Patents

Literature

48results about How to "Extend high temperature service life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultralow-expansion coefficient high transparent glass-ceramics and method for producing its product

The present invention relates to a Li2O-Al2O3-SiO2 system ultra-low expansion coefficient high-transparency glass-ceramic and production method of the products. Calculated by weight percentage, the ultra-low expansion coefficient high-transparency glass-ceramic is composed of 3.2 to 4.6 percent of Li2O, 18.0 to 23.6 percent of Al2O3, 64.1 to 69.4 percent of SiO2, 0.3 to 0.8 percent of MgO, 0.8 to 2.5 percent of BaO, 0.3 to 0.8 percent of R2O, 0.01 to 0.4 percent of Y2O3, 1.8 to 2.5 percent of TiO2, 1.6 to 2.4 percent of ZrO2, 1.1 to 1.8 percent of P2O5, 0.6 to 1.5 percent of Sb2O3, 0.3 to 1.0 percent of NaCl and 1.0 to 2.0 percent of NH4NO3. The heat-resistant glass plates and heat-resistant glass products can be manufactured by using the formula and the corresponding forming die. The present invention has the advantages that the production technique is simple, the produced products have low expansion coefficient, good transparency, high thermal impact temperature, high strength, have constant transparency when being used under the temperature of 700 Celsius system for a long time, the products have long service life, etc.

Owner:广东科迪微晶玻璃实业有限公司 +1

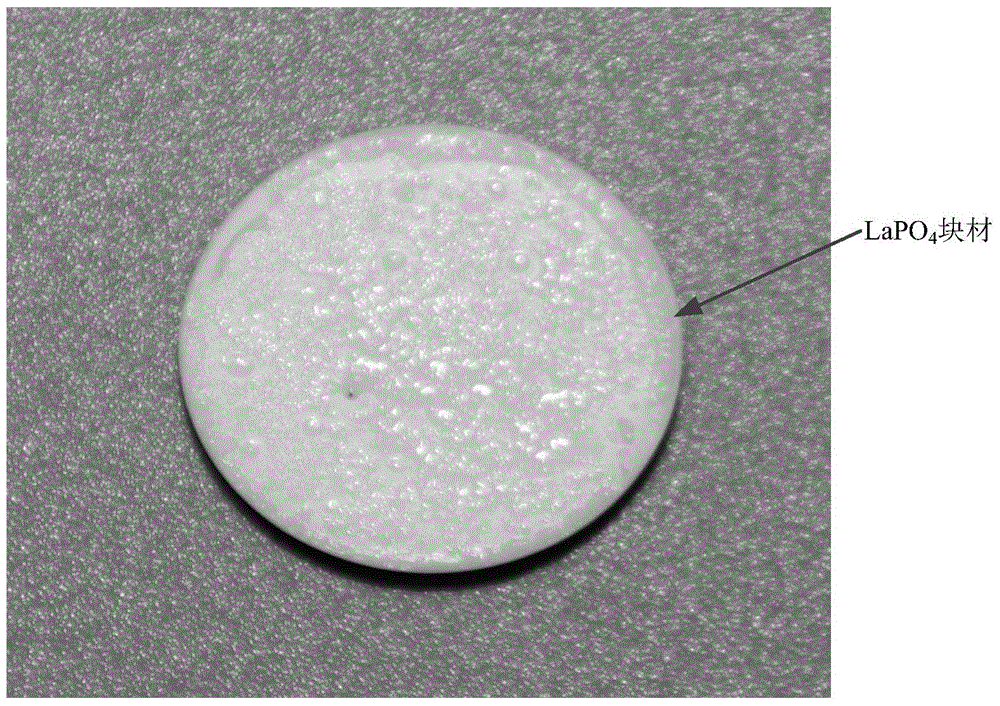

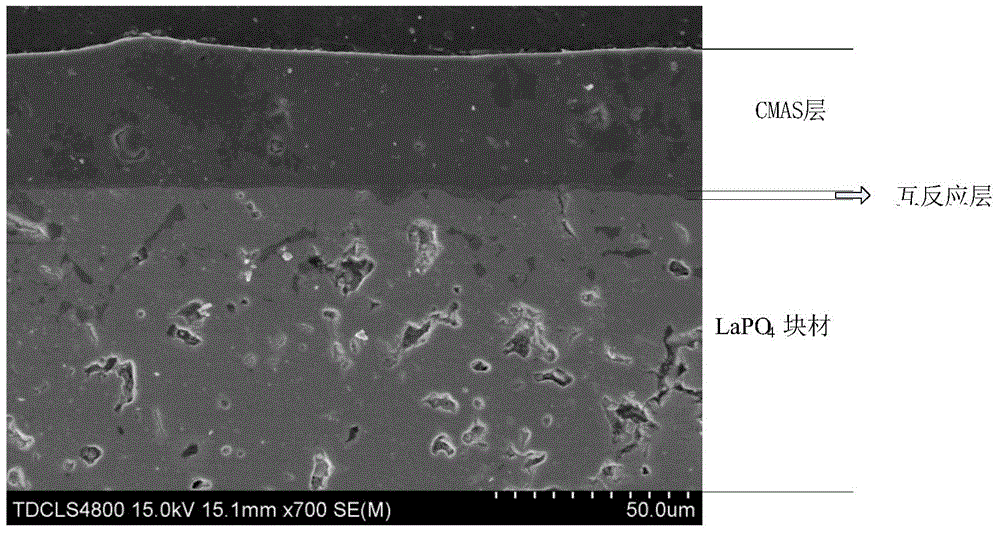

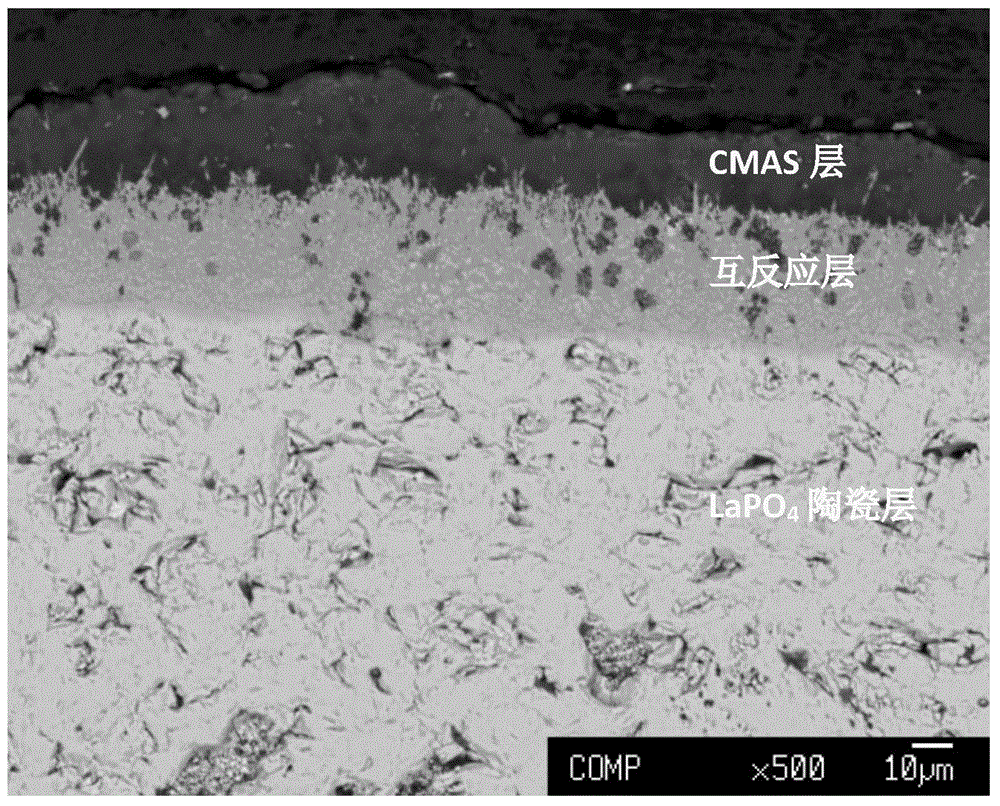

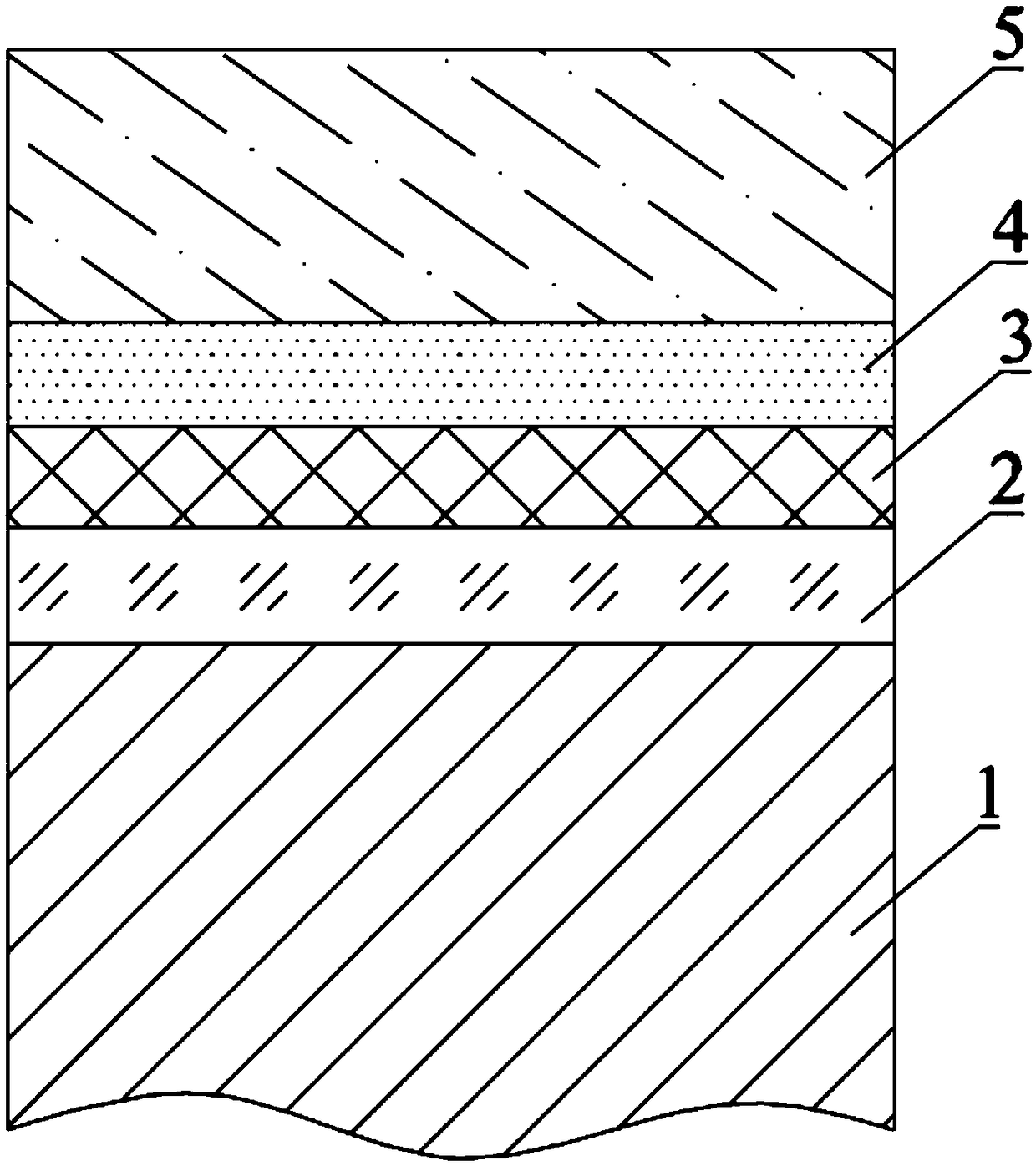

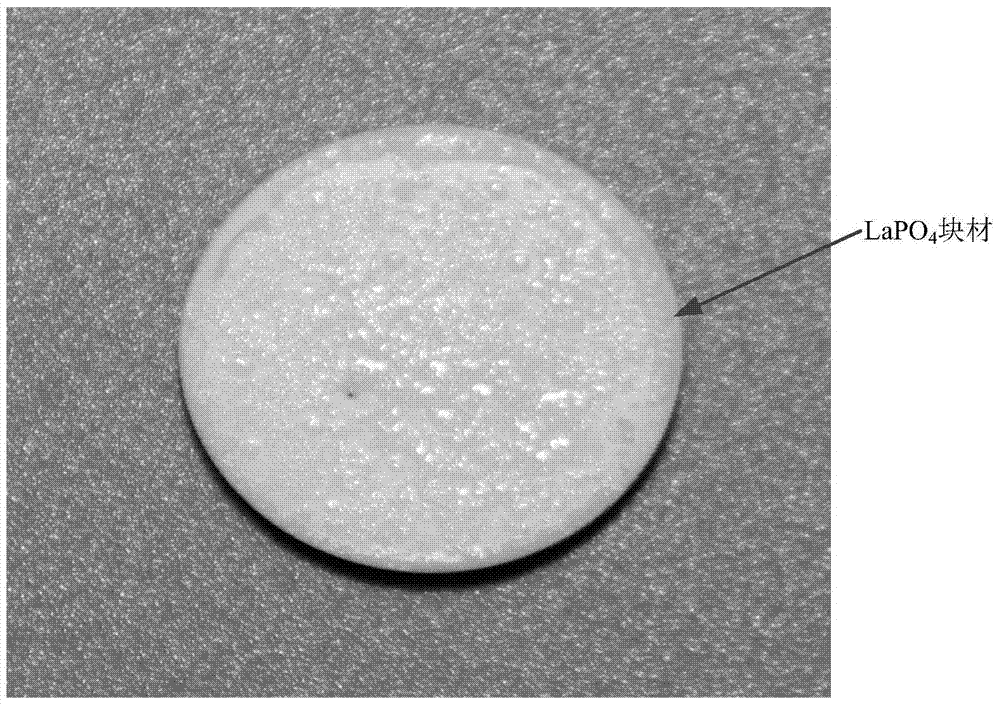

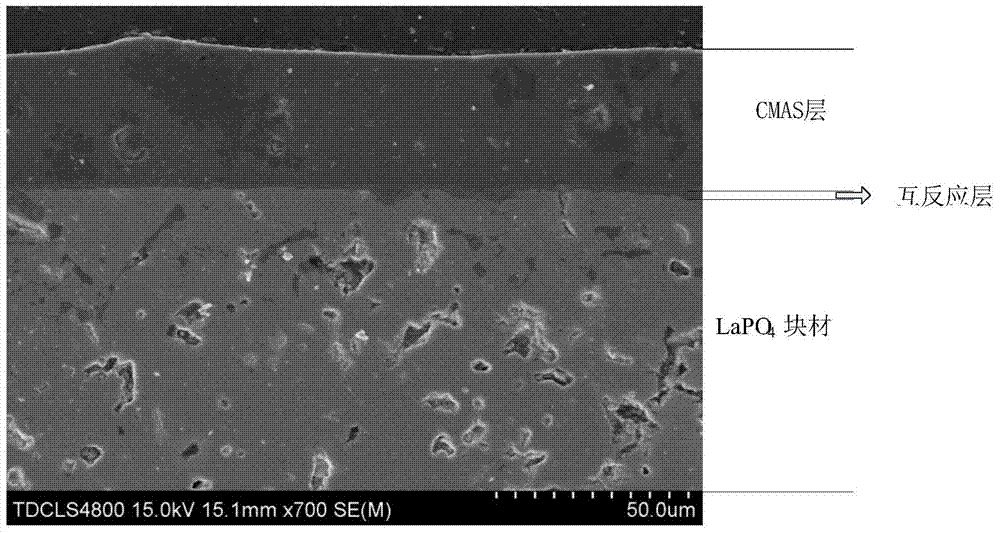

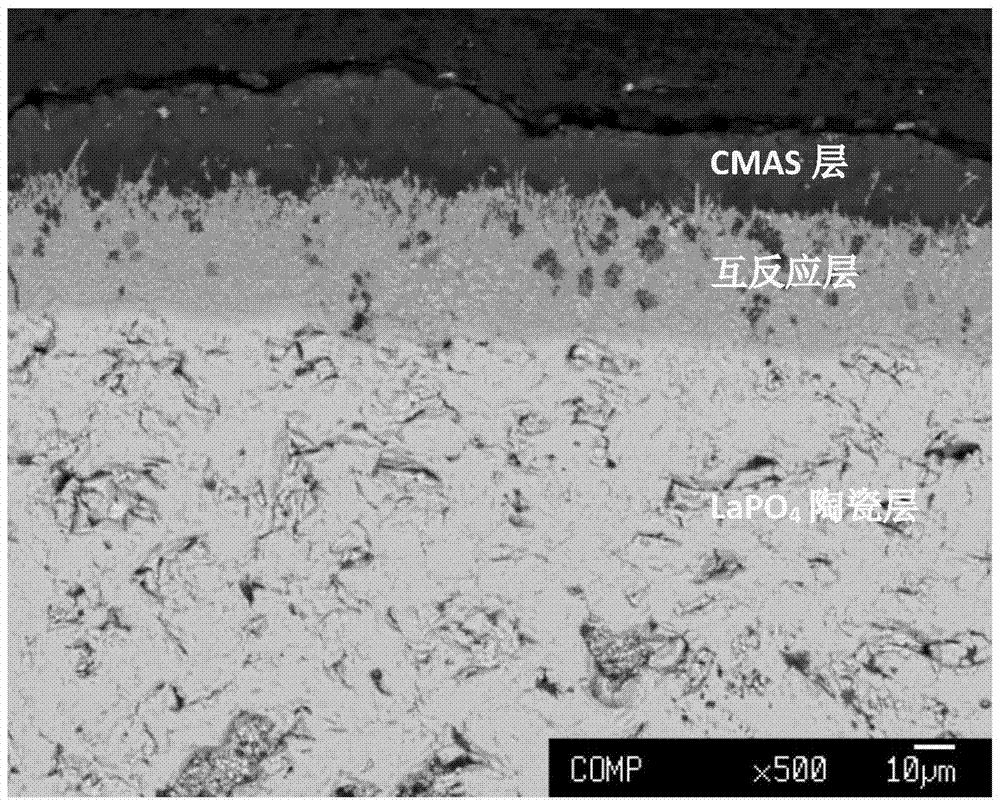

CMAS-resisting ceramic layer and slurry method for preparing CMAS-resisting ceramic layer

ActiveCN105039894APrevent infiltrationMaintain phase stabilityMolten spray coatingReaction layerSlurry

The invention discloses a CMAS-resisting ceramic layer and a slurry method for preparing the CMAS-resisting ceramic layer, and belongs to the field of thermal barrier coating materials and preparation for the same. The CMAS-resisting ceramic layer is a LaPO4 ceramic layer. The slurry method is used for preparing the LaPO4 ceramic layer on a YSZ ceramic layer, and the wettability of the LaPO4 ceramic layer to molten CMAS is poor; after thermal treatment of 1250 DEG C is carried out, a mutual reaction layer is formed on the interface between the LaPO4 ceramic layer and the CMAS, so that further permeation of the molten CMAS is effectively prevented, and the original phase stability of the YSZ ceramic layer is maintained. Accordingly, the prepared LaPO4 ceramic layer can prevent permeation of the molten CMAS, has superior CMAS corrosion resistance and obviously prolongs the service life of a thermal barrier coating under the CMAS coupling effect.

Owner:BEIHANG UNIV

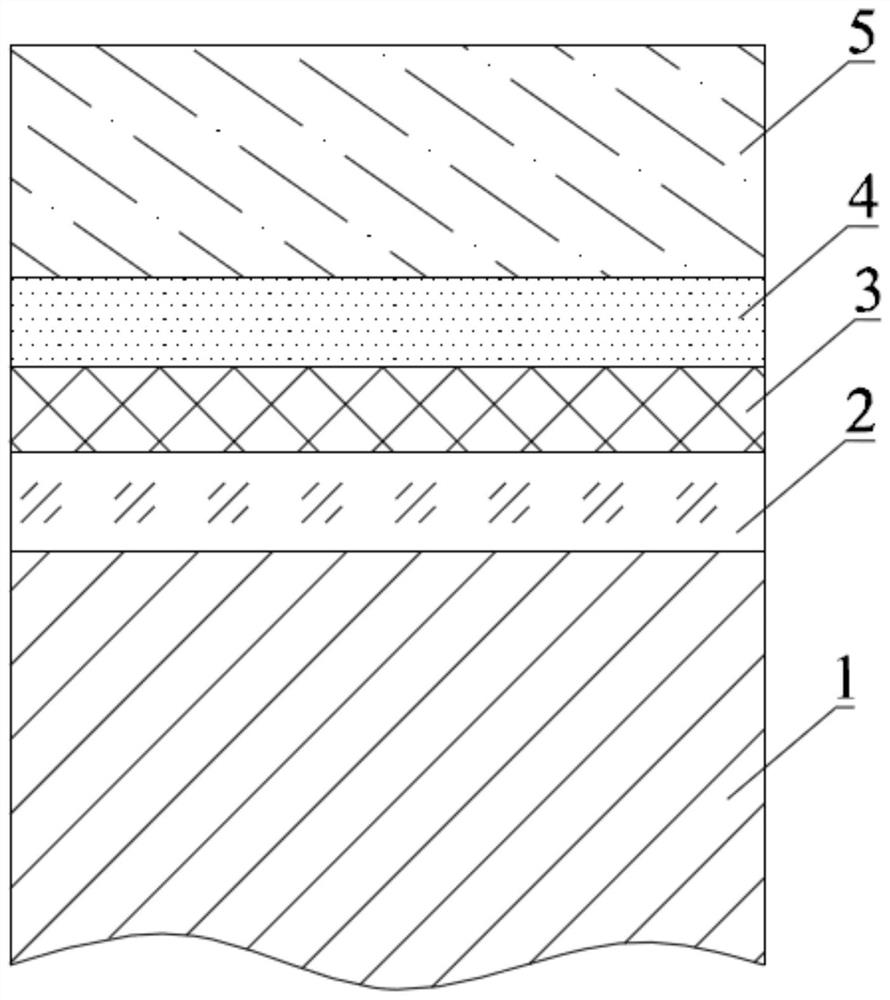

Thermal/environment barrier coating based on ceramic composite material and preparation method of thermal/environment barrier coating

ActiveCN109336647AGive full play to the high temperature water vapor corrosion resistanceHigh temperature water vapor corrosion resistance performance guaranteeCeramic compositeThermal insulation

The invention relates to a thermal / environment barrier coating based on a ceramic composite material and a preparation method of the thermal / environment barrier coating. The thermal / environment barrier coating comprises a silicon layer, a ytterbium silicate layer, a transition layer and a hafnium oxide layer in sequence from inside to outside, wherein the transition layer is made by mixing hafniumoxide and ytterbium silicate. The preparation method comprises the following steps: respectively loading silicon powder, ytterbium silicate powder and hafnium oxide powder into a powder conveyer of low-pressure plasma spraying equipment, and carrying out drying treatment; immobilizing a ceramic composite material on a rotating platform in a vacuum chamber of the low-pressure plasma spraying equipment; preparing the silicon layer, the ytterbium silicate layer, the transition layer and the hafnium oxide layer in sequence on the surface of the ceramic composite material by using a low-pressure plasma spraying method to obtain the thermal / environment barrier coating on the surface of the ceramic composite material. The thermal / environment barrier coating provided by the invention is good in thermal insulation effect and excellent in high-temperature moisture corrosion resistance, and the preparation method provided by the invention has the advantages of being high in deposition efficiency, low in cost, uniform in coating and the like, and the thermal / environment barrier coating can be rapidly and integrally prepared.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Heat treatment method for high-temperature alloy steel

The invention belongs to the technical field of alloy steel and particularly relates to a heat treatment method for high-temperature alloy steel. The heat treatment method comprises the steps of a, a high-temperature diffusion annealing process, wherein a high-temperature alloy steel ingot is heated for 22-26 h at the temperature of 1,150 plus or minus 10 DEG C, then heating is conducted for 70-74 h at the temperature of 1,190 plus or minus 10 DEG C, and then air cooling is conducted; b, pretreatment after forging, wherein the heating temperature is 950 plus or minus 10 DEG C, the temperature is kept for 0.5-1.5 h, and then air cooling is conducted; c, high-temperature solid solution treatment, wherein the heating temperature is 910 plus or minus 10 DEG C, the temperature is kept for 18-24 h, and then air cooling is conducted; and reheating is conducted, the heating temperature is 960 plus or minus 10 DEG C, the temperature is kept for 1-2 h, and air cooling is conducted; and d, low-temperature aging treatment, wherein the heating temperature is 710 plus or minus 10 DEG C, the temperature is kept for 7-10 h, then the temperature is decreased to 610 plus or minus 10 DEG C at the speed of 50-60 DEG C / h with furnace cooling, then the temperature is kept for 7-10 h, air cooling is conducted, and a forging is obtained. By the adoption of the heat treatment method for the GH4169 high-temperature alloy steel, the heating pretreatment after forging, high-temperature solid solution treatment and low-temperature aging treatment thermal treatment process system is adopted, the high-temperature plasticity is good and the creep resistance life is long.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

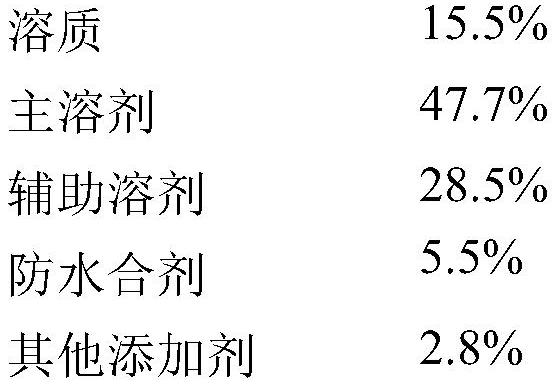

Heat treatment process improving hot hardness and high temperature abrasion resisting performance of hot mold steel

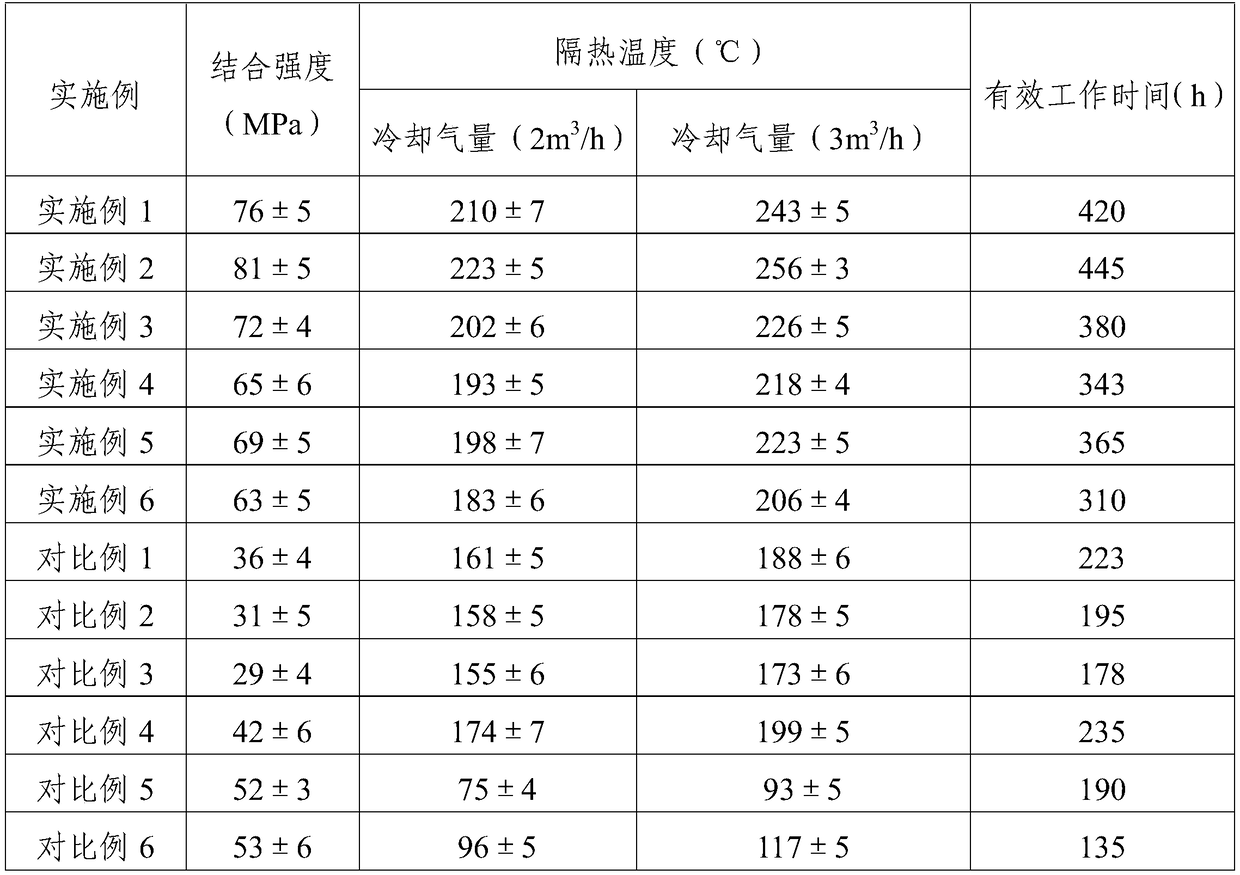

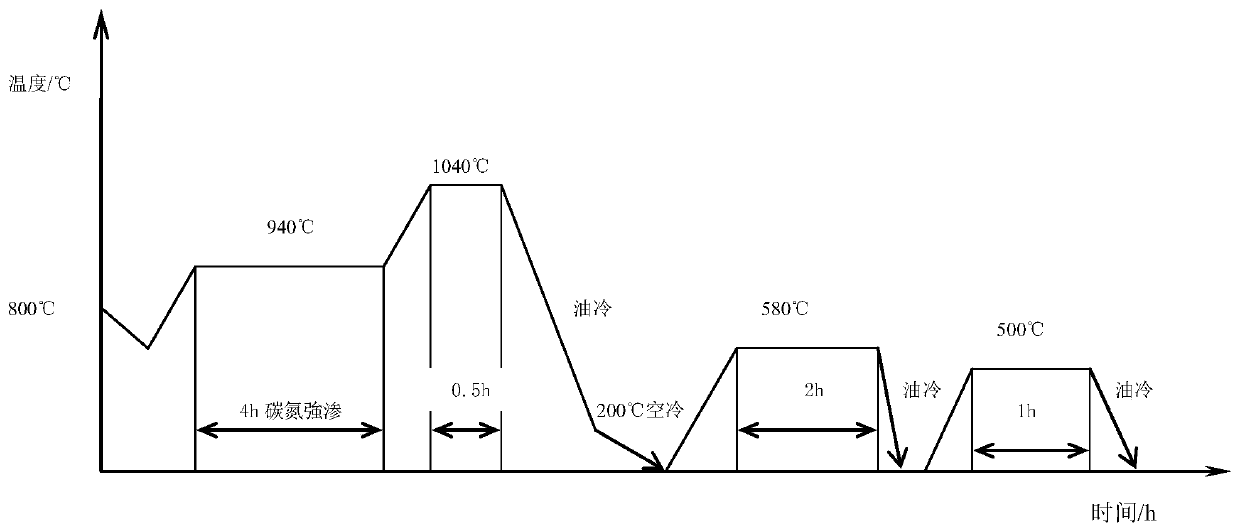

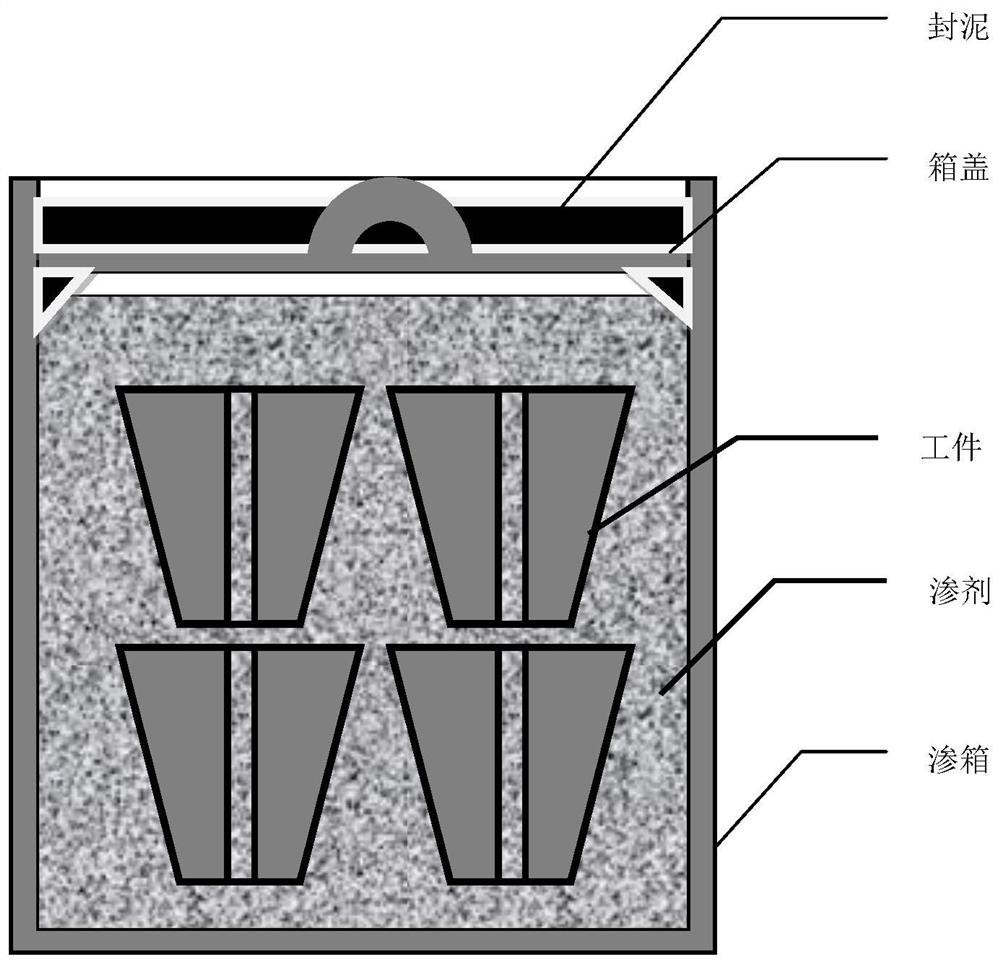

ActiveCN110565048AExtend high temperature service lifeSimple methodSolid state diffusion coatingHigh-temperature corrosionHeat treated

The invention provides a heat treatment process improving the hot hardness and the high temperature abrasion resisting performance of hot mold steel. Charcoal, urea particles, sodium carbonate powderand chromic anhydride are mixed to obtain a carbon-nitrogen strong permeating mixture; a hot mold steel workpiece and the carbon-nitrogen strong permeating mixture are installed in a permeating box atthe same time, and a box cover of the permeating box is sealed; the permeating box is placed into a crucible type electric furnace to be subjected to constant temperature carbon-nitrogen strong permeating at 850-950 DEG C; after quenching treatment, the hot mold steel workpiece is directly immersed into quenching oil to be cooled; and after air cooling, placing into a box type intermediate temperature tempering furnace for tempering twice is performed, and the hot mold steel workpiece high in hot hardness and high in high temperature abrasion resisting performance is obtained. The heat treatment process has the advantages of being easy and convenient to operate, low in cost and obvious in effect, the surface hardness of the obtained hot mold steel can reach 62 HRC or above, the high temperature abrasion resisting performance under the temperature of 600 DEG C exceeds that of a same hot mold steel conventional heat treatment piece twice or above, and the service life of a hot working mold can be effectively prolonged.

Owner:锦州捷通铁路机械股份有限公司

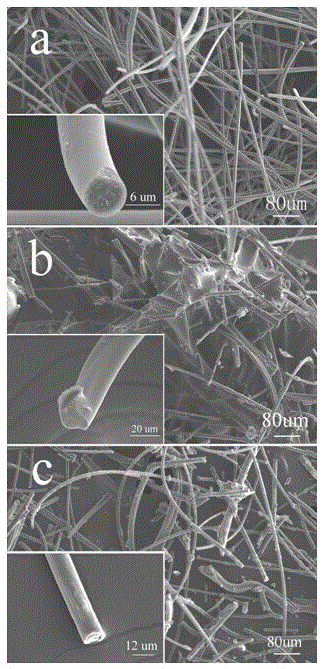

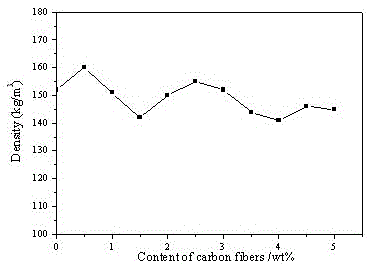

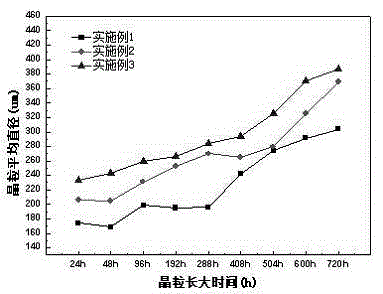

Porous mullite fiber product

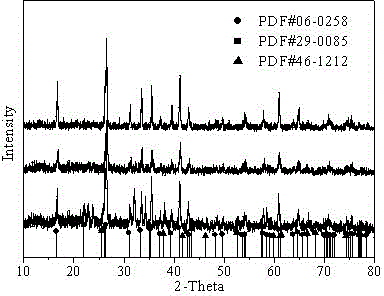

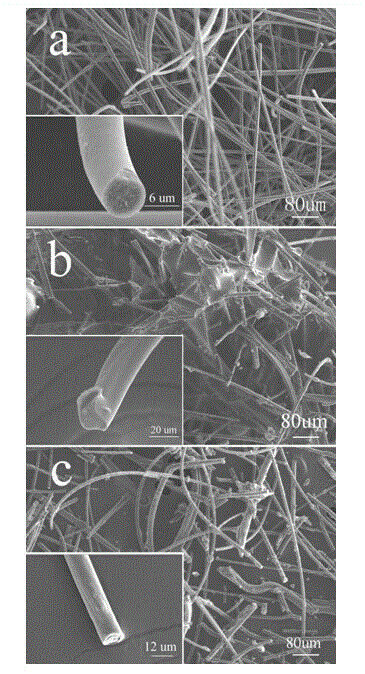

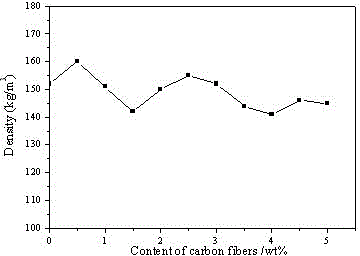

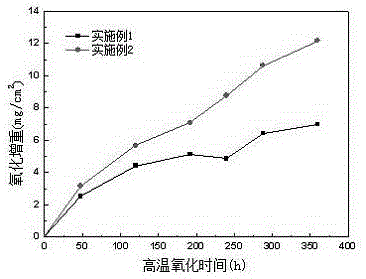

ActiveCN104131363AImprove toughnessIncrease the lengthInorganic material artificial filamentsArtificial filament chemical after-treatmentFiberChemical composition

The invention belongs to the technical field of refractory material, and in particular relates to a porous mullite fiber product. The fiber product comprises the following components according to weight percentage: 85wt%-95wt% of modified mullite fiber, 1wt%-5wt% modified carbon fiber, 0.1wt%-1wt% of calcined alumina powder, 0.5wt%-2wt% silica sol, 0.2wt%-1.2wt% of sodium hypochlorite, 0.7wt%-1.3wt% of starch, and 0.5wt%-1.5wt% of an additive; the mullite fiber comprises the following chemical components: 50wt%<= Al2O3<= 70wt%, 25wt%<= SiO2<= 28wt%, and oily substances > 2wt%. The invention can prolong the service life of the mullite fiber porous product, and enhance the thermal insulation effect.

Owner:HUZHOU TEACHERS COLLEGE

Electric heating alloy material with excellent high-temperature oxidation resistance and preparing method for material

ActiveCN105154776AImprove embrittlement abilityOvercome high temperature embrittlementHeat resistanceHigh-temperature corrosion

The invention discloses an electric heating alloy material with excellent high-temperature oxidation resistance and a preparing method for the material. The electric heating alloy material comprises, by mass percent, not larger than 0.06% of C, 19.5% to 23.5% of Cr, 5.5% to 6.5% of Al, not larger than 0.03% of N, not larger than 0.5% of Si, not larger than 0.5% of Mn, not larger than 0.03% of P, not larger than 0.03% of S, 0.5% to 2.5% of Co, 0.1% to 1.0% of Nb, 0.1% to 0.25% of Zr, 0.02% to 0.2% of Y and the balance Fe and inevitable impurities. A vacuum induction smelting technology is adopted, casting moulding is achieved after smelting, and the material is finally prepared through hot forging, hot rolling, recrystallizing heat treatment, cold rolling and cold drawing. The electric heating alloy material overcomes high-temperature embrittlement of an existing Fe-Cr-Al alloy and improves oxidation resistance, heat resistance of the material is improved, the high-temperature oxidation resistance is enhanced, and the excellent comprehensive performance of the material is achieved.

Owner:江苏金达电热电器有限公司

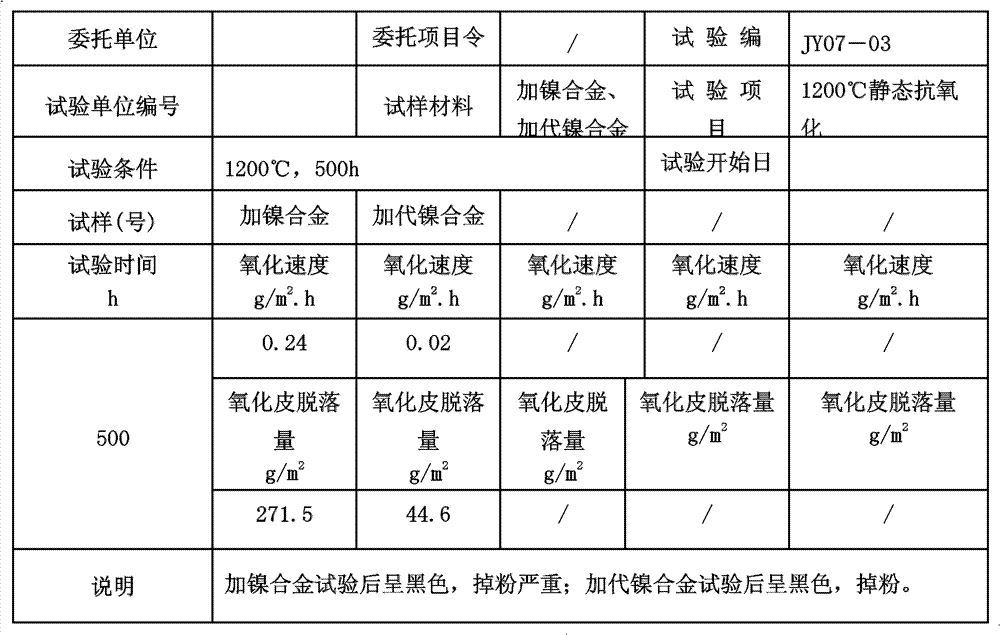

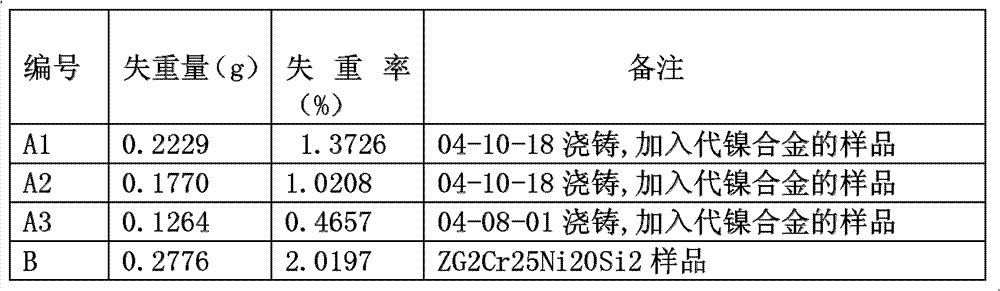

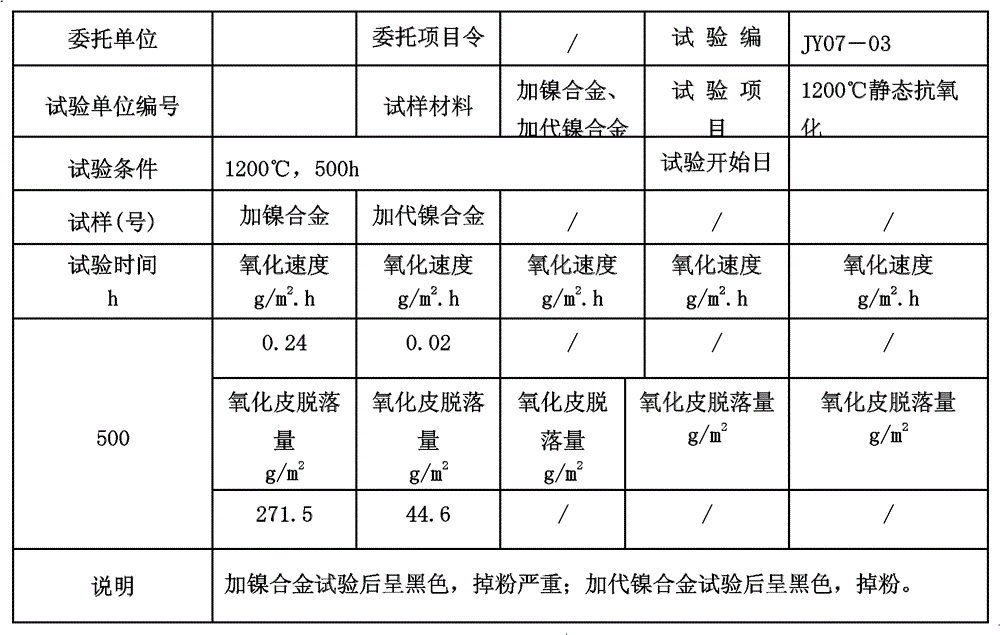

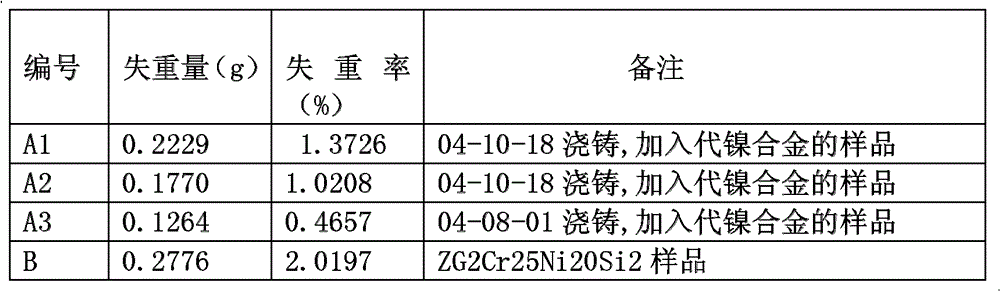

High temperature resistant alloy and its preparation method

The invention relates to a high temperature resistant alloy and its preparation method, and concretely relates to a high temperature resistant alloy containing zero or less nickel. A nanometer ceramic composite nickel substitute alloy (nickel substitute alloy D for short) is adopted to replace isometric nickel generally used in high temperature alloys to make the alloys have a good casting performance, good mechanical performances in a casting state and a good weldability. The high temperature resistant alloy which is a steel has oxidation, carburizing and sulfuration resistances at a high temperature of 1250-1350DEG C; and compared with traditional high temperature alloys (such as ZG2Cr25Ni20Si2), the high temperature resistant alloy provided by the invention has the advantages of above 20% tensile strength increase, above 40% service life prolongation, and 30% cost reduction. The high temperature resistant alloy has a high high-temperature strength, can be widely applied to structural parts having high temperature resistance requirements, comprising heat treatment bed plates, bottom rollers, quenching normalising trays, material frames, power plant boiler high temperature burners, combustors, ash falling tubes, steel factory steel rolling rollers, guide rollers, magnesium melting reduction tanks and the like, and has the characteristics of great cost reduction and service life prolongation on the premise that use requirements are satisfied.

Owner:辽宁瑞朗纳米新材料有限公司

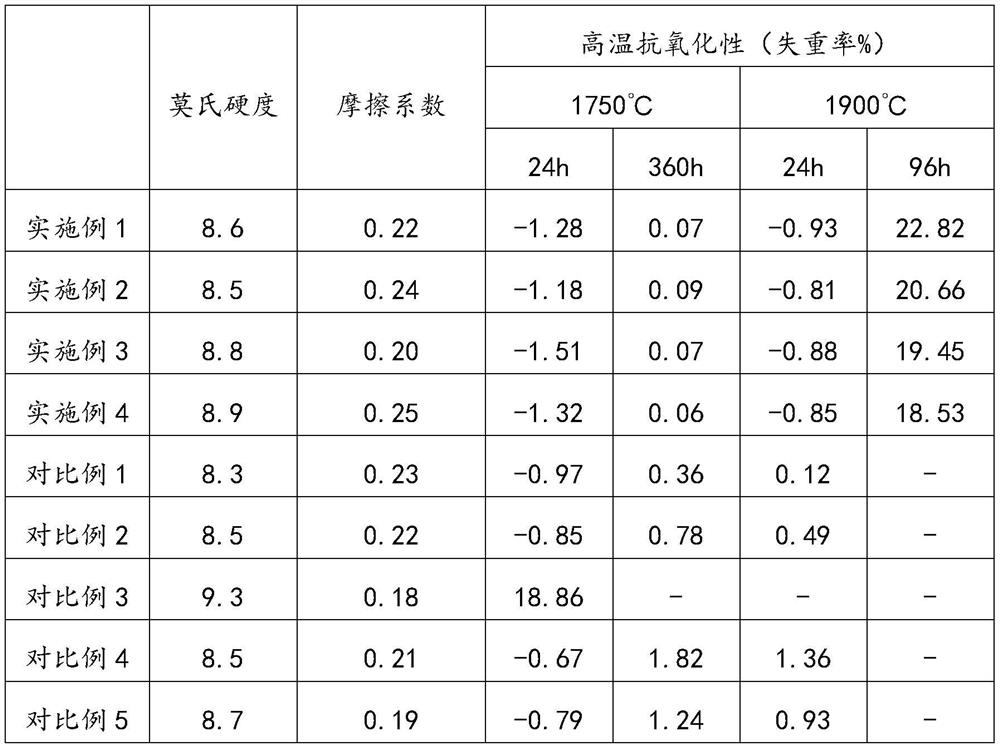

High-performance carbon-carbon crucible surface coating and preparation method thereof

ActiveCN113773119AImprove high temperature oxidation resistanceImprove wear resistanceThermal dilatationOxidation resistant

The invention discloses a high-performance carbon-carbon crucible surface coating and a preparation method thereof, and relates to the technical field of carbon-based composite materials. The invention discloses a high-performance carbon-carbon crucible surface coating. The coating is mainly characterized in that a SiC transition layer and a LaB6 / Y3Al5O12 outer coating are sequentially deposited on a substrate of a carbon-carbon crucible, the SiC transition layer is deposited by adopting a multi-time embedding method, and the LaB6 / Y3Al5O12 outer coating is formed by coating by adopting a slurry method; and the SiC transition layer is formed by dipping treatment of an organic silicon impregnant and then brushing of outer coating slurry. The invention further discloses a preparation method of the carbon-carbon crucible surface coating. The carbon-carbon crucible surface coating provided by the invention has excellent high-temperature strength, high-temperature toughness and high wear resistance, is good in thermal shock resistance and chemical stability, and has relatively high thermal expansion compatibility with a carbon-carbon matrix, so that the service life of the carbon-carbon crucible is remarkably prolonged, the damage resistance degree of the carbon-carbon crucible is remarkably improved, and the carbon-carbon crucible can be used for resisting oxidation for a long time at 1,750 DEG C.

Owner:醴陵市东方电瓷电器有限公司

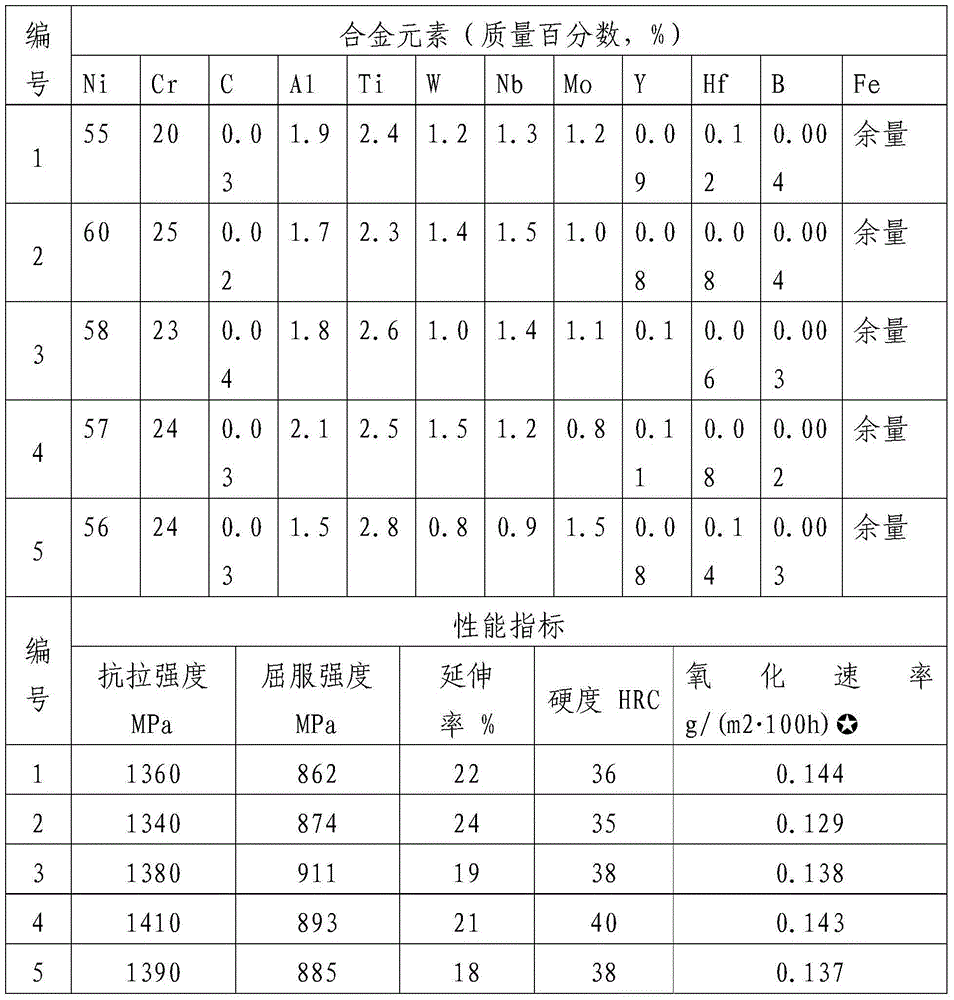

Nickel-based air valve alloy and preparation method thereof

The invention discloses nickel-based air valve alloy. The nickel-based air valve alloy comprises 55.0 to 60.0% of Ni, 20.0 to 25.0% of Cr, 0.01 to 0.05% of C, 1.0 to 3.0% of Al, 1.0 to 3.0% of Ti, 0.5 to 1.5% of W, 0.5 to 1.5% of Nb, 0.5 to 1.5% of Mo, 0.05 to 0.20% of Y, 0.05 to 0.20% of Hf, 0.001 to 0.005% of B, not greater than 0.02% of S, not greater than 0.02% of P, not greater than 0.02% of O, not greater than 0.02% of N, and the balance of Fe and inevitable impurities, wherein the impurity content is not greater than 0.5%. The preparation method comprises the steps of sensing and melting under a vacuum condition; casting an electrode; remelting electroslag; thermally forging; locally modifying and grinding a quadrate ingot blank; thermally rolling; compensating temperature online; thermally rolling a steel wire rod. The nickel-based air valve alloy has high-temperature durability, high-temperature oxidation resistance, high wearability and high-temperature corrosion resistance.

Owner:JIANGSU SHENYUAN SPECIAL STEEL +1

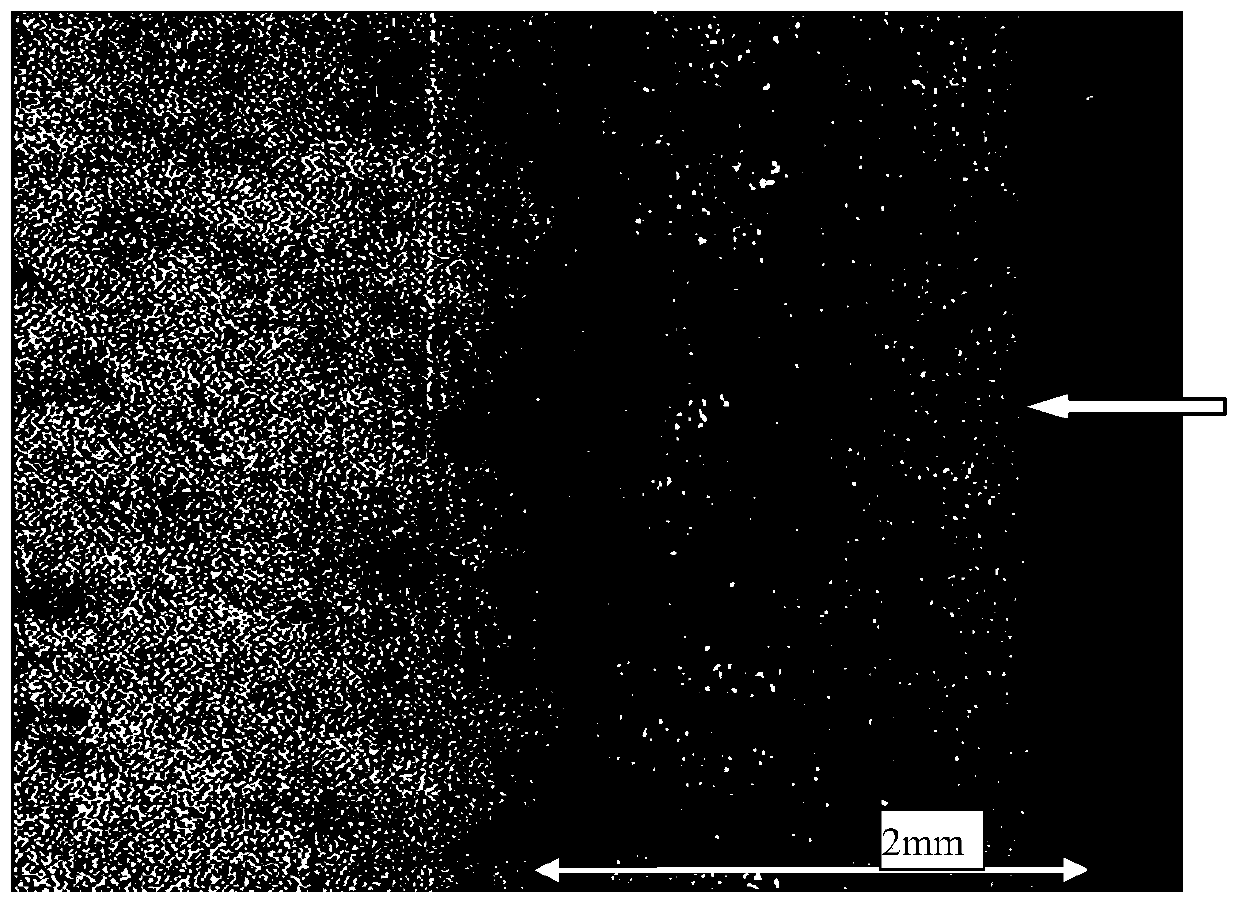

Method for preparing low-oxygen molybdenum and molybdenum alloy clad with Al4SiC4-HfC

ActiveCN103981383AStrong antioxidant capacityGood hardness and wear resistanceBonding strengthSintering

The invention discloses a method for preparing low-oxygen molybdenum and molybdenum alloy clad with Al4SiC4-HfC. The method for preparing low-oxygen molybdenum and molybdenum alloy clad with Al4SiC4-HfC adopts an injection filling method, and specifically comprises that Al4SiC4-HfC powder and a compound binding agent are mixed in a volume ratio of 1:(3-2) into slurry, and the slurry is injected and filled at the periphery of molybdenum and molybdenum alloy powder in a pressing mould with the filling thickness of 1-3mm; pressing at a pressure of 50-100KN is carried out, so that a molybdenum and molybdenum alloy pressed blank clad with Al4SiC4-HfC is formed; then the conventional sintering and annealing are carried out on molybdenum and molybdenum alloy, so that a Al4SiC4-HfC clad low-oxygen molybdenum and molybdenum alloy material is prepared. The prepared Al4SiC4-HfC clad low-oxygen molybdenum and molybdenum alloy material has the advantages of excellent oxidation resistance, long service life, high bonding strength between a cladding layer and a matrix, good compatibility, low cost and simple technology.

Owner:XIAN RUIKE NEW MATERIAL CO LTD

Heat-resistant filter felt, preparation method thereof and composite filter felt prepared from heat-resistant filter felt

ActiveCN111346431ASimple processLow costDispersed particle filtrationMembrane filtersPolymer scienceSulfide

The invention relates to a heat-resistant filter felt, a preparation method thereof and a composite filter felt prepared from the heat-resistant filter felt. The preparation method comprises the stepsthat modified polyphenylene sulfide fibers and polytetrafluoroethylene fibers are blended and then subjected to needling or spunlace processing, the heat-resistant filter felt is prepared, wherein the modified polyphenylene sulfide is polyphenylene sulfide with each sulfur atom randomly connected with N oxygen atoms, and the molar ratio of the oxygen atoms to the sulfur atoms in the modified polyphenylene sulfide is 1.50-1.77: 1. After the prepared heat-resistant filter felt is subjected to thermo-oxidative aging for 100 hours under the air condition that the temperature is 280 DEG C, the tensile strength retention rate is 90% or above. The composite filter felt prepared from the heat-resistant filter felt is mainly composed of base cloth and the heat-resistant filter felt compounded withthe base cloth. The preparation method disclosed by the invention is simple in process and low in cost; the prepared heat-resistant filter felt is excellent in heat resistance; the composite filter felt prepared from the heat-resistant filter felt is excellent in heat resistance and mechanical property and has a great application prospect.

Owner:上海钱丰纺织品有限公司

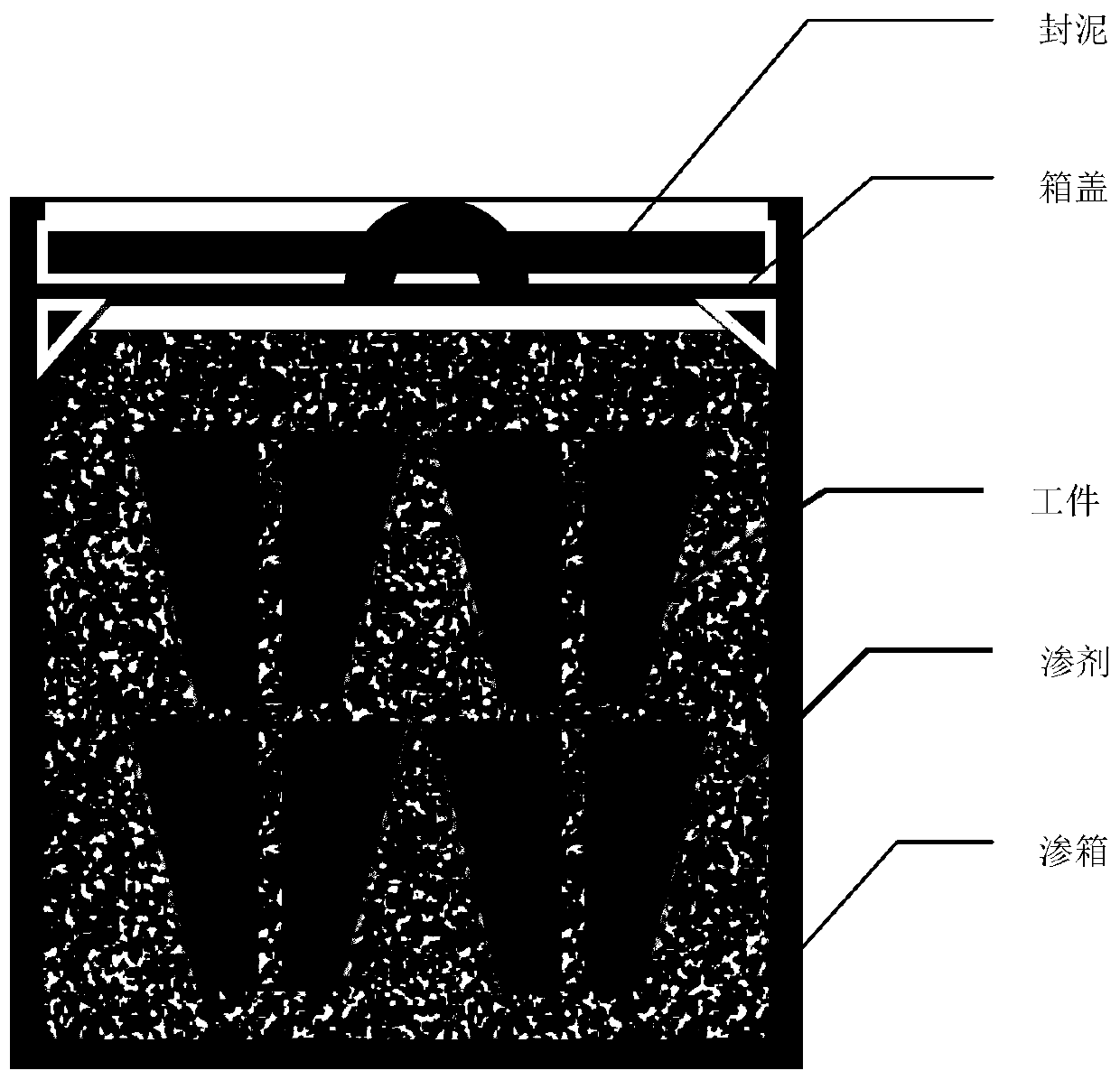

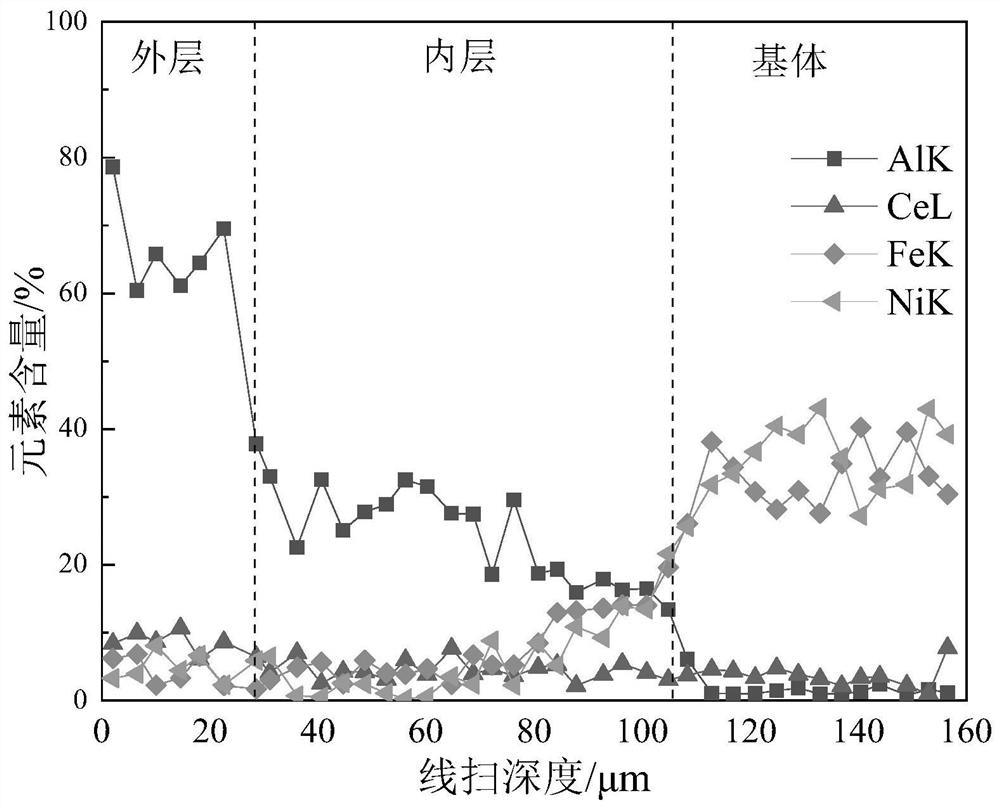

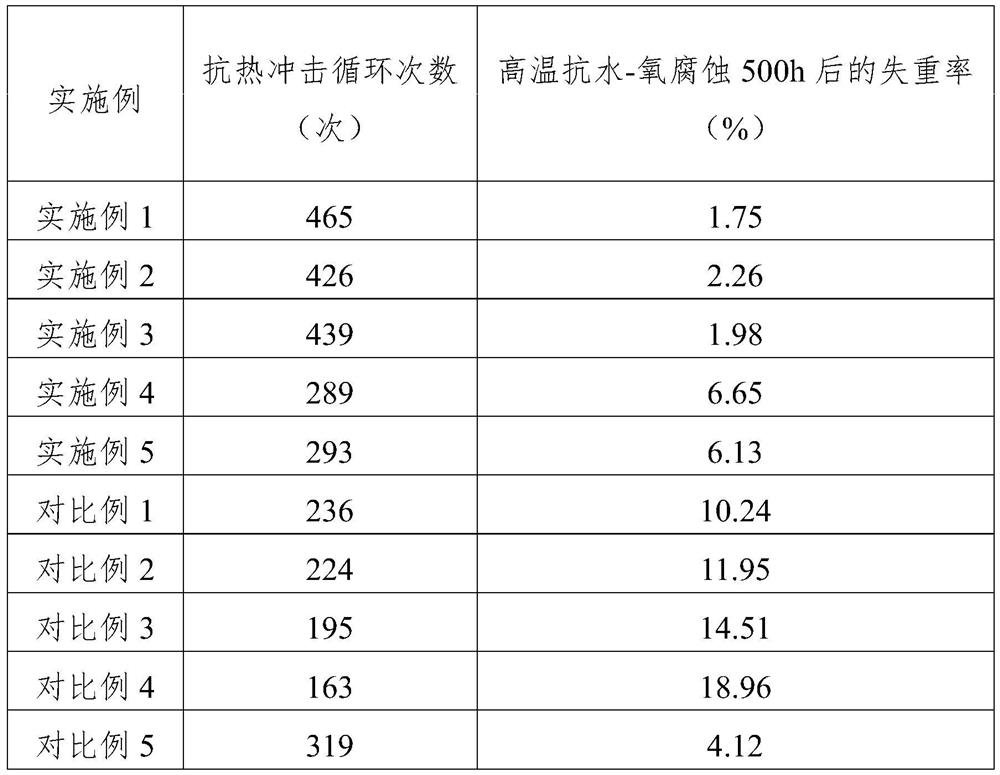

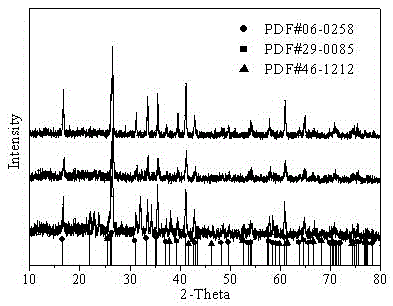

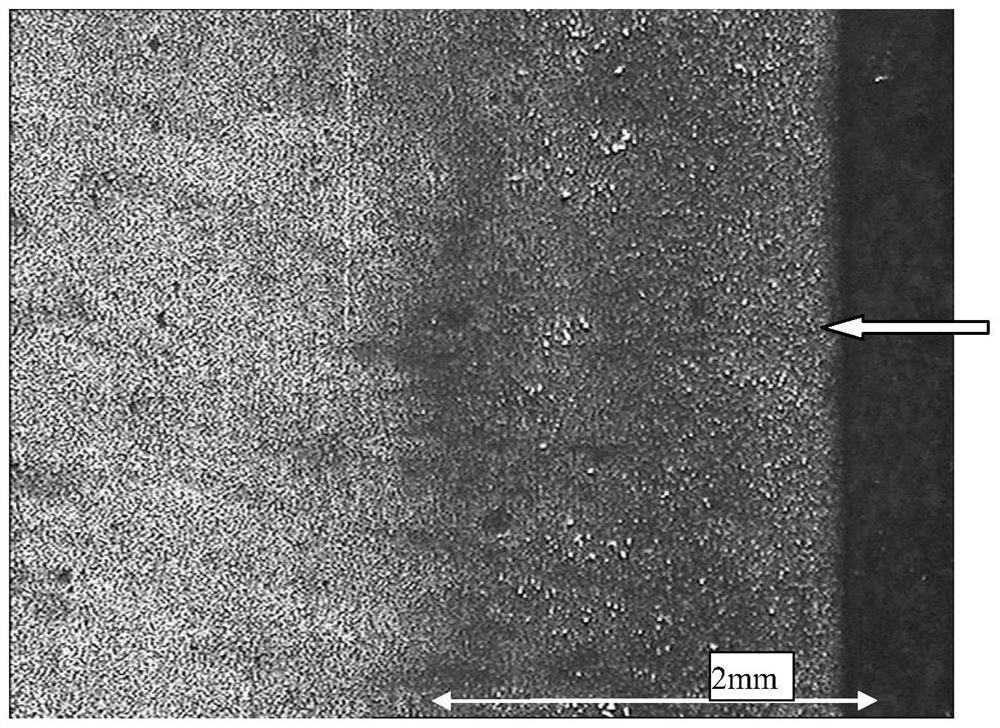

Preparation method of impregnation coating based on powder embedding

ActiveCN112853260AImprove carbon potential atmospherePrevent decarbonizationSolid state diffusion coatingCoated surfaceGraphite

The invention relates to a preparation method of an impregnation coating based on powder embedding. The preparation method comprises the following steps: performing ball milling on metallic powder, aluminum oxide, an activating agent, silicon powder, rare earth and graphite powder and uniformly mixing the materials; putting workpieces and impregnation agents subjected to ball milling into an impregnation box, and sealing the impregnation box; putting the impregnation box into thermal treatment for heating and then performing element diffusion and impregnation chemical thermal treatment so as to obtain a coating with compact and flat surface, and the thickness of the impregnation coating can be up to 100 micrometers. According to the preparation method disclosed by the invention, graphite can be added into the impregnation agents, so that high-temperature consolidation of the impregnation agents can be effectively prevented, and the surface quality of the coating is improved; and because of addition of the silicon powder and the rare earth, the structure property of the coating can be further improved.

Owner:EAST CHINA UNIV OF SCI & TECH

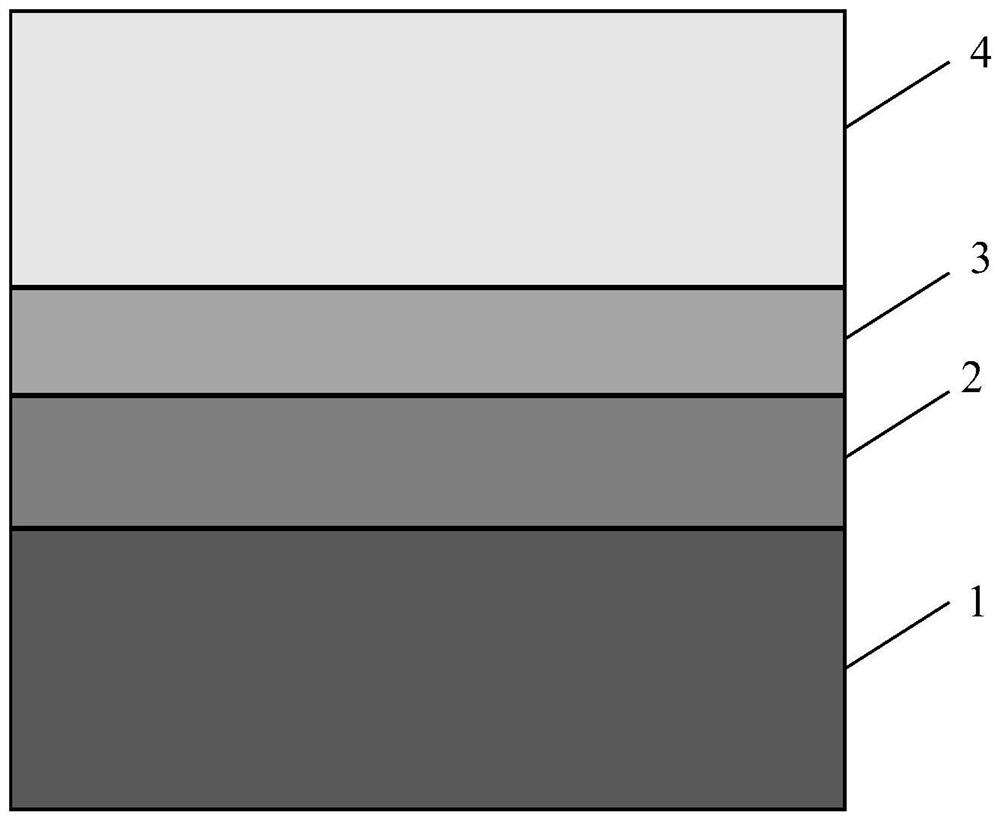

Multiphase environmental barrier coating formed on base material and preparation method thereof

ActiveCN111876714AImprove the performance of high temperature water-oxygen corrosion resistanceAlleviate thermal expansion mismatchMolten spray coatingEfficient propulsion technologiesLutetiumLutetium oxyorthosilicate

The invention relates to a multiphase environmental barrier coating formed on a base material and a preparation method thereof. The multiphase environmental barrier coating sequentially comprises a silicon bonding layer, a mullite layer and a Lu2SiO5-Sc2Si2O7 multiphase ceramic layer from the base material to the outside, wherein the Lu2SiO5-Sc2Si2O7 multiphase ceramic layer is formed by mixing lutetium silicate and scandium silicate. The method comprises the following steps: filling silicon powder, mullite powder and mixed powder formed by mixing lutetium silicate powder and scandium silicatepowder into a powder feeder of ultra-low pressure plasma spraying equipment and carrying out drying treatment; fixing the base material to a rotating table in a spraying cabin; and sequentially preparing the silicon bonding layer, the mullite layer and the Lu2SiO5-Sc2Si2O7 multiphase ceramic layer on the surface of the base material to prepare the multiphase environmental barrier coating. The multiphase environmental barrier coating is long in thermal shock resistance life and excellent in high-temperature water-oxygen corrosion resistance; and the method provided by the invention can be usedfor rapidly and integrally preparing the multiphase environmental barrier coating at low cost in an ultra-low pressure environment.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

A kind of porous mullite fiber product

ActiveCN104131363BImprove toughnessIncrease the lengthInorganic material artificial filamentsArtificial filament chemical after-treatmentFiberChemical composition

The invention belongs to the technical field of refractory material, and in particular relates to a porous mullite fiber product. The fiber product comprises the following components according to weight percentage: 85wt%-95wt% of modified mullite fiber, 1wt%-5wt% modified carbon fiber, 0.1wt%-1wt% of calcined alumina powder, 0.5wt%-2wt% silica sol, 0.2wt%-1.2wt% of sodium hypochlorite, 0.7wt%-1.3wt% of starch, and 0.5wt%-1.5wt% of an additive; the mullite fiber comprises the following chemical components: 50wt%<= Al2O3<= 70wt%, 25wt%<= SiO2<= 28wt%, and oily substances > 2wt%. The invention can prolong the service life of the mullite fiber porous product, and enhance the thermal insulation effect.

Owner:HUZHOU TEACHERS COLLEGE

Electrothermal alloy material with excellent high-temperature resistant grain growth behavior and manufacturing method thereof

InactiveCN105039858AImprove embrittlement abilityImproved embrittlement abilityHeat resistanceGrain growth

The invention discloses an electrothermal alloy material with an excellent high-temperature resistant grain growth behavior and a manufacturing method thereof. The electrothermal alloy material comprises, by mass, not larger than 0.06% of C, 19.5% to 23.5% of Cr, 5.5% to 6.5% of Al, not larger than 0.03% of N, not larger than 0.5% of Si, not larger than 0.5% of Mn, not larger than 0.03% of P, not larger than 0.03% of S, 0.05% to 0.25% of Zr, 0.01% to 0.2% of Y, 0.5% to 2.5% of Co, and the balance Fe and inevitable impurities. A vacuum induction melting process method is adopted, casting molding is performed after melting, and the material is finally manufactured through hot forging, hot rolling, recrystallization heat treatment, cold rolling and cold drawing. By the adoption of the electrothermal alloy material, the abnormal high-temperature grain growth behavior of Fe-Cr-Al alloy is overcome, the oxidation resistance is improved, heat resistance is improved as well, high-temperature corrosion resistance is enhanced, and the comprehensive performance is excellent.

Owner:江苏金达电热电器有限公司

A thermal/environmental barrier coating for ceramic matrix composites and its preparation method

ActiveCN109336647BGive full play to the high temperature water vapor corrosion resistanceHigh temperature water vapor corrosion resistance performance guaranteeCeramic compositeThermal insulation

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Single-component high-temperature self-crosslinking waterborne polyurethane preparation method

The invention relates to a single-component high-temperature self-crosslinking waterborne polyurethane preparation method. Single-component high-temperature self-crosslinking waterborne polyurethane is prepared by copolymerization of alkenyl end capped waterborne polyurethane, alkenyl oxazoline and acrylate monomer, wherein the use amount of the alkenyl oxazoline is 1 to 40% of the total amount ofresin. A solid content of prepared emulsion polymer is 15 to 60%, a pH value is 6 to 8, and a molecular weight is 10000 to 200000. According to the preparation method disclosed by the invention, oxazoline radicals are introduced into a waterborne polyurethane structure through copolymerization of the polyurethane, the alkenyl oxazoline and the acrylate; no crosslinking agent is utilized; comparedwith normal-temperature self-crosslinking waterborne polyurethane, storage stability of the obtained emulsion polymer is improved, and high-temperature service life of the obtained emulsion polymer is prolonged; after film formation, the obtained emulsion polymer has excellent water resistance, acid and alkali resistance and chemical resistance; meanwhile, the obtained emulsion polymer further has excellent physical and mechanical properties of large hardness, high elasticity, scratch resistance and the like.

Owner:LUOYANG SHENGJIA CHEM CO LTD

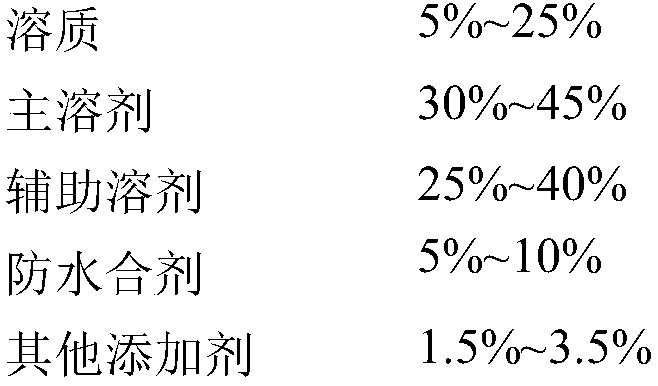

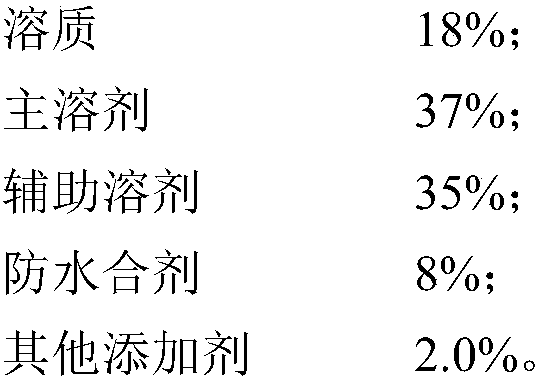

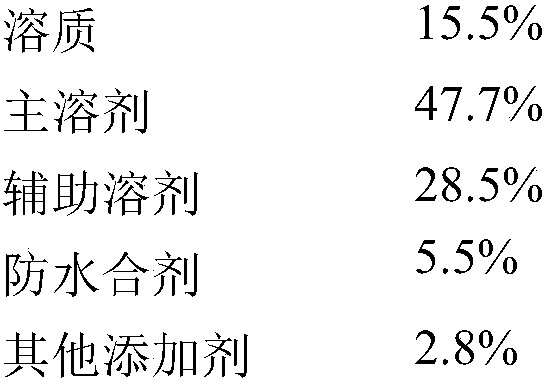

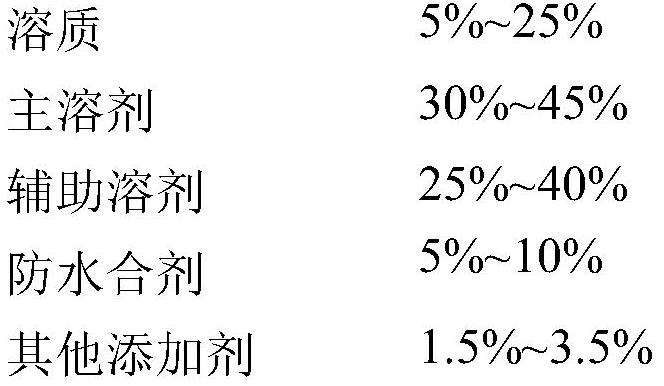

Waterproofing and low-voltage aluminum electrolytic capacitor working electrolyte

ActiveCN109659136AGood high temperature stabilityExtend high temperature service lifeElectrolytic capacitorsSolventHexadecyl phosphate

The invention provides a waterproofing and low-voltage aluminum electrolytic capacitor working electrolyte and a preparation method and application thereof. The electrolyte includes a solute, a main solvent, an auxiliary solvent, a water repellent and other additives, and the water repellent is a mixture of ethylene glycol, lauryl phosphate and hexadecyl phosphate and is obtained by mixing the ethylene glycol, the lauryl phosphate and the hexadecyl phosphate with the ratio of 8:1:1 by the mass percent at the temperature of 100-120 DEG C. The electrolyte provided has good high-temperature stability, and the capacitor assembled by the electrolyte has a long service life at a high temperature, and can achieve a life of more than 20000h at a working voltage U<=100V under the temperature of 105DEG C.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

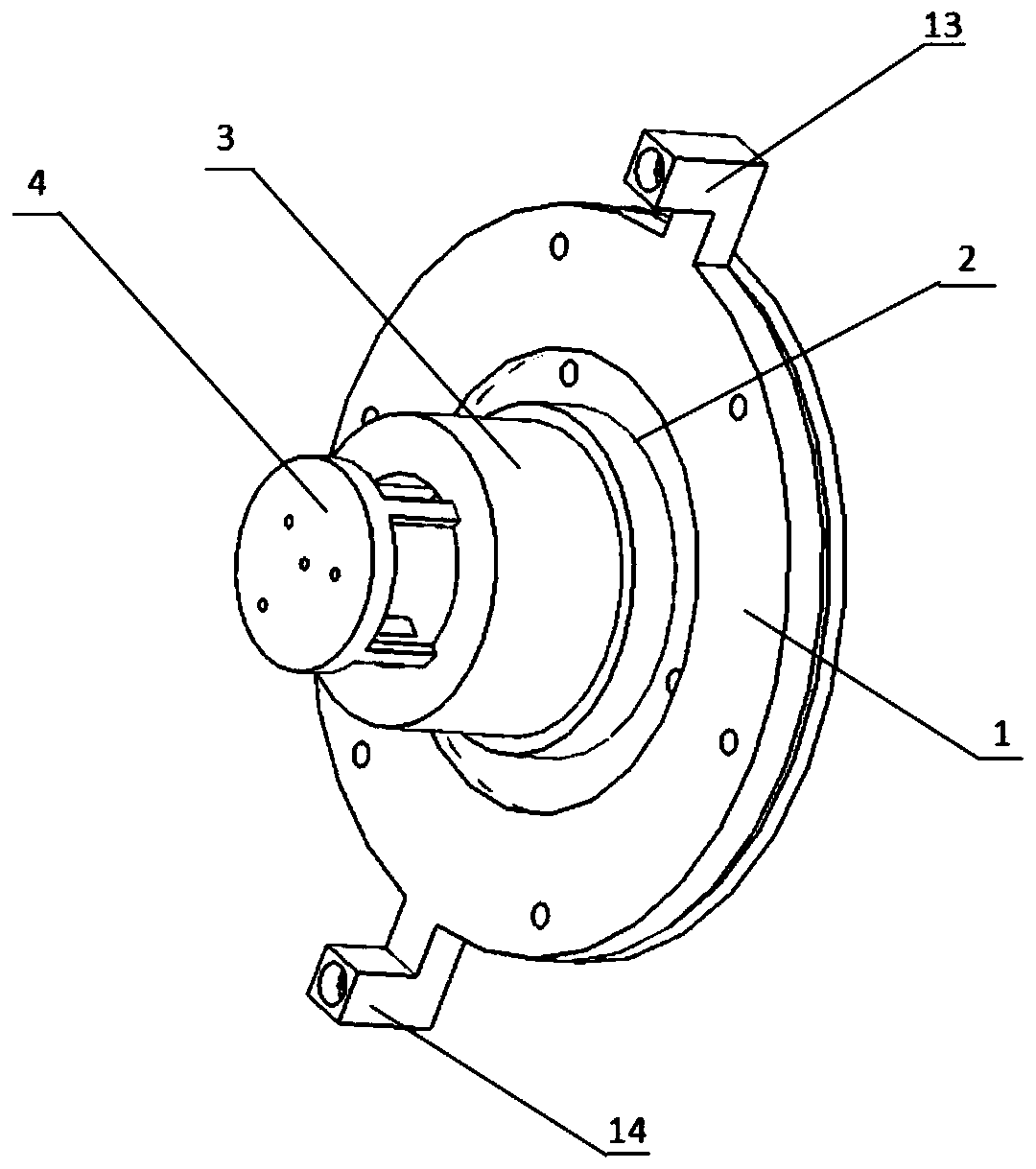

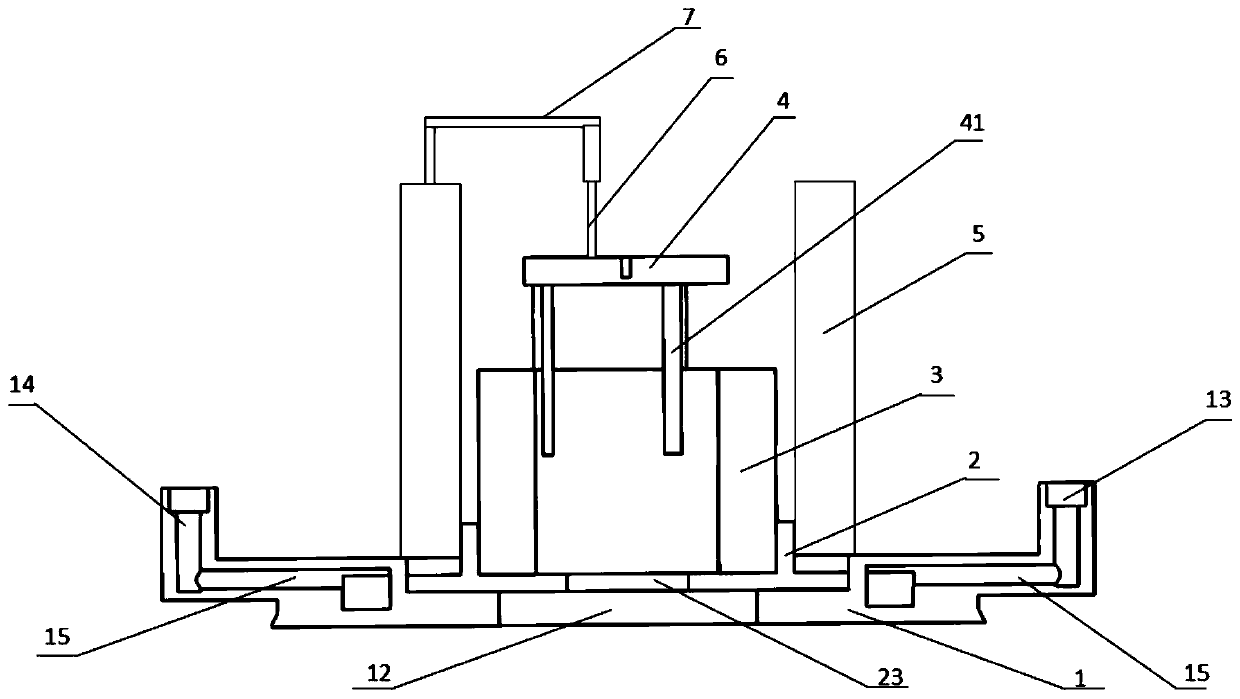

Graphite Support System for Gas Cannon/Cannon Preheated Shock Experiments

ActiveCN108147816BImprove flexural strengthHigh temperature resistantStrength propertiesSupporting systemEngineering

The invention discloses a graphite support system for a preheating impact experiment of a gas gun / a fire gun. The graphite support system comprises a water cooling disc, a metal base and a graphite support body, wherein the middle part of the water cooling disc is provided with an accommodating groove; the metal base is connected with the interior ofinto the accommodation groove of the water cooling disc; the graphite support body is connected with the interior ofinto the metal base; the graphite support body is uniformly provided with a plurality of grooves for fixing a preheating impact experiment sample; a plurality of support legs for the preheating impact experiment sample are arranged in the multiple grooves to fix the preheating impact experiment sample. The graphite support systemhas the advantages that by adopting the leg support type, the graphite support body is arranged away from an induction coil, and an electromagnetic filed field produced by the induction coil can moreeffectively act onto the sample; the graphite support body is fixedly arranged on the water cooling disc through the metal base, so that the heat transferred out by the graphite support body is carried away by cooling water, and the temperature rise of the equipment after water cooling circulation is controlled within the an acceptable range; proofed by experiment, the sample with high temperatureof 2200 DEG C can be effectively supported, and the integrity of the graphite support body is maintained.

Owner:SOUTHWEAT UNIV OF SCI & TECH

A kind of anti-CMAS ceramic layer and preparation method thereof by slurry method

ActiveCN105039894BUniform thickness distributionHigh densityMolten spray coatingReaction layerSlurry

The invention discloses a CMAS-resistant ceramic layer and a preparation method thereof by a slurry method, and belongs to the field of thermal barrier coating materials and preparation thereof. The anti-CMAS ceramic layer of the present invention is a LaPO4 ceramic layer. The invention utilizes slurry method to prepare a layer of LaPO4 ceramic layer on the YSZ ceramic layer. The wettability of the LaPO4 ceramic layer to molten CMAS is poor. After heat treatment at 1250°C, a layer of mutual reaction layer is formed at the interface between the LaPO4 ceramic layer and CMAS. , effectively preventing the further infiltration of molten CMAS, and the YSZ ceramic layer maintains the original phase stability. Therefore, the LaPO4 ceramic layer prepared by the invention can prevent the infiltration of molten CMAS, has excellent CMAS corrosion resistance, and significantly improves the life of the thermal barrier coating under the coupling effect of CMAS.

Owner:BEIHANG UNIV

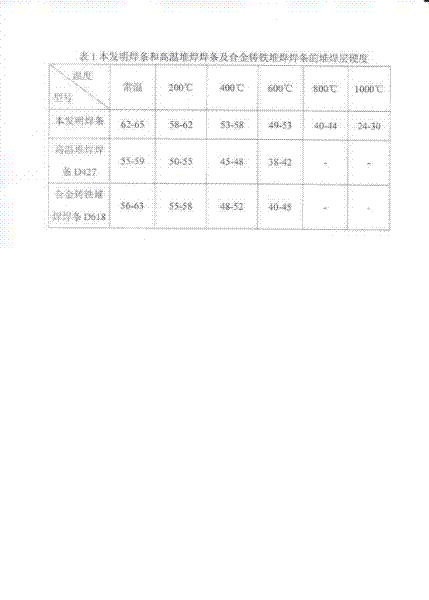

High temperature resistance and corrosion resistance wear-resistant surfacing electrode

InactiveCN101961821BExtend high temperature service lifeReduce maintenance costsArc welding apparatusWelding/cutting media/materialsWear resistantRare earth

The invention discloses a high temperature resistance and corrosion resistance abrasion-resistant surfacing electrode, which comprises a core wire and a coating, wherein the coating comprises the following components in parts by weight: 1 to 4 parts of marble, 2 to 6 parts of fluorite, 1 to 5 parts of titanium white, 3 to 9 parts of quartz, 20 to 60 parts of chrome carbide, 20 to 60 parts of high-carbon ferrochrome, 2 to 10 parts of mid-carbon Fe-Mn, 2 to 10 parts of molybdenum powder, 2 to 10 parts of tungsten carbide, 5 to 20 parts of ferrocolumbium, 2 to 10 parts of ferrovanadium, 3 to 10 parts of ferrous powder, 1 to 5 parts of aluminum powder, 0.2 to 1.5 parts of ferrotitanium, 5 to 20 parts of crystalline flake graphite, 0.5 to 3 parts of ferrosilicon, 0.5 to 1.5 parts of potassium carbonate, 0.5 to 2 parts of rare earth ferrosilicon and 10 to 20 parts of potassium sodium water glass. The workpiece subjected to surfacing by the electrode can continuously work at the high temperature of 800 DEG C and maintains high hardness and excellent corrosion resistance performance and abrasion resistance performance to abrasive materials, and the high temperature service life of the workpiece can be effectively enhanced.

Owner:SHENGYANG HAWEIER SURFACE ENG TECH

Heat-resistant filter felt and its preparation method and composite filter felt made therefrom

ActiveCN111346431BSimple processLow costDispersed particle filtrationMembrane filtersPolymer scienceComposite filter

The invention relates to a heat-resistant filter felt, a preparation method thereof and a composite filter felt prepared therefrom. The preparation method is as follows: blending modified polyphenylene sulfide fibers and polytetrafluoroethylene fibers and performing acupuncture or water The modified polyphenylene sulfide is a polyphenylene sulfide in which each sulfur atom is randomly connected to N oxygen atoms, and the molar ratio of oxygen atoms to sulfur atoms in the modified polyphenylene sulfide is It is 1.50~1.77:1. After the prepared heat-resistant filter felt is subjected to thermo-oxidative aging for 100 hours under air conditions at a temperature of 280° C., the tensile strength retention rate is above 90%. The composite filter felt made from it is mainly composed of a base cloth and a heat-resistant filter felt compounded with the base cloth. The preparation method of the present invention has simple process and low cost; the prepared heat-resistant filter felt has excellent heat resistance; the composite filter felt made of the heat-resistant filter felt has excellent heat resistance and mechanical properties, and has great application prospects .

Owner:上海钱丰纺织品有限公司

Ultralow-expansion coefficient high transparent microcrystalline glass and method for producing its product

ActiveCN101139171BTransparency unchangedThe physical and chemical properties remain unchangedThermal impactCelsius Degree

The present invention relates to a Li2O-Al2O3-SiO2 system ultra-low expansion coefficient high-transparency glass-ceramic and production method of the products. Calculated by weight percentage, the ultra-low expansion coefficient high-transparency glass-ceramic is composed of 3.2 to 4.6 percent of Li2O, 18.0 to 23.6 percent of Al2O3, 64.1 to 69.4 percent of SiO2, 0.3 to 0.8 percent of MgO, 0.8 to 2.5 percent of BaO, 0.3 to 0.8 percent of R2O, 0.01 to 0.4 percent of Y2O3, 1.8 to 2.5 percent of TiO2, 1.6 to 2.4 percent of ZrO2, 1.1 to 1.8 percent of P2O5, 0.6 to 1.5 percent of Sb2O3, 0.3 to 1.0 percent of NaCl and 1.0 to 2.0 percent of NH4NO3. The heat-resistant glass plates and heat-resistant glass products can be manufactured by using the formula and the corresponding forming die. The present invention has the advantages that the production technique is simple, the produced products have low expansion coefficient, good transparency, high thermal impact temperature, high strength, have constant transparency when being used under the temperature of 700 Celsius system for a long time, the products have long service life, etc.

Owner:广东科迪微晶玻璃实业有限公司 +1

A kind of preparation method of zirconia ceramic fiberboard

The invention belongs to the field of inorganic refractory materials and relates to a method for preparing a refractory thermal insulation fiber board based on superhigh temperature zirconia ceramic fibers. The method comprises the following steps: by taking the superhigh temperature zirconia ceramic fibers as a base phase, by taking fine zirconia ceramic fibers as a filler, adding an organic binding agent and an inorganic binding agent for preparing slurry, and performing suction filtration molding and drying to prepare the zirconia ceramic fiber board. The preparation process is simple, and the prepared fiber board is uniform and single in component and high-temperature-resistant and can be used in an environment at the temperature below 2250 DEG C for a long time.

Owner:宜兴市恒祥耐火材料有限公司

A waterproof and low-voltage aluminum electrolytic capacitor working electrolyte

ActiveCN109659136BImprove high temperature stabilityExtend high temperature service lifeElectrolytic capacitorsElectrolytic agentAluminium electrolysis

The invention provides a waterproof and low-voltage aluminum electrolytic capacitor working electrolyte, its preparation method and application. Described electrolytic solution comprises solute, main solvent, auxiliary solvent, water-repelling agent and other additives, and wherein, water-repelling agent is the mixture of ethylene glycol, dodecyl phosphate and hexadecyl phosphate, consists of ethylene glycol, decyl phosphate It is obtained by mixing dialkyl phosphate and hexadecyl phosphate at a mass percentage of 8:1:1 at a temperature of 100-120°C. The electrolytic solution provided by the invention has good high-temperature stability, and the capacitor assembled therefrom has a long high-temperature service life, and can realize a service life of more than 20,000 hours at an operating voltage U≤100V and 105°C.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

A Heat Treatment Process for Improving Hot Hardness and High Temperature Wear Resistance of Hot Die Steel

ActiveCN110565048BExtend high temperature service lifeSimple methodSolid state diffusion coatingTemperingCarburizing

A heat treatment process for improving the thermal hardness and high temperature wear resistance of hot mold steel, mixing charcoal, urea particles, sodium carbonate powder and chromic anhydride to obtain a strong carbon-nitrogen binder; Put it into the infiltration box, seal the box cover of the infiltration box; put the infiltration box in a crucible electric furnace at a constant temperature of 850°C to 950°C for strong carbonitriding, and then after quenching, immerse the hot molded steel workpiece directly in quenching oil After cooling and air cooling, put it into a box-type medium-temperature tempering furnace for two temperings to obtain hot mold steel workpieces with high thermal hardness, high temperature and high wear resistance. The advantages are: easy operation, low cost and obvious effect, the surface hardness of the obtained hot mold steel can reach above 62HRC, and the high temperature wear resistance at 600 ℃ is more than twice that of the conventional heat treatment parts of the same kind of hot mold steel, which can effectively Improve the service life of hot work dies.

Owner:锦州捷通铁路机械股份有限公司

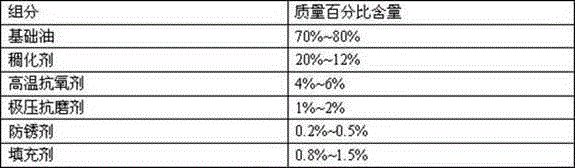

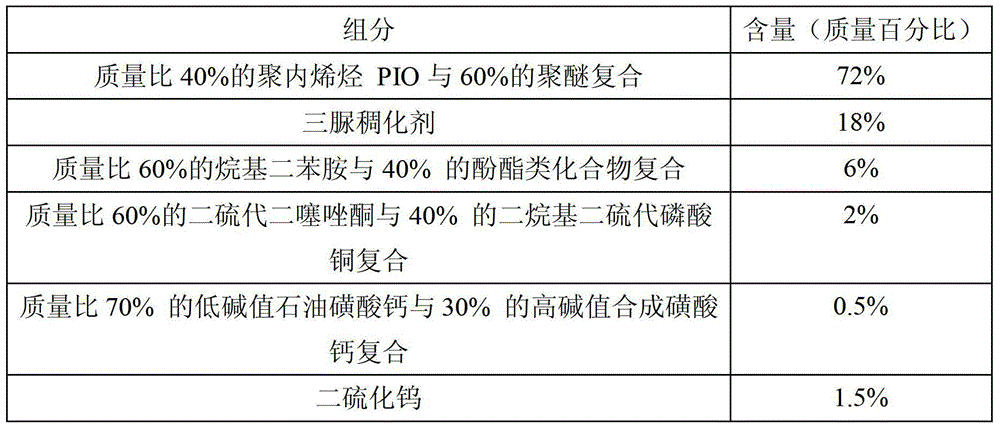

Heat-resistant grease

ActiveCN103265998BHigh strengthHigh and low intensityLubricant compositionAdditive ingredientFrictional coefficient

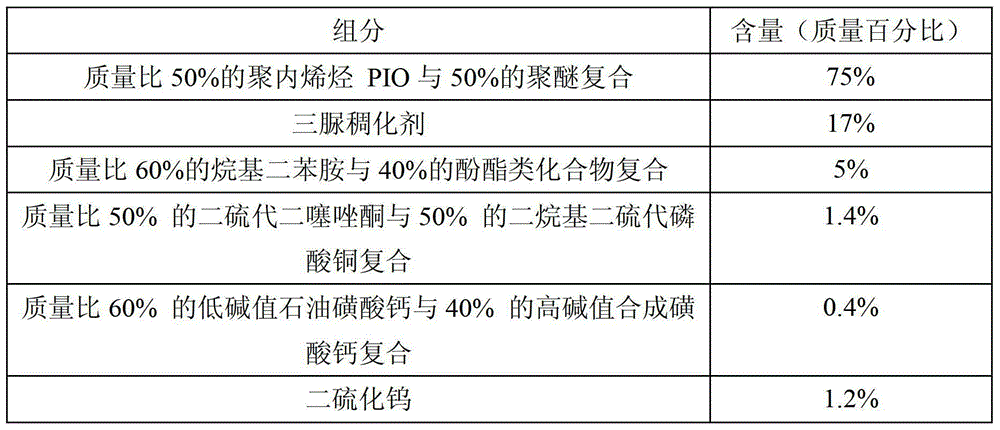

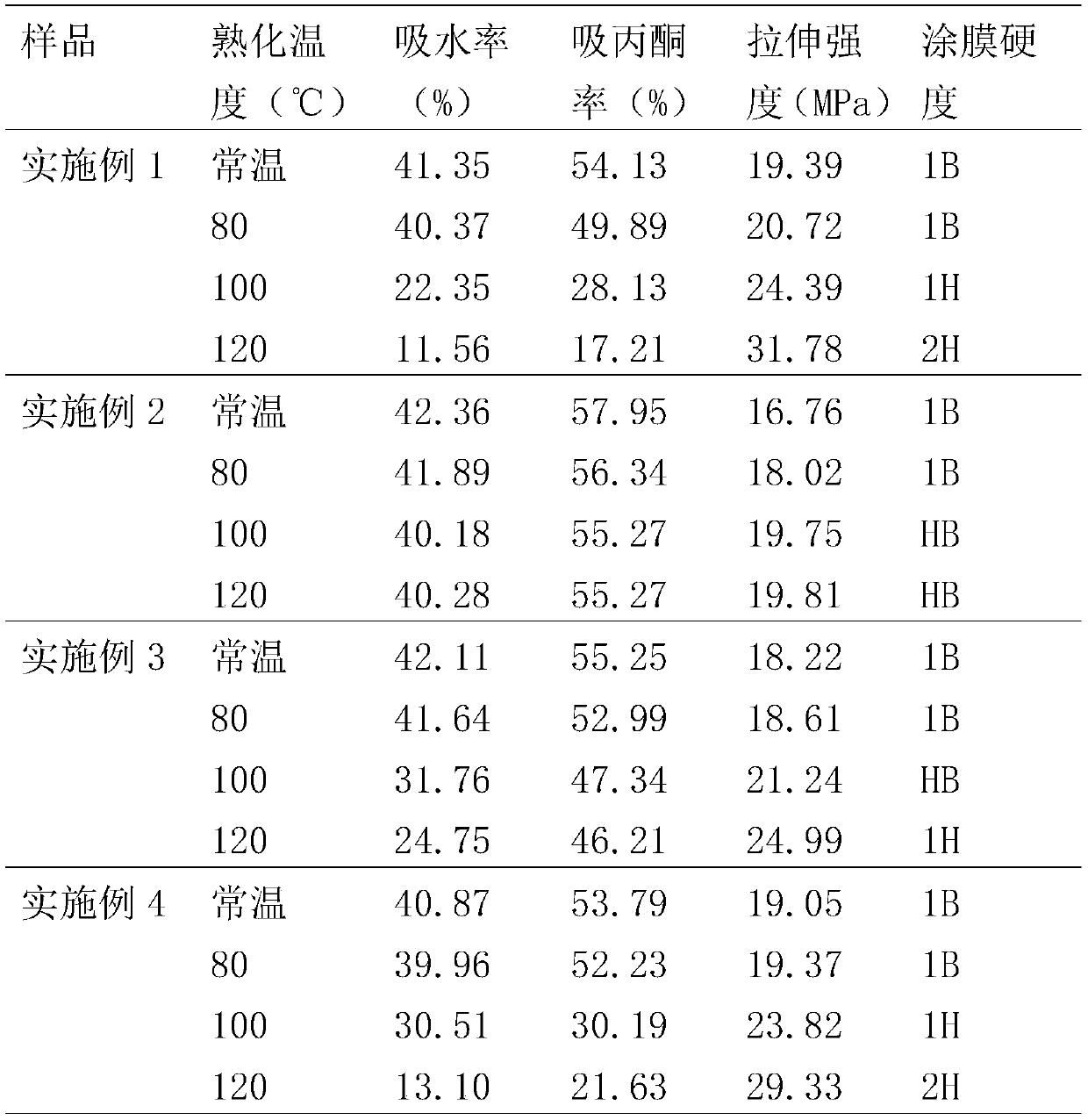

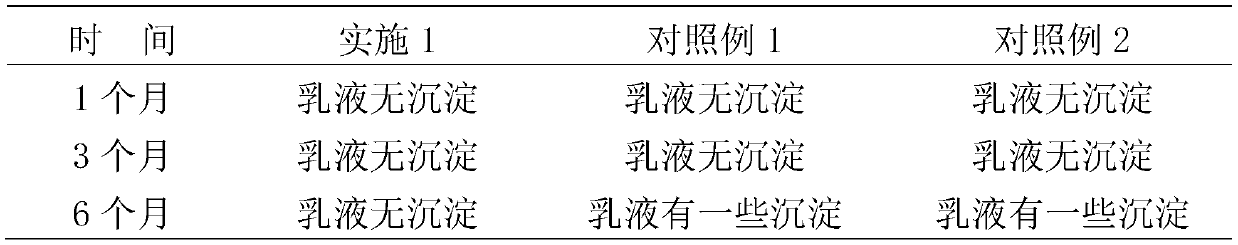

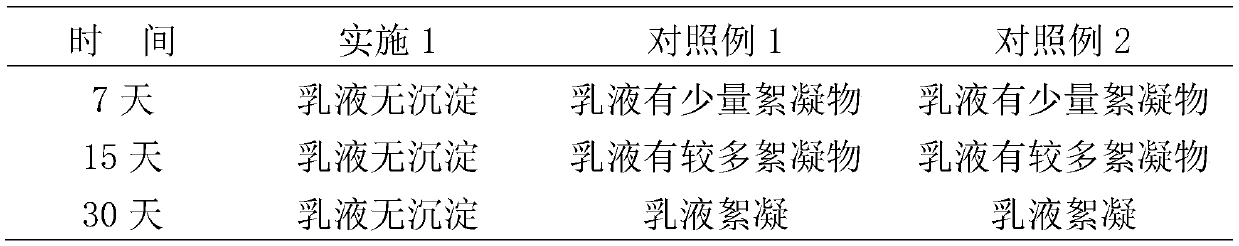

The invention discloses heat-resistant grease. The heat-resistant grease is characterized by comprising the following ingredients by mass percent: 70-80% of base oil, 20-12% of thickening agent, and 10-8% of other additives, wherein polyinternalolefin (PIO) is compounded with polyether to serve as the base oil of the heat-resistant grease, and a triuret thickener is utilized. The heat-resistant grease composition disclosed by the invention is good in overall performance, has good high-and-low temperature performance and lubricating property, excellent high temperature and oxidation stability, long high-temperature service life, excellent extreme pressure property and wear resistance, low frictional coefficient, strong carrying capacity, excellent mechanical stability and water resistance, high oil film strength, and excellent anti-rust and anti-corrosion performances and biodegradability, is suitable for lubricating and sealing of a bearing, a valve and a friction component which run under bad work conditions such as extreme high temperature, heavy load, and humid and polluted conditions, and can provide the maximal anti-wear, anti-rust and anti-corrosion protection.

Owner:GUANGXI UNIV

A kind of preparation method of one-component high-temperature self-crosslinking waterborne polyurethane

The invention relates to a single-component high-temperature self-crosslinking waterborne polyurethane preparation method. Single-component high-temperature self-crosslinking waterborne polyurethane is prepared by copolymerization of alkenyl end capped waterborne polyurethane, alkenyl oxazoline and acrylate monomer, wherein the use amount of the alkenyl oxazoline is 1 to 40% of the total amount ofresin. A solid content of prepared emulsion polymer is 15 to 60%, a pH value is 6 to 8, and a molecular weight is 10000 to 200000. According to the preparation method disclosed by the invention, oxazoline radicals are introduced into a waterborne polyurethane structure through copolymerization of the polyurethane, the alkenyl oxazoline and the acrylate; no crosslinking agent is utilized; comparedwith normal-temperature self-crosslinking waterborne polyurethane, storage stability of the obtained emulsion polymer is improved, and high-temperature service life of the obtained emulsion polymer is prolonged; after film formation, the obtained emulsion polymer has excellent water resistance, acid and alkali resistance and chemical resistance; meanwhile, the obtained emulsion polymer further has excellent physical and mechanical properties of large hardness, high elasticity, scratch resistance and the like.

Owner:LUOYANG SHENGJIA CHEM CO LTD

High temperature resistant alloy and its preparation method

The invention relates to a high temperature resistant alloy and its preparation method, and concretely relates to a high temperature resistant alloy containing zero or less nickel. A nanometer ceramic composite nickel substitute alloy (nickel substitute alloy D for short) is adopted to replace isometric nickel generally used in high temperature alloys to make the alloys have a good casting performance, good mechanical performances in a casting state and a good weldability. The high temperature resistant alloy which is a steel has oxidation, carburizing and sulfuration resistances at a high temperature of 1250-1350DEG C; and compared with traditional high temperature alloys (such as ZG2Cr25Ni20Si2), the high temperature resistant alloy provided by the invention has the advantages of above 20% tensile strength increase, above 40% service life prolongation, and 30% cost reduction. The high temperature resistant alloy has a high high-temperature strength, can be widely applied to structural parts having high temperature resistance requirements, comprising heat treatment bed plates, bottom rollers, quenching normalising trays, material frames, power plant boiler high temperature burners, combustors, ash falling tubes, steel factory steel rolling rollers, guide rollers, magnesium melting reduction tanks and the like, and has the characteristics of great cost reduction and service life prolongation on the premise that use requirements are satisfied.

Owner:辽宁瑞朗纳米新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com