Lithium-sulfur battery binder, preparation method thereof, cathode slurry and preparation method thereof

A lithium-sulfur battery and positive electrode slurry technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of easy shuttle, poor battery cycle performance, easy dissolution, etc., and achieve the goal of improving easy dissolution and improving battery cycle performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

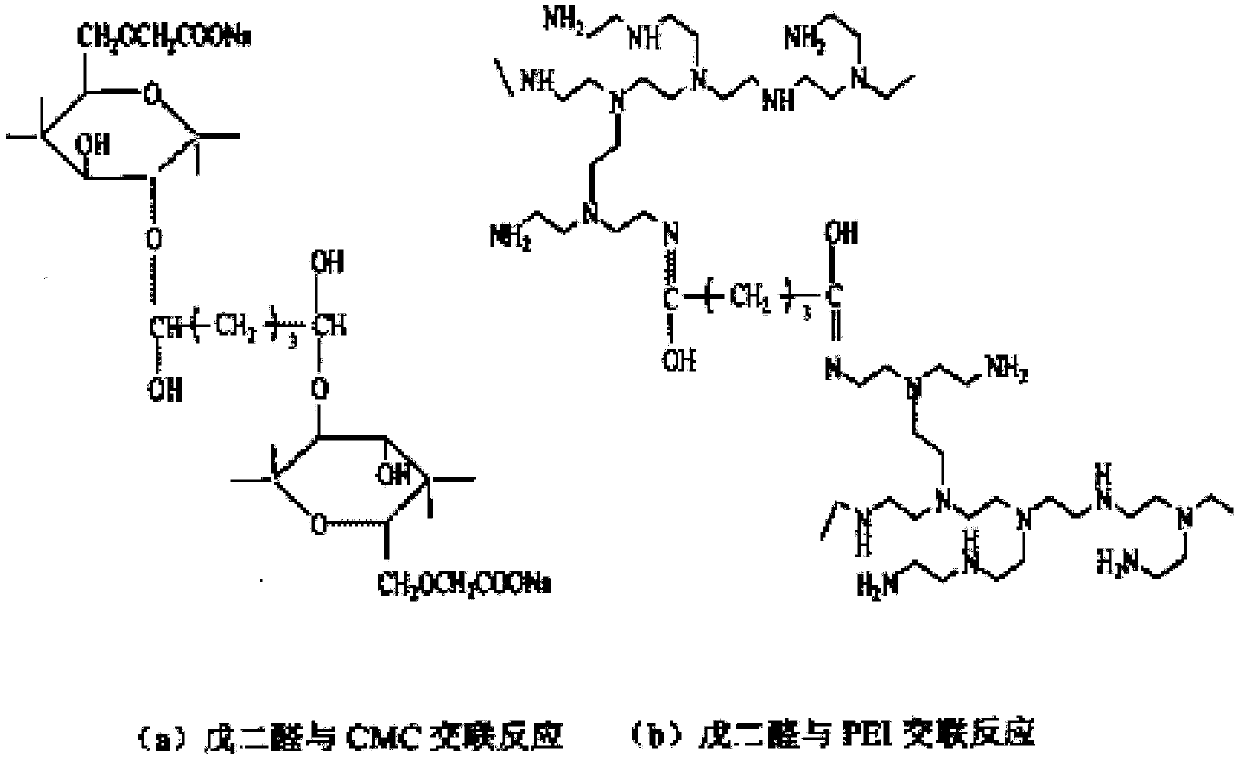

[0036] According to another aspect of the present invention, a kind of preparation method of above-mentioned binder is provided, and it comprises the following steps: mixing carboxymethyl cellulose, polyethyleneimine, cross-linking agent and solvent to obtain raw material mixed liquid; The mixed solution undergoes a cross-linking reaction to obtain a lithium-sulfur battery binder. The binder prepared by the method contains a three-dimensional network macromolecule formed by a crosslinking reaction of carboxymethyl cellulose and polyethyleneimine under the action of a crosslinking agent. This three-dimensional network macromolecular skeleton can bind polysulfides, and the many polar groups (such as amino groups) carried on the molecules can also adsorb polysulfides, preventing them from dissolving in the electrolyte and avoiding other A shuttle effect occurs into the negative terminal of the battery. For the above reasons, the binder provided by the present invention can effec...

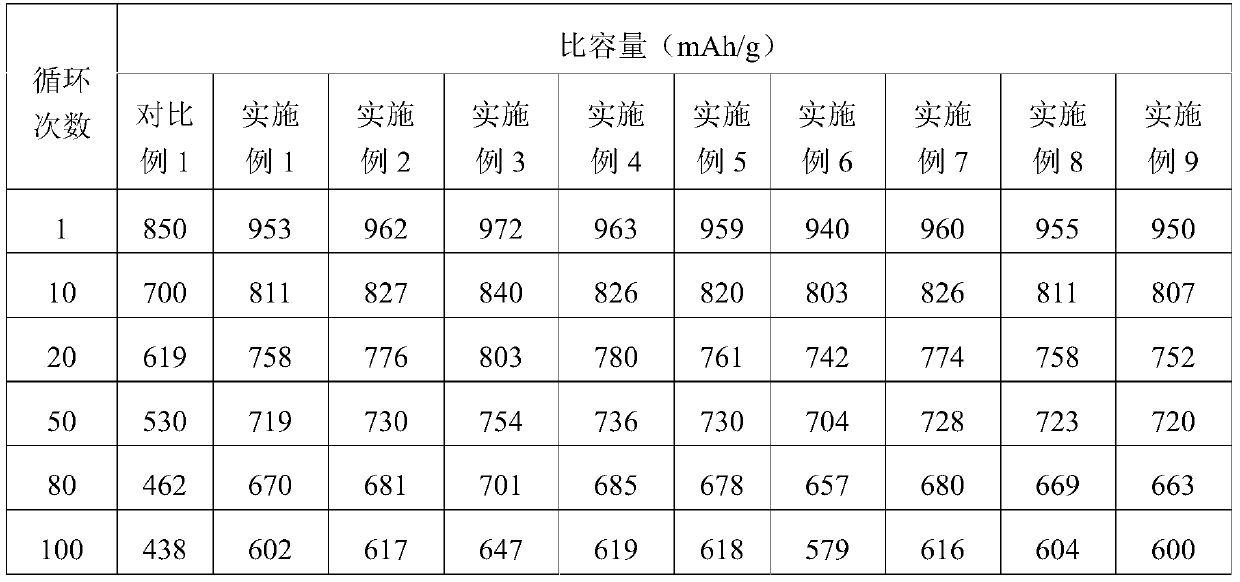

Embodiment 1

[0052] Take 20g of distilled water, add 1g of carboxymethyl cellulose (CMC, average relative molecular weight 800~1200), and obtain a uniform CMC aqueous solution after mechanical stirring; then continue to add 1g of polyethyleneimine with a mass concentration of 30% to the CMC aqueous solution (PEI, weight-average molecular mass 3000-3500) aqueous solution, mechanically stirred to obtain a uniformly dispersed CMC-PEI mixed solution (CMC:PET mass ratio 1:0.3).

[0053] Get 2g S / C compound, 0.25g CNT (carbon nanotube) and 4.231g CMC-PEI mixed solution (CMC-PEI accounts for 10% of the dry weight mass of the total substance of the three), after grinding uniformly, dropwise add mass concentration 0.5 g of 10% glutaraldehyde aqueous solution, the slurry was stirred at high speed during the dropwise addition, and after in-situ cross-linking at room temperature of 25° C., the positive electrode slurry was obtained.

[0054] The obtained positive electrode slurry was coated on an alum...

Embodiment 2

[0056] Get 20g distilled water, add 1g carboxymethylcellulose (CMC, average relative molecular mass 800~1200), obtain uniform CMC aqueous solution after mechanical stirring; Then continue to add 3.333g mass concentration to CMC aqueous solution and be 30% polyethylene Amine (PEI, weight average molecular weight 3000-3500) aqueous solution, mechanically stirred to obtain a uniformly dispersed CMC-PEI mixed solution (CMC:PET mass ratio 1:1).

[0057] Get 2g S / C composite, 0.25g CNT (carbon nanotube) and 3.042g CMC-PEI mixed solution (CMC-PEI accounts for 10% of the dry weight mass of the total substance of the three), after grinding uniformly, dropwise add mass concentration 0.5 g of 10% glutaraldehyde aqueous solution, the slurry was stirred at high speed during the dropwise addition, and after in-situ cross-linking at room temperature of 25° C., the positive electrode slurry was obtained.

[0058] The obtained positive electrode slurry was coated on an aluminum foil, and dried...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com