High-temperature-resistant shield tail sealing grease and preparation method thereof

A shield tail sealing and high temperature resistant technology, applied in the engineering field, can solve problems such as safety production accidents, increase construction costs, affect construction period, etc., and achieve the effects of good water pressure resistance, high pumpability, and good peristalsis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

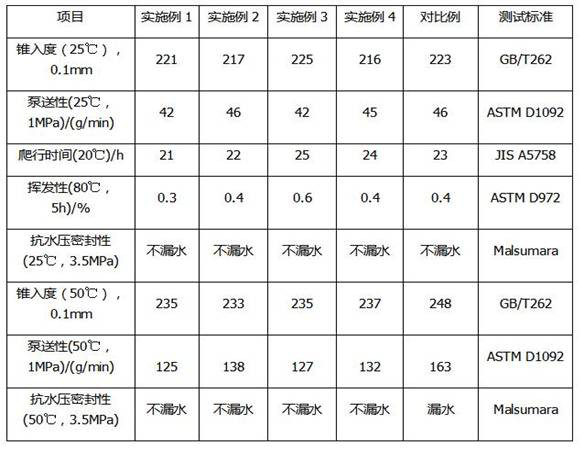

Examples

Embodiment 1

[0009] The mass fraction is 12% base oil, 8% high temperature stabilizer, 22% tackifier, 1% emulsifier, 0.5% preservative, 2.5% water absorbing material, 50% powder filler, 4% The structure forming agent is kneaded uniformly.

[0010] The base oil is 150SN mineral oil; the high temperature stabilizer is polyurea grease; the tackifier is a mixture of polyisobutylene and hydrogenated styrene diene copolymer in a mass ratio of 1:1; the emulsifier is sorbitan monooleate ; The preservative is sodium benzoate; the water-absorbing material is sodium bentonite; the powdery filler is barite; the structural forming agent is cotton fiber, and the length is 0.5-3.5mm.

Embodiment 2

[0012] The mass fraction is 14% base oil, 5% high temperature stabilizer, 21.5% tackifier, 1.5% emulsifier, 0.5% preservative, 3% water absorbing material, 50% powder filler, 4.5% The structure forming agent is kneaded uniformly.

[0013] The base oil is No. 68 naphthenic oil, the high temperature stabilizer is polyurea grease, the tackifier is polyisobutylene; the emulsifier is sorbitan dioleate; the preservative is tert-butyl-p-hydroxyanisole; The water-absorbing material is sodium bentonite; the powdery filler is calcium carbonate; the structural forming agent is cotton fiber, and the length is 0.5-3.5mm.

Embodiment 3

[0015] The mass fraction is 15% base oil, 10% high temperature stabilizer, 15.5% tackifier, 1% emulsifier, 1% preservative, 3.5% water absorbing material, 50% powder filler, 4% The structure forming agent is kneaded uniformly.

[0016] The base oil is 400SN mineral oil; the high temperature stabilizer is polyurea grease; the tackifier is a mixture of polyisobutylene and ethylene propylene copolymer in a mass ratio of 1:2; the emulsifier is sorbitan monooleate; preservative It is tert-butyl-p-hydroxyanisole; the water-absorbing material is polyacrylamide; the powdery filler is calcium carbonate and barite in a mass ratio of 5:1; the structural molding agent is bamboo fiber, with a length of 0.5-3.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com