High temperature resistant alloy and its preparation method

A high-temperature heat-resistant alloy technology, applied in the field of ferrous metal smelting, can solve the problems of high-temperature heat-resistant steel that have not yet been retrieved, and achieve the effects of reducing weight, prolonging service life, and improving high-temperature service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

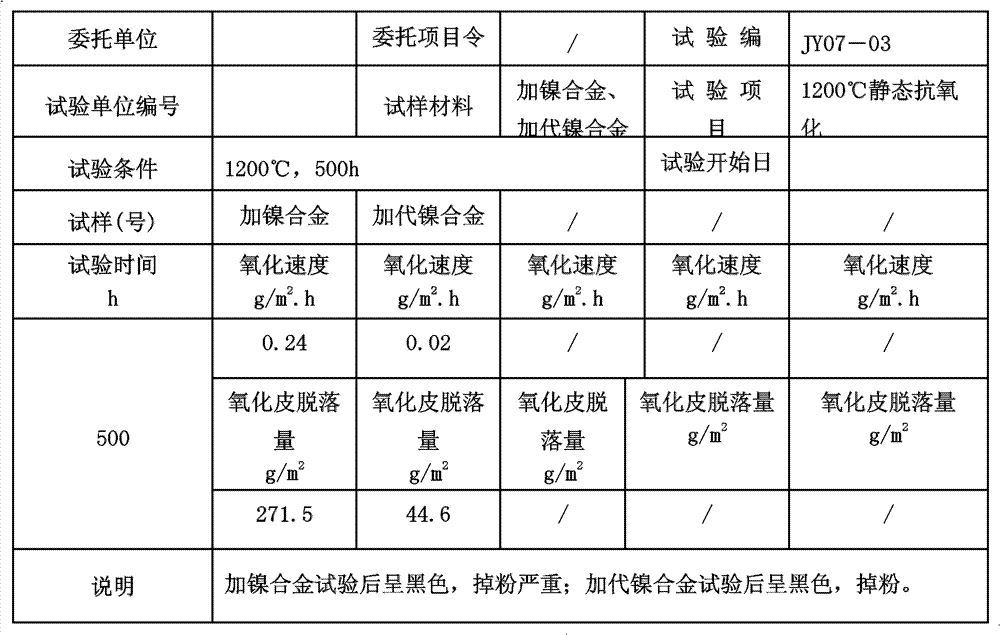

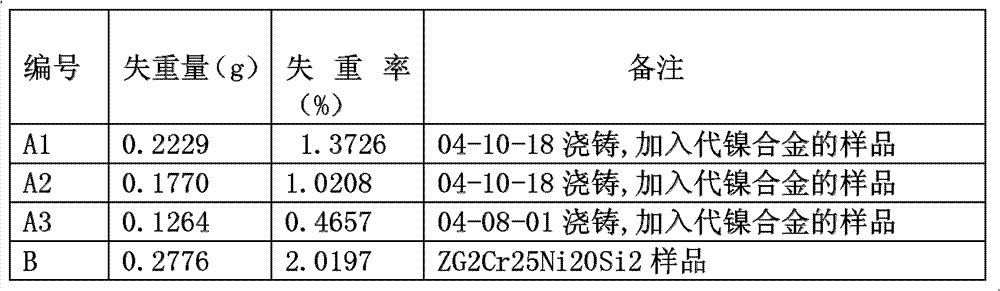

Image

Examples

Embodiment 1

[0035] To produce quenching trays, the tray weighs three tons, and the charge is distributed according to the following composition ratio (Wt%):

[0036] C: 0.22, Cr: 25, Mn: 0.89, S: 0.029, P: 0.024, Si: 1.4,

[0037] D (substitute nickel alloy): 5.0, Ni: 2.3, and the balance is iron.

[0038] Casting is carried out, and other alloy components except the D-generation nickel alloy are smelted in an electric furnace. When the temperature reaches the pouring temperature of 1620°C, pour out one-third of the molten steel and add the D-generation nickel alloy at the same time. Continue to heat and increase the 1650 ~ 1670 ℃ outlet water pouring. After annealing treatment, the mechanical properties are tensile strength 710Mpa, yield strength 560Mpa, elongation 7%, hardness HB241. After two years and seven months of use, the tray is still in good condition, without defects such as oxidation, cracking, and serious deformation.

Embodiment 2

[0040] Production of 180KW high temperature furnace bottom plate. Furnace charge according to following composition ratio (Wt%):

[0041] C: 0.24, Cr: 23, Mn: 1.0, S: 0.03, P: 0.022, Si: 1.5,

[0042] D (substitute nickel alloy): 5.40, Ni: 1.56, and the balance is iron.

[0043] The D-generation nickel alloy and other alloys are smelted in an electric furnace at the same time. When the temperature reaches 1620°C, continue heating and increase the temperature by 30-50°C to tap molten steel and pour. After finishing, heat preservation at 650-750°C for 3-5 hours for furnace cold annealing treatment, and it is still intact after more than three years of use.

Embodiment 3

[0045] Production of heat-treated material frames. Furnace charge according to following composition ratio (Wt%):

[0046] C: 0.20, Cr: 22, Mn: 1.1, S: 0.03, P: 0.022, Si: 1.6,

[0047] D (substitute nickel alloy): 4.80, Ni: 0, and the balance is iron.

[0048]The D-generation nickel alloy and other alloys are smelted in an electric furnace, and when the temperature reaches the pouring temperature of 1650°C, the molten steel is poured. After the material frame is cooled, heat it at 650-750°C for 3-5 hours for furnace cooling annealing treatment, and it is still intact after 30 months of use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com