A Heat Treatment Process for Improving Hot Hardness and High Temperature Wear Resistance of Hot Die Steel

A hot-hardness and wear-resistance technology, which is applied in the field of heat treatment process for improving hot-hardness and high-temperature wear resistance of hot die steel, can solve the problems of complicated operation, insignificant effect and high production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

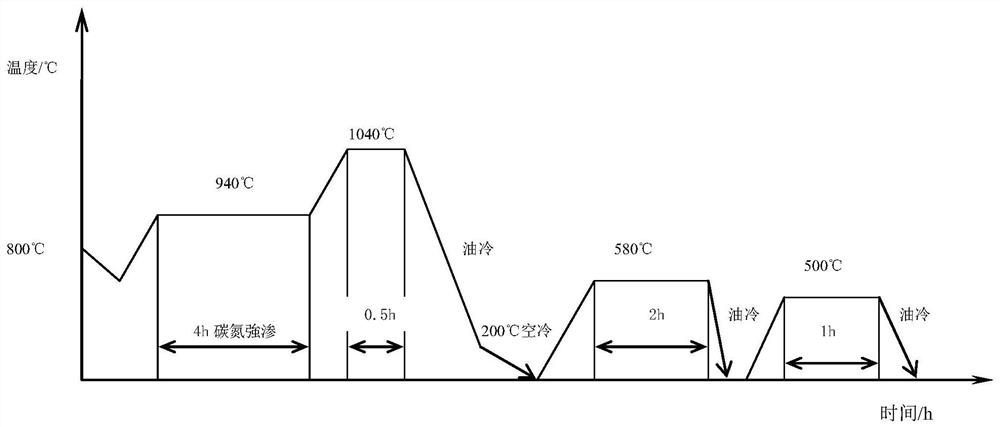

[0044] (940℃×4h strong carburizing and nitriding, then heating up to 1040℃ for 0.5h oil cooling, 580℃×2h and 500℃×1h twice tempering)

[0045] (1) Sample preparation and preparation of strong carbon-nitrogen infiltration agent

[0046] The workpiece materials are H11, H13, and H21 hot die steels in the annealed state. The chemical compositions of the three test materials are shown in Table 1. The size of metallographic and hardness workpiece samples is Ф25×6mm, the size of worn workpiece samples is Ф40×4mm, and the surface roughness of workpiece samples is 0.8mm;

[0047] According to the weight percentage, the carbon-nitrogen strong infiltration agent is composed as follows: 4.5kg of charcoal with a particle size of ≤5mm, 5.3kg of urea particles with a particle size of 1mm-2mm, 0.15kg of sodium carbonate powder, chromic anhydride (CrO 3 ) 0.05kg mixed to obtain carbon-nitrogen strong infiltration agent;

[0048] (2) Strong carbonitriding

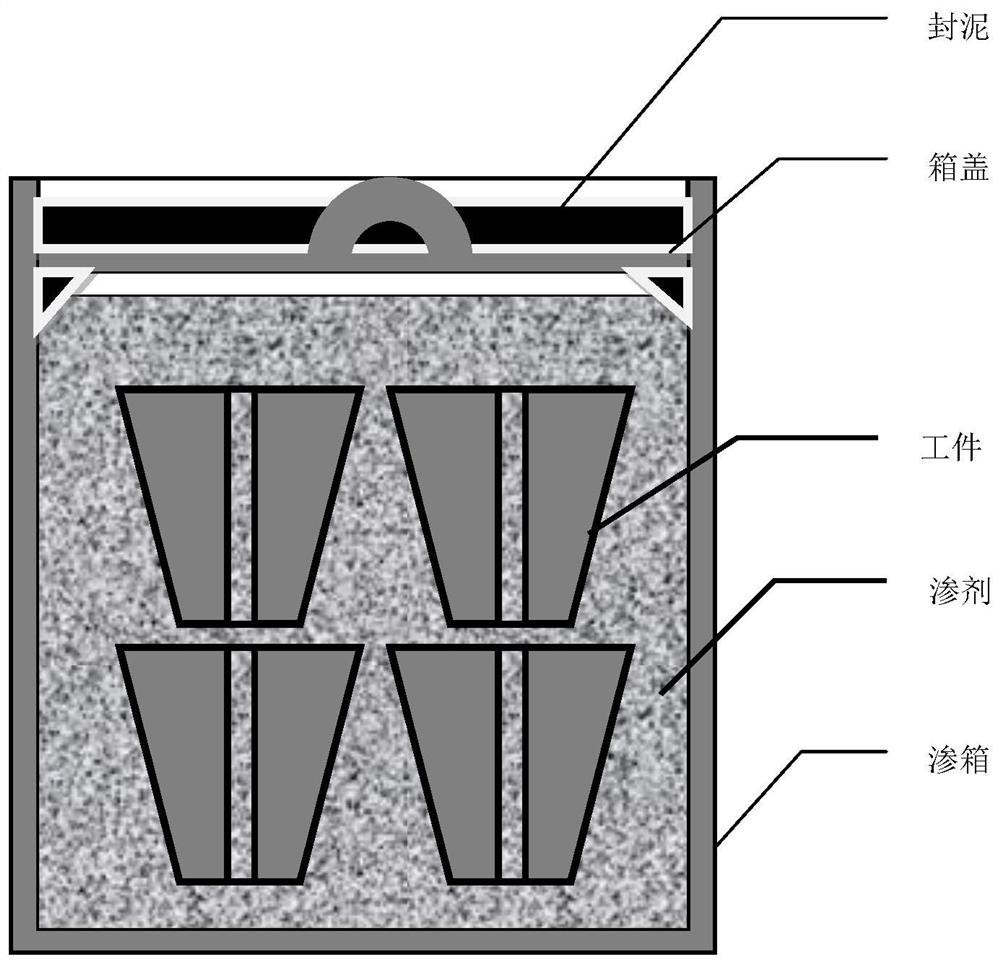

[0049] Weld the infiltration box ...

Embodiment 2

[0078] (1) Sample and preparation of strong carbon-nitrogen infiltration agent

[0079] The workpiece materials are H11, H13, and H21 hot die steels in the annealed state. The chemical compositions of the three test materials are shown in Table 1. The size of metallographic and hardness workpiece samples is Ф25×6mm, the size of worn workpiece samples is Ф40×4mm, and the surface roughness of workpiece samples is 0.8mm;

[0080] According to the weight percentage, the carbon-nitrogen strong infiltration agent is composed as follows: 4.3kg of charcoal with a particle size of ≤5mm, 5.5kg of urea particles with a particle size of 1mm-2mm, 0.12kg of sodium carbonate powder, chromic anhydride (CrO 3 ) 0.08kg mixed to obtain carbon-nitrogen strong infiltration agent;

[0081] (3) Strong carbonitriding

[0082] Weld the infiltration box with 6mm thick 1Cr18Ni9Ti stainless steel plate on both sides, put H11 hot mold steel workpiece, H13 hot mold steel workpiece and H21 hot mold steel ...

Embodiment 3

[0088] (1) Sample and preparation of strong carbon-nitrogen infiltration agent

[0089] The workpiece materials are H11, H13, and H21 hot die steels in the annealed state. The chemical compositions of the three test materials are shown in Table 1. The size of metallographic and hardness workpiece samples is Ф25×6mm, the size of worn workpiece samples is Ф40×4mm, and the surface roughness of workpiece samples is 0.8mm;

[0090] According to the weight percentage, the carbon-nitrogen strong infiltration agent is composed as follows: 4.8kg of charcoal with a particle size of ≤5mm, 5.0kg of urea particles with a particle size of 1mm-2mm, 1.4kg of sodium carbonate powder, chromic anhydride (CrO 3 ) 0.6kg mixed to obtain carbon-nitrogen strong infiltration agent;

[0091] (3) Strong carbonitriding

[0092] Weld the infiltration box with 6mm thick 1Cr18Ni9Ti stainless steel plate on both sides, put H11 hot mold steel workpiece, H13 hot mold steel workpiece and H21 hot mold steel wo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com