Surface-modified lithium ion battery diaphragm with high ionic conductivity, ultralow moisture and high temperature resistance and preparation method of surface-modified lithium ion battery diaphragm

An ultrasonic and dispersant technology, applied in secondary batteries, battery pack parts, circuits, etc., can solve the problems of battery bulging, affecting the moisture content of the battery pack, and scrapping, etc., to improve safety, improve battery safety, and improve durability. The effect of thermal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

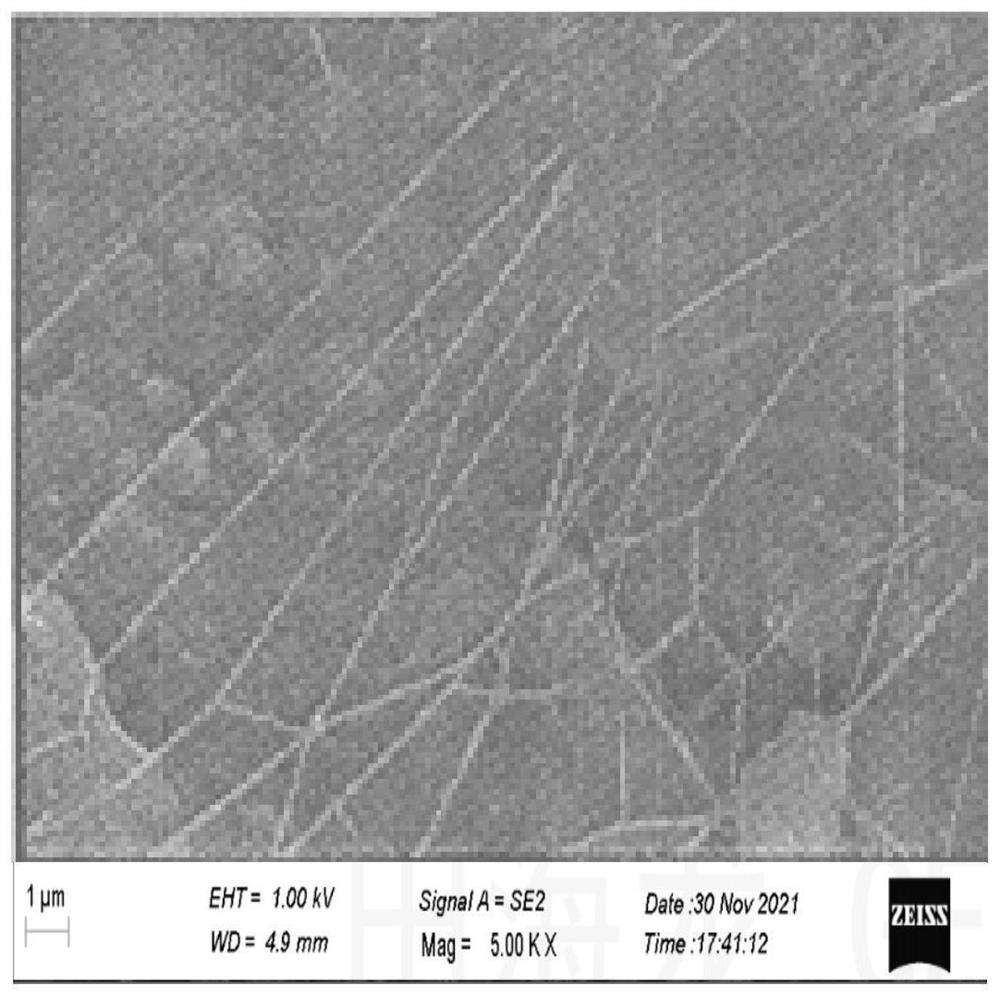

Image

Examples

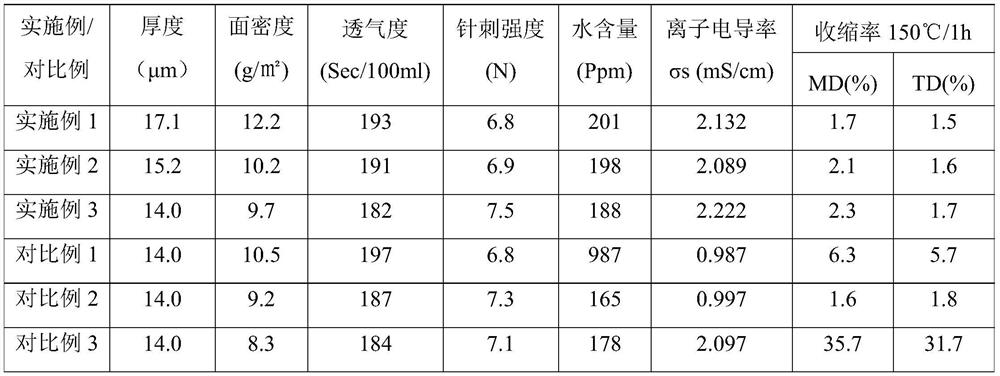

Embodiment 1

[0043] A preparation method for coating slurry, comprising the following steps:

[0044] In the planetary stirring equipment, the dispersant, water, PTFE / CNTs nanocomposite material and amorphous LTO mixed powder were stirred at the speed of rotation 3100r / min and revolution 20r / min for 10min until uniform, and then at 50kHz ultrasonic frequency, Ultrasound for 3 minutes to obtain the mixed liquid, put it in a vacuum, high-speed dispersion, and planetary stirring equipment with ultrasonic oscillation function, stir at the rotation speed of 1000r / min, the revolution speed of 40r / min for 15min, and add the adhesive to the mixed liquid, at the same time Sonicate at an ultrasound frequency of 5 kHz. In parts by mass, the ratio of dispersant, water, PTFE / CNTs nanocomposite material, amorphous LTO mixed powder and adhesive is 0.2:74.8:5:20:5.

[0045] A method for preparing a lithium-ion battery diaphragm with high ion conductivity, ultra-low moisture, and high temperature resistan...

Embodiment 2

[0049] A preparation method for coating slurry, comprising the following steps:

[0050] In the planetary mixing equipment, the dispersant, water, PTFE / CNTs nanocomposite material and amorphous LTO mixed powder were stirred at a speed of 2000r / min for rotation and 30r / min for 15min until uniform, and then at an ultrasonic frequency of 30kHz, Ultrasound for 4 minutes to obtain the mixed liquid, put it in a vacuum, high-speed dispersion, and planetary stirring equipment with ultrasonic oscillation function, stir at the rotation speed of 2800r / min and the revolution speed of 30r / min for 20min, and add the adhesive to the mixed liquid, at the same time Sonicate at an ultrasound frequency of 6 kHz. In parts by mass, the ratio of dispersant, water, PTFE / CNTs nanocomposite material, amorphous LTO mixed powder and adhesive is 0.3:63.7:10:20:6.

[0051] A method for preparing a lithium-ion battery diaphragm with high ion conductivity, ultra-low moisture, and high temperature resistanc...

Embodiment 3

[0055] A preparation method for coating slurry, comprising the following steps:

[0056] In the planetary stirring equipment, the dispersant, water, PTFE / CNTs nanocomposite material and amorphous LTO mixed powder were stirred at the speed of rotation 1500r / min and revolution 50r / min for 20min until uniform, and then at 50kHz ultrasonic frequency, Ultrasound for 5 minutes to obtain the mixed liquid, put it in a vacuum, high-speed dispersion, and planetary stirring equipment with ultrasonic oscillation function, stir at the rotation speed of 3800r / min, the revolution speed of 20r / min for 25min, and add the adhesive to the mixed liquid, at the same time Sonicate at an ultrasound frequency of 8 kHz. In parts by mass, the ratio of dispersant, water, PTFE / CNTs nanocomposite material, amorphous LTO mixed powder and adhesive is 0.5:71.5:10:10:8.

[0057]A method for preparing a lithium-ion battery diaphragm with high ion conductivity, ultra-low moisture, and high temperature resistan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com