Porous mullite fiber product

A technology of porous mullite and mullite fibers, which can be applied in the fields of chemical characteristics of fibers, rayon manufacturing, textiles and papermaking, etc., can solve the problems of high labor cost, complicated process, difficult continuous production, etc. Thermal effect, high thermal decomposition temperature, effect of reducing expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

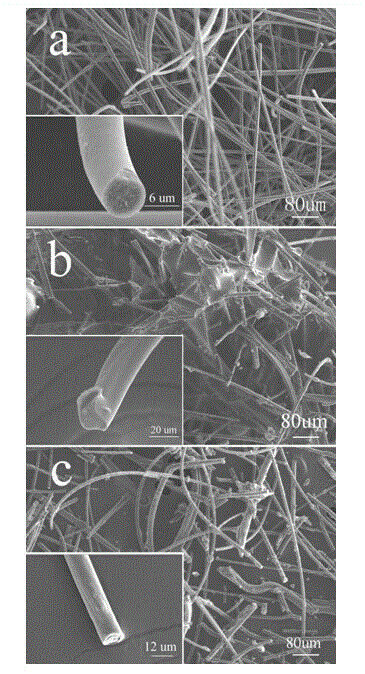

[0027] The invention provides a porous mullite fiber product, which comprises the following three key process steps.

[0028] The first step is to modify the mullite fiber. Mullite can use Al 4+2x Si 2-2x o 10-x where x represents an oxygen vacancy (value range 0.2 to 0.9), and its structure terminates at the crystal surface, which will generate paired electrons, that is, dangling bonds. -OH structure can be formed in water. This structure is the reason why the mullite fiber can be chemically combined with the coupling agent. (1) Mix unmodified mullite fiber with aluminum-zirconium coupling agent, as a preference, the ratio of mass fraction is 100:10. Considering that any agitation has the possibility of fragmentation and shortening for brittle mullite inorganic fibers, once the fibers are shortened, on the one hand, it will affect the quality of the product, on the other hand, short and thin fibers will have an impact on industrial workers and the environment , so in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com