A kind of hot water resistant coating for lithium battery diaphragm and its preparation method and application

A lithium battery separator, heat-resistant water-resistant technology, applied in battery pack parts, separators/films/diaphragms/spacers, circuits, etc. The effect of high temperature resistance and battery cycle performance, high uniformity, comprehensive electrochemical performance and high temperature resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method of preparing a separator with hot water separator and a lithium battery comprising coating the aqueous coating of the heat-lithium, the following steps:

[0026] (1) The aqueous emulsion of polyvinylidene fluoride and an aqueous RC-10246 YH-1066 polyimide in effective mass of solids ratio of 80: 3 were mixed and stirred at the first rotation speed 1200rpm 30min, mixed, after 3500rpm speed stirring 1h, and finally stirring 1100rpm 20min, to obtain a homogeneous composite aqueous dispersion coating slurry;

[0027] (2) Method of the complex aqueous knife coating slurry onto the surface of a polypropylene separator, formed 0.6um thick lithium ion battery separator by hot water resistance after coating the surface of a polypropylene separator 70 ℃ dried 18s while obtaining lithium battery separator comprises hot water resistance of the coating.

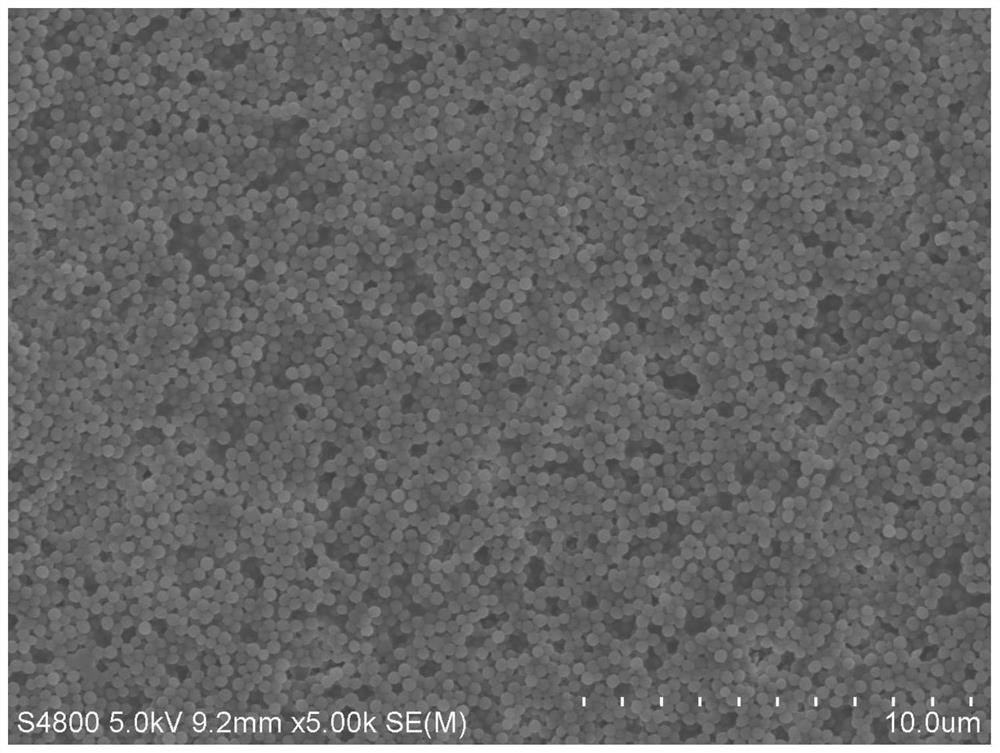

[0028] Depend on figure 1 Understood, the present invention is a lithium battery separator obtained with a high degree of co...

Embodiment 2

[0030] A method of preparing a separator with hot water separator and a lithium battery comprising coating the aqueous coating of the heat-lithium, the following steps:

[0031] (1) The aqueous emulsion of polyvinylidene fluoride and an aqueous polytetrafluoroethylene RC-10280 D1610F in effective mass of solids ratio of 85: 4 mixture, stirred at the first rotation speed 1100rpm 40min, mixed well, then at 3800rpm speed stirred for 2h, and finally stirring 1000rpm 30min, to obtain a homogeneous composite aqueous dispersion coating slurry;

[0032] (2) Method of coating the aqueous coating composite slurry was applied to a polyethylene separator surface to form 1um thick lithium ion battery separator in polyethylene separator surface was dried at 60 deg.] C hot water with a coating 30s, while to give lithium battery separator comprises hot water resistance of the coating.

Embodiment 3

[0034] A method of preparing a separator with hot water separator and a lithium battery comprising coating the aqueous coating of the heat-lithium, the following steps:

[0035] (1) The aqueous emulsion of polyvinylidene fluoride and an aqueous XPH-838 PIW-1066 polyimide in effective mass of solids ratio of 86: 7 after mixing, was first stirred for 45 min at a rotation speed 1300rpm, mixing uniformly, after 3600rpm speed stirring 1.5h, and finally stirring 1200rpm 25min, to obtain a homogeneous composite aqueous dispersion coating slurry;

[0036] (2) the method of the composite roll coating aqueous coating slurry was applied to the surface of a polypropylene separator, and dried at 65 deg.] C 25s formed 1.5um thick lithium ion battery separator in the hot water resistance coating the surface of a polypropylene separator, while lithium battery separator comprises hot water to obtain a coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com