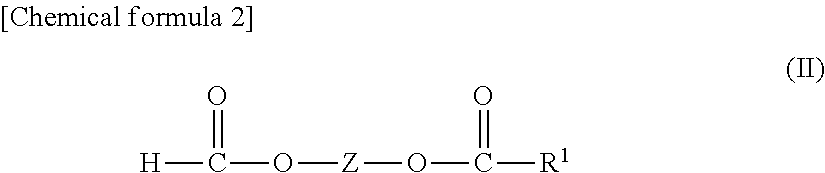

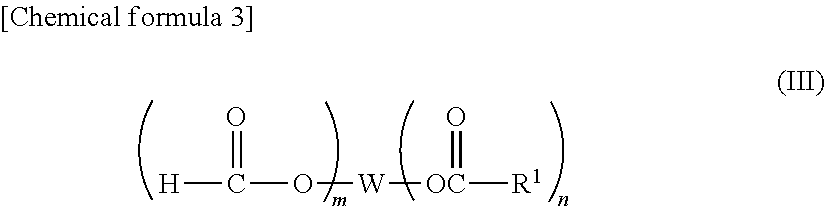

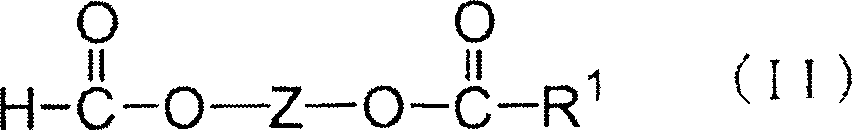

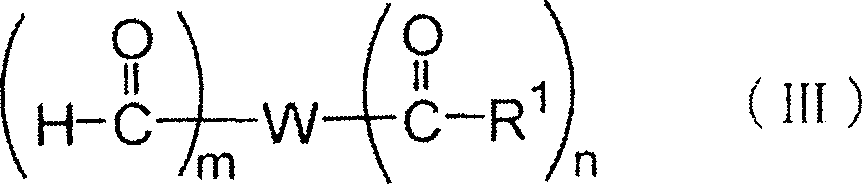

The present invention provides a lithium secondary battery having excellent battery characteristics such as battery cycling property, electrical capacity and storage property.The present invention relates to a nonaqueous electrolytic solution for lithium secondary batteries in which an electrolyte salt is dissolved in a nonaqueous solvent, the nonaqueous electrolytic solution comprising a formic ester compound having a specific structure in an amount of 0.01 to 10% by weight of the nonaqueous electrolytic solution, and a lithium secondary battery using the same.

Owner:UBE IND LTD

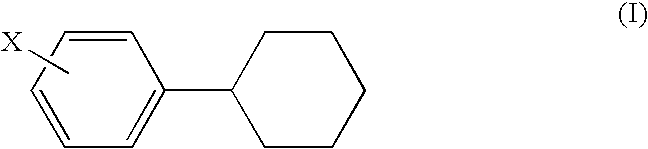

Lithium secondary battery

ActiveUS20050250007A1Improve battery cycle performanceIncrease capacityNon-aqueous electrolyte accumulatorsCell electrodesLithiumElectric capacity

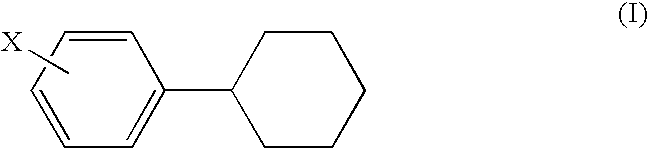

A lithium secondary battery comprising a positive electrode, a negative electrode of artificial graphite or natural graphite and a nonaqueous electrolytic solution having an electrolyte dissolved in a nonaqueous solvent, wherein 0.1 to 20 wt. % of a cyclohexylbenzene having a halogen atom bonded to a benzene ring thereof is contained in the nonaqueous electrolytic solution exhibits large electric capacity and excellent cycle performance.

Owner:MU IONIC SOLUTIONS CORP

Nonaqueous Electrolyte Solution and Lithium Secondary Battery Using Same

InactiveUS20080241704A1Excellent battery charactristicsImprove battery cycle performanceOrganic electrolyte cellsNon-aqueous electrolyte accumulator electrodesSolventChemistry

The present invention provides a lithium secondary battery having excellent battery characteristics such as battery cycling property, electrical capacity and storage property.The present invention relates to a nonaqueous electrolytic solution for lithium secondary batteries in which an electrolyte salt is dissolved in a nonaqueous solvent, the nonaqueous electrolytic solution comprising a formic ester compound having a specific structure in an amount of 0.01 to 10% by weight of the nonaqueous electrolytic solution, and a lithium secondary battery using the same.

Owner:UBE IND LTD

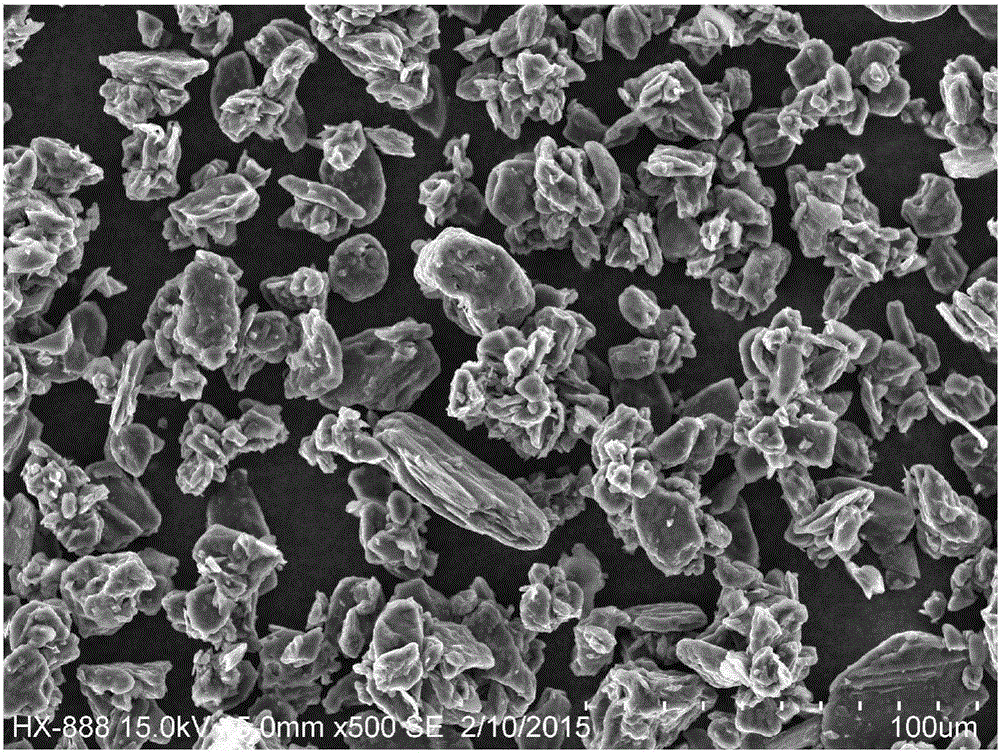

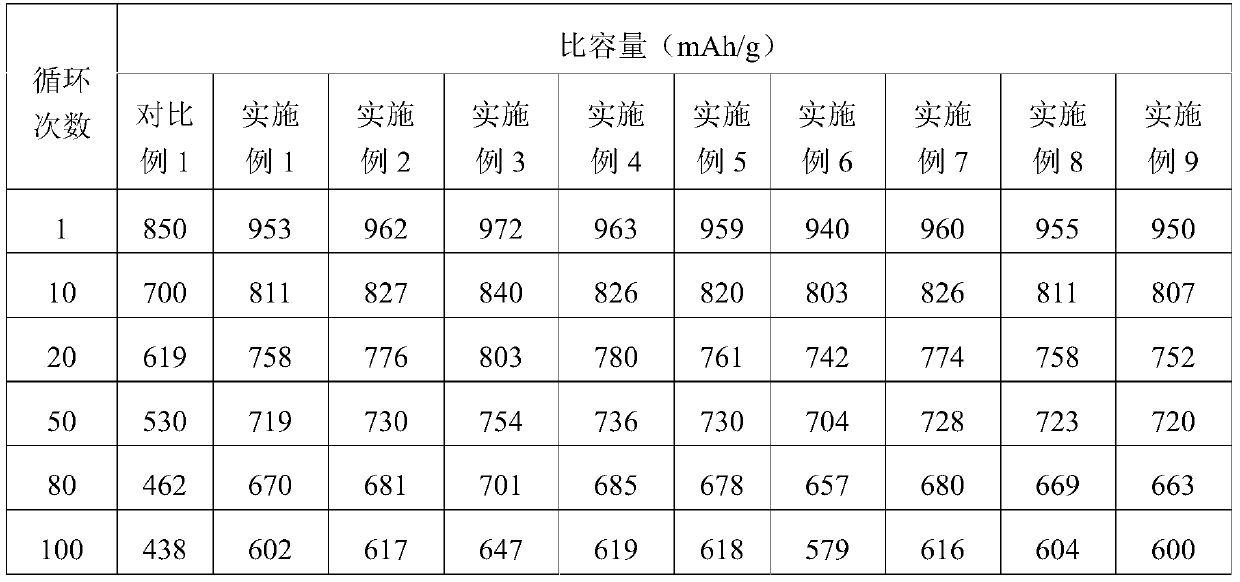

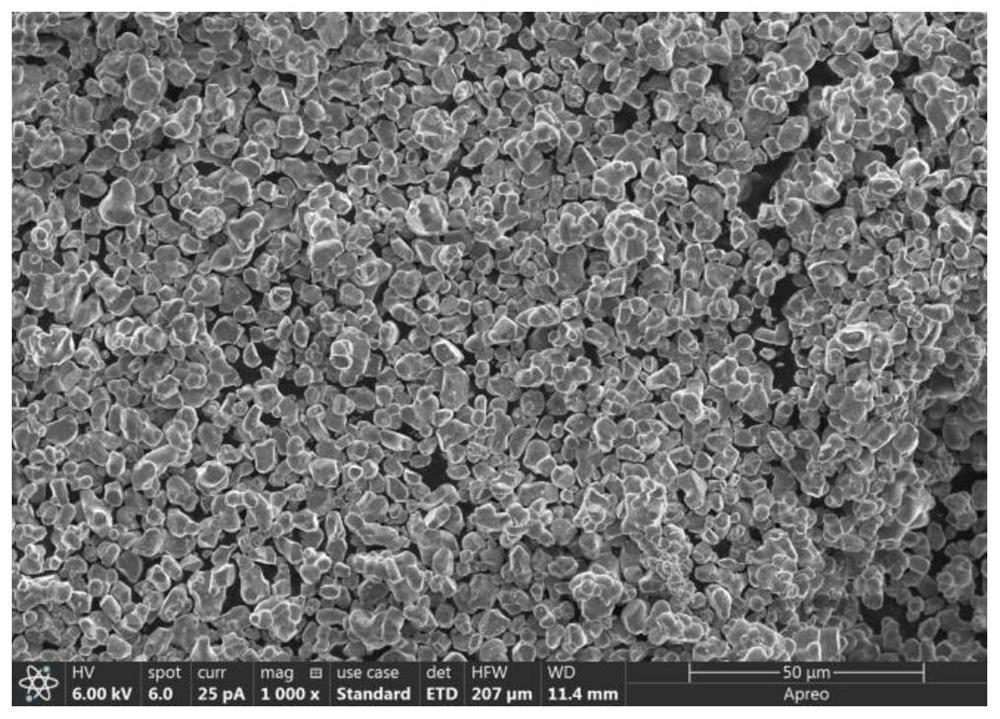

High-capacity and high-rate lithium battery anode material and preparation method thereof

InactiveCN105355841AGood battery cycle performanceImprove liquid absorption performanceElectrode manufacturing processesLi-accumulatorsUltra high pressureHigh rate

The invention discloses a preparation method of a high-capacity and high-rate lithium battery anode material, and is characterized in that the preparation method includes the following steps: stirring needle-coke and a binder in a high-speed stirrer evenly; pressing the mixture after stirring under an ultra-high pressure of an isostatic pressing machine, to obtain an initially-pressed block; heating and sintering the initially-pressed block under a nitrogen atmosphere protection, cooling, and then crushing and shaping the semi-finished block, to obtain a carbon powder; and carrying out high temperature graphitization on the carbon powder, cooling, and then carrying out iron removal screening, to obtain the graphite powder with high rate, high capacity and high compaction. The graphite anode material prepared by the preparation method has the characteristics of high capacity, high rate and good cycling performance.

Owner:JIANGSU SAINTY HI TECH & CARBON MATERIALS

Nonaqueous electrolyte solution and lithium secondary battery using same

InactiveCN1934743AExcellent battery characteristicsGood battery cycle performanceSecondary cellsPhysical chemistryLithium-ion battery

Disclosed is a lithium secondary battery which is excellent in cycle characteristics, battery capacity and battery characteristics such as storage characteristics. A nonaqueous electrolyte solution for lithium secondary batteries wherein an electrolyte salt is dissolved in a nonaqueous solvent is characterized in that a formate compound having a specific structure is contained in the nonaqueous electrolyte solution in an amount of 0.01-10 weight% relative the nonaqueous electrolyte solution. A lithium secondary battery uses such a nonaqueous electrolyte solution.

Owner:UBE IND LTD

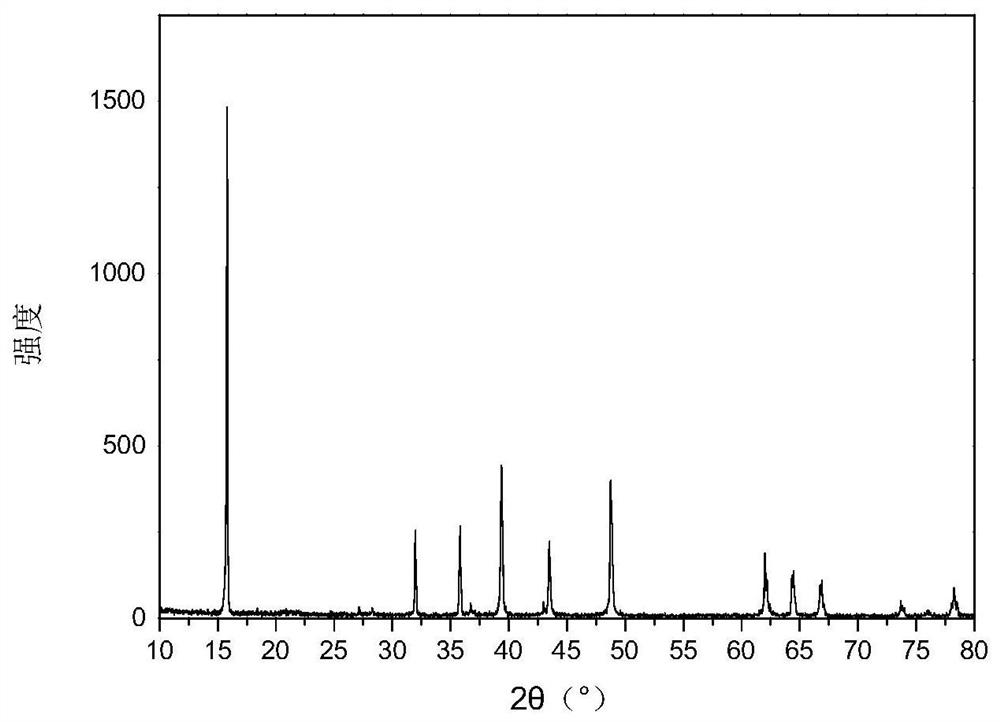

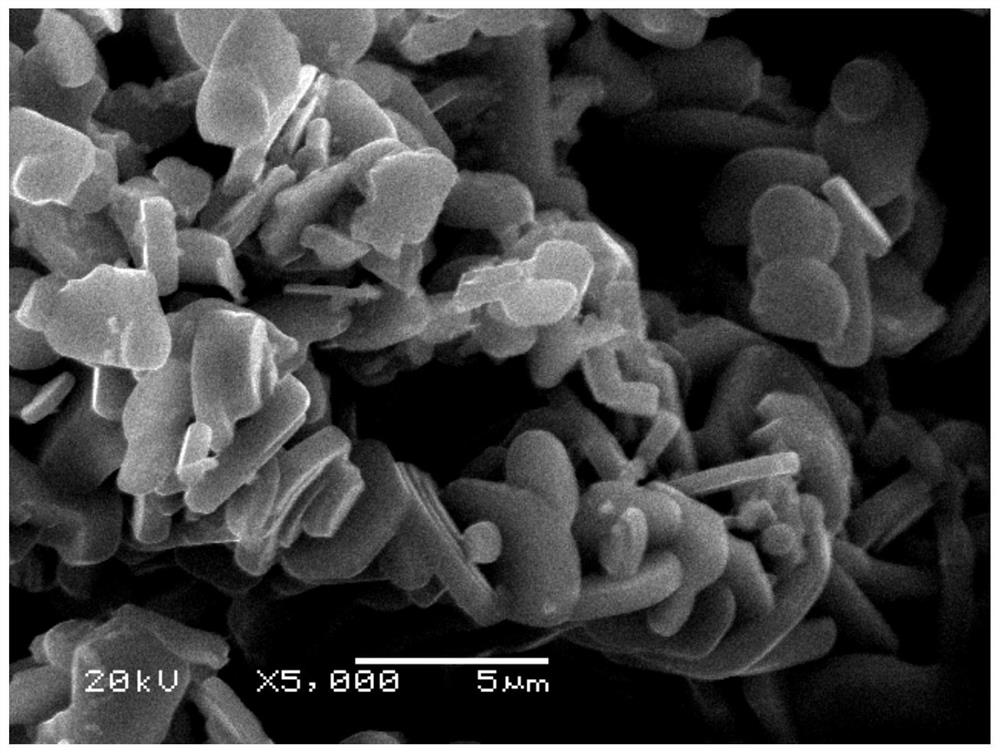

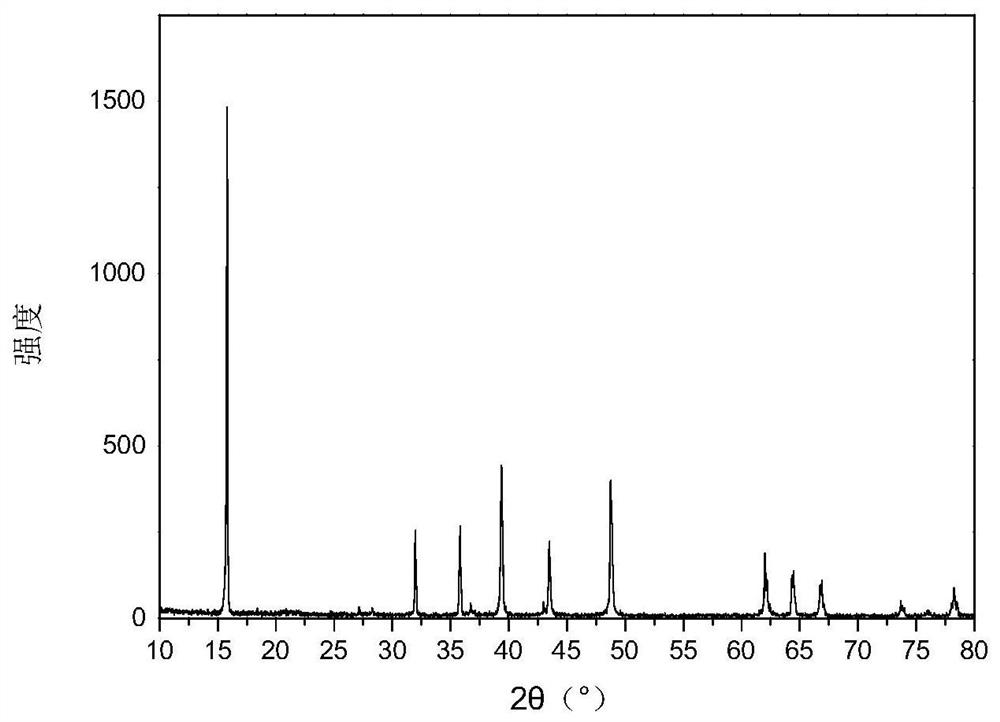

Sodium-ion battery multi-element positive electrode material and preparation method thereof

ActiveCN111697210AImprove structural stabilityImprove conductivitySecondary cellsPositive electrodesPhysical chemistrySodium-ion battery

A sodium-ion battery multi-element positive electrode material and a preparation method thereof are provided. The chemical general formula of the sodium-ion battery multi-element positive electrode material is Na<0.67>Mn<x>Mg<y>Ni<z>W<n>O<2-q>B<q>, 0.65 <= x <= 0.8, 0 < y < = 0.2, 0 < z < = 0.2, 0 < n < = 0.2, 0 < q < = 0.05, and x + y + z + n = 1. The preparation method comprises the following steps: adding a sodium source, a manganese source, a nickel source, a magnesium source, a tungsten source and a boron source into citric acid to generate sol, drying the sol to obtain gel, and carryingout heat treatment on the gel to obtain the sodium-ion battery multi-element positive electrode material. According to the preparation of the sodium ion battery multi-element positive electrode material, a cation or anion doping or co-doping means is utilized, so the structural stability and the conductivity of the material are enhanced. The material has good rate capability and excellent cyclingstability, the required raw materials are rich in resource and low in cost, and the preparation method is simple and controllable.

Owner:帕瓦(兰溪)新能源科技有限公司

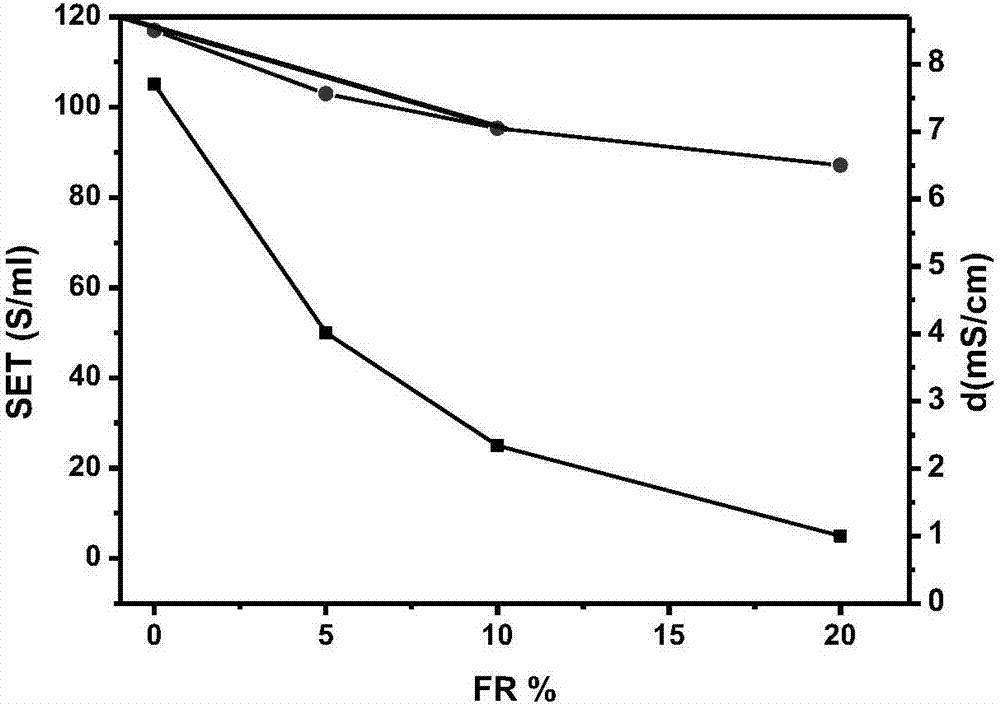

Additive, non-aqueous electrolyte and lithium ion battery

ActiveCN106997959AGood battery cycle performancePromote circulationSecondary cells servicing/maintenanceOrganic electrolytesPhysical chemistryLithium-ion battery

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a non-aqueous electrolyte and a lithium ion battery. The invention provides an additive, the additive is a phosphate compound containing thienyl, and the phosphate compound containing thienyl has a structure shown as a formula I; the invention also discloses a non-aqueous electrolyte and a lithium ion battery; and according to the additive and the non-aqueous electrolyte provided by the invention, the technical defects that the lithium ion battery is easy to break out a fire and explode under the conditions, such as high temperature, overcharging, acupuncture penetration and extrusion, of the lithium ion battery can be solved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Method of charging and discharging a non-aqueous electrolyte secondary battery

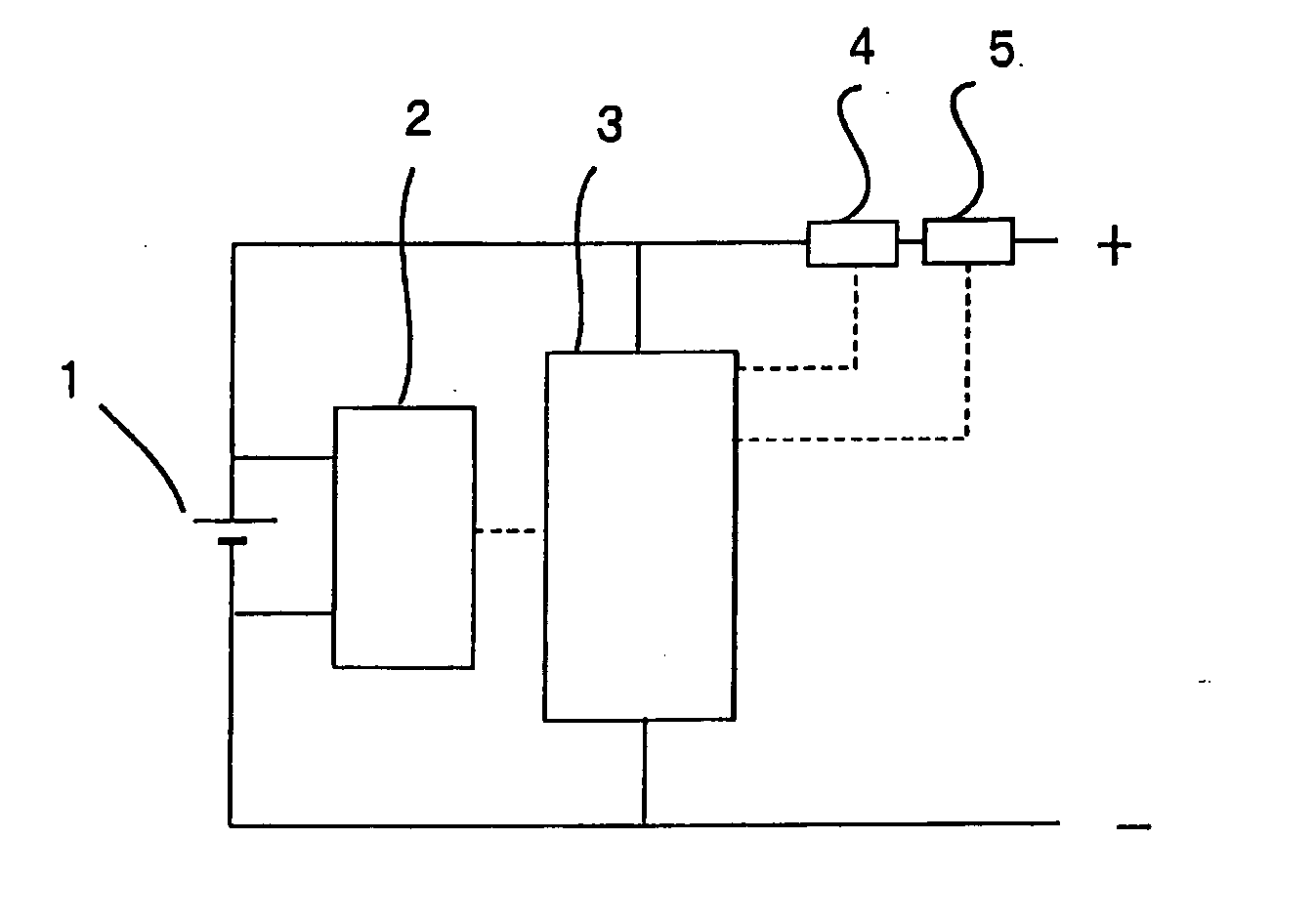

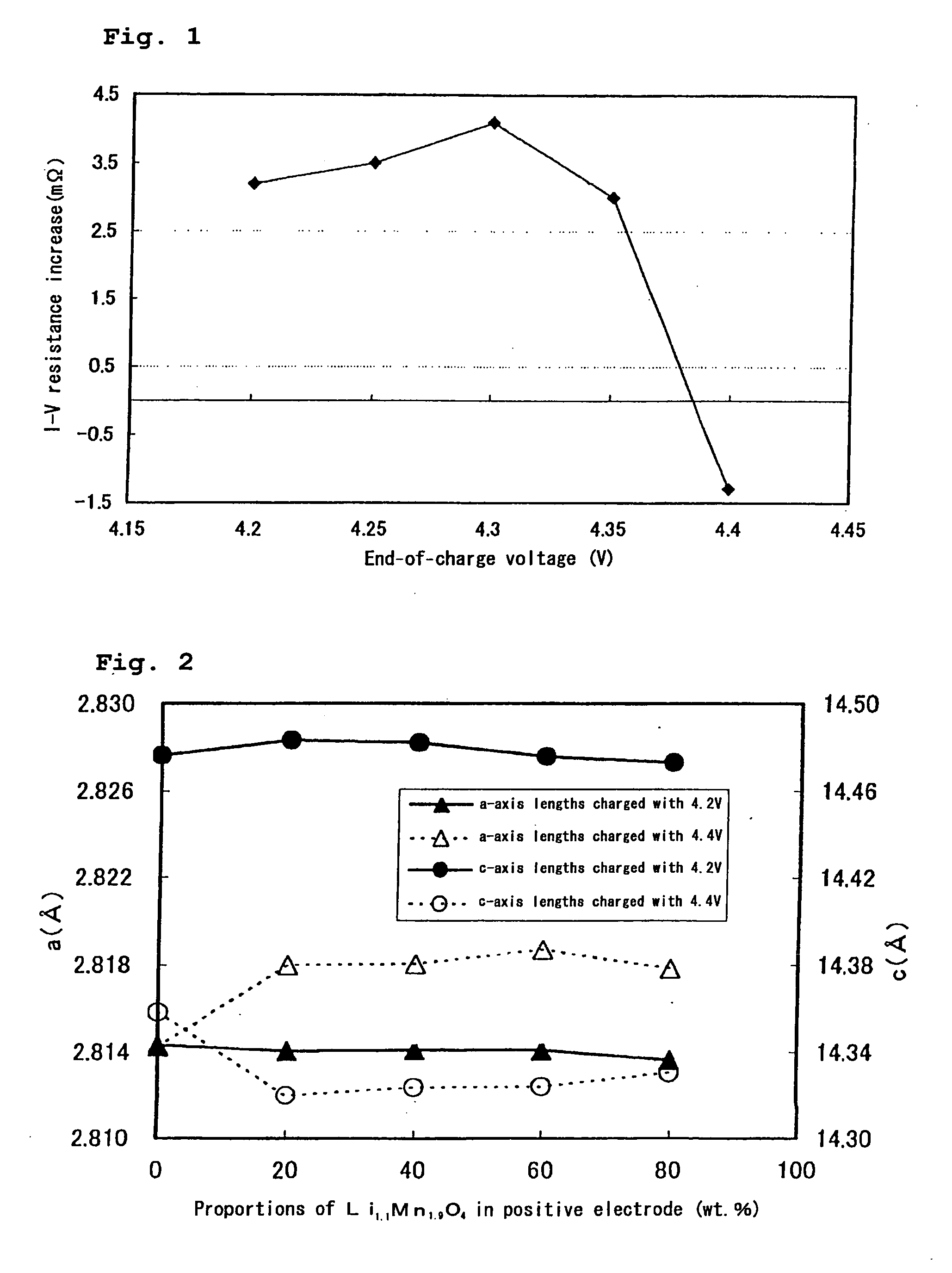

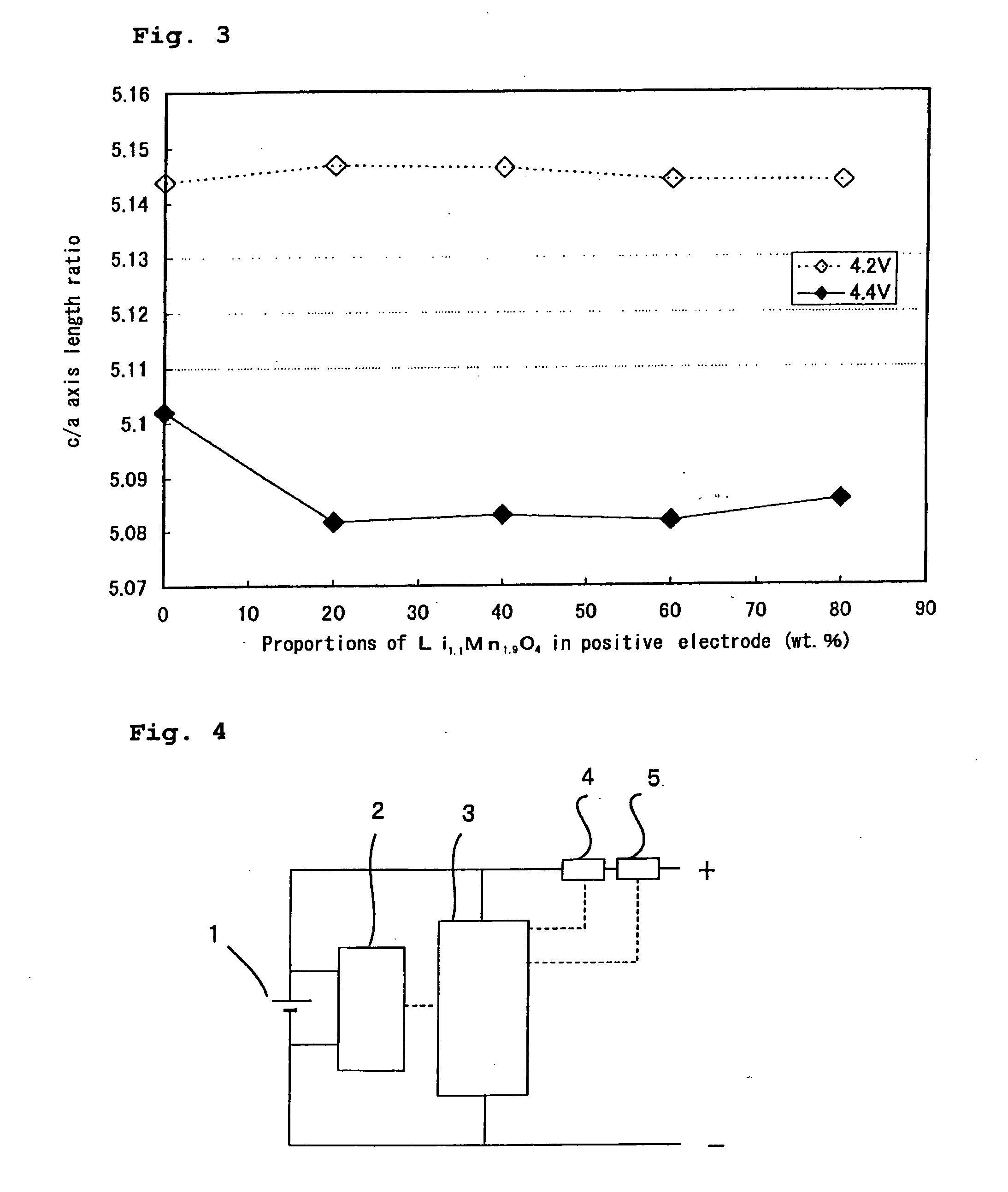

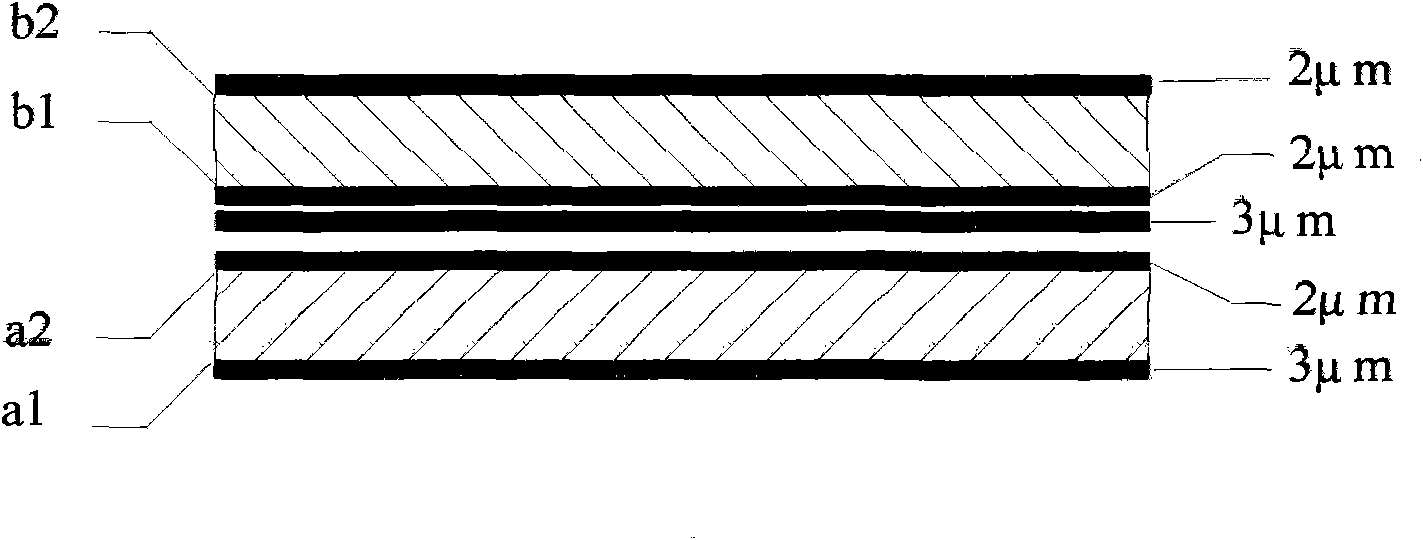

ActiveUS20070072059A1Improve battery performanceImprove battery cycle performanceNon-aqueous electrolyte accumulatorsActive material electrodesComposite oxideMaterials science

Good cycle performance is obtained with a non-aqueous electrolyte secondary battery having a positive electrode, a negative electrode, and a non-aqueous electrolyte. The positive electrode contains as positive electrode active material a mixture of a lithium-manganese composite oxide and a lithium-transition metal composite oxide containing at least Ni and Mn as transition metals. The negative electrode contains as a negative electrode active material a material capable of intercalating and deintercalating lithium. Charging of the non-aqueous electrolyte secondary battery is controlled so that the end-of-charge voltage becomes higher than 4.3 V.

Owner:PANASONIC ENERGY CO LTD

Lithium ion secondary battery cathode, preparation method thereof and lithium ion secondary battery

InactiveCN101877394ASolve poor battery cycle performanceImprove battery cycle performanceElectrode manufacturing processesElectrode carriers/collectorsPhysicsCharge and discharge

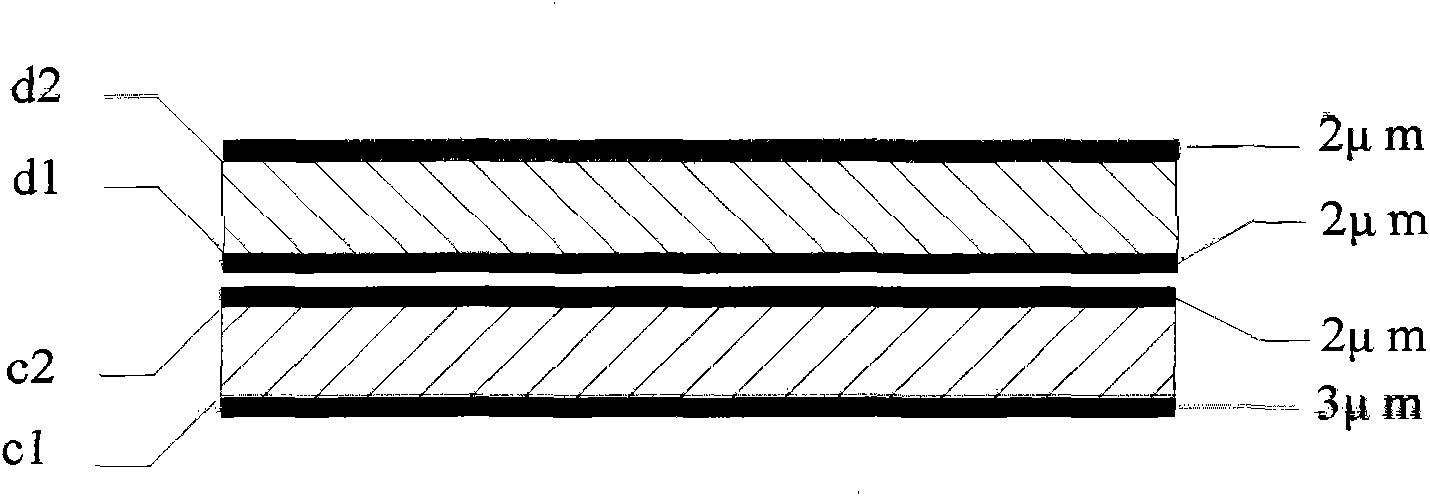

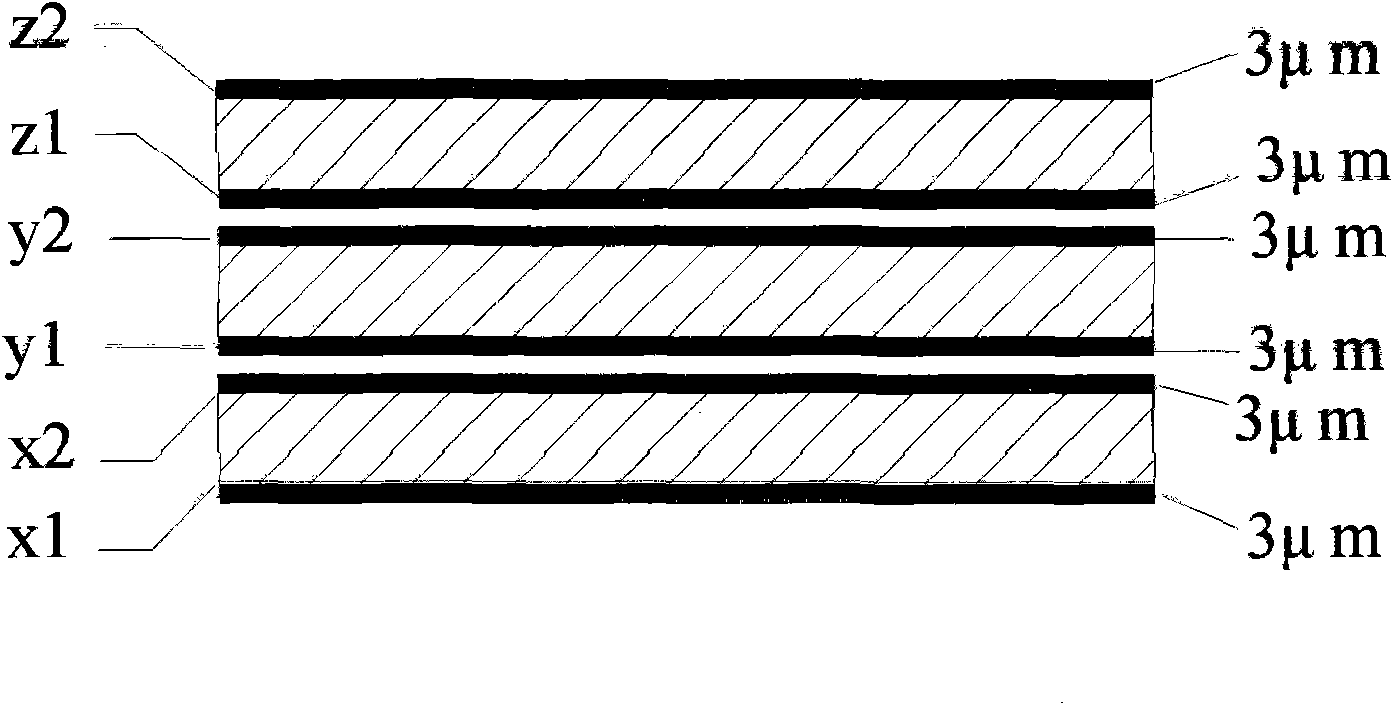

The invention belongs to the field of lithium ion secondary batteries and provides a lithium ion secondary battery cathode which comprises cathode current collectors and silicon films deposited on the surface of the cathode current collectors, wherein the amount of the current collectors is two, each current collector is provided with a via hole, and the silicon films are deposited on the two surfaces of each current collector, at least one layer of the silicon film is provided with the via hole, and the average pore size of the via hole on the silicon film is 0.2-0.6mm; and the cathode current collectors are mutually overlaid, and at least one layer of silicon film is deposited on the adjacent surfaces of every two overlaying cathode current collectors. The lithium ion secondary battery cathode is adopted to overcome the defect of poor circulation performance of a battery when the silicon films are used as cathode active substances to greatly enhance the circulation performance of the battery under the room temperature: under the room temperature, the capacity retention can reach 100 percent after 200 charging and discharging circulations, and the capacity of the battery is increased less than the initial discharging capacity after 200-500 circulations.

Owner:SHANGHAI BYD

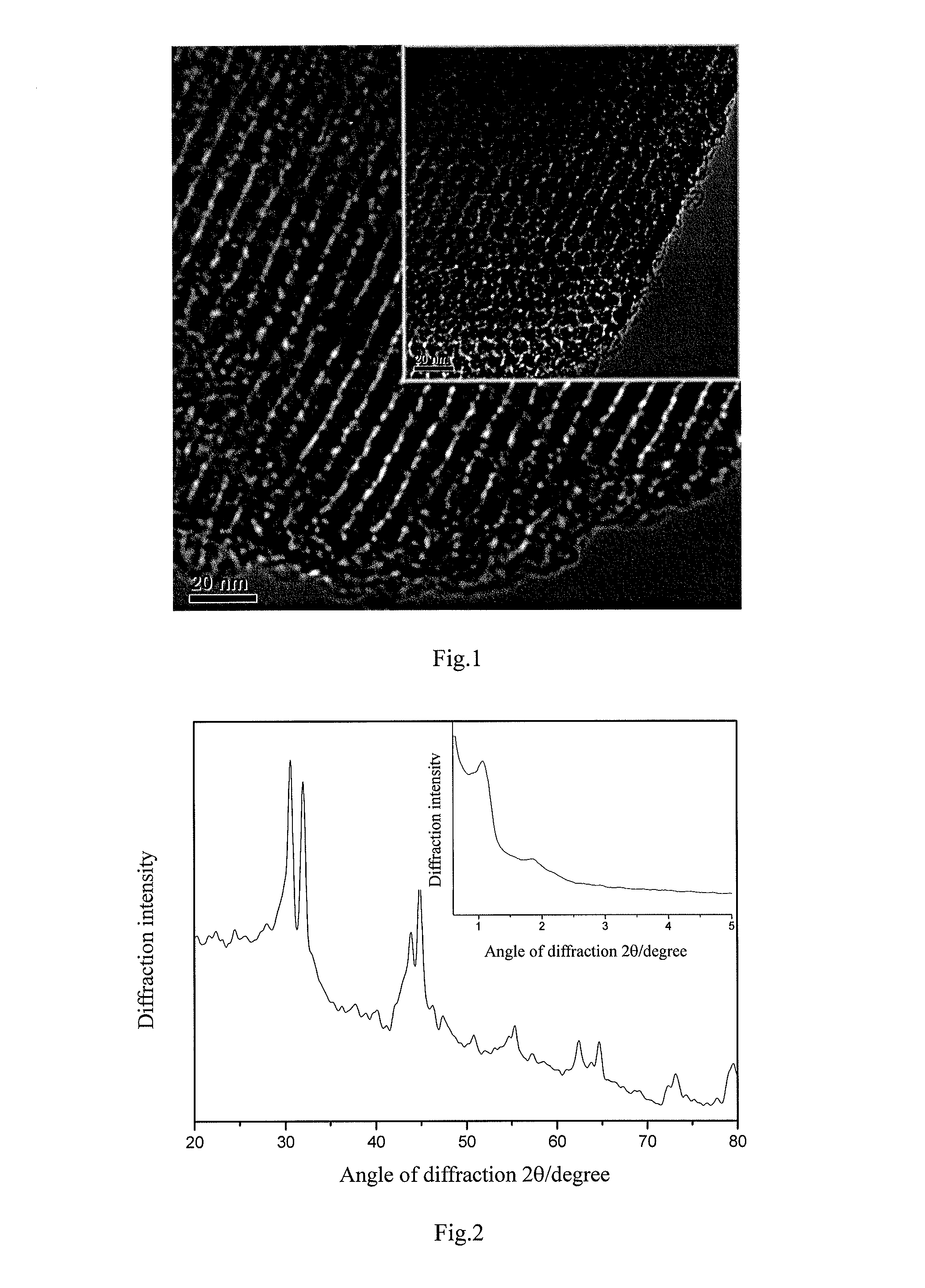

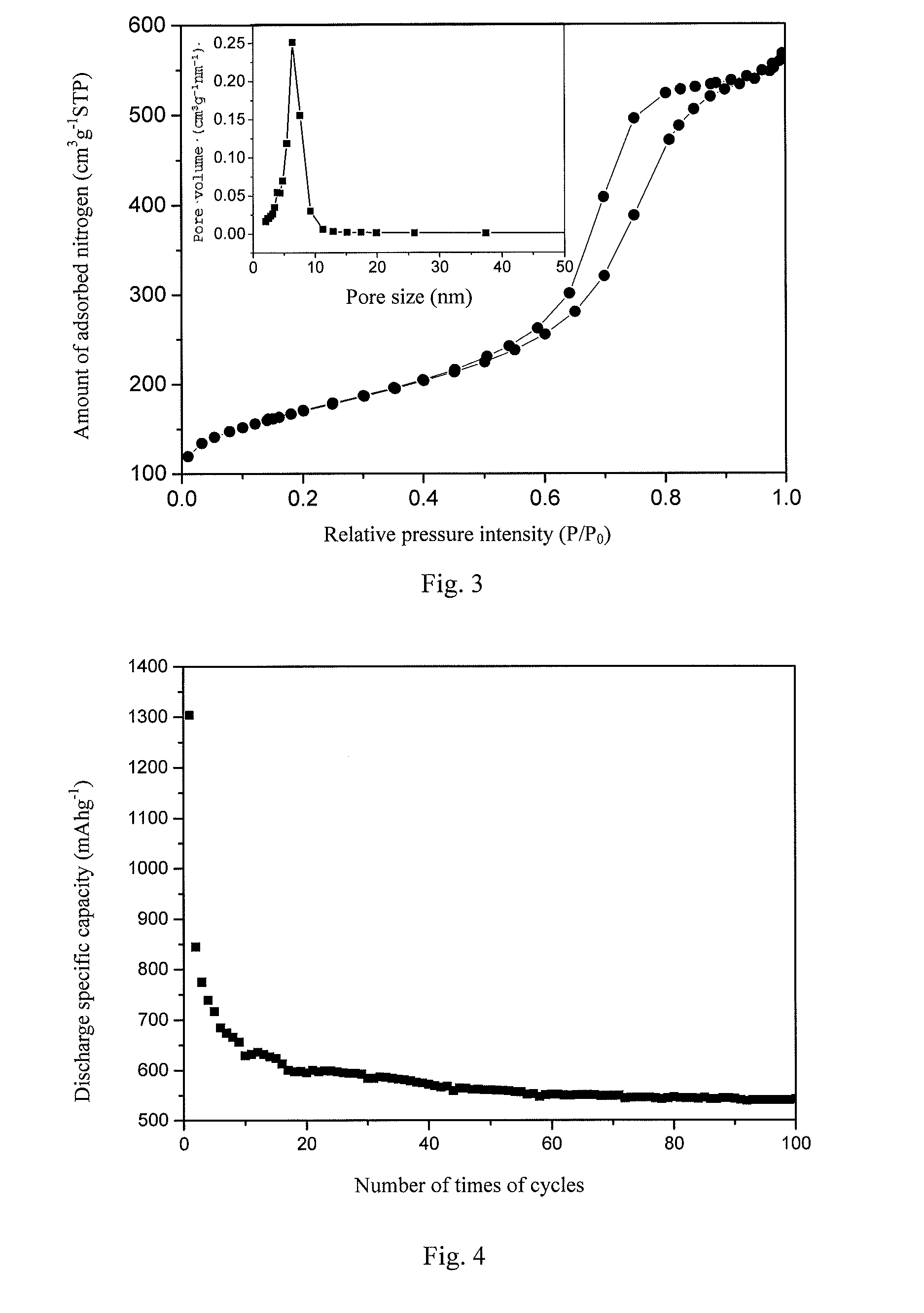

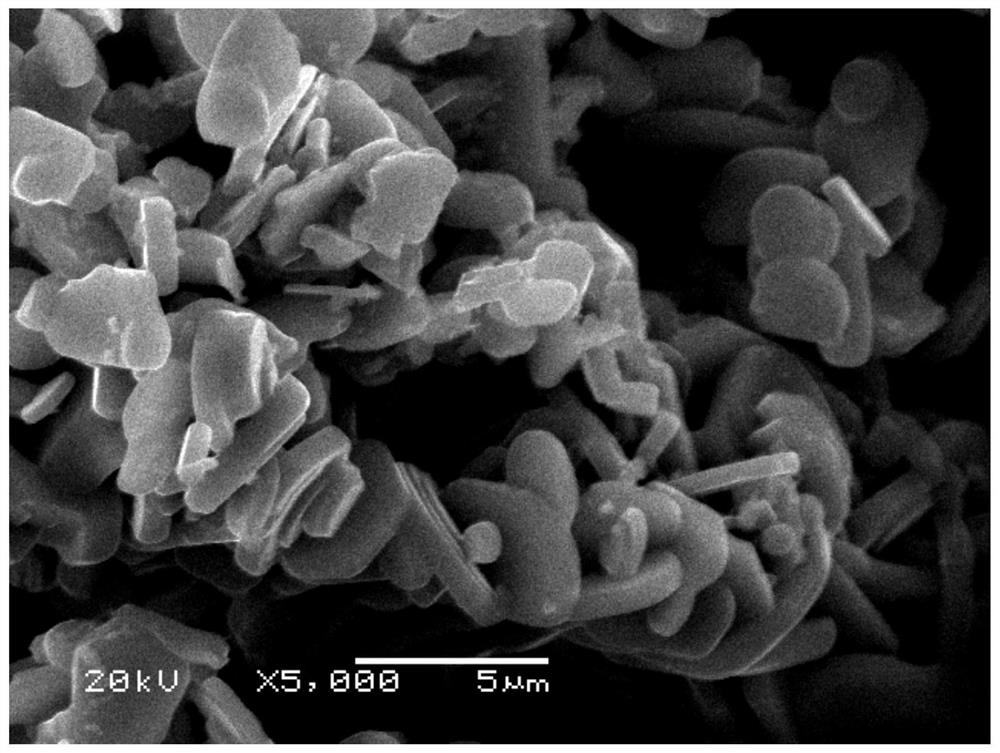

Tin carbon composite, method for preparing same, battery negative electrode component comprising same, and battery having the negative electrode component

InactiveUS20130344394A1Improve electrochemical performanceLarge specific surface areaElectrode manufacturing processesSecondary cellsCarbon compositesEtching

Disclosed is a tin-carbon mesoporous composite for a lithium ion battery negative electrode material, and a method for preparing the same. Using a mesoporous molecular sieve as a template, the precursors of tin and carbon are caused to fill the mesopores of the template and carbonized under nitrogen to obtain a composite of stannic oxide and carbon, and the stannic oxide is encapsulated by the carbon; and then the tin-carbon mesoporous composite for lithium ion battery negative electrode material is obtained by hydrothermal treatment, carbonization, etching, and high temperature carbothermic reduction. The tin-carbon mesoporous composite for lithium ion battery negative electrode material synthesized in the present invention has a reversible capacity of 550 mAh·g−1, after 100 cycles at a current density of 500 mA·g−1.

Owner:TOYOTA JIDOSHA KK +1

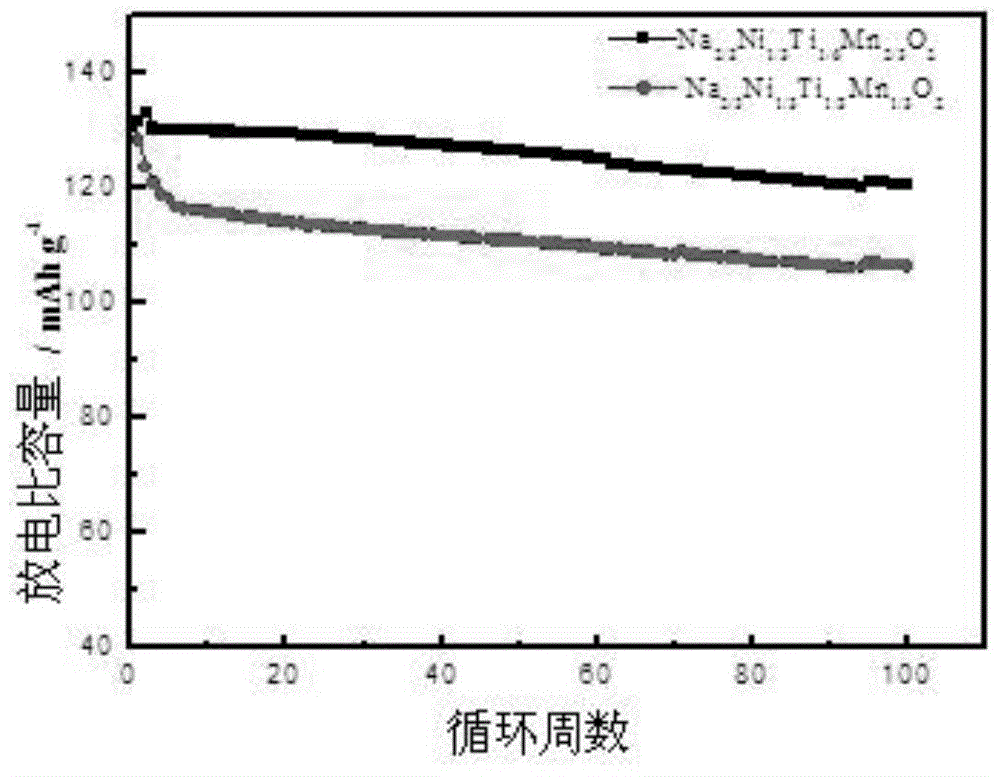

Sodium ion positive electrode material with ternary layered structure, and preparation method for sodium ion positive electrode material

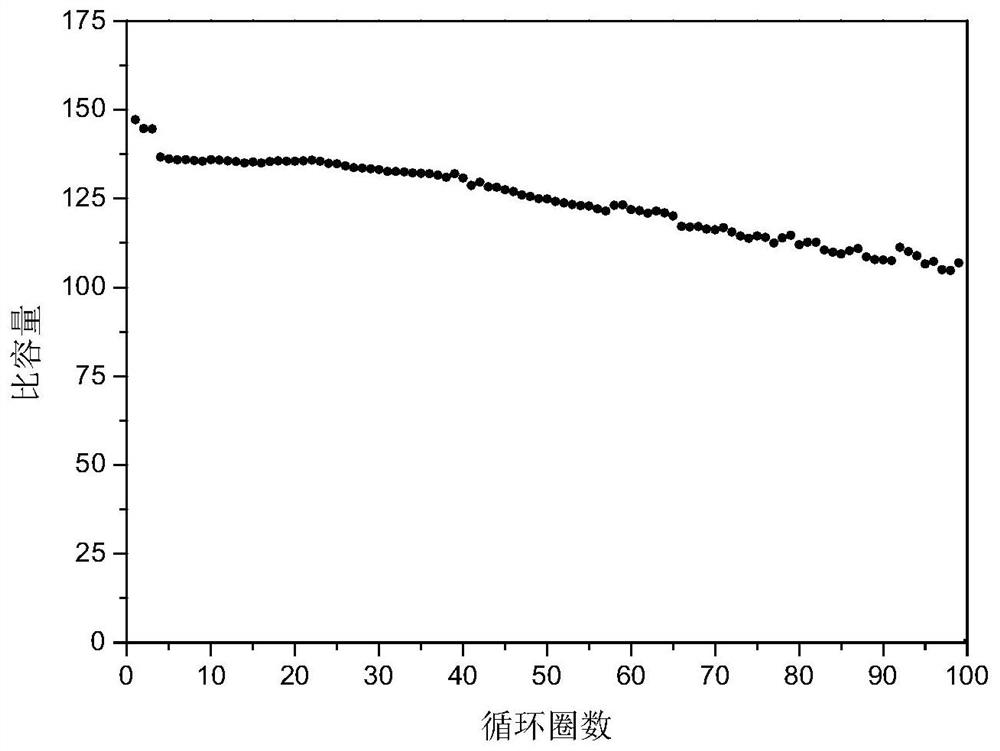

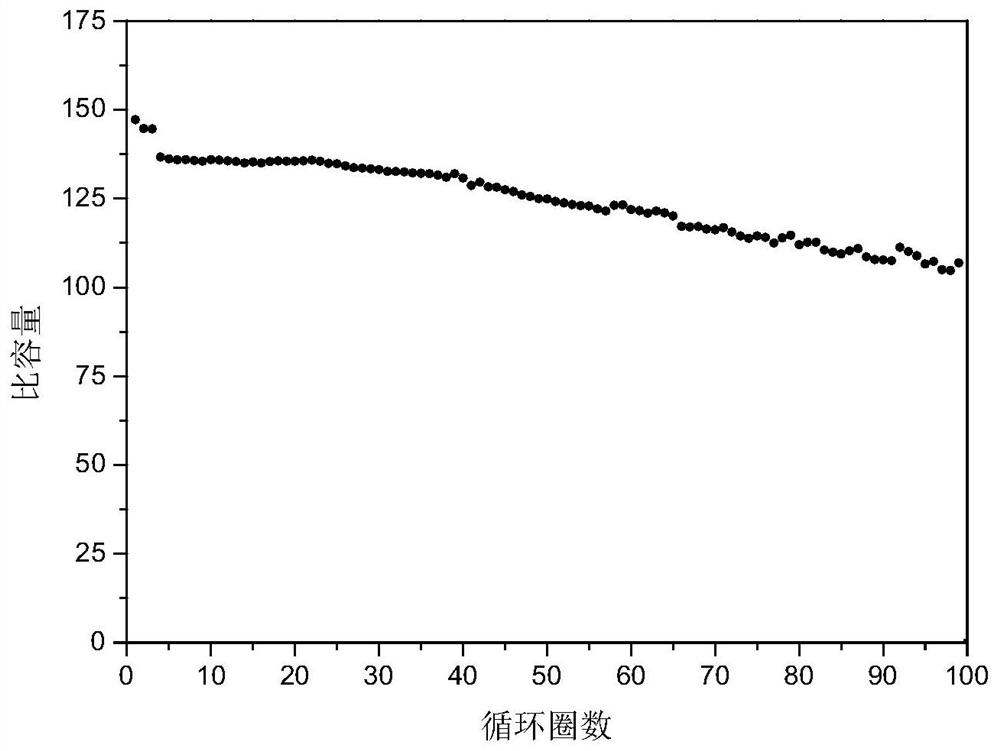

PendingCN105226268AImprove battery cycle performanceHigh specific capacityCell electrodesSecondary cellsPhysical chemistrySpecific discharge

The invention provides a sodium ion positive electrode material with a ternary layered structure, and a preparation method for the sodium ion positive electrode material. The sodium ion positive electrode material comprises Na2 / 3Ni1 / 3TixMn(2 / 3-x)O2, wherein the x is greater than 0 and less than 2 / 3. The sodium ion positive electrode material provided by the invention is provided with the ternary layered structure; when the sodium ion positive electrode material is charged or discharged at the 0.1 C, the specific discharge capacity is greater than 120mAhg-1; and the retention rate of the specific capacity reaches greater than 90% after the sodium ion positive electrode material is charged or discharged for 100 times.

Owner:HUNAN RESHINE NEW MATERIAL

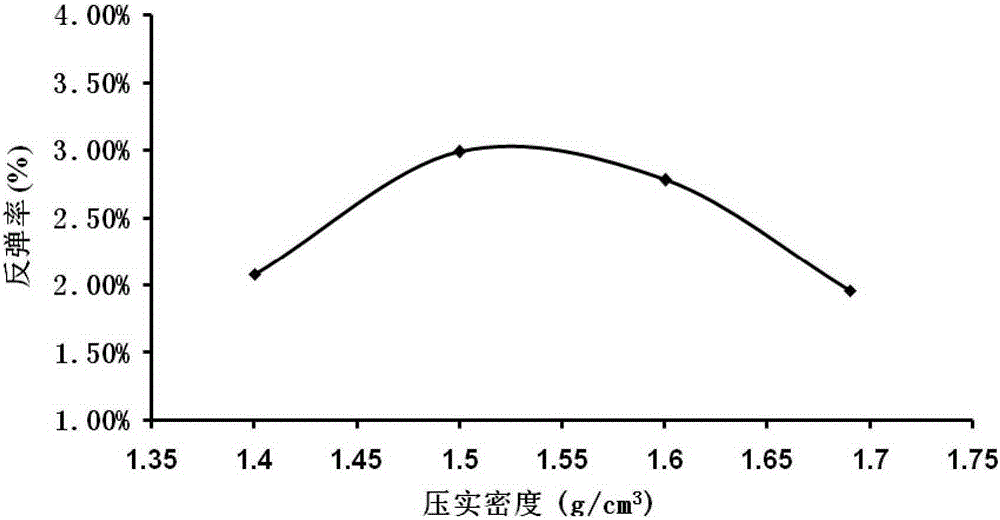

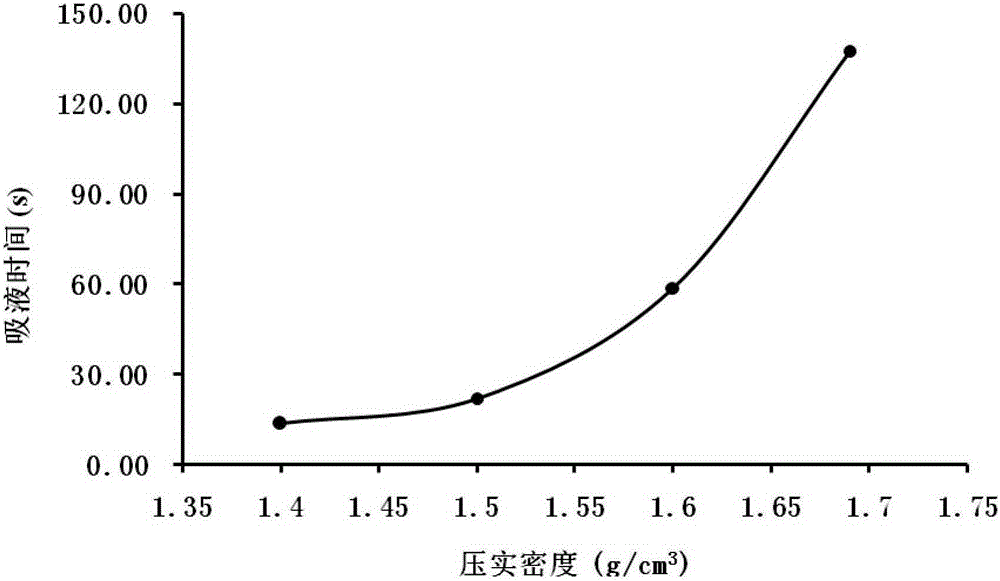

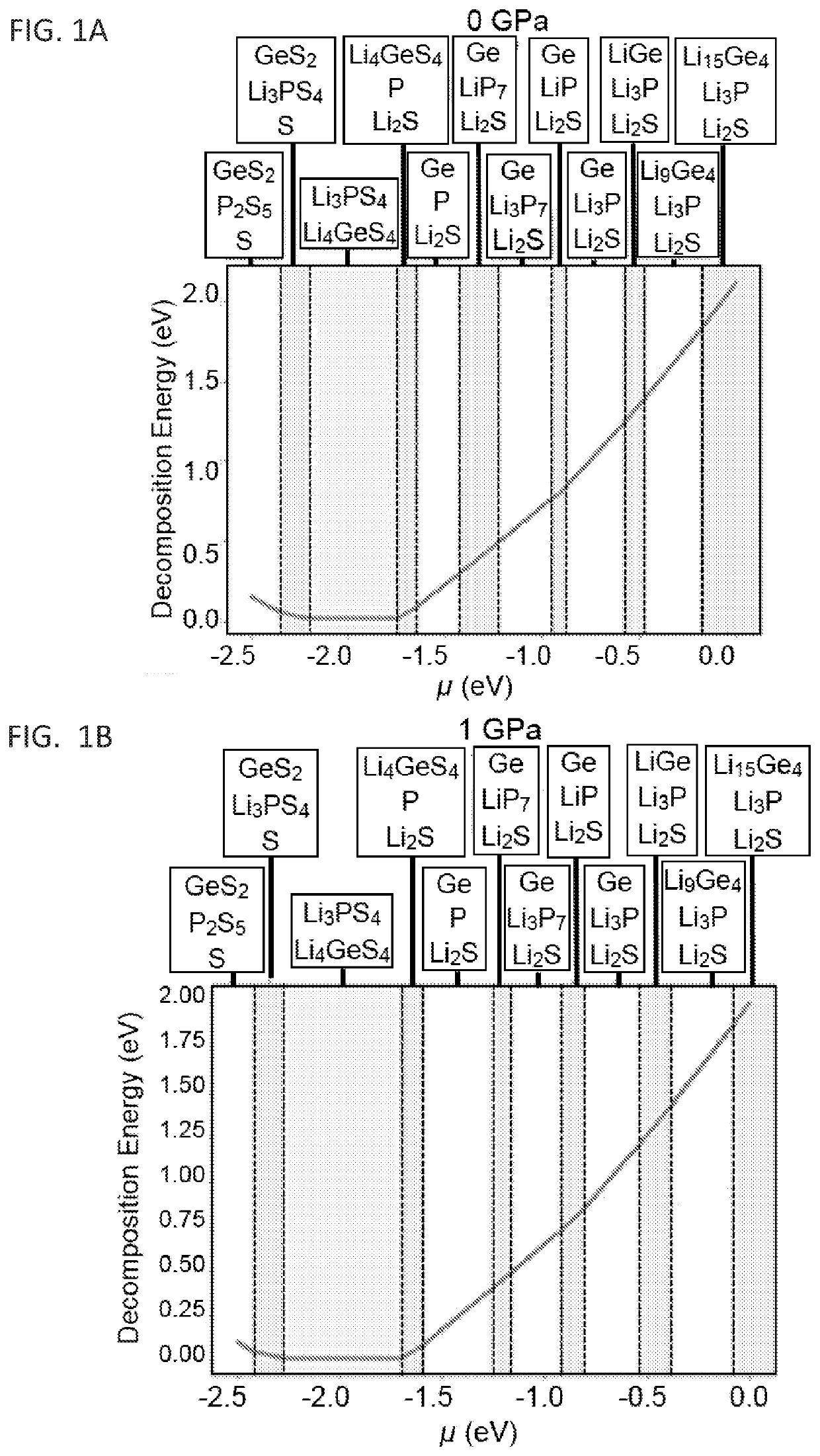

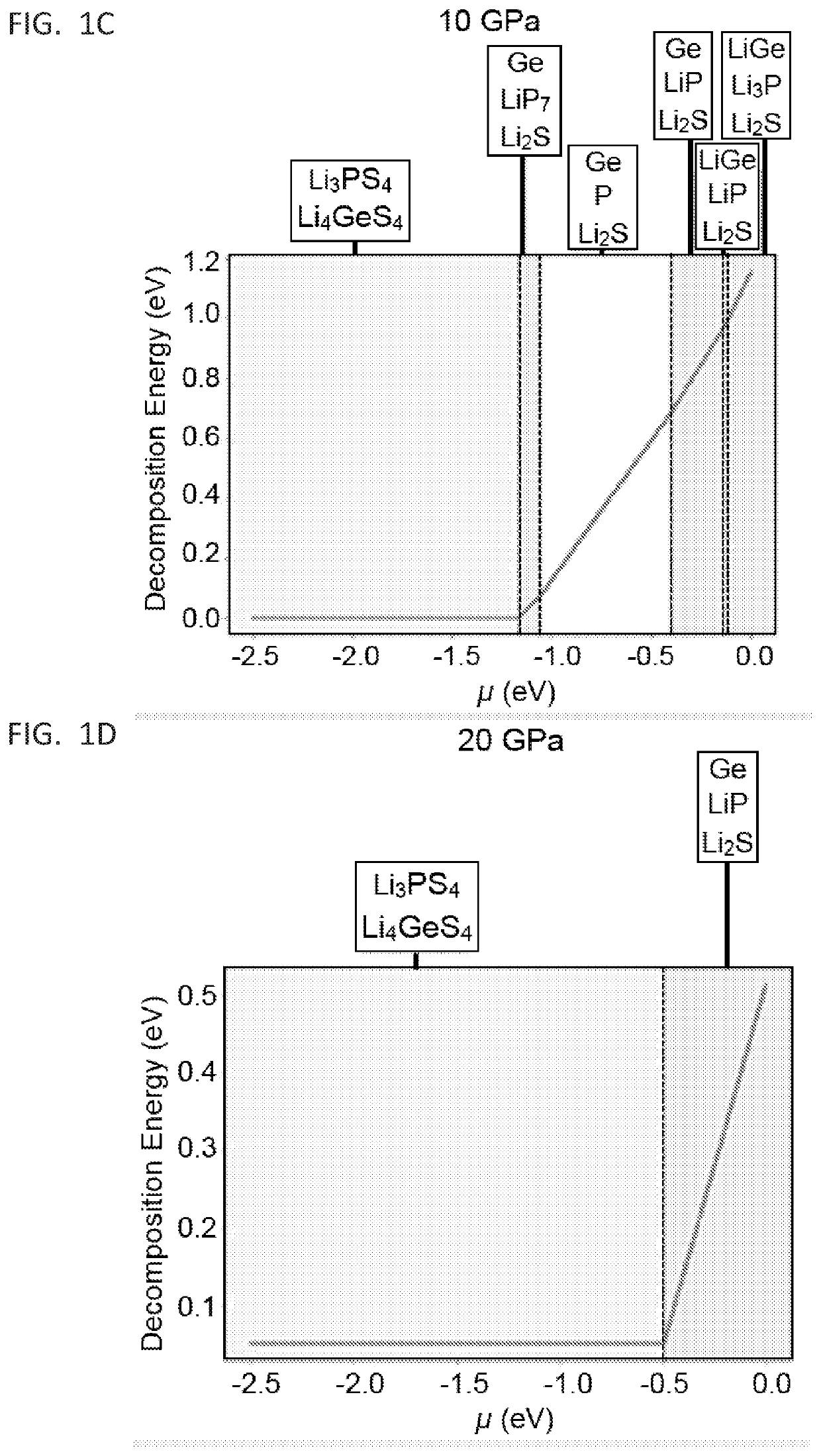

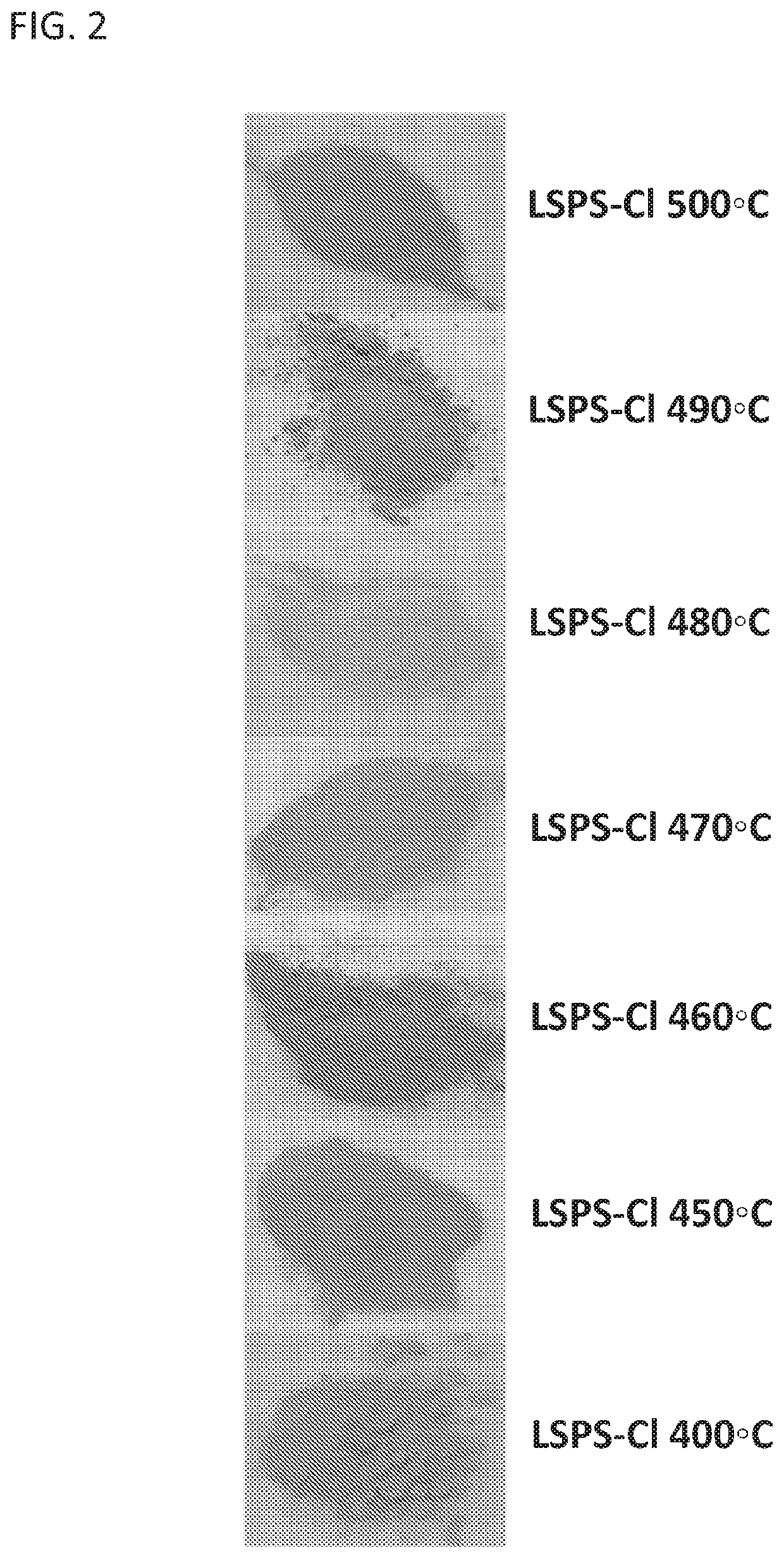

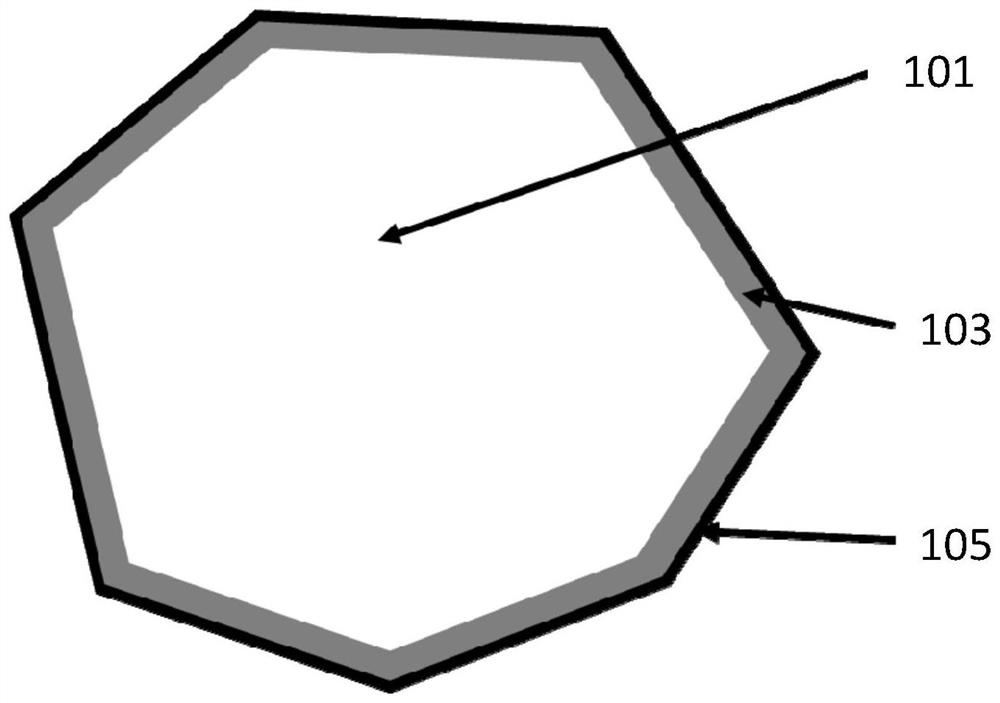

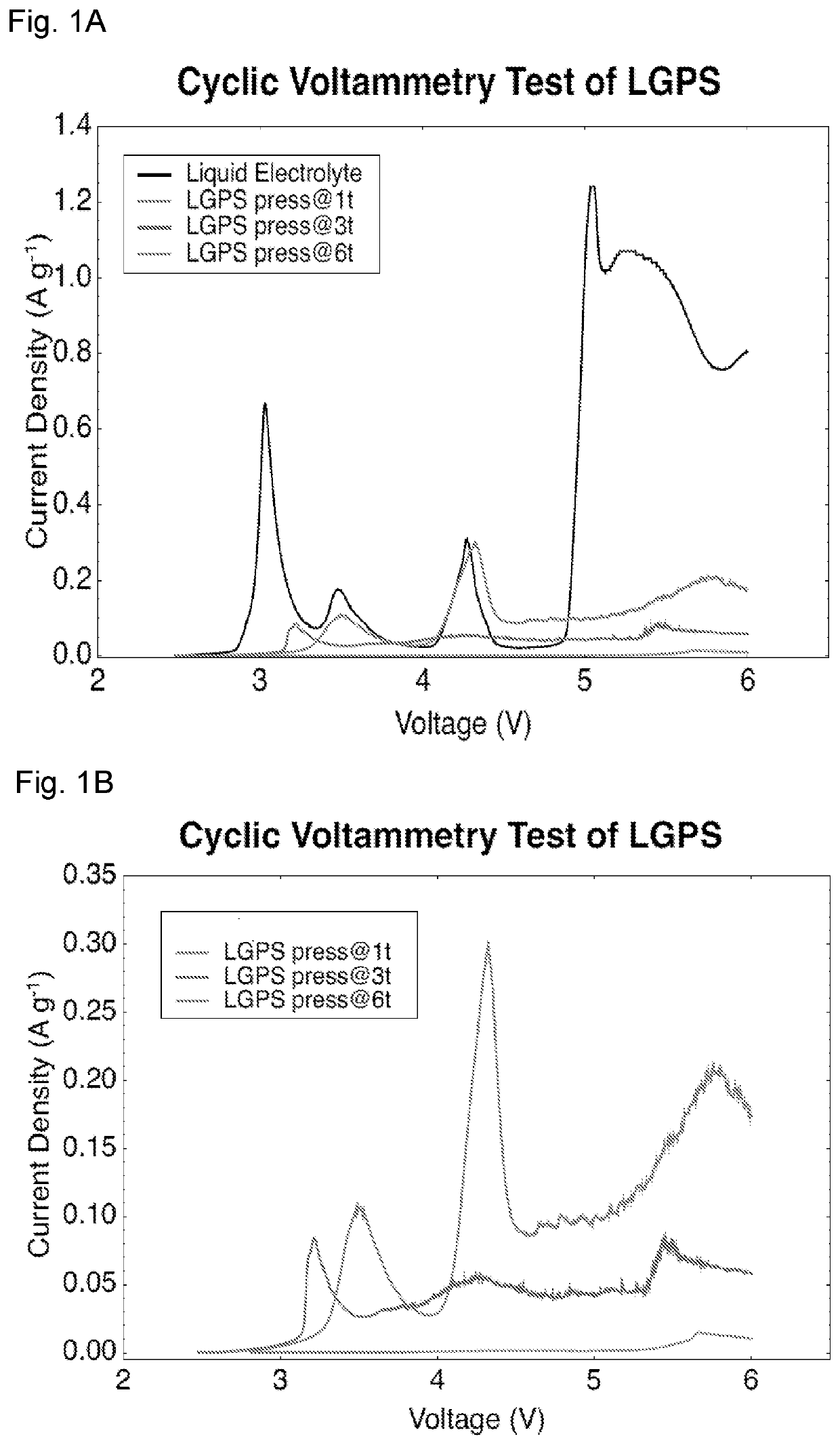

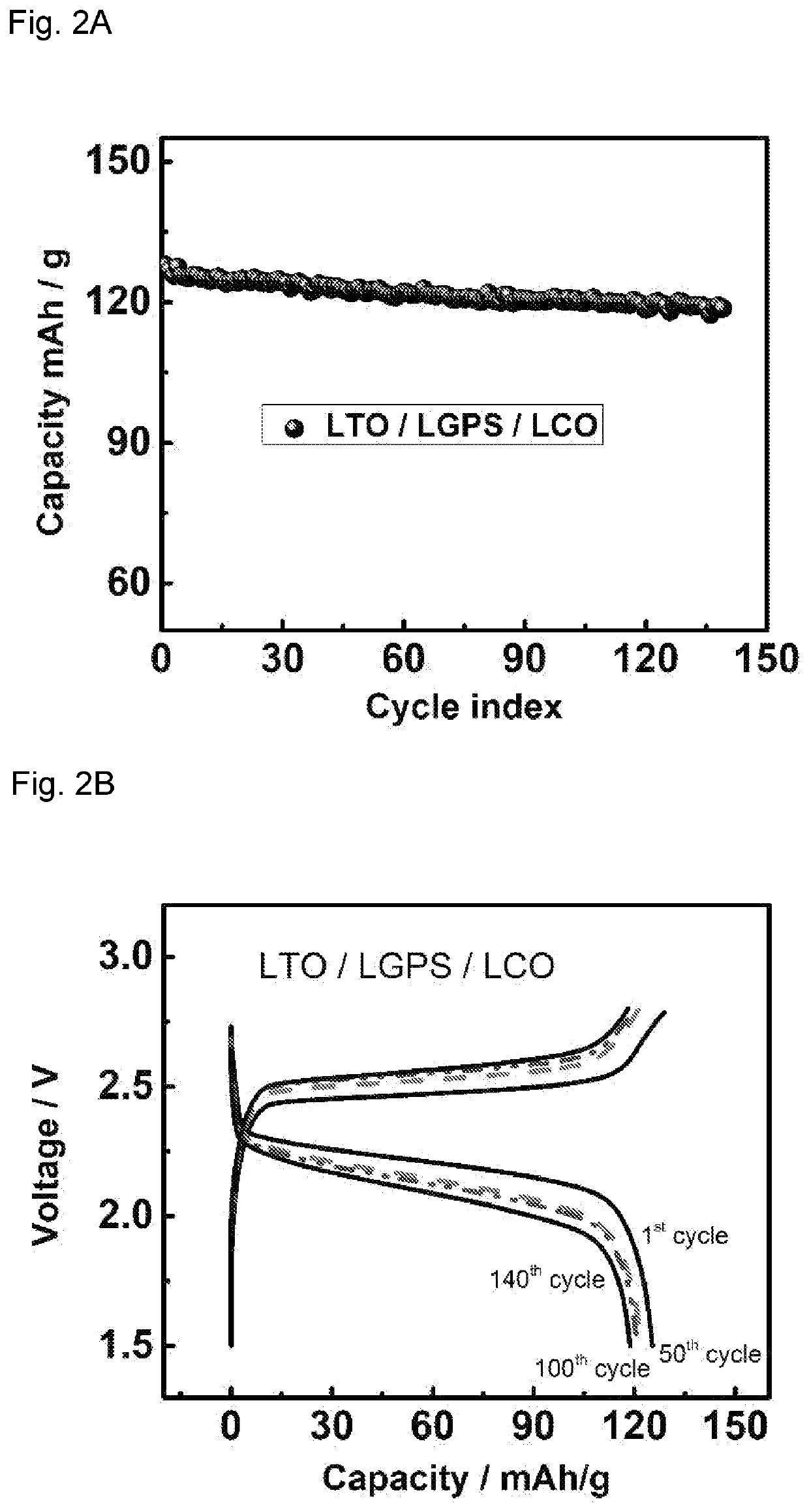

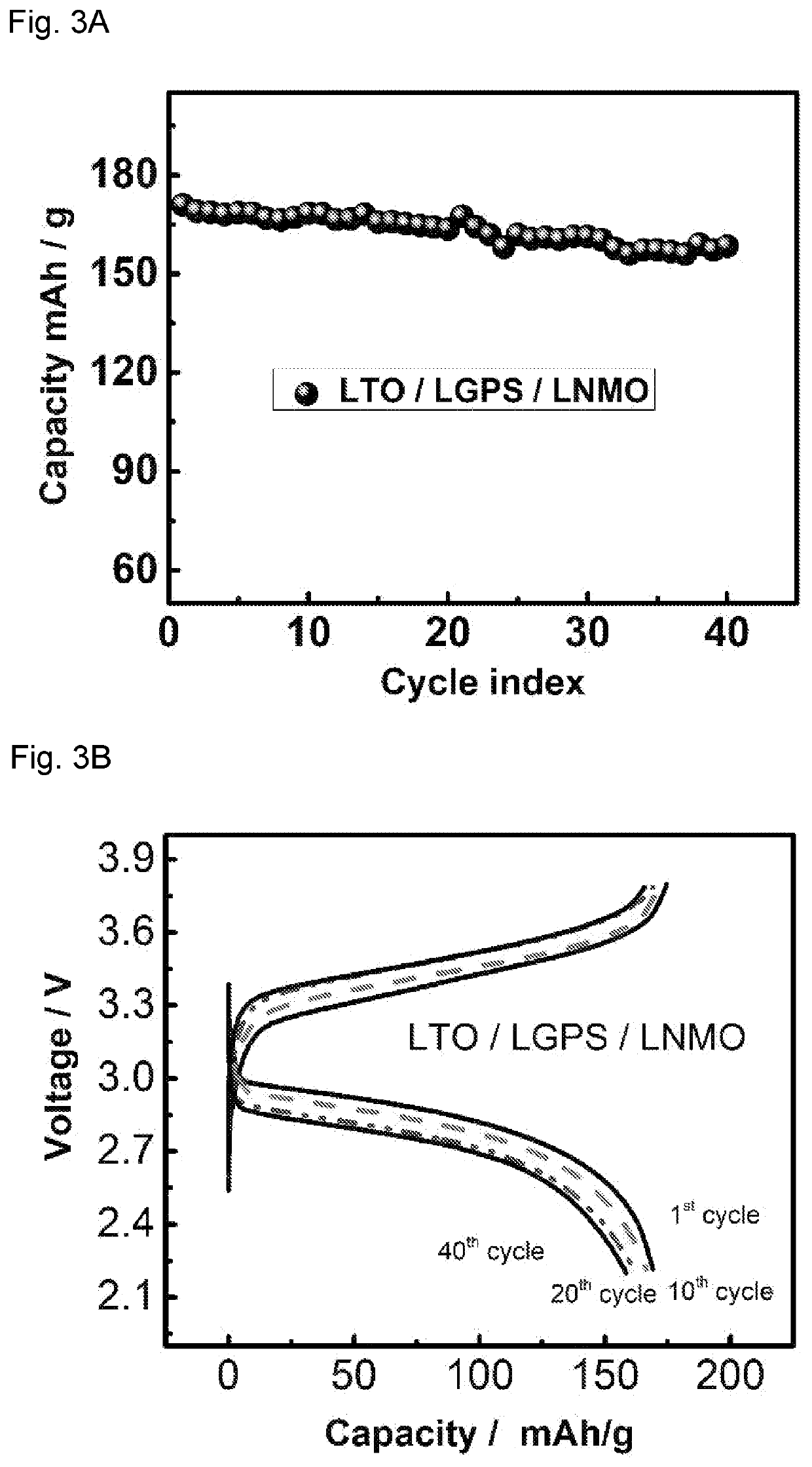

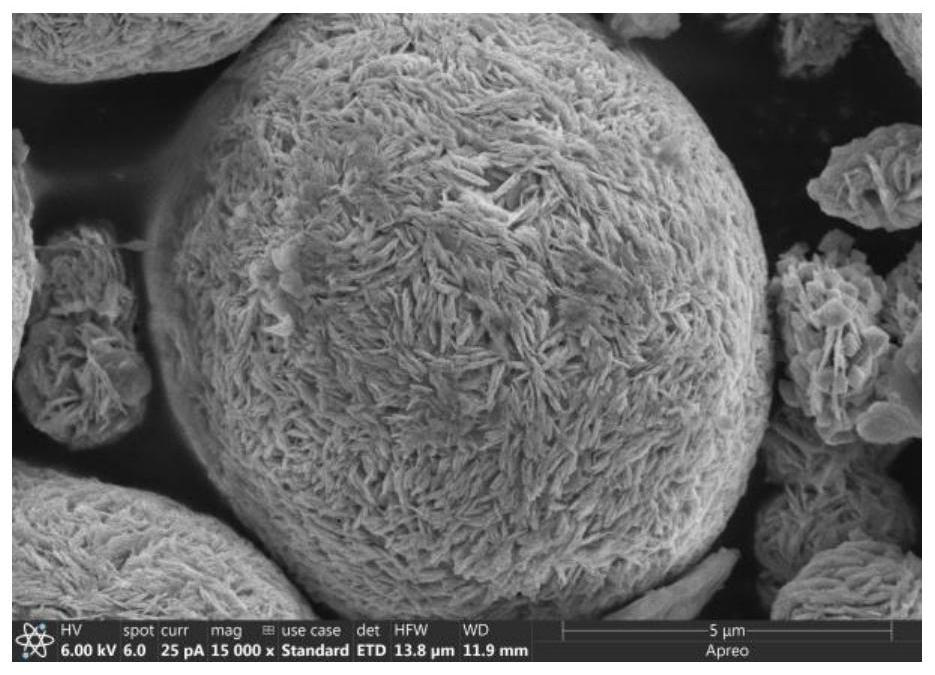

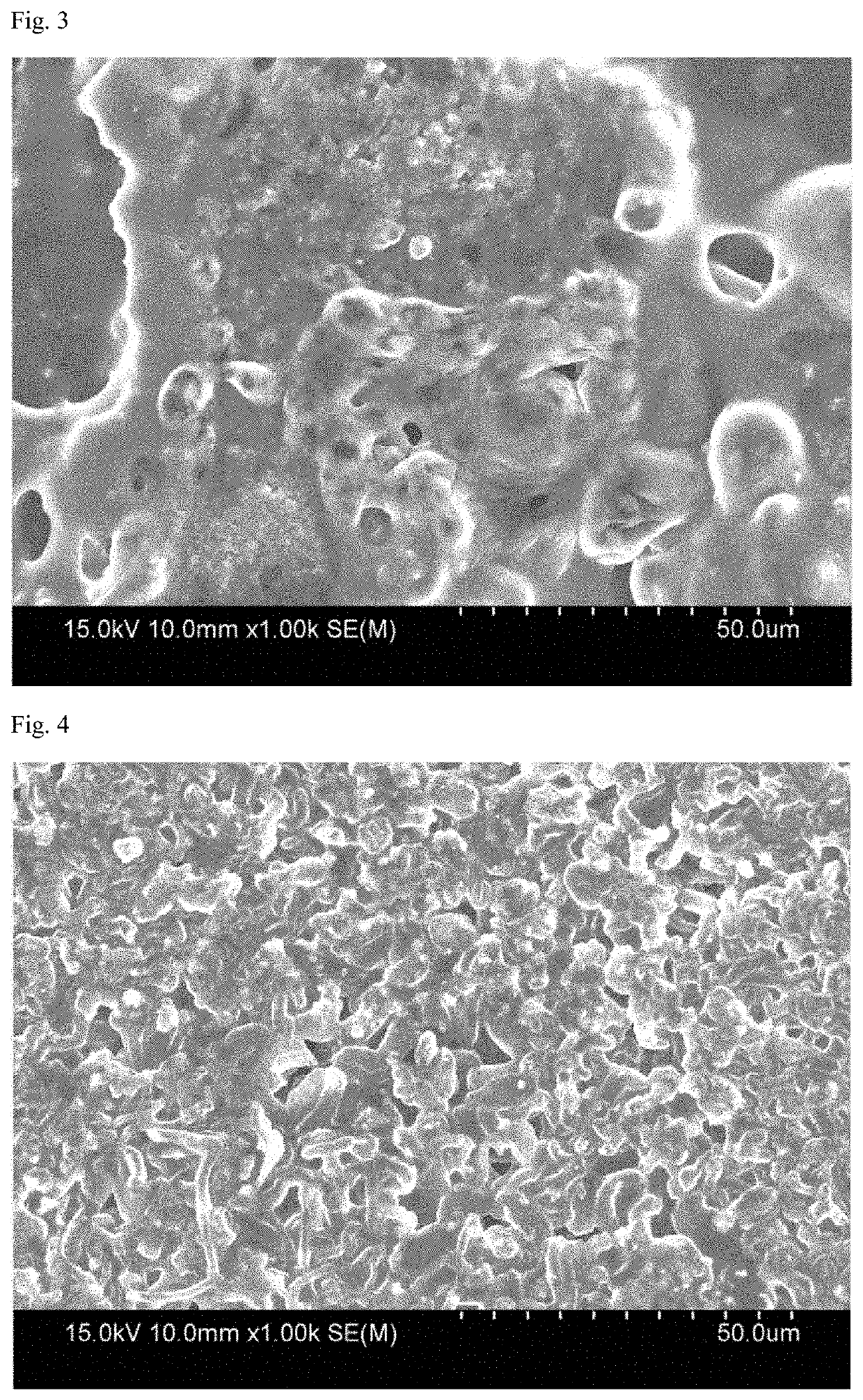

Solid state electrolytes and methods of production thereof

ActiveUS20200350618A1Improve voltage stabilityImprove battery cycle performanceSolid electrolytesCell electrodesSolid state electrolytePhysical chemistry

The invention provides compositions containing a solid state electrolyte (SSE) containing an alkali metal and a sulfide for use as the electrolyte matrix in a solid state rechargeable battery. The SSE compositions may further contain phosphorous, silicon, or a dopant atom, such as a halogen. These compositions are advantageous as they use Earth-abundant elements, have high voltage stability, excellent battery cycle performance, and are fabricated and used under conditions that do not require excessive external pressures which would otherwise limit their use in a production battery. In particular, the SSEs have a controllable microstructure, e.g., core-shell structure, that enhances their inherent stability while obviating the need for excessively large pressures to control the electrolyte stability. Methods of producing the compositions and rechargeable batteries including the composition are also provided.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

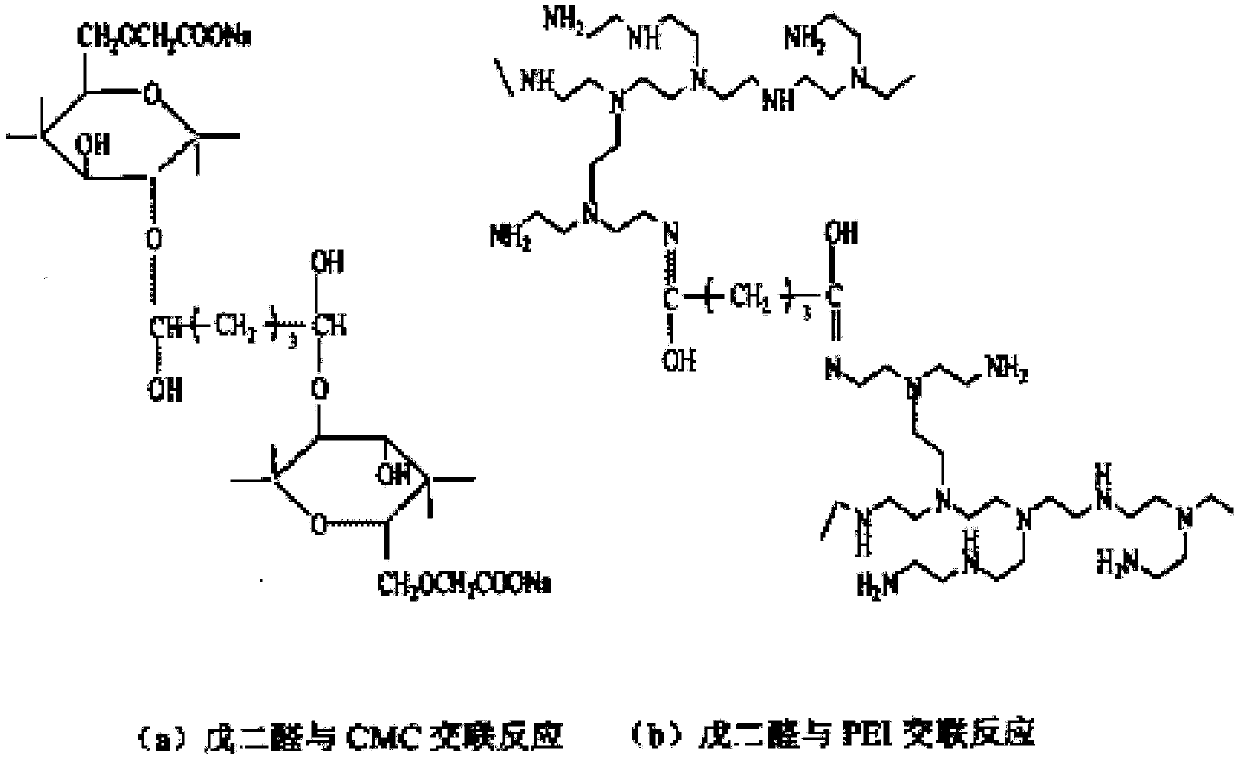

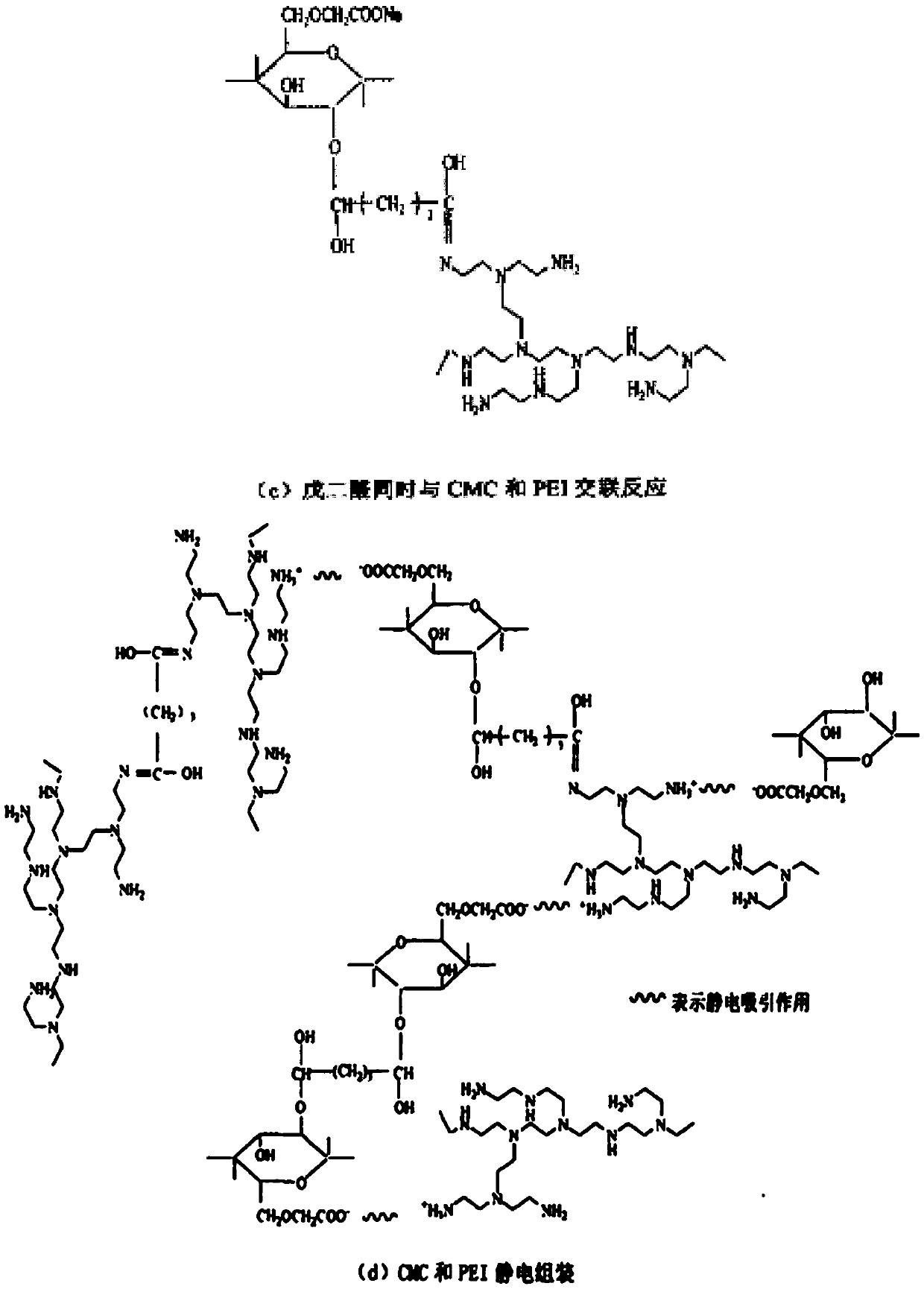

Lithium-sulfur battery binder, preparation method thereof, cathode slurry and preparation method thereof

ActiveCN109802137AImprove battery cycle performanceCell electrodesSecondary cellsCross-linkCarboxymethyl cellulose

The invention provides a lithium-sulfur battery binder, a preparation method thereof, cathode slurry and a preparation method thereof. The lithium-sulfur battery binder comprises three-dimensional network macromolecules, wherein the three-dimensional network macromolecules are obtained by the cross-linking reaction of carboxymethyl cellulose, polyethyleneimine and a cross-linking agent. The binderprovided by the invention can effectively improve the problems of high dissolubility and each shuttle of polysulfide, and thus can effectively improve the cycle performance of the battery when the sulfur-based active material is used as an active substance of a cathode material of the lithium-sulfur battery.

Owner:桑德新能源技术开发有限公司 +1

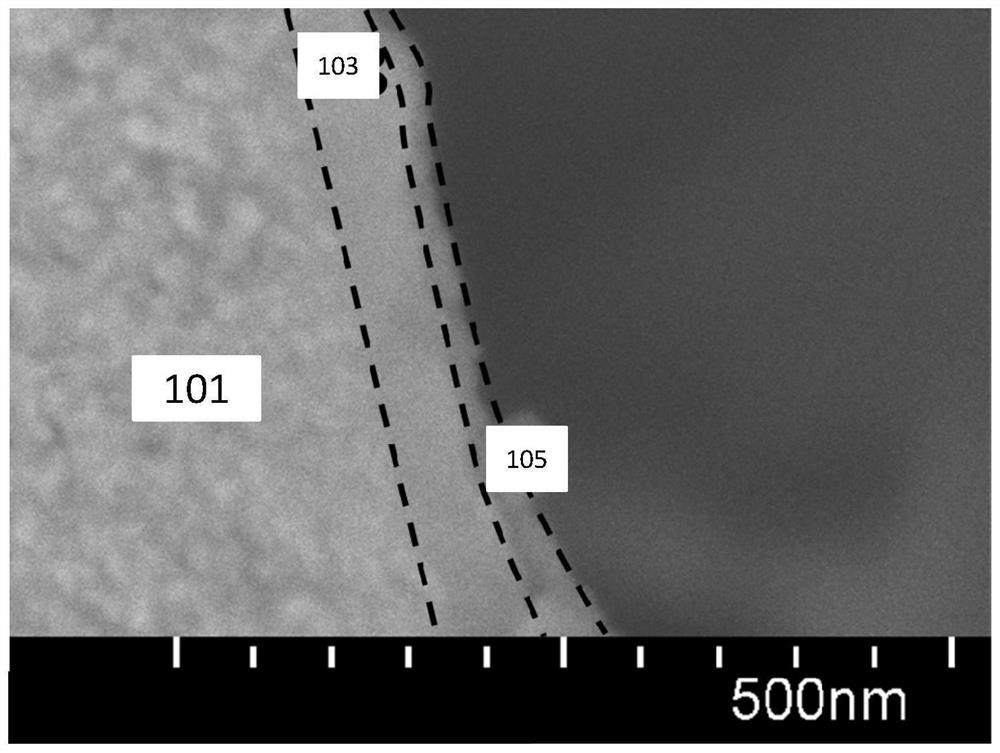

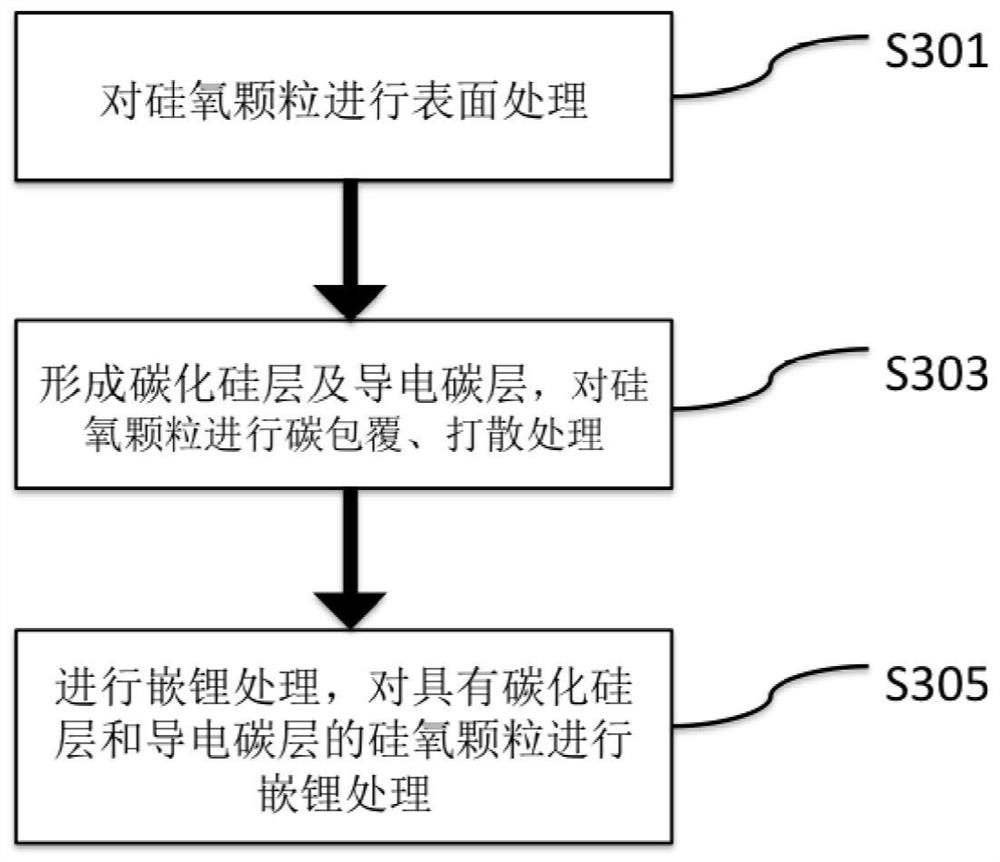

Lithium silicon oxide particle, preparation method thereof, negative electrode material, pole piece and battery

ActiveCN112687852AReduce sheddingReduce polarizationMaterial nanotechnologyCell electrodesCarbon layerCarbide silicon

The present invention provides a lithium silicon oxide particle having a core-shell structure. The lithium silicon oxide particle comprises: an inner core particle comprising a lithium silicate compound matrix and an elemental silicon nanoparticle, wherein the molar ratio of lithium element / silicon element in the inner core particle is X, the molar ratio of oxygen element / silicon element is Y, 0.1 < = X < 2, and 0.5 < = Y < = 1.5; a silicon carbide shell layer which coats the inner core particle; and a conductive carbon layer, wherein the silicon carbide shell layer is coated with the conductive carbon layer. The lithium silicon oxide particle has the characteristics of good water resistance, low expansion rate, long cycle life, high coulombic efficiency and the like.

Owner:BERZELIUS (NANJING) CO LTD +1

Solid state batteries

PendingUS20210408580A1Improve voltage stabilityImprove battery cycle performanceSolid electrolytesCell electrodesSolid state electrolyteAll solid state

The invention provides rechargeable batteries including a solid state electrolyte (SSE) containing an alkali metal disposed between two electrodes. The batteries are volumetrically constrained imparting increased stability under voltage cycling conditions, e.g., through microstructure mechanical constriction on the solid state electrolyte and the electrolyte-electrode interface. These batteries of the invention are advantageous as they may be all-solid-state batteries, e.g., no liquid electrolytes are necessary, and can achieve higher voltages with minimal electrolyte degradation.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

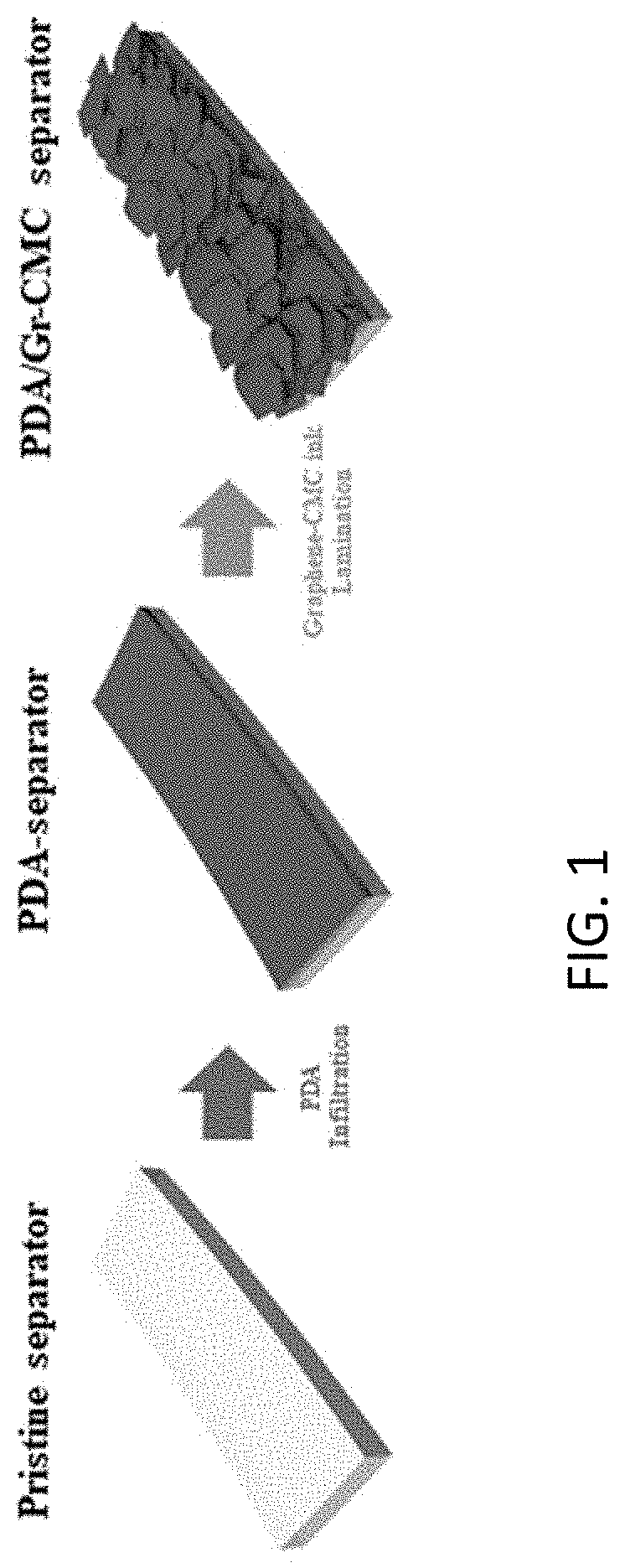

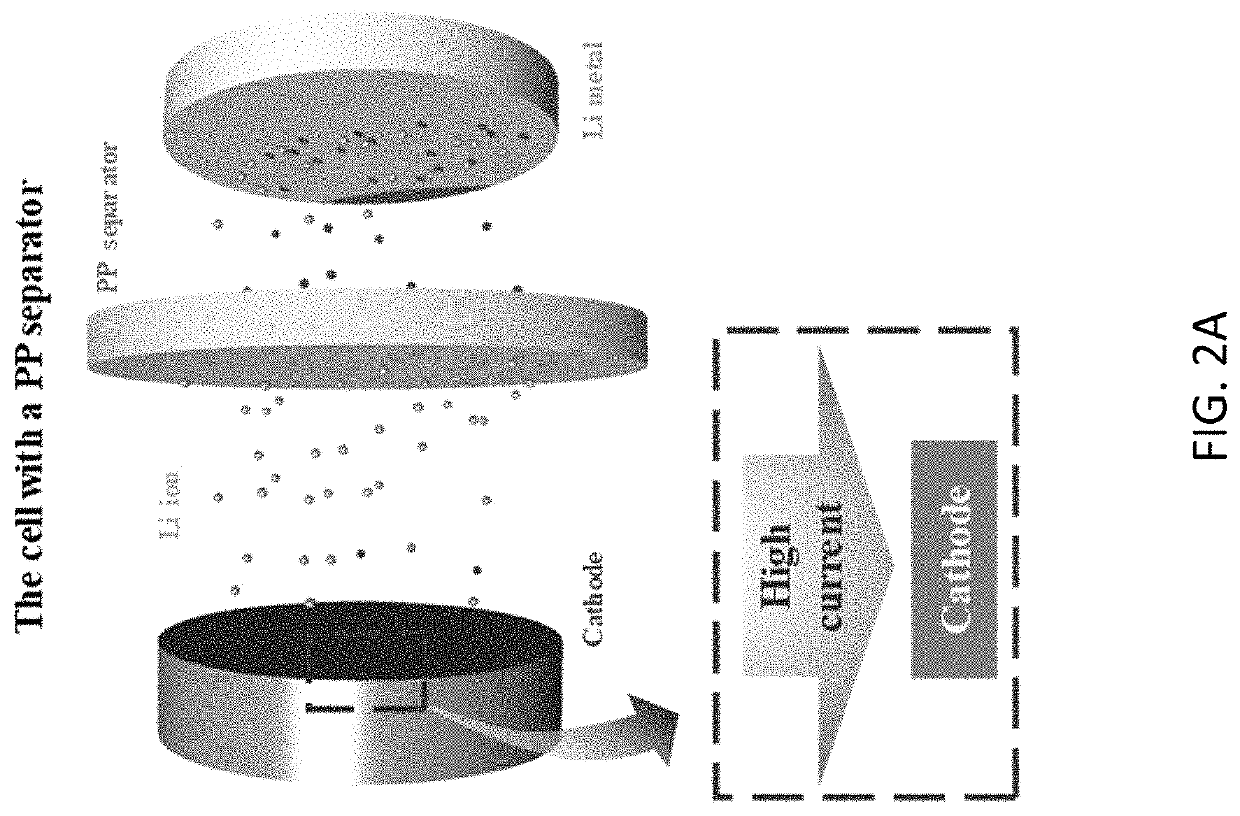

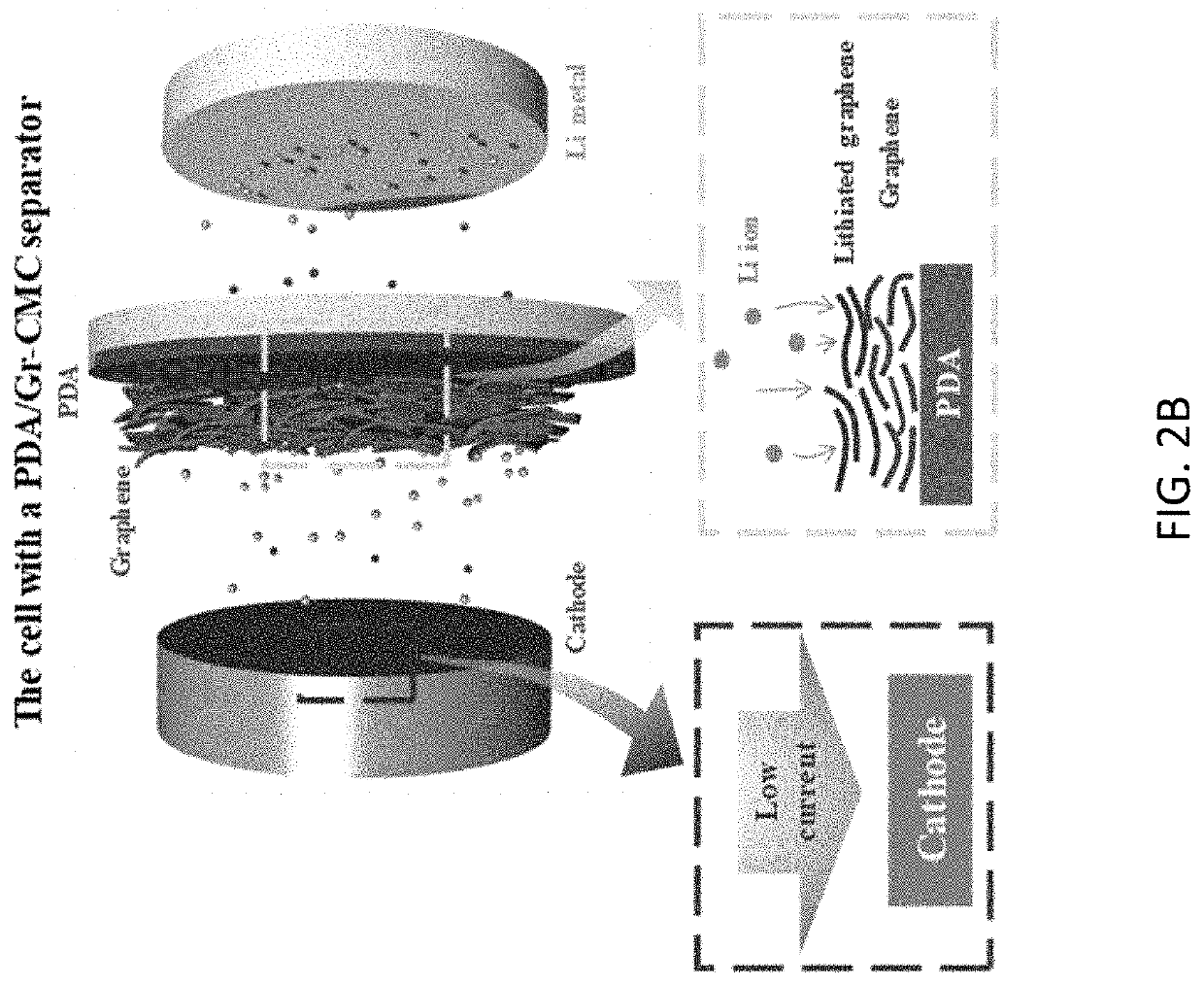

Separators for electrochemical cells and methods of making the same

ActiveUS20200295333A1Improve battery cycle performanceImprove cycle performance stabilityCell electrodesLi-accumulatorsElectrical batteryLithium metal

Separators, materials, and processes for producing electrochemical cells, for example, lithium (Li) metal batteries, and electrochemical cells produced therefrom. Such a separator includes a permeable membrane formed of a first polymer that is hydrophobic and has oppositely-disposed first and second surfaces, a second polymer that is hydrophilic and is incorporated into the first surface of the first polymer so that the first surface of the first polymer is a hydrophilic surface, and a conductive composite layer on the hydrophilic surface. The composite layer contains at least one layer of a carbonaceous material and an aqueous binder that binds the carbonaceous material together and to the hydrophilic.

Owner:PURDUE RES FOUND INC

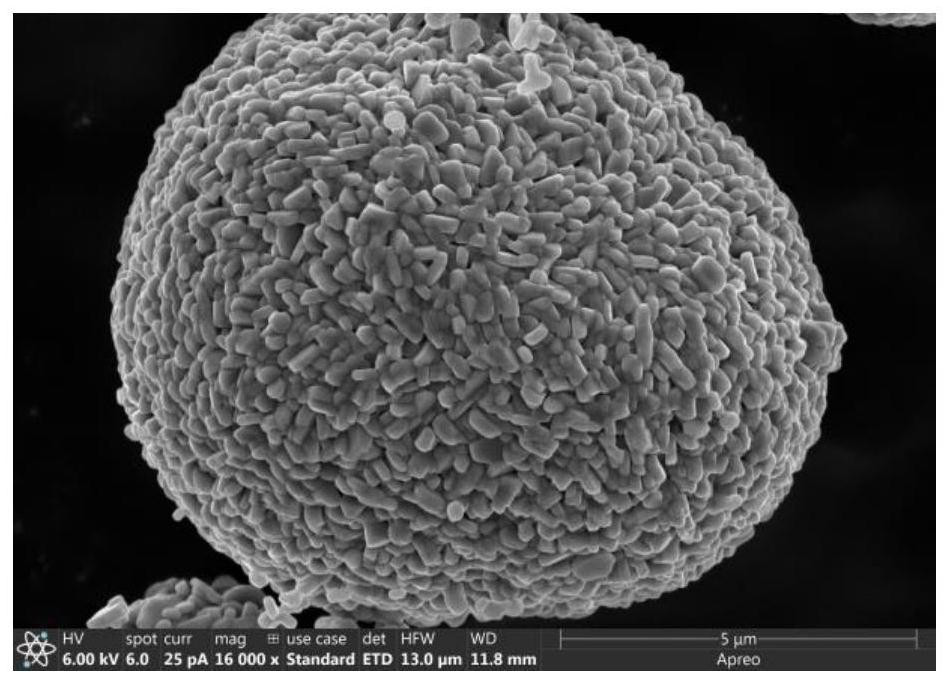

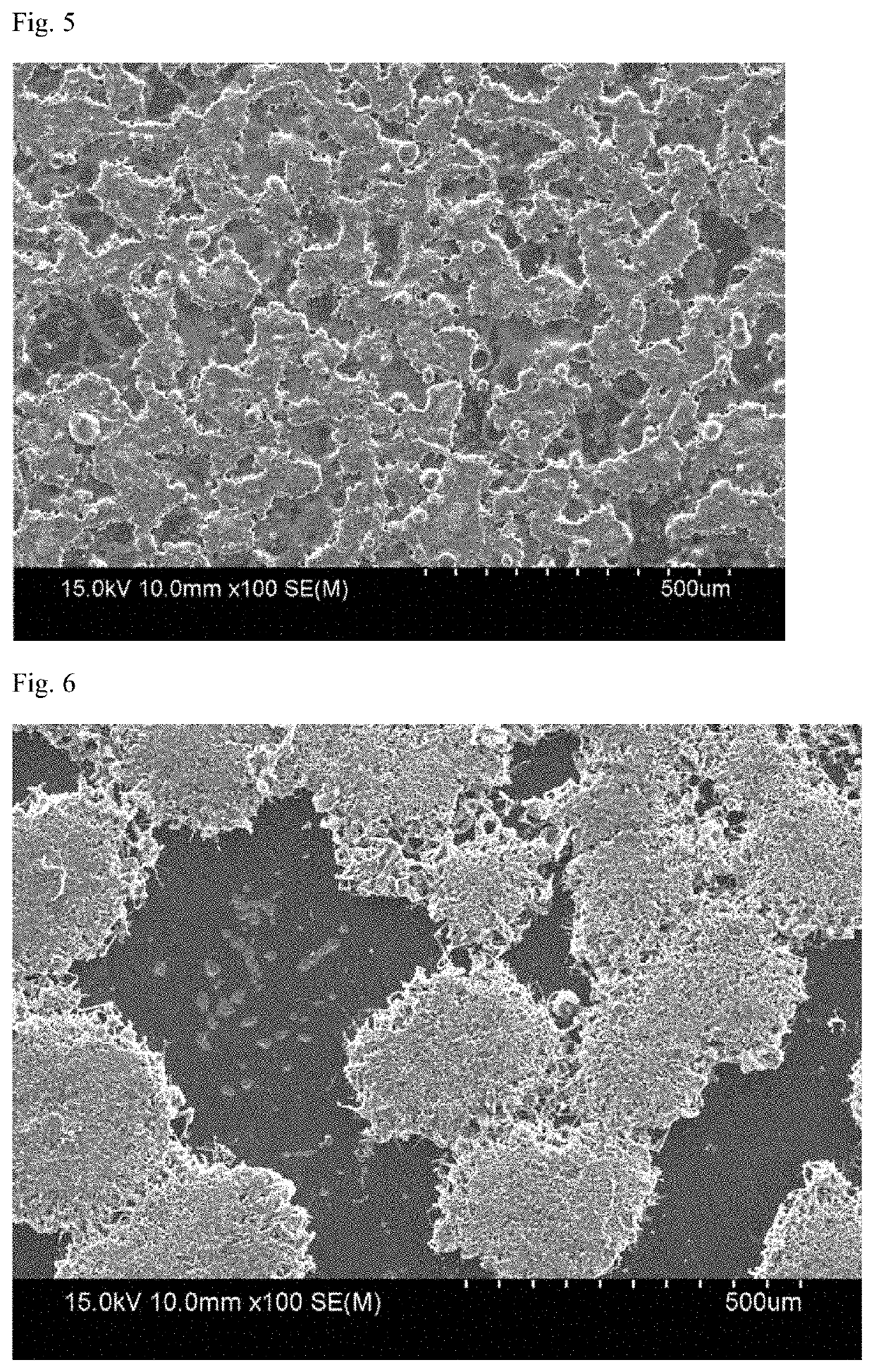

Sodium-ion battery nickel-based precursor capable of being used for filling conductive material and positive electrode material

PendingCN113871582AEasy to prepareEasy to industrializeCell electrodesElectrically conductiveCharge and discharge

The invention discloses a sodium-ion battery nickel-based precursor capable of being used for filling a conductive material and a positive electrode material. The chemical formula of the precursor is NixMyMoz (OH) 2, wherein x is greater than or equal to 0.6 and less than 1, y is greater than 0 and less than or equal to 0.2, z is greater than 0 and less than or equal to 0.2, x + y + z = 1, and M is Cr or Nb. The chemical formula of the positive electrode material is NamNixMyMozO2, wherein m is greater than or equal to 0.67 and less than or equal to 1, and the conductive material is a conductive polymer material. According to the invention, the loose and porous precursor of the sodium-ion battery is prepared by adopting an industrially mature precursor preparation process, then the loose and porous positive electrode material is synthesized by adopting a high-temperature solid-phase method, and finally, the conductive material is filled into internal gaps of the positive electrode material, so that the conductivity of the conductive material is fully exerted, mechanical stress accumulation of the positive electrode material in the charging and discharging process is buffered, and the effect of protecting the structure of the positive electrode material is achieved. The traditional manganese element is not used, the influence of structural collapse and capacity fading caused by the Jahn-Taller effect of the manganese element is reduced, meanwhile, the nickel content is increased, the nickel and Mo, Cr or Nb are coordinated, and the structural stability and electrochemical performance of the positive electrode material are further improved.

Owner:CENT SOUTH UNIV

A kind of method of conductive polymer coating nickel cobalt lithium manganese oxide cathode material

ActiveCN104466135BHigh specific capacityImprove cycle lifeCell electrodesSecondary cellsConductive polymerDissolution

The invention discloses a method for coating a conductive polymer on a Ni-Co-Mn acid lithium positive electrode material, and relates to the technical field of electrode materials of lithium ion batteries and preparation. The method comprises the following steps: (1) preparing LiNi1 / 3Co1 / 3Mn1 / 3 precursor mixed liquid by means of mechanical activation; (2) adding aqueous solution or organic solution of the conductive polymer into the LiNi1 / 3Co1 / 3Mn1 / 3 precursor mixed liquid; (3) performing spray drying on the mixture prepared in the step (2) to obtain precursor powder which is uniformly mixed; and (4) calcining the precursor powder which is subjected to jolt ramming or compaction, and cooling to a room temperature to obtain a conductive polymer coated Ni-Co-Mn acid lithium positive electrode material. According to the method, the conductive polymer is coated on the surface of the Ni-Co-Mn acid lithium positive electrode material, the dissolution of transition metals in the positive electrode material in electrolytes during charging / discharging circulation is inhibited, and the battery cycle performance and capacity retention ratio of the positive electrode material are improved.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

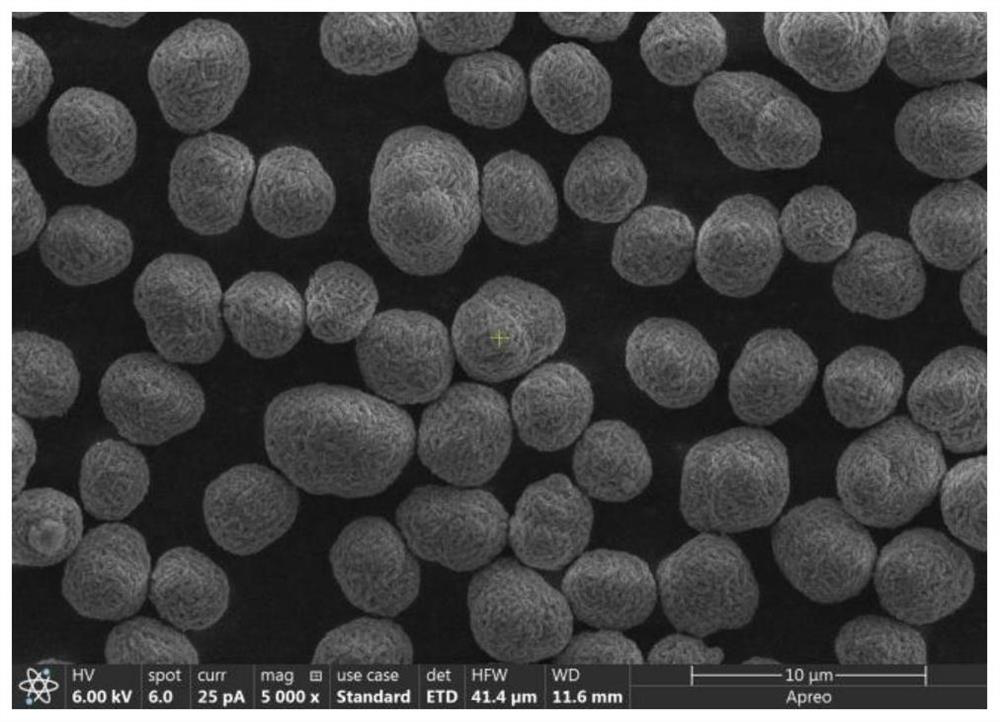

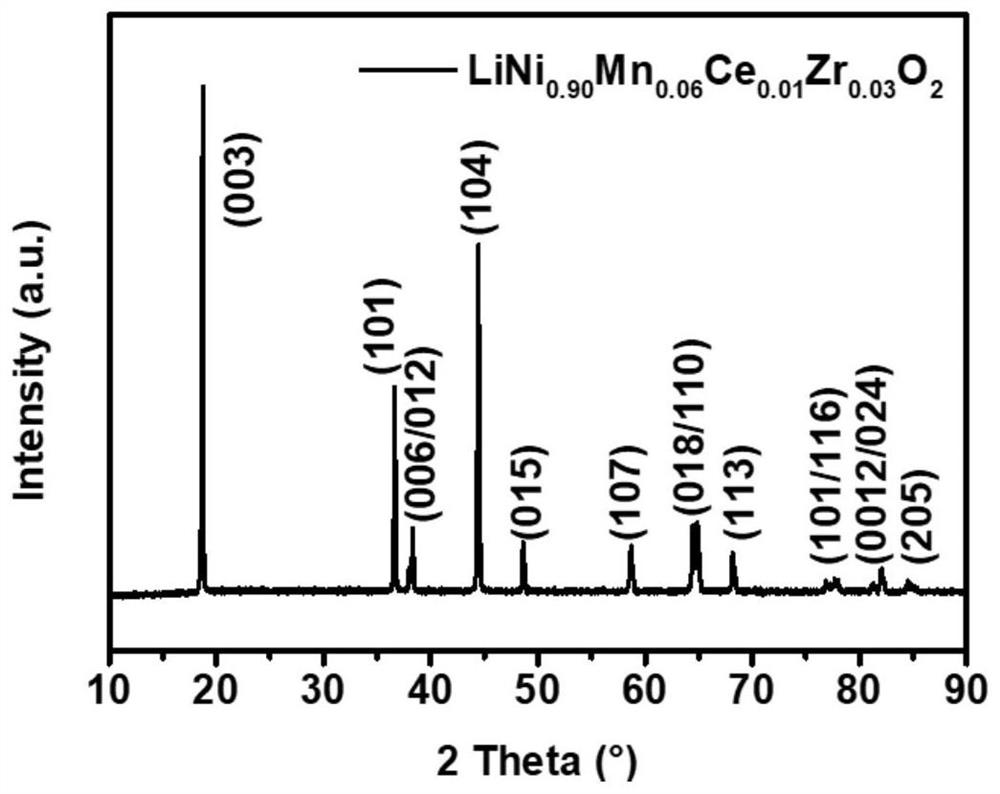

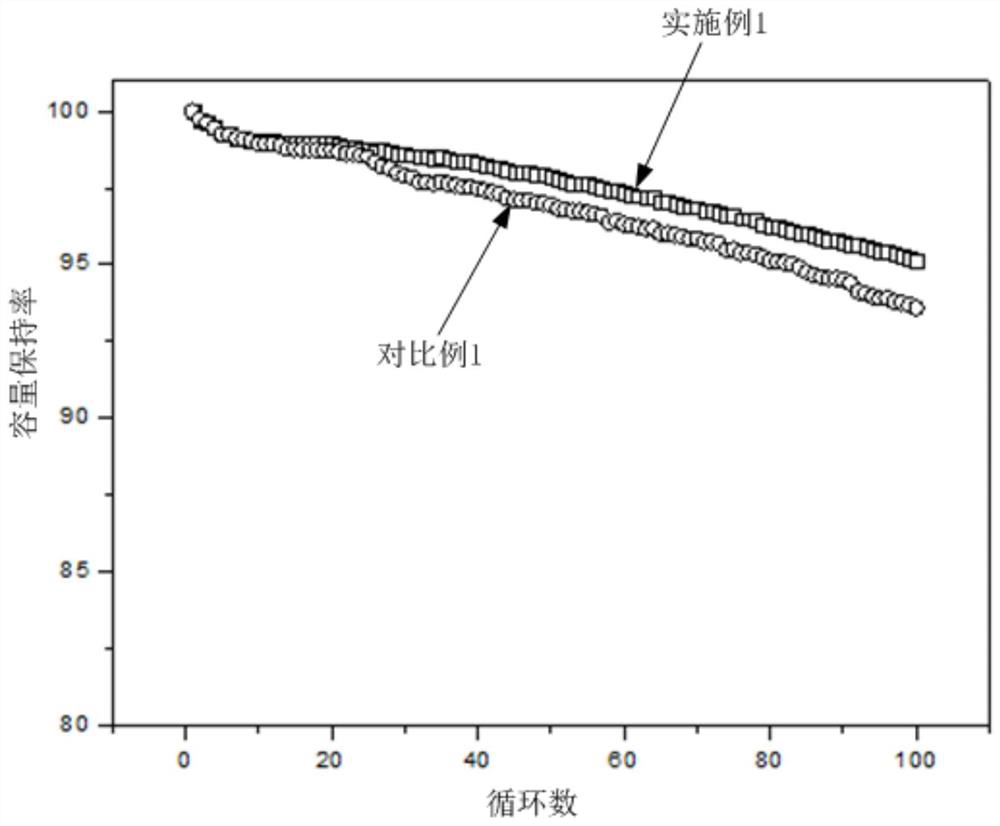

Layered quaternary cobalt-free single crystal precursor and preparation method of positive electrode material

The invention discloses a preparation method of a layered quaternary cobalt-free single crystal precursor and a positive electrode material. The chemical formula of the layered single crystal precursor is Ni < x > Mn < y > Ce < m > Zr < n > (OH) < 2 >, and the chemical formula of the single crystal positive electrode material is LiNi < x > Mn < y > Ce < m > Zr < n > O < 2 >, 1, 0lt; y is less than or equal to 0.2, 0lt; m is less than or equal to 0.2, 0lt; n < = 0.1, and x + y + m + n = 1. The layered quaternary cobalt-free single crystal precursor is prepared by adopting an industrially mature precursor preparation process. And then synthesizing the layered quaternary cobalt-free single crystal positive electrode material through a segmented high-temperature method. The layered quaternary precursor is composed of internal nickel manganese hydroxide with the size of 3-4 microns and external nickel manganese cerium zirconium hydroxide with the size of 1-1.5 microns, and is different from academic and industrial core-shell structures, and the interior of the precursor and the interior of the positive electrode material are dense. The dense layered structure and the element coordination effect improve the stability of the whole single crystal material on the bulk phase on one hand and play the coordination effect among the elements on the other hand, the cerium and zirconium on the outer layer effectively reduce side reactions, side effects caused by no cobalt are reduced, and the stability and the electrochemical performance of the single crystal material are further improved.

Owner:CENT SOUTH UNIV

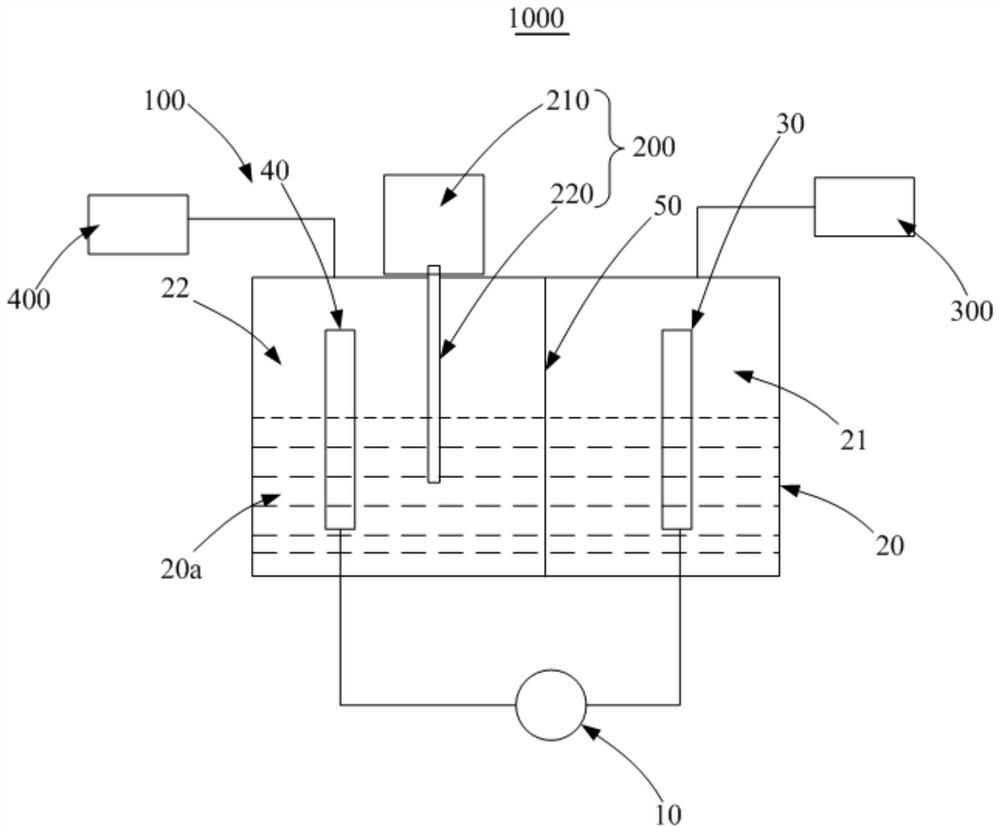

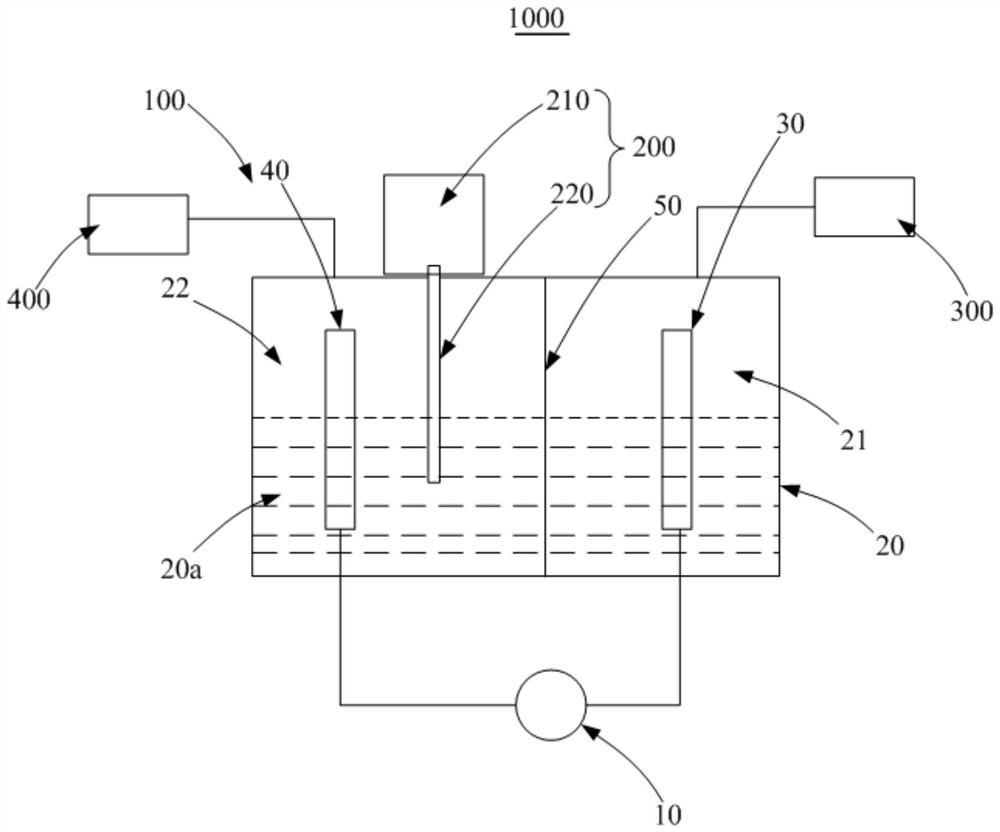

Water washing method and system for high-nickel ternary cathode material

ActiveCN113249776AImprove battery cycle performanceReduce productionElectrolysis componentsElectrolysisPhysical chemistry

The invention discloses a water washing method and system for a high-nickel ternary cathode material. The water washing method of the high-nickel ternary cathode material comprises the following steps of preparing a high-nickel ternary cathode material matrix; mixing the high-nickel ternary cathode material matrix with water to obtain an electrolyte solution; and electrolyzing the electrolyte solution to remove residual alkali on the surface of the high-nickel ternary cathode material matrix. According to the technical scheme, lattice lithium on the surface of the material can be inhibited from being separated out, and the generation amount of waste water is reduced.

Owner:贝特瑞(江苏)新材料科技有限公司

Water washing method and system for high-nickel ternary cathode material

ActiveCN113249776BImprove battery cycle performanceReduce productionElectrolysis componentsElectrolysisPhysical chemistry

The invention discloses a water washing method and system for a high-nickel ternary positive electrode material. Wherein, the water washing method of the high-nickel ternary positive electrode material comprises the following steps: preparing a high-nickel ternary positive electrode material matrix; mixing the high-nickel ternary positive electrode material matrix with water to obtain an electrolyte solution; electrolysis to remove the residual alkali on the surface of the high-nickel ternary positive electrode material substrate. The technical solution of the invention can suppress the lithium precipitation on the surface of the material and reduce the amount of waste water produced.

Owner:贝特瑞(江苏)新材料科技有限公司

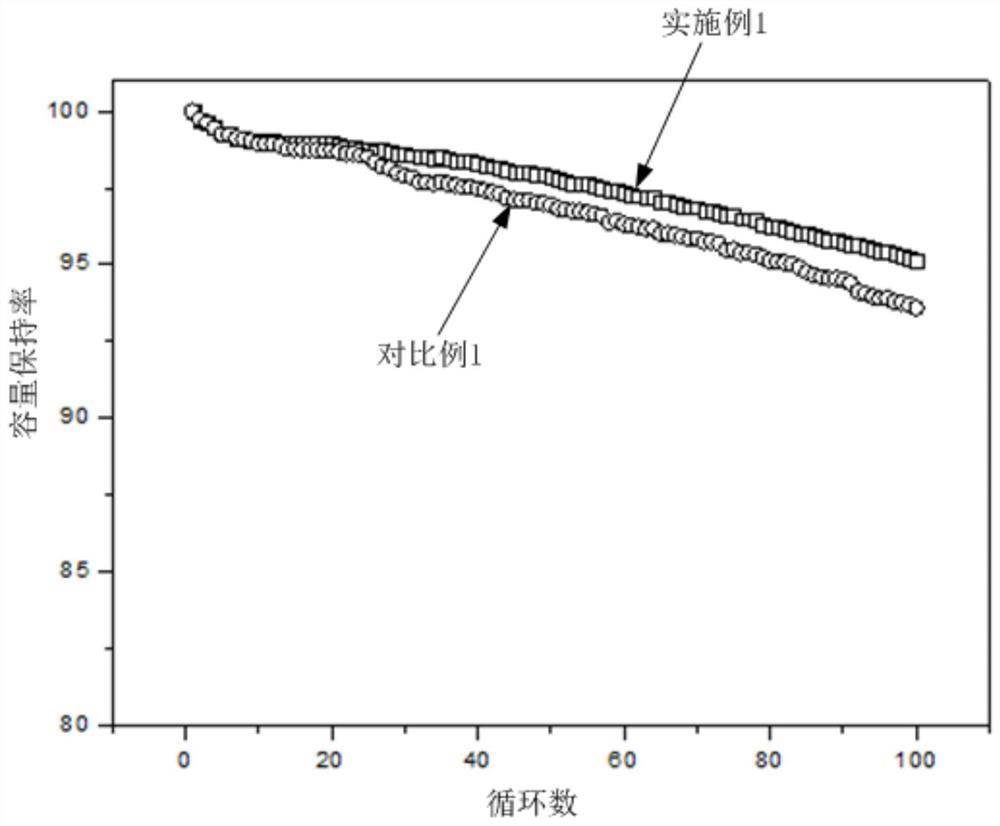

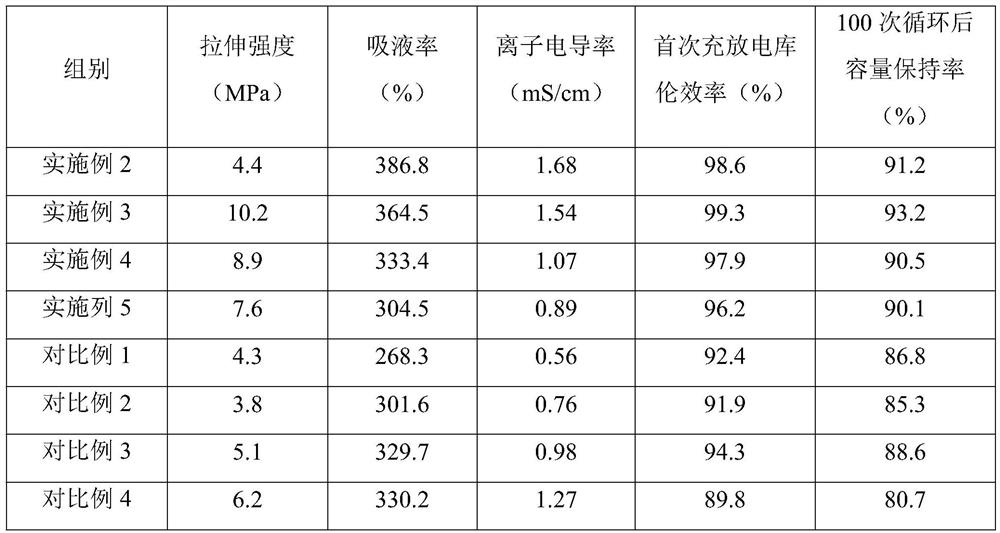

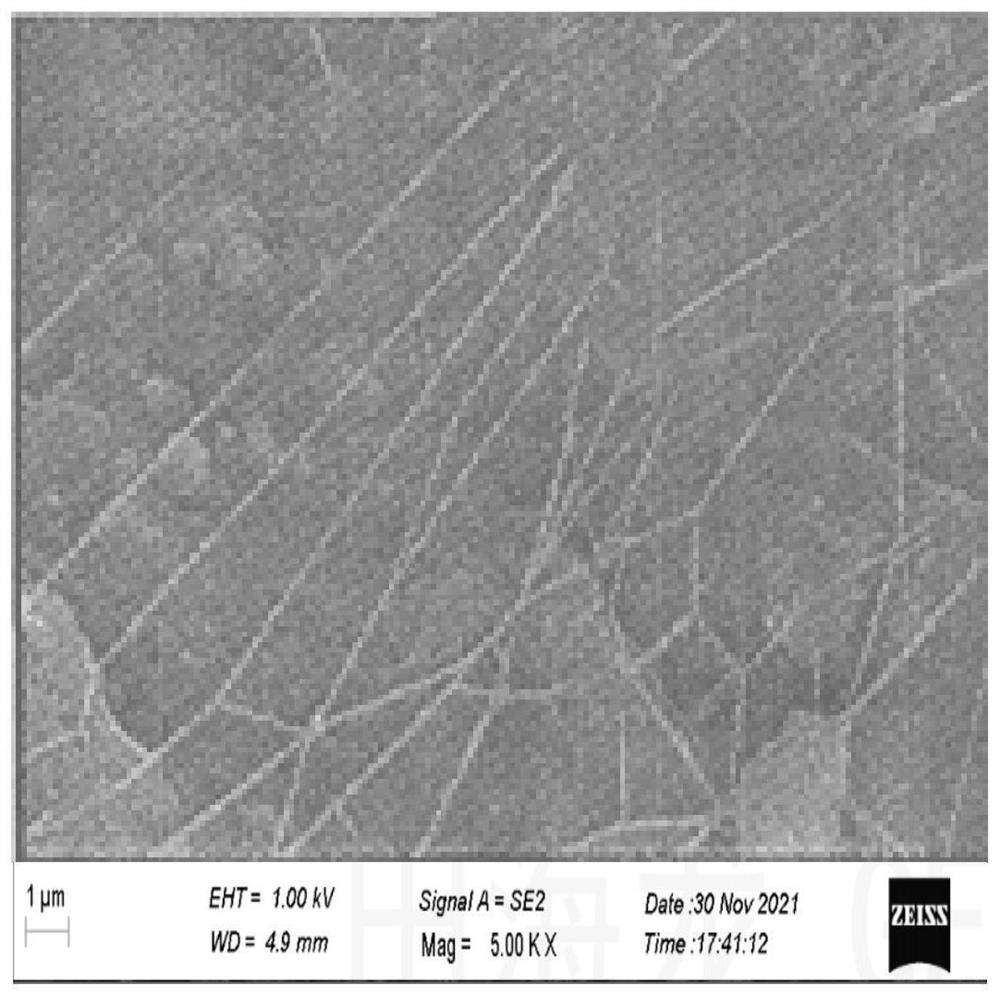

Composite nanofiber lithium battery diaphragm and preparation method thereof

ActiveCN113745752AImprove high temperature resistanceImprove mechanical propertiesCell seperators/membranes/diaphragms/spacersSpinningComposite nanofibers

The invention discloses a composite nanofiber lithium battery diaphragm which has a coaxial three-layer structure, the outer layer is a TiO2 nano layer, the middle layer is a polyacrylonitrile (PAN) pre-oxidized fiber layer, and the core layer is a polyimide (PI) fiber layer; the preparation method specifically comprises the following steps: by taking a PAA spinning solution as a core material and a PAN spinning solution as a shell material, preparing a PAN@PAA nanofiber membrane with a coaxial double-layer structure through coaxial electrostatic spinning; dipping the PAN@PAA nanofiber membrane in a TiOSO4 solution, taking out the PAN@PAA nanofiber membrane, and naturally airing the PAN@PAA nanofiber membrane to prepare a TiO (OH) 2 nanolayer@PAN@PAA nanofiber membrane; and carrying out heat treatment on the TiO (OH) 2 nano layer@PAN@PAA nano fiber membrane to obtain the coaxial three-layer structure TiO2@PAN pre-oxidized@PI composite nano fiber membrane. The composite diaphragm has excellent thermal stability, excellent mechanical performance, good electrochemical performance and battery cycle performance.

Owner:HENAN INST OF ENG

Rapid and efficient lithium ion battery negative electrode homogenate stirring method

PendingCN113244831AImprove stabilityImproved rheological propertiesElectrode manufacturing processesTransportation and packagingButadiene-styrene rubberLithium electrode

The invention provides a rapid and efficient lithium ion battery negative electrode homogenate stirring method. The method comprises the following steps: 1) adding a glue solution into powder while stirring; 2) continuing to add the glue solution, and stirring; (3) adding the glue solution and N-methyl pyrrolidone, and stirring; and 4) adding the butadiene styrene rubber, then adding the rest of the glue solution, and stirring. Compared with the prior art, the glue solution is divided into four parts, the mixing sequence of each step and the amount of the added glue solution are controlled, and the stirring speed and time of each step are controlled, so that uniform dispersion of the slurry is facilitated, and the fineness, stability and rheological property of the slurry and the cycle performance of a battery cell are improved.

Owner:河南克能新能源科技有限公司

Application of gallium-germanium nanowire as lithium ion battery electrode material

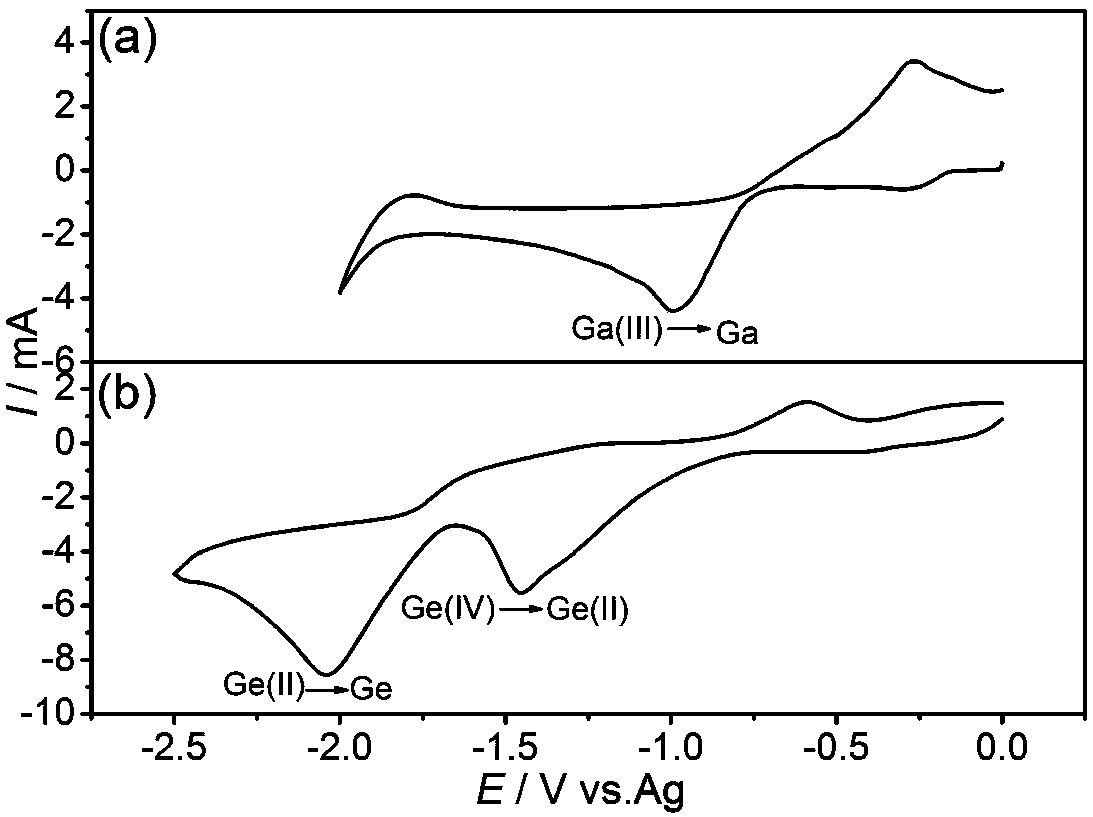

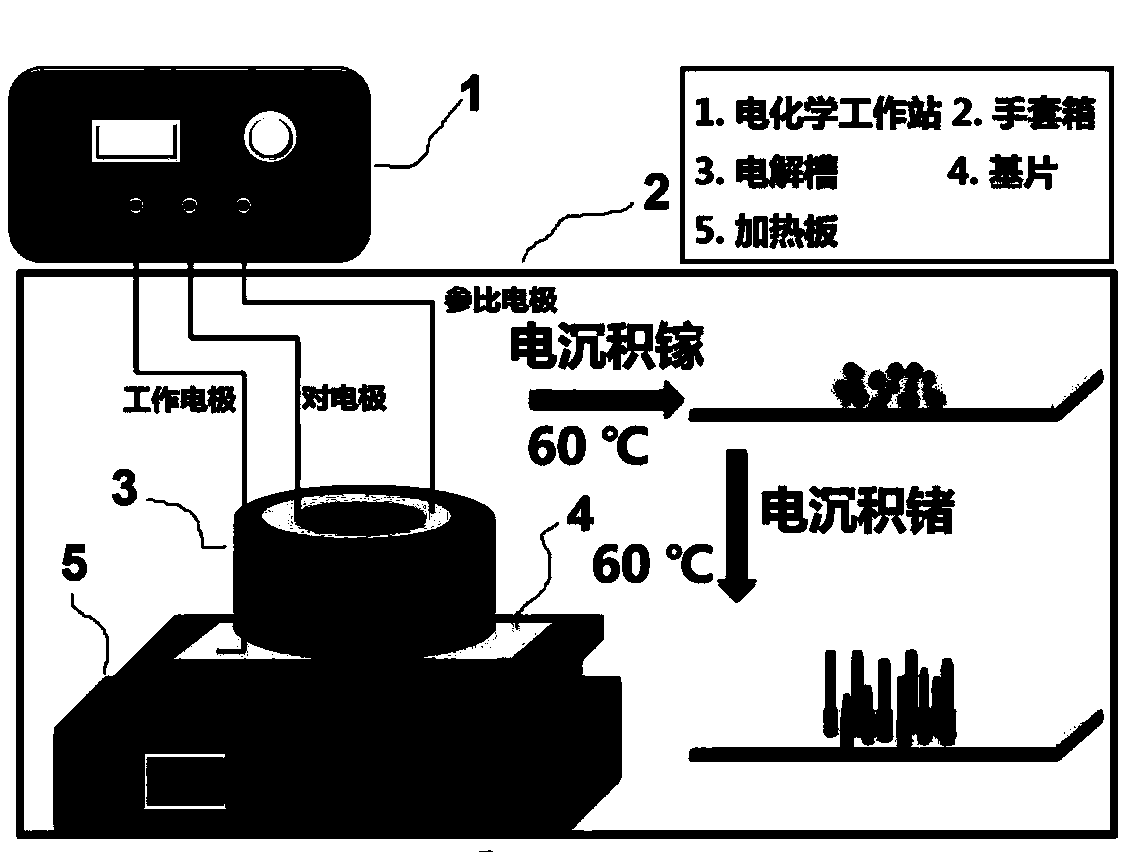

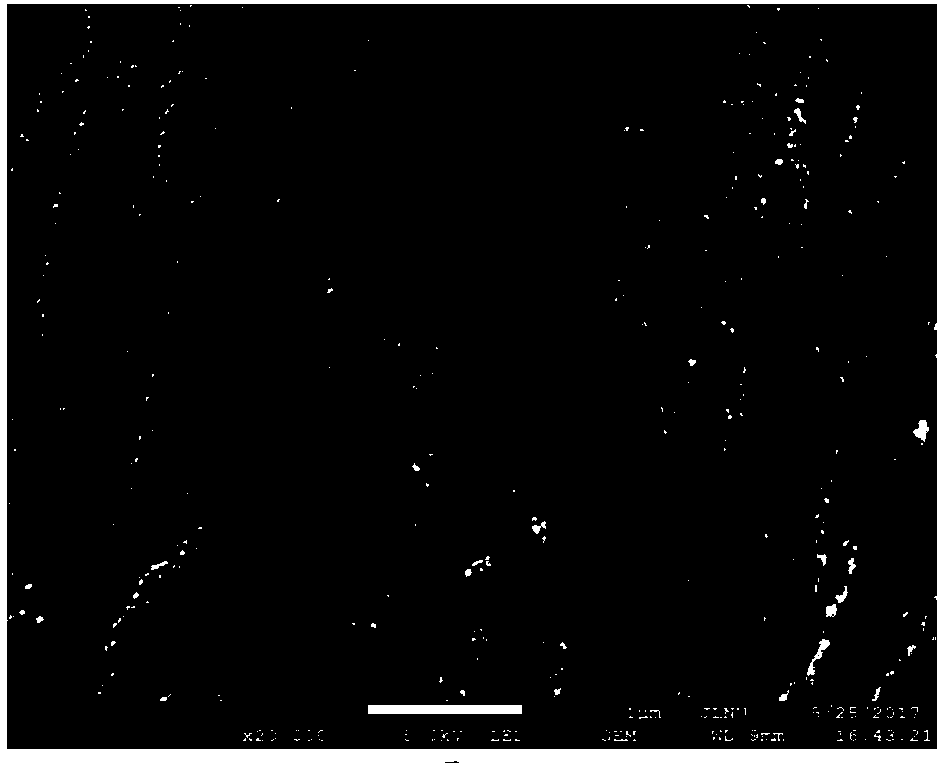

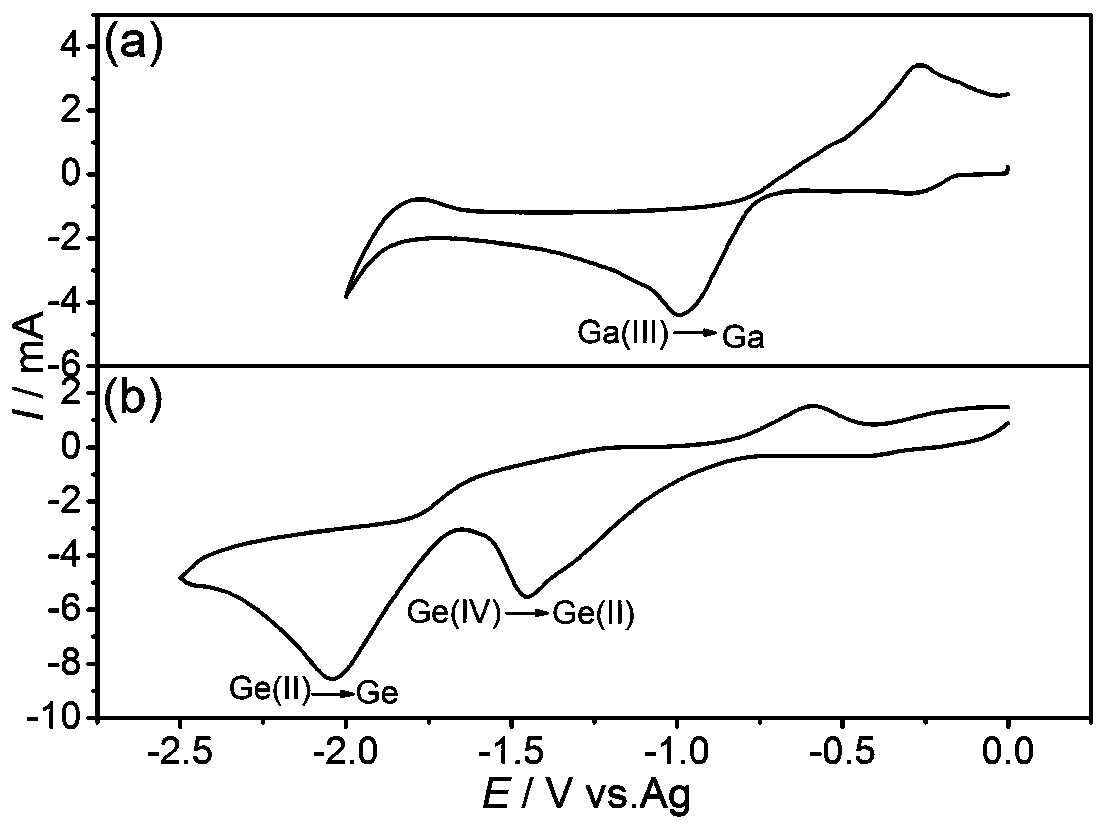

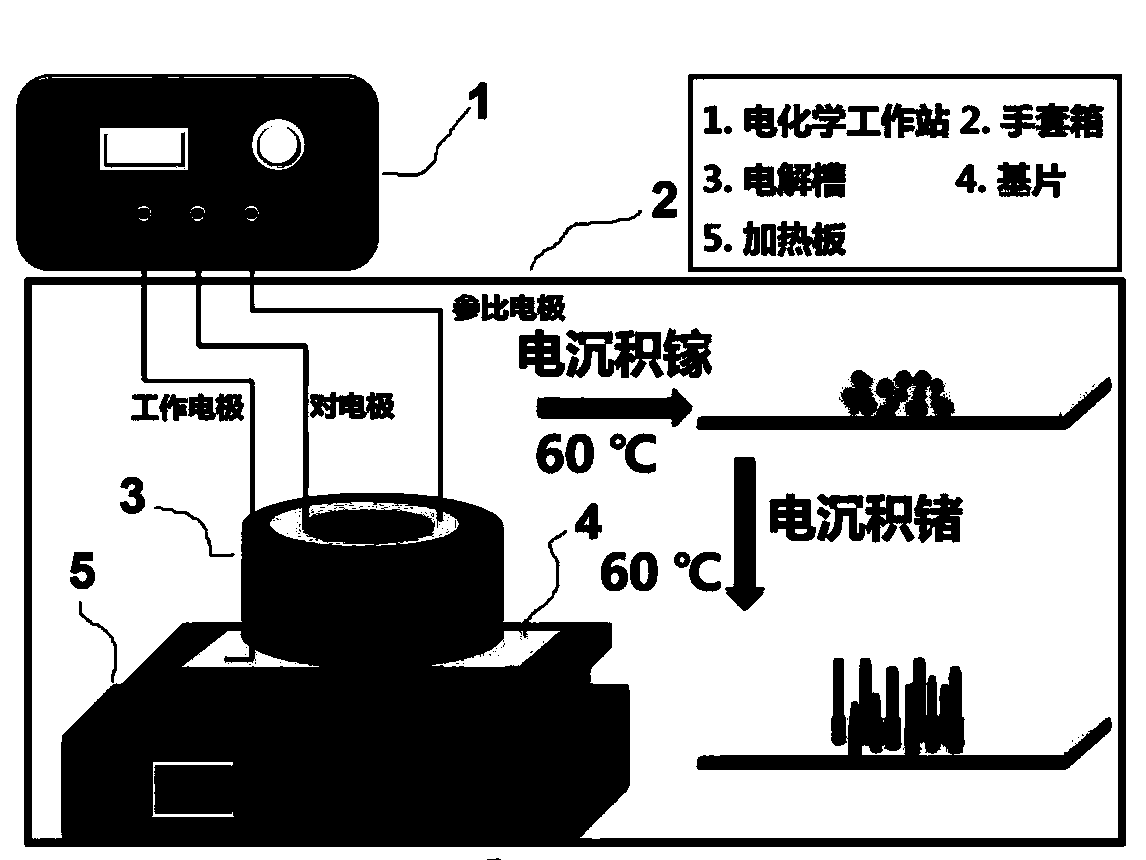

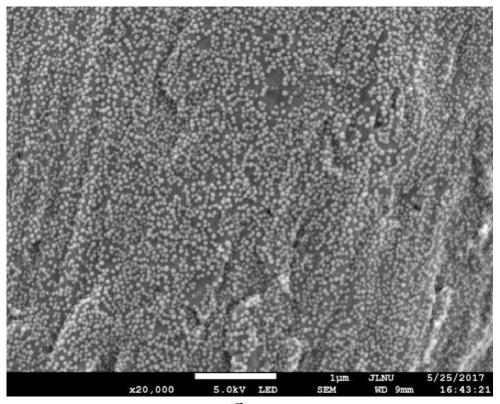

ActiveCN108336346AImprove battery cycle performanceImproved magnification performanceMaterial nanotechnologyElectrode manufacturing processesNanowirePower performance

The invention provides an application of a gallium-germanium nanowire as a lithium ion battery electrode material. The gallium-germanium nanowire comprises a simple substance germanium and a simple substance gallium, and an atomic ratio of the simple substance germanium to the simple substance gallium in the gallium-germanium nanowire is (4-9):1. The gallium-germanium nanowire as the electrode material of a lithium ion battery can improve the cell cycle performance and multiplying power performance of the lithium ion battery.

Owner:吉林省东驰新能源科技有限公司

Method for manufacturing secondary battery using lithium metal as negative electrode

ActiveUS20200067070A1Decrease in ion conductivityReduce variationElectrode manufacturing processesFinal product manufactureLithium metalPhysical chemistry

A method of manufacturing a secondary battery using lithium metal as a negative electrode, and more particularly, a method of manufacturing a secondary battery capable of removing an oxide film formed on a lithium metal by performing some initial discharges during the initial period of the activation process to thereby improve the cycling performance of the battery by allowing lithium to be uniformly precipitated. The result minimizes the reduction of ion conductivity by removing the oxide film formed on the surface of the lithium metal through the initial partial discharge and improves the battery cycle performance since the precipitation reaction of lithium becomes uniform.

Owner:LG ENERGY SOLUTION LTD

A diverse positive material and preparation method of a sodium ion battery

ActiveCN111697210BImprove structural stabilityImprove conductivitySecondary cellsPositive electrodesElectrical batterySodium-ion battery

A kind of sodium ion battery multiple positive electrode material and preparation method thereof: the chemical general formula of this sodium ion battery multiple positive electrode material is Na 0.67 mn x Mg y Ni z W n o 2‑q B q , wherein, 0.65≤x≤0.8, 0<y≤0.2, 0<z≤0.2, 0<n≤0.2, 0<q≤0.05, x+y+z+n=1. The preparation method firstly adds sodium source, manganese source, nickel source, magnesium source, tungsten source and boron source into citric acid to generate a sol, then dries the sol to obtain a gel, and heat-treats the gel to obtain the multi-component sodium ion battery. Cathode material. The preparation of multi-element cathode materials for sodium ion batteries utilizes cation or anion doping or co-doping to enhance the structural stability and conductivity of the material. The material has good rate performance and excellent cycle stability, and the required raw material resources are abundant, the cost is low, and the preparation method is simple and controllable.

Owner:帕瓦(兰溪)新能源科技有限公司

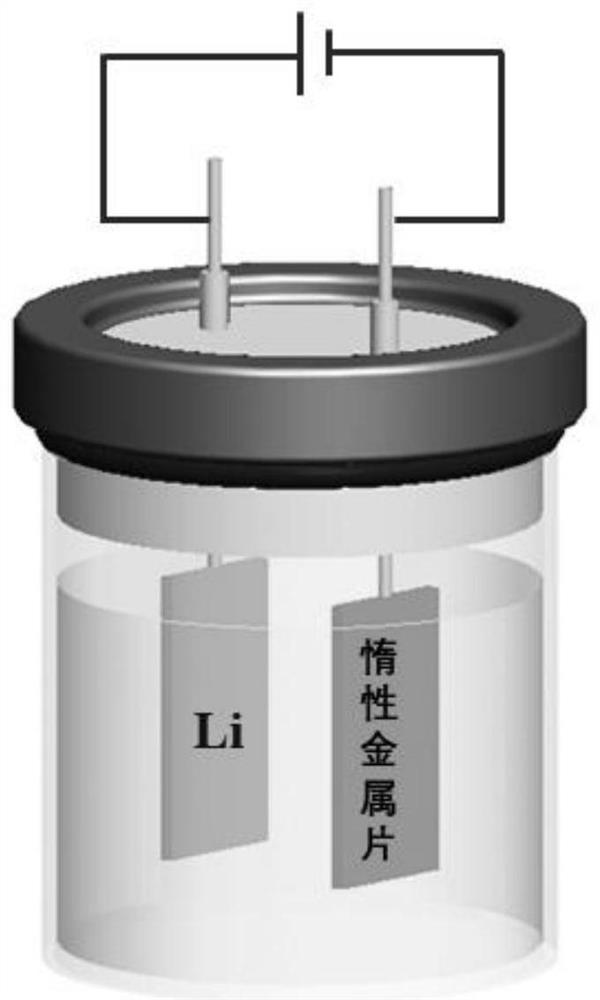

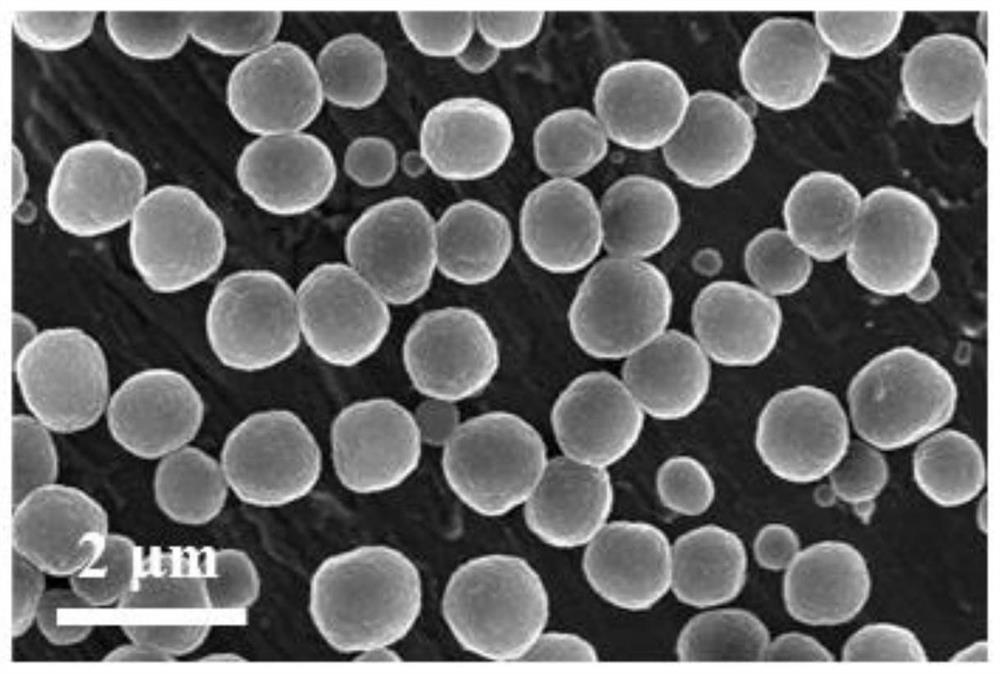

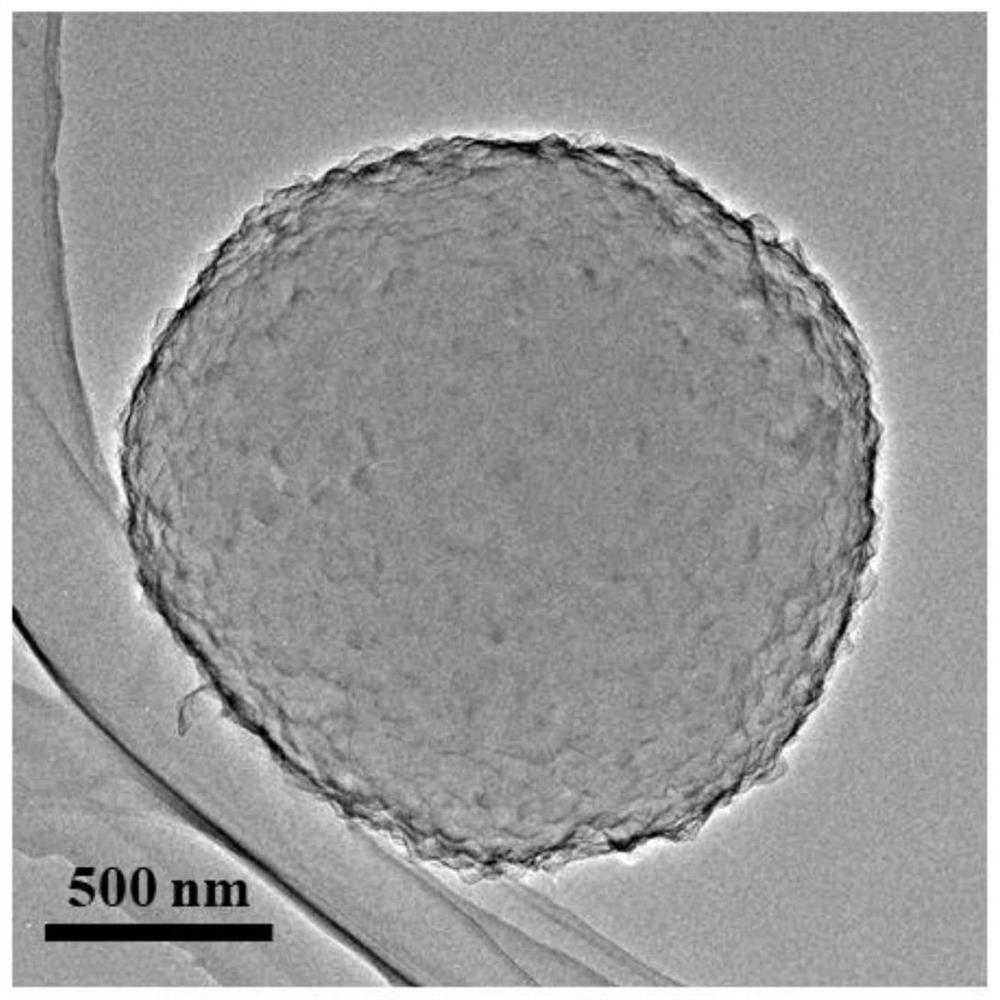

A kind of passivation lithium powder and its preparation method and application

The invention provides a passivated lithium powder and a preparation method and application thereof, which belong to the technical field of lithium ion batteries. The preparation method of passivated lithium powder provided by the present invention comprises the following steps: using lithium salt as electrolyte, lithium sheet as anode, and inert metal as cathode, performing electroplating in the presence of organic solvents and fluorine-containing compounds to obtain passivation Lithium powder. The passivated lithium powder prepared by the method provided by the invention is placed in the air with a humidity below 20% for 1 month, and the structure of the passivated lithium powder does not change significantly; it is used for pre-lithiation / complementation of graphite negative electrodes and silicon carbon negative electrodes. Lithium, the first cycle Coulombic efficiency can be increased to more than 99.8%; pre-lithiated graphite negative electrode and silicon carbon negative electrode and LiCoO 2 The first-cycle coulombic efficiency of the full battery assembled with the positive electrode can be increased to more than 98%, and the energy consumption is low, easy to operate and can be prepared continuously, and is suitable for mass production.

Owner:YANSHAN UNIV

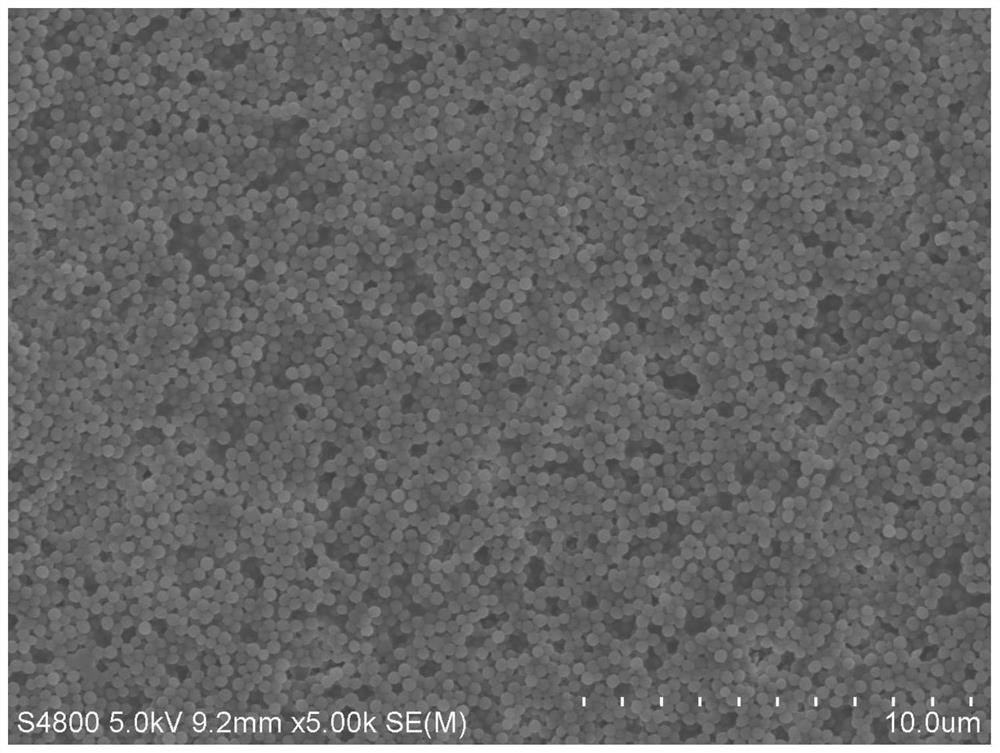

Surface-modified lithium ion battery diaphragm with high ionic conductivity, ultralow moisture and high temperature resistance and preparation method of surface-modified lithium ion battery diaphragm

PendingCN114142163AImprove battery cycle performanceImprove heat resistanceSecondary cellsCell component detailsElectric vehicleHigh energy

The invention discloses a high-ionic-conductivity ultralow-moisture high-temperature-resistant surface-modified lithium ion battery diaphragm and a preparation method thereof.The lithium ion battery diaphragm is formed by coating of coating slurry, and the preparation method of the coating slurry comprises the following steps that firstly, a dispersing agent, water, a PTFE / CNTs nano composite material and amorphous LTO mixed powder are evenly mixed and subjected to ultrasonic treatment, and the surface-modified lithium ion battery diaphragm is obtained; according to the coating slurry, the amorphous LTO mixed powder and the PTFE / CNTs nano composite material are used for forming a mixed material, the amorphous LTO mixed powder and the PTFE / CNTs nano composite material are compounded to form brand-new slurry, the safety performance of the battery is improved, and meanwhile the cycle performance of the battery can be improved; meanwhile, the heat resistance of the lithium ion diaphragm can be effectively improved, the ionic conductivity is improved, and the moisture content of the diaphragm is reduced, so that the battery safety is improved, and the safety of an electric vehicle driven by a high-energy-density battery is further improved.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

A kind of hot water resistant coating for lithium battery diaphragm and its preparation method and application

ActiveCN109244321BImprove uniformityImprove electrochemical performanceCell seperators/membranes/diaphragms/spacersPolyolefinAdhesive

Owner:HUIQIANG WUHAN NEW ENERGY MATERIAL TECH

Application of a germanium-gallium nanowire as an electrode material for lithium-ion batteries

ActiveCN108336346BImprove battery cycle performanceImproved magnification performanceMaterial nanotechnologyElectrode manufacturing processesNanowireLithium-ion battery

The invention provides an application of a gallium-germanium nanowire as a lithium ion battery electrode material. The gallium-germanium nanowire comprises a simple substance germanium and a simple substance gallium, and an atomic ratio of the simple substance germanium to the simple substance gallium in the gallium-germanium nanowire is (4-9):1. The gallium-germanium nanowire as the electrode material of a lithium ion battery can improve the cell cycle performance and multiplying power performance of the lithium ion battery.

Owner:吉林省东驰新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com