Thermal/environment barrier coating based on ceramic composite material and preparation method of thermal/environment barrier coating

A composite material and environmental barrier technology, which is applied in the thermal/environmental barrier coating of ceramic matrix composites and its preparation, can solve the problems of low deposition rate, high cost, powder oxidation, etc., to ensure heat insulation performance and prolong high temperature Good service life and heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In a second aspect, the present invention provides a method for preparing the thermal / environmental barrier coating described in the first aspect of the present invention, said method comprising the steps of:

[0035] (1) Silicon powder, ytterbium silicate powder and hafnium oxide powder are respectively loaded into the powder feeder of the low-pressure plasma spraying equipment and dried;

[0036] (2) fixing the ceramic matrix composite material on a rotary table in the vacuum chamber of the low-pressure plasma spraying equipment; and

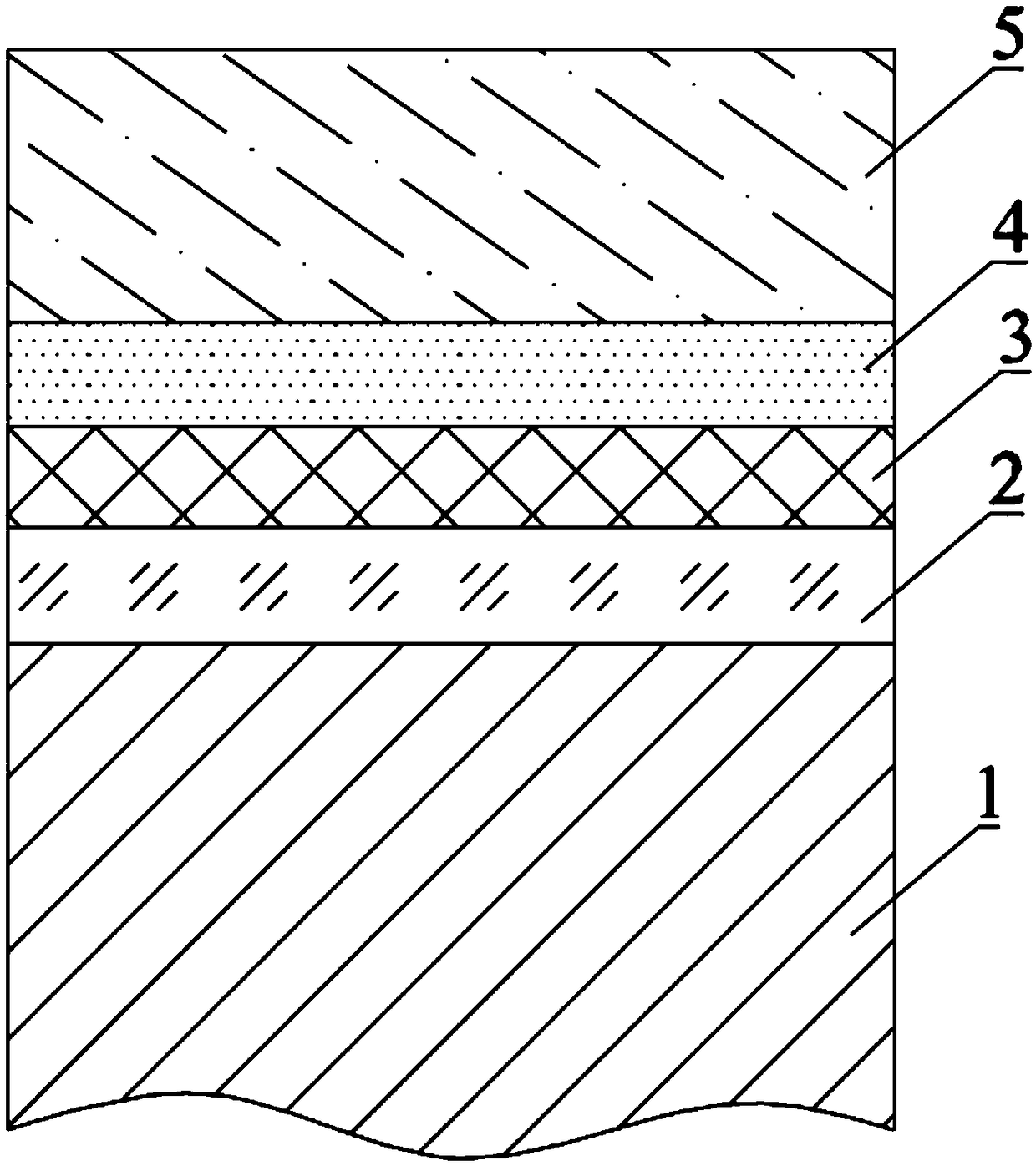

[0037] (3) Prepare the silicon layer, the ytterbium silicate layer, and the transition layer formed by mixing hafnium oxide and ytterbium silicate sequentially on the surface of the ceramic matrix composite material (ceramic matrix composite material matrix) by low-pressure plasma spraying method. layer and the hafnium oxide layer, thereby producing the thermal / environmental barrier coating on the surface of the ceramic matrix composite...

Embodiment 1

[0061] ① Prepare SiC f / SiC ceramic matrix composite matrix original piece, the size is Φ25×4mm, the surface is polished on 400#, 800#, 1200# sandpaper respectively, put into acetone and ultrasonically cleaned for 10min before use.

[0062] ②Select Si and HfO after spray granulation 2 and Yb 2 SiO 5 powder, HfO 2 The particle size of the powder is 5-40μm, Yb 2 SiO 5 The particle size of the powder is 5-30 μm, and the particle size of the Si powder is 3-10 μm; the above three powders are added to the powder feeder of the low-pressure plasma spraying equipment, and the temperature is raised to 60 ° C and then dried for 4 hours.

[0063] ③The Si bonding layer was prepared on the substrate by low-pressure plasma spraying method: the pretreated SiC f / SiC ceramic matrix composite material matrix is installed on the automatic workpiece rotating table in the vacuum chamber, and the process parameters are adjusted: spraying power 10kW, spraying current 500A, powder feeding rat...

Embodiment 2

[0070] Embodiment 2 is basically the same as Embodiment 1, the difference is:

[0071] In ⑤, after the jet is stabilized, open the HfO2 and Yb 2 SiO 5 The powder feeder, the powder feeding rate is 13.5g / min and 29.5g / min respectively, the deposition time is 1min, and the HfO with a thickness of 102μm is obtained 2 -Yb 2 SiO 5 Composition transition layer, where, HfO 2 with Yb 2 SiO 5 The molar ratio of the ingredients is 1:1.

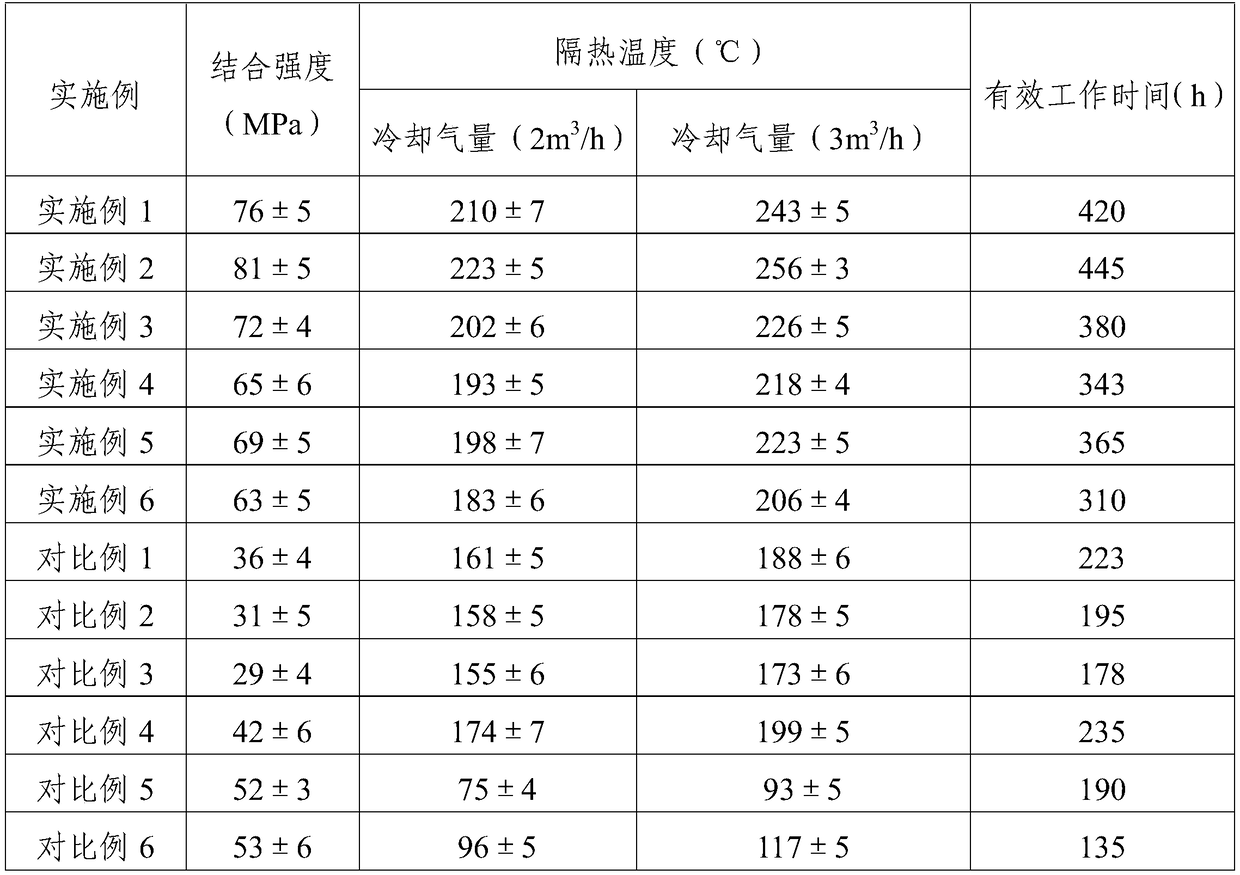

[0072] The same test method as in Example 1 was used to test the heat insulation performance, high temperature water vapor corrosion resistance and the bonding strength of the hafnium oxide layer of the thermal / environmental barrier coating prepared in this example. The performance test results are shown in Table 1. Show.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com