Water washing method and system for high-nickel ternary cathode material

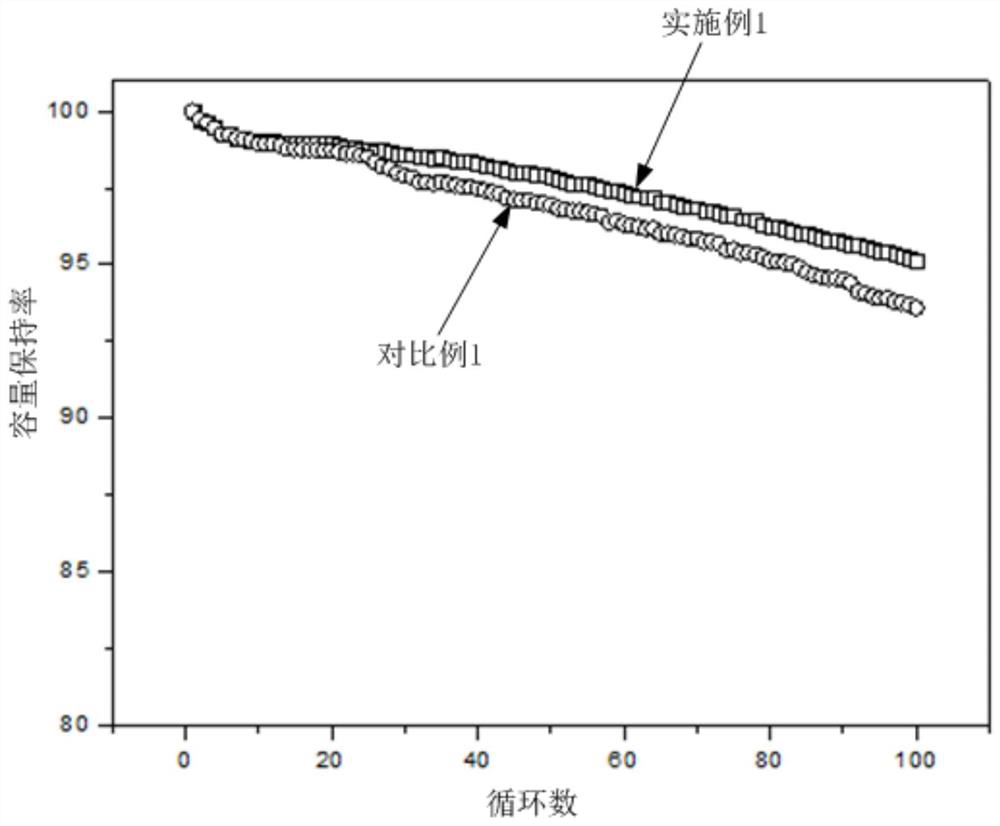

A positive electrode material, high-nickel technology, applied in the electrolysis process, electrolytic components, etc., can solve the problems of lattice lithium precipitation, poor battery cycle performance, high-nickel materials can not be industrialized, etc., to reduce the amount of production and inhibit the surface of the material Lattice lithium precipitation and the effect of improving battery cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] (1) Preparation of high-nickel ternary cathode material matrix: at room temperature, lithium hydroxide, Ni 0.8 co 0.1 mn 0.1 (OH) 2 The ternary precursor is added into the high-speed mixer at a molar ratio of 1.03:1, and mixed evenly to obtain a mixed powder. The mixed powder is sintered at a high temperature. The sintering temperature is 810°C and the sintering holding time is 10h. Oxygen, oxygen flow rate is 0.5m 3 / h, keep the oxygen concentration up to 99.5%, crush and sieve after cooling, you can get LiNi 0.8 co 0.1 mn 0.1 o 2 High nickel ternary cathode material matrix.

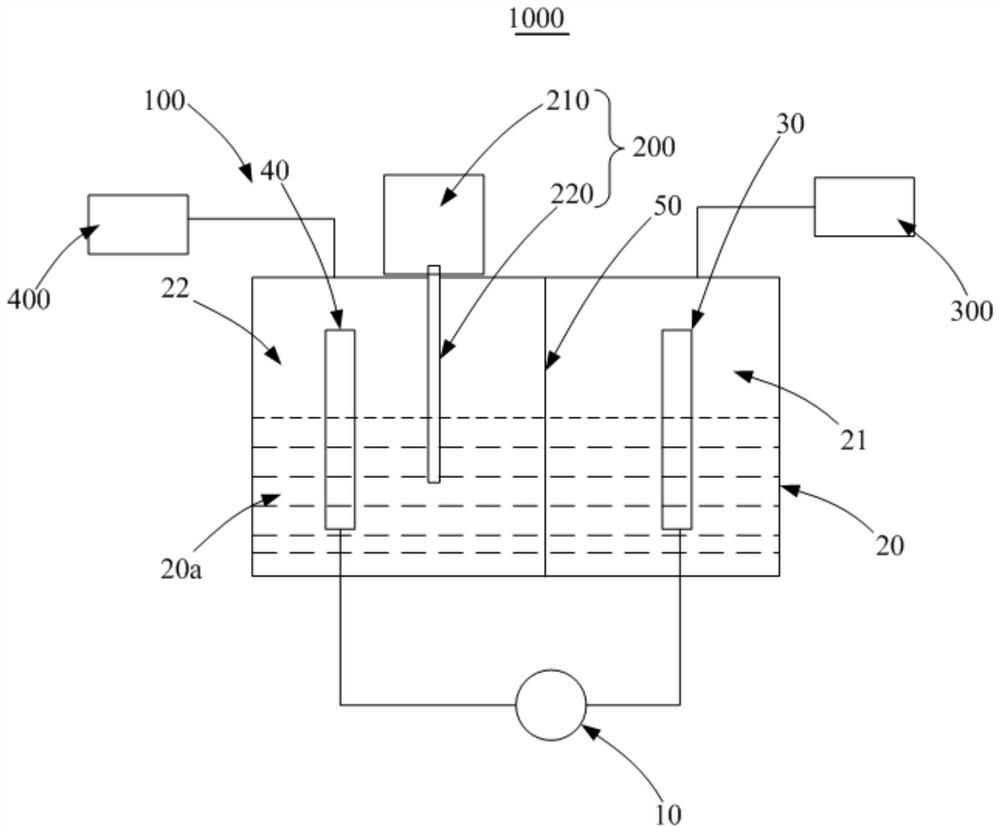

[0086] (2) Water-washed high-nickel ternary positive electrode material: a. Prepare a reaction kettle, add an electrolytic positive electrode and an electrolytic negative electrode into the reaction kettle, and a power supply is connected between the positive and negative electrodes, and the power supply voltage is set to 18V. b. According to deionized water, prepared LiNi 0.8 co 0.1 mn...

Embodiment 2

[0088] (1) Preparation of high-nickel ternary cathode material matrix: at room temperature, lithium hydroxide, Ni 0.8 co 0.1 mn 0.1 (OH) 2 The ternary precursor is added into the high-speed mixer at a molar ratio of 1.03:1, and mixed evenly to obtain a mixed powder. The mixed powder is sintered at a high temperature. The sintering temperature is 810°C and the sintering holding time is 15h. Oxygen, oxygen flow rate is 1.0m 3 / h, keep the oxygen concentration up to 99.5%, crush and sieve after cooling, you can get LiNi 0.8 co 0.1 mn 0.1 o 2 High nickel ternary cathode material matrix.

[0089] (2) Water-washed high-nickel ternary positive electrode material: a. Prepare a reaction kettle, add an electrolytic positive electrode and an electrolytic negative electrode into the reaction kettle, and a power supply is connected between the positive and negative electrodes, and the power supply voltage is set to 5V. b. According to deionized water, prepared LiNi 0.8 co 0.1 mn ...

Embodiment 3

[0091] (1) Preparation of high-nickel ternary cathode material matrix: at room temperature, lithium hydroxide, Ni 0.8 co 0.1 mn 0.1 (OH) 2 The ternary precursor is added into the high-speed mixer at a molar ratio of 1.03:1, and mixed evenly to obtain a mixed powder. The mixed powder is sintered at a high temperature. The sintering temperature is 850°C and the sintering holding time is 15h. Oxygen, oxygen flow rate is 0.8m 3 / h, keep the oxygen concentration up to 99.5%, crush and sieve after cooling, you can get LiNi 0.8 co 0.1 mn 0.1 o 2 High nickel ternary cathode material matrix.

[0092] (2) Water-washed high-nickel ternary positive electrode material: a. Prepare a reaction kettle, add electrolytic positive electrode and electrolytic negative electrode into the reaction kettle, and connect a power supply between the positive and negative electrodes, and set the power supply voltage to 36V. b. According to deionized water, prepared LiNi 0.8 co 0.1 mn 0.1 o 2 Add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com