Transition metal element-doped bismuth calcium niobate ceramic material and preparation method thereof

A transition metal element, bismuth-calcium niobate technology, applied in the field of lead-free piezoelectric materials, can solve the problems of unsuitability for large-scale industrial production, poor piezoelectric performance of bismuth-calcium niobate ceramics, and high cost of plasma sintering. The effect of advancing application progress, improving piezoelectric performance, and good high-temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

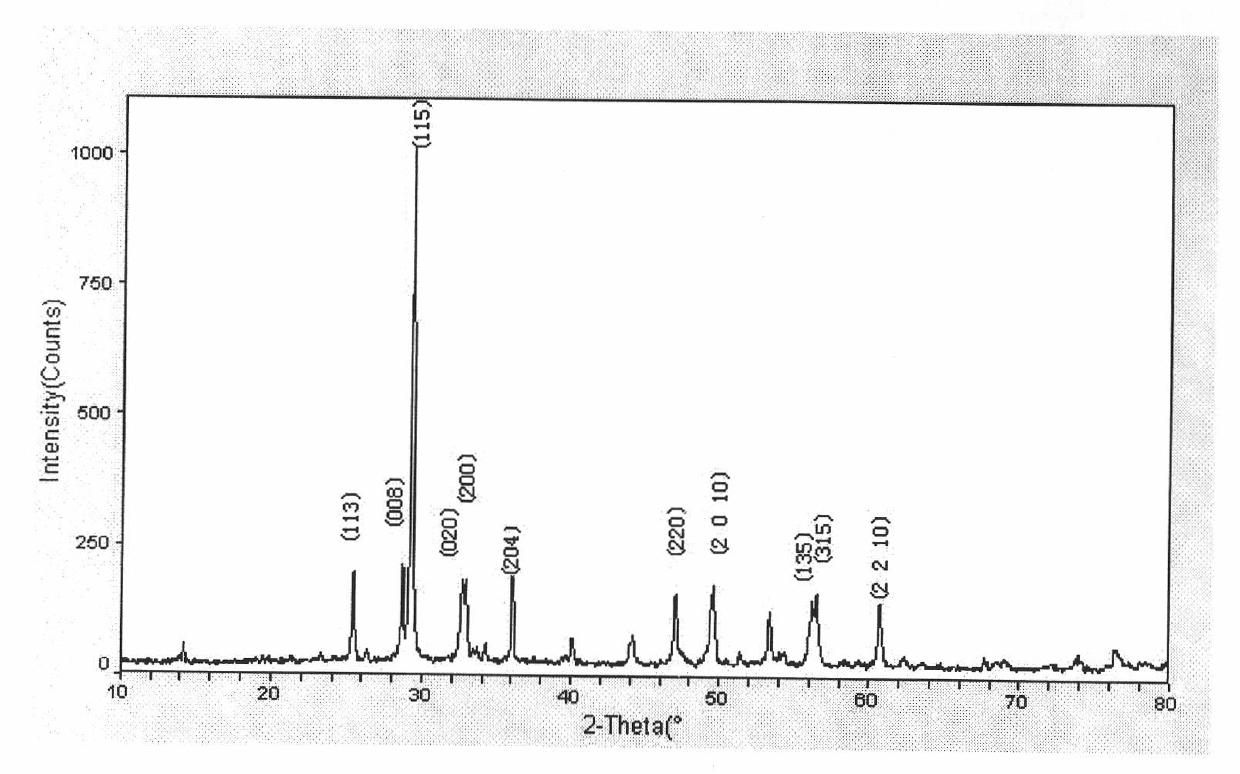

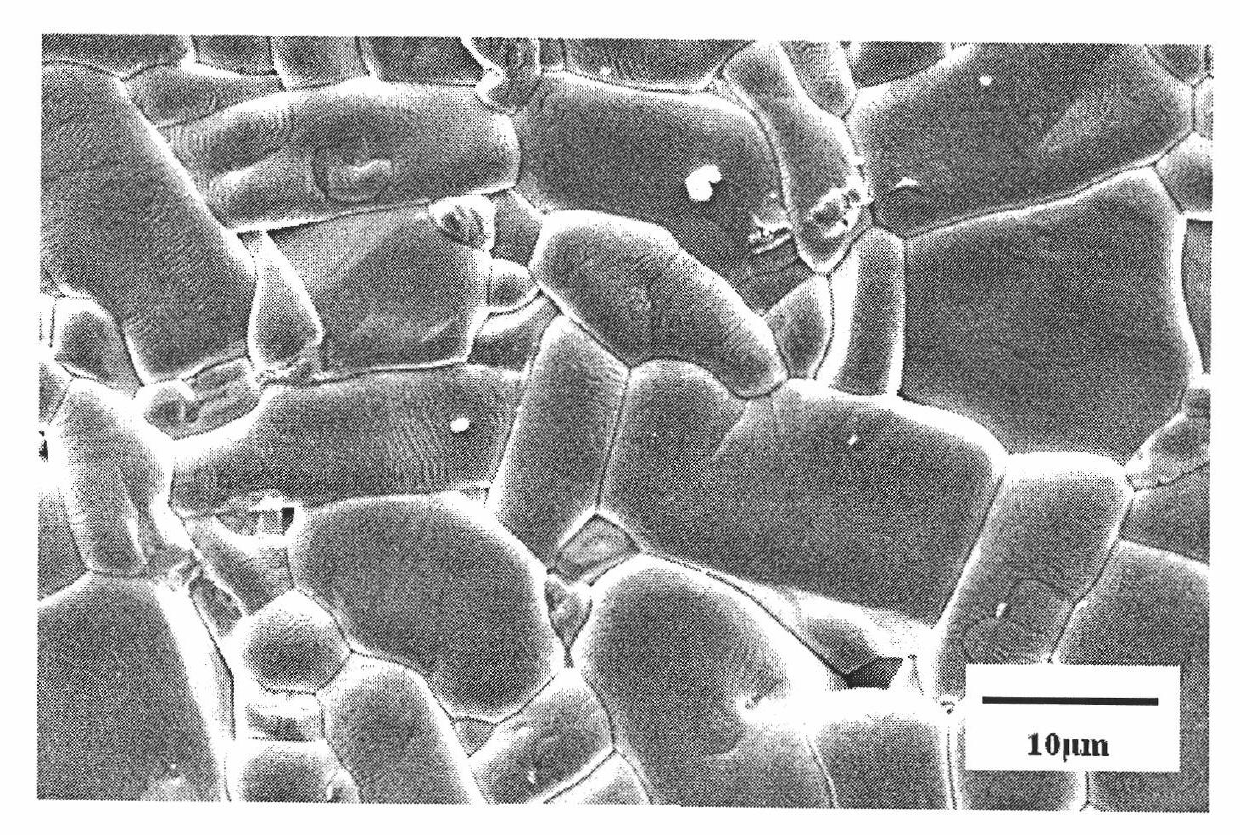

[0033] The preparation conforms to the general chemical formula Ca 1-x Fe x Bi 2 Nb 2 o 9 , and Fe-doped calcium bismuth niobate ceramics when x=0.05.

[0034] The analytically pure powder raw material: 0.100g Fe 2 o 3 , 2.377 g CaCO 3 , 11.882gBi 2 o 3 and 6.645gNb2 o 5 According to the ordinary ceramic preparation process, the ingredients are mixed, and then the raw materials are mixed with alcohol, ball milled for 24 hours, pre-fired at 900 ° C for 2 hours, secondary ball milled for 24 hours, dried, ground in a mortar, pressed into tablets, plastic ejected at 550 ° C, After sintering at 1200°C for 4 hours, Fe-doped bismuth calcium bismuth niobate layered structure lead-free piezoelectric ceramic material was obtained. Grind the obtained ceramic sample to a thin slice with a thickness of 0.4mm, and cover the upper and lower surfaces of the thin slice with Pt electrodes, and polarize it in 200°C silicone oil at a voltage of 10KV / mm-20KY / mm for 10 minutes to test its...

Embodiment 2

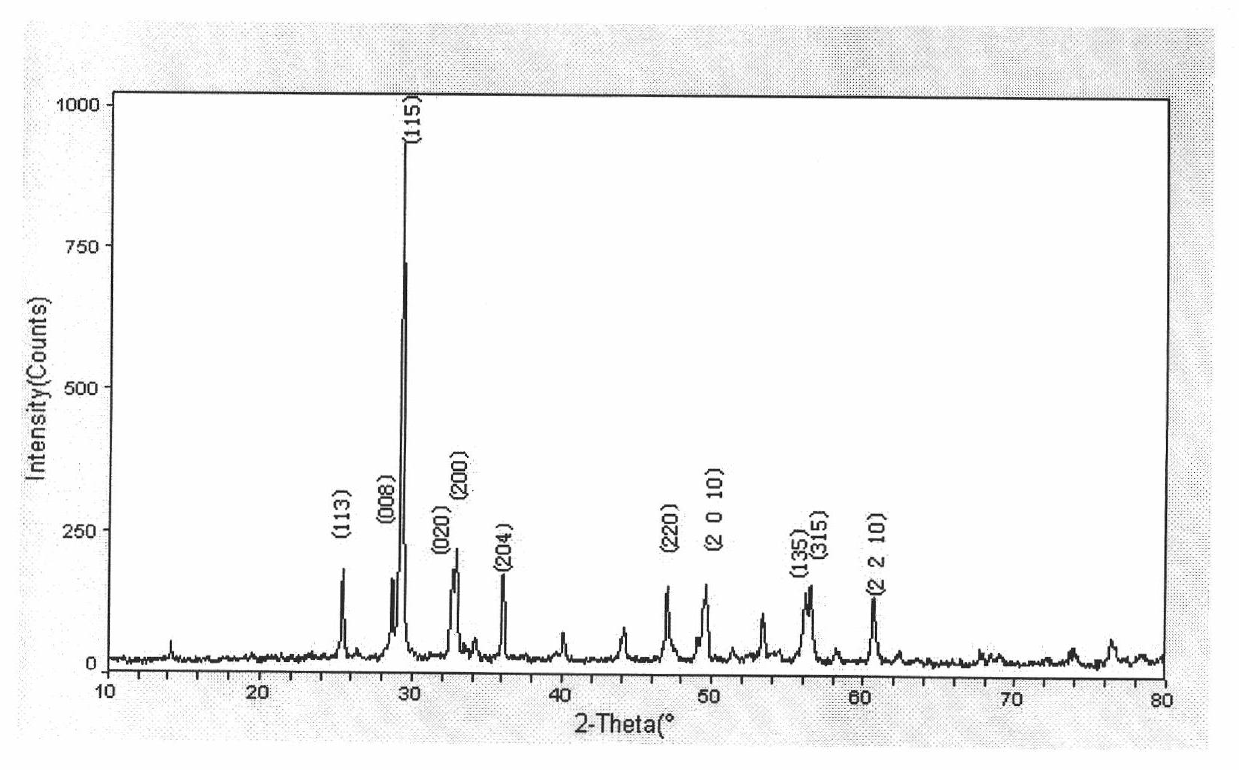

[0038] The preparation conforms to the general chemical formula Ga 1-x mn x Bi 2 Nb 2 o 9 , and Mn-doped calcium bismuth niobate ceramics when x=0.05.

[0039] The analytically pure powder raw material: 0.144g MnCO 3 , 2.377 g CaCO 3 , 11.882gBi 2 o 3 and 6.645gNb 2 o 5 According to the ordinary ceramic preparation process, the ingredients are mixed, and then the raw materials are mixed with alcohol, ball milled for 24 hours, pre-fired at 900 ° C for 2 hours, secondary ball milled for 24 hours, dried, ground in a mortar, pressed into tablets, plastic ejected at 550 ° C, After sintering at 1200°C for 4 hours, the Mn-doped bismuth calcium bismuth niobate layered structure lead-free piezoelectric ceramic material was obtained. Grind the obtained ceramic sample into a thin slice with a thickness of 0.4mm, and cover the upper and lower surfaces of the thin slice with Pt electrodes, and polarize it in 200°C silicone oil at a voltage of 10KV / mm-20KV / mm for 10 minutes to tes...

Embodiment 3

[0043] The preparation conforms to the general chemical formula Ca 1-x co x Bi 2 Nb 2 o 9 , and Co-doped calcium bismuth niobate ceramics when x=0.05.

[0044] Analytical pure powder raw material: 0.104g Co 2 o 3 , 2.377 g CaCO 3 , 11.882gBi 2 o 3 and 6.645gNb 2 o 5 According to the ordinary ceramic preparation process, the ingredients are mixed, and then the raw materials are mixed with alcohol, ball milled for 24 hours, pre-fired at 900 ° C for 2 hours, secondary ball milled for 24 hours, dried, ground in a mortar, pressed into tablets, plastic ejected at 550 ° C, After sintering at 1200°C for 4 hours, a Co-doped bismuth calcium bismuth niobate layered structure lead-free piezoelectric ceramic material was obtained. Grind the obtained ceramic sample into a thin slice with a thickness of 0.4mm, and cover the upper and lower surfaces of the thin slice with Pt electrodes, and polarize it in 200°C silicone oil at a voltage of 10KV / mm-20KV / mm for 10 minutes to test its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com