A kind of passivation lithium powder and its preparation method and application

A technology for passivating lithium and lithium salts, which is applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems of high complexity of equipment, large size of passivated lithium powder, and uniform dispersion of lithium powder, so as to improve the pre-lithium The effects of globalization, reduction of production costs, and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

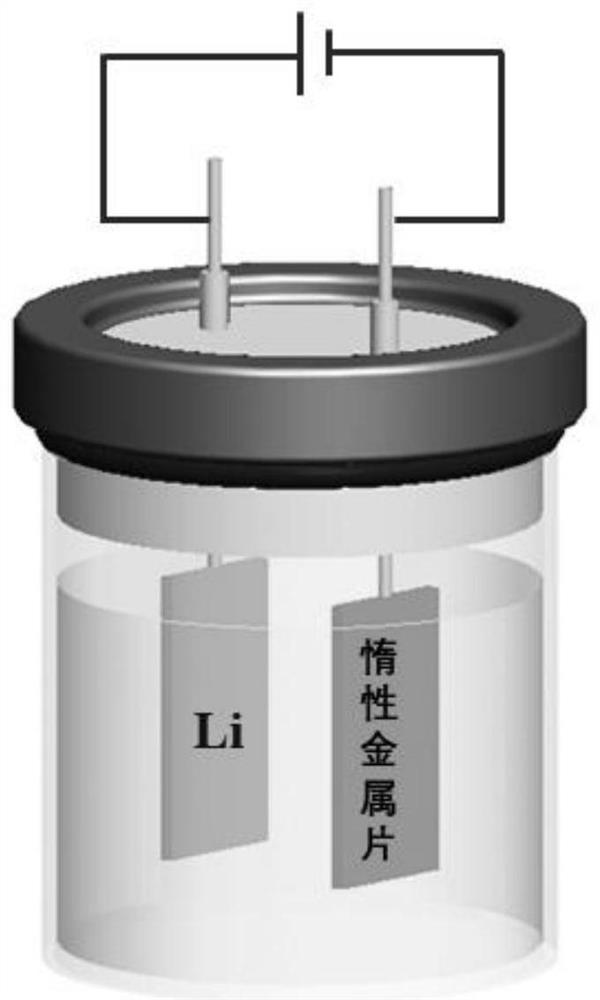

[0030] The invention provides a preparation method of passivated lithium powder, comprising the following steps: using lithium salt as an electrolyte, a lithium sheet as an anode, and an inert metal as a cathode, performing electroplating in the presence of an organic solvent and a fluorine-containing compound, Obtain passivated lithium powder.

[0031] In the present invention, the preparation of the passivated lithium powder is preferably carried out in an electroplating device, such as figure 1 As shown, a metal lithium sheet is used as an anode, and an inert metal is used as a cathode.

[0032] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0033] In the present invention, the lithium salt preferably includes LiPF 6 , LiAsF 6 One or more of , LiTFSI and LiFSI. In the present invention, the fluorine-containing compound preferably includes fluoroethylene carbo...

Embodiment 1

[0048] use as figure 1 In the electroplating device shown, in the glove box, the mixed solvent of EC:DEC volume ratio = 1:1 is used as the organic solvent, and LiPF 6 As the electrolyte, the copper sheet is the cathode, the lithium sheet is the anode, and FEC is the additive. At a current density of 0.1mA·cm -2 Under the conditions of electroplating for 3h, a passivated lithium powder film loaded on the copper sheet is obtained; among them, LiPF 6 , The dosage ratio of FEC and organic solvent is 1mol: 0.1mol: 1L;

[0049] Transfer the copper sheet loaded with passivated lithium powder film to DOL solvent, and ultrasonically peel it off for 20 minutes to obtain passivated lithium powder slurry, and place the passivated lithium powder slurry in an argon-protected glove box or a dry room for batteries Solvent DOL was volatilized to obtain passivated lithium powder.

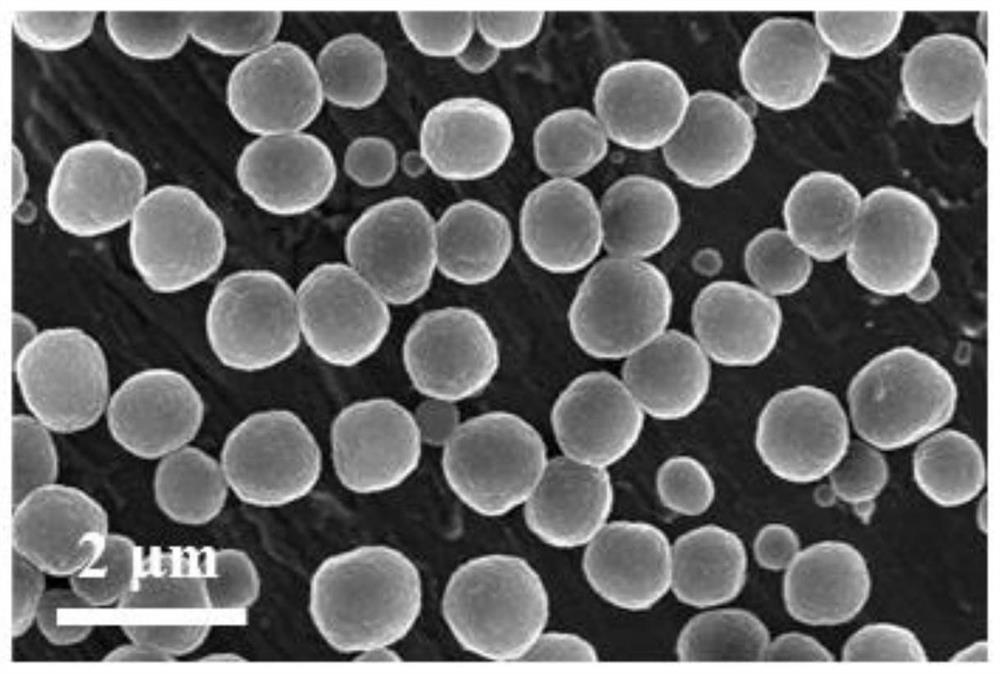

[0050] The scanning electron microscope picture of gained passivation lithium powder is as follows figure 2 A...

Embodiment 2

[0052] In the glove box, use the mixed solvent of EC:DEC:DMC volume ratio = 1:1:1 as the organic solvent, LiPF 6 As the electrolyte, the copper sheet is the cathode, the lithium sheet is the anode, and FEC is the additive. At a current density of 0.05mA·cm -2 Under the conditions of electroplating for 1h, a passivated lithium powder film loaded on the copper sheet is obtained; among them, LiPF 6 , The dosage ratio of FEC and organic solvent is 1mol: 0.05mol: 1L;

[0053] The obtained copper sheet loaded with passivated lithium powder film was transferred to a DOL solvent, and ultrasonically peeled off for 10 minutes to obtain a passivated lithium powder slurry, which was placed in an argon-protected glove box to evaporate the solvent DOL, Obtain passivated lithium powder.

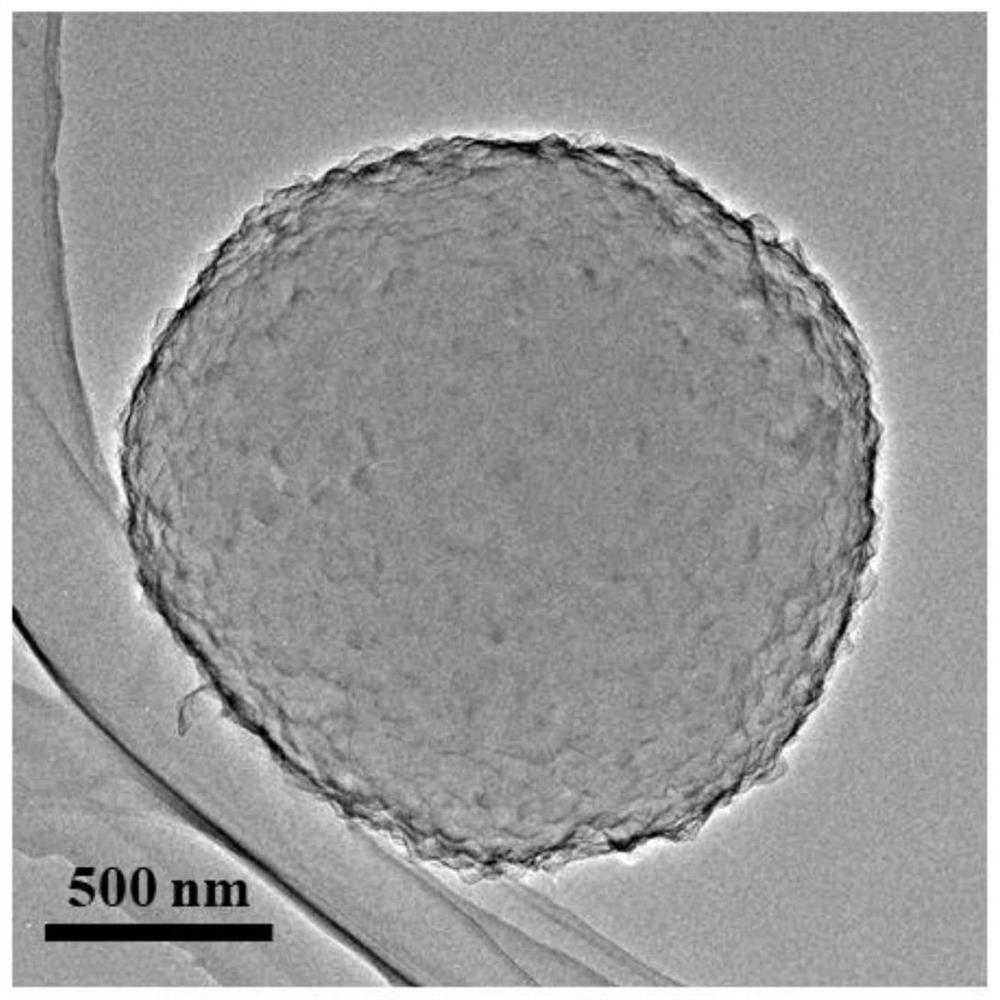

[0054] The structure of the obtained passivated lithium powder is a spherical particle of a core-shell structure with metal lithium as the core and lithium fluoride / lithium oxide composite; the scanning e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com