Electrolyte for lithium ion battery and lithium ion battery

A lithium-ion battery and electrolyte technology, which is applied in secondary batteries, electrolyte battery manufacturing, non-aqueous electrolyte batteries, etc., can solve problems such as decomposition, and achieve the effect of good high temperature stability and good battery cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

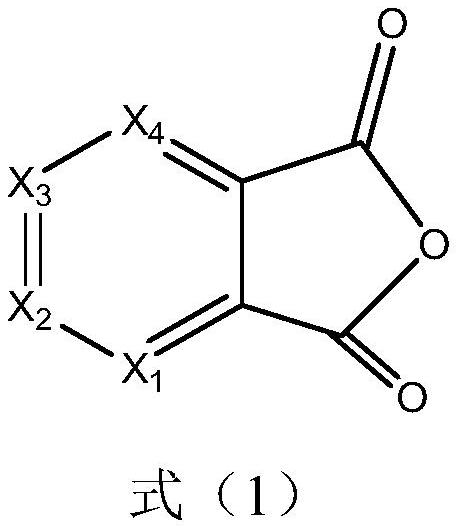

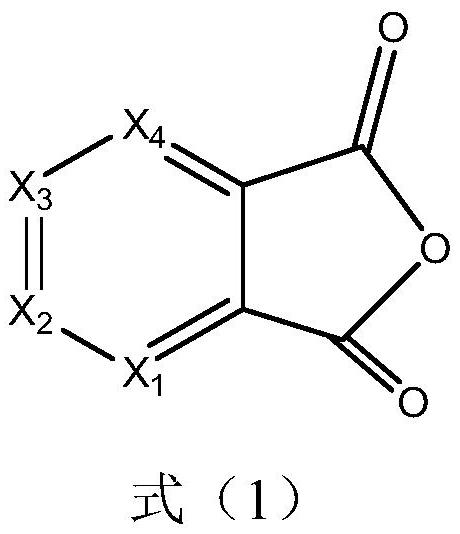

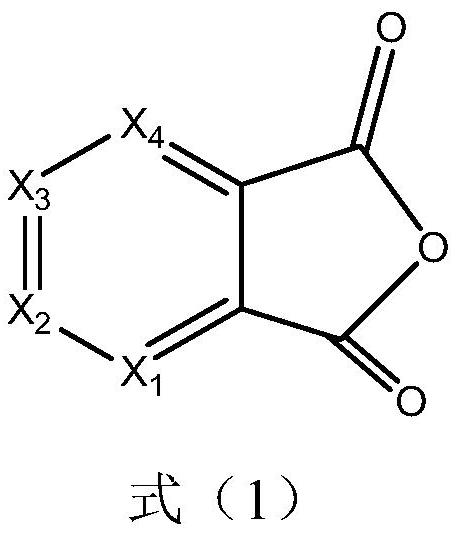

Method used

Image

Examples

Embodiment 1

[0038] (1) Preparation of non-aqueous electrolyte:

[0039] In an argon glove box, 26 parts by weight of ethylene carbonate (EC), 61 parts by weight of diethyl carbonate (DEC), 12 parts by weight of lithium hexafluorophosphate (LiPF 6 ), 0.5 parts by weight of 2,3 pyridinedicarboxylic acid anhydride are mixed uniformly to obtain the lithium-ion battery electrolyte of the present embodiment, which is denoted as C1;

[0040] (2) Preparation of lithium ion battery:

[0041] The positive active material (LiNi 0.5 mn 1.5 o 4 ), acetylene black, and polyvinylidene fluoride are uniformly mixed according to the ratio of 90:5:5, and then pressed on the aluminum foil to obtain the positive electrode sheet; the metal lithium sheet is used as the negative electrode sheet; the PE / PP composite diaphragm is used as the ion exchange membrane. The electrolyte C1 of the example is made into a button battery S1 by a conventional method in the art.

Embodiment 2

[0043] The same steps as in Example 1 were used to prepare the electrolyte and button cells, except that in step (1), 0.5 parts by weight of 2,3 pyridinedicarboxylic anhydride was replaced by 1 part by weight of 3,4 pyridinedicarboxylate Acid anhydride, the non-aqueous electrolyte solution C2 of the lithium ion battery and the button battery S2 are prepared.

Embodiment 3

[0045] Adopt the same steps as in Example 1 to prepare non-aqueous electrolyte and button cell, the difference is that in step (1), 0.5 parts by weight of 2,3 pyridine dicarboxylic anhydride is replaced by 3 parts by weight of 2,3 pyridine Oxine dicarboxylic anhydride, obtain lithium ion battery non-aqueous electrolyte solution C3 and button battery S3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com