High-capacity and high-rate lithium battery anode material and preparation method thereof

A negative electrode material and high rate technology, applied in the field of high capacity and high rate lithium battery negative electrode material and its preparation, can solve the problems of high binder content and complex bonding process, achieve good liquid absorption, overcome many equipment, The effect of good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

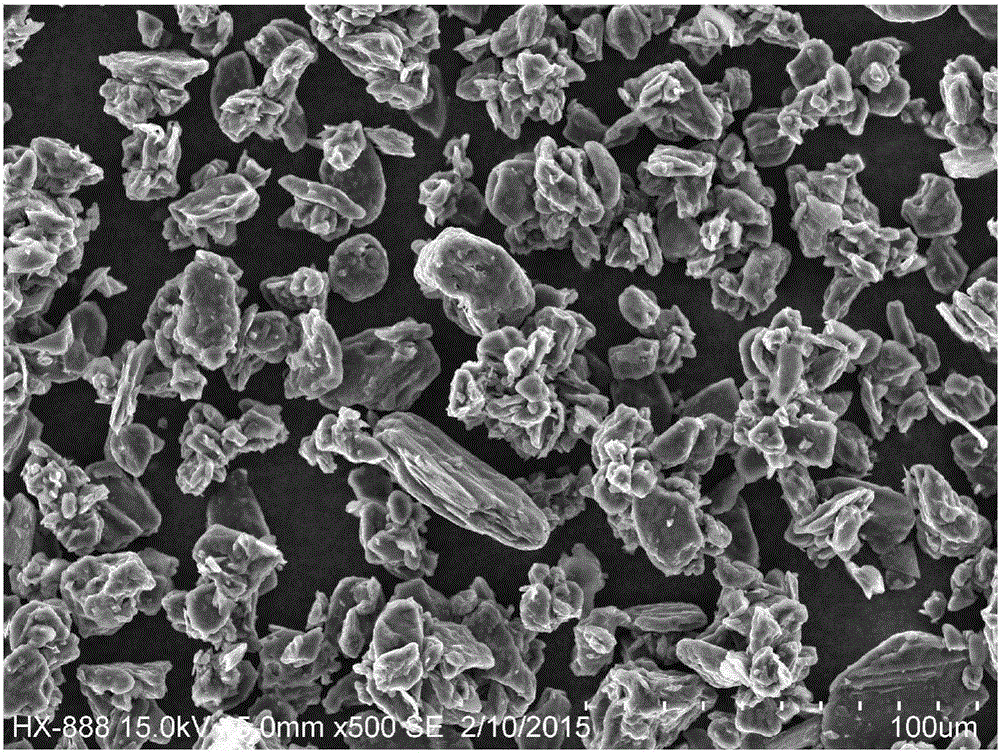

[0037] Select needle coke with D50 of 5 μm, D50 is measured by LS-POP-6 European and American laser particle size analyzer, the asphalt is softened at high temperature, 700g needle coke and 300g asphalt are mixed and stirred evenly in a high-speed mixer, and the stirring speed is 800r / min , the stirring time is 20min, and the stirred mixture is pressed under the pressure of 200MPa in an isostatic press, and the obtained initial compact is fired at 800°C for 15 hours under the protection of a nitrogen atmosphere, and naturally cooled to room temperature after the firing is completed, and then The semi-finished block is crushed and shaped to obtain carbon powder with a D50 of 16.51 μm, and then the carbon powder is graphitized at a high temperature of 3000 ° C, and after natural cooling, iron removal and screening are performed to obtain high-magnification, high-capacity, and high-pressure graphite powder, the resulting graphite powder has no impurities, and the tap density is 1....

Embodiment 2

[0040]Choose needle coke with a D50 of 4 μm. D50 is measured by LS-POP-6 Occidental laser particle size analyzer. The tar is softened at high temperature. Mix 750g of needle coke and 250g of tar in a high-speed mixer and stir evenly at a stirring speed of 500r / min , the stirring time is 30min, and the stirred mixture is pressed under the pressure of 200MPa in an isostatic press, and the obtained initial compact is fired at 1000°C for 10 hours under the protection of a nitrogen atmosphere, and naturally cooled to room temperature after the firing is completed, and then The semi-finished block is crushed and reshaped to obtain carbon powder with a D50 of 17.23 μm, then the carbon powder is graphitized at a high temperature at 2500 ° C, and after natural cooling, iron removal and screening are performed to obtain high-magnification, high-capacity, high-pressure graphite powder, the resulting graphite powder has no impurities, and the tap density is 1.053g / cm 3 , the specific surf...

Embodiment 3

[0043] Select needle coke with a D50 of 6 μm. D50 is measured by LS-POP-6 European and American laser particle size analyzer. The resin is softened at high temperature. Mix 800g needle coke and 200g resin in a high-speed mixer and stir evenly at a stirring speed of 1000r / min , the stirring time is 20min, and the stirred mixture is pressed under the pressure of 100MPa in an isostatic press, and the obtained initial compact is fired at 500°C for 20 hours under the protection of a nitrogen atmosphere, and naturally cooled to room temperature after the firing is completed, and then The semi-finished block is crushed and shaped to obtain carbon powder with a D50 of 14.97 μm, and then the carbon powder is graphitized at a high temperature at 3000 ° C, and after natural cooling, iron removal and screening are performed to obtain high-magnification, high-capacity, and high-pressure graphite powder, the resulting graphite powder has no impurities, and the tap density is 1.107g / cm 3 , t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com