Layered quaternary cobalt-free single crystal precursor and preparation method of positive electrode material

A positive electrode material and precursor technology, applied in the field of lithium-ion battery materials, can solve the problems of battery capacity reduction, uneven coating, etc., and achieve the effect of maintaining stability, improving structural stability, and good layered structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

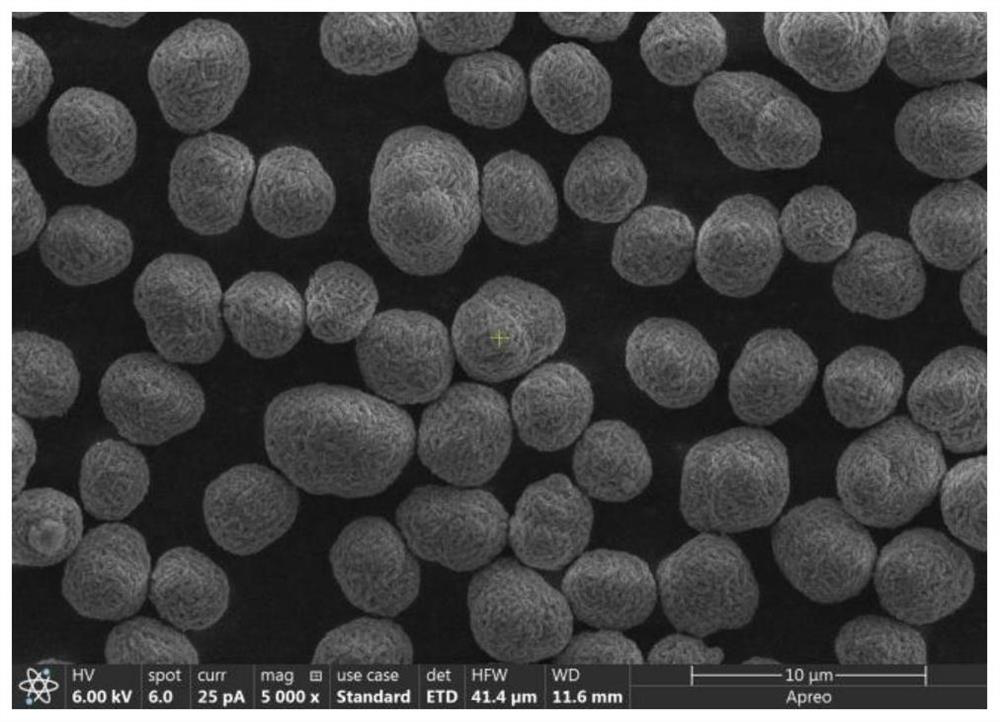

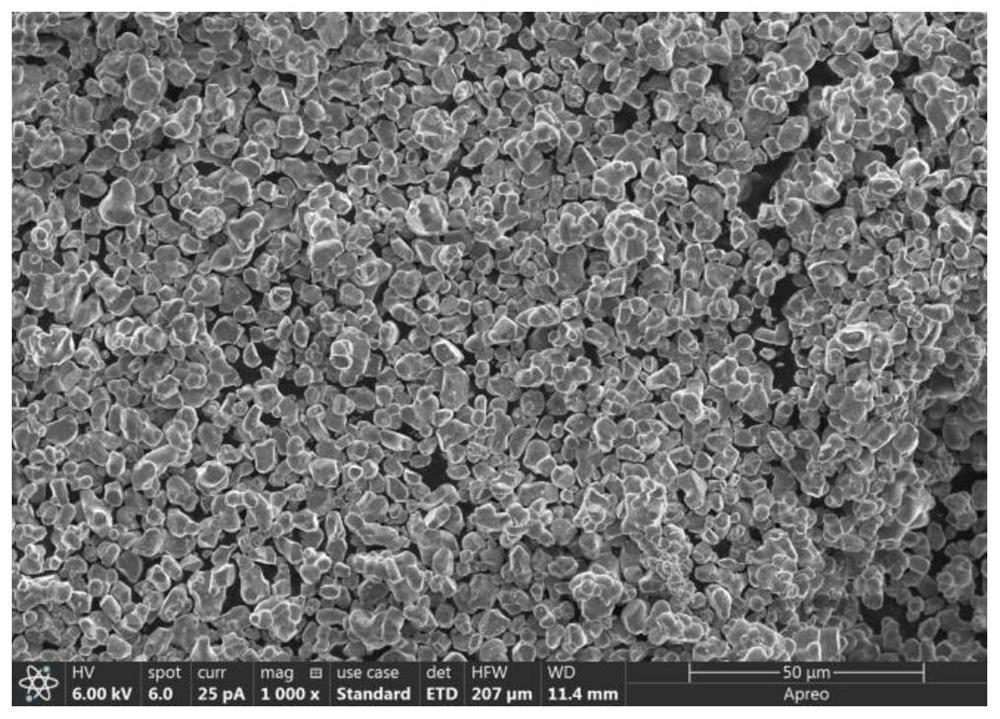

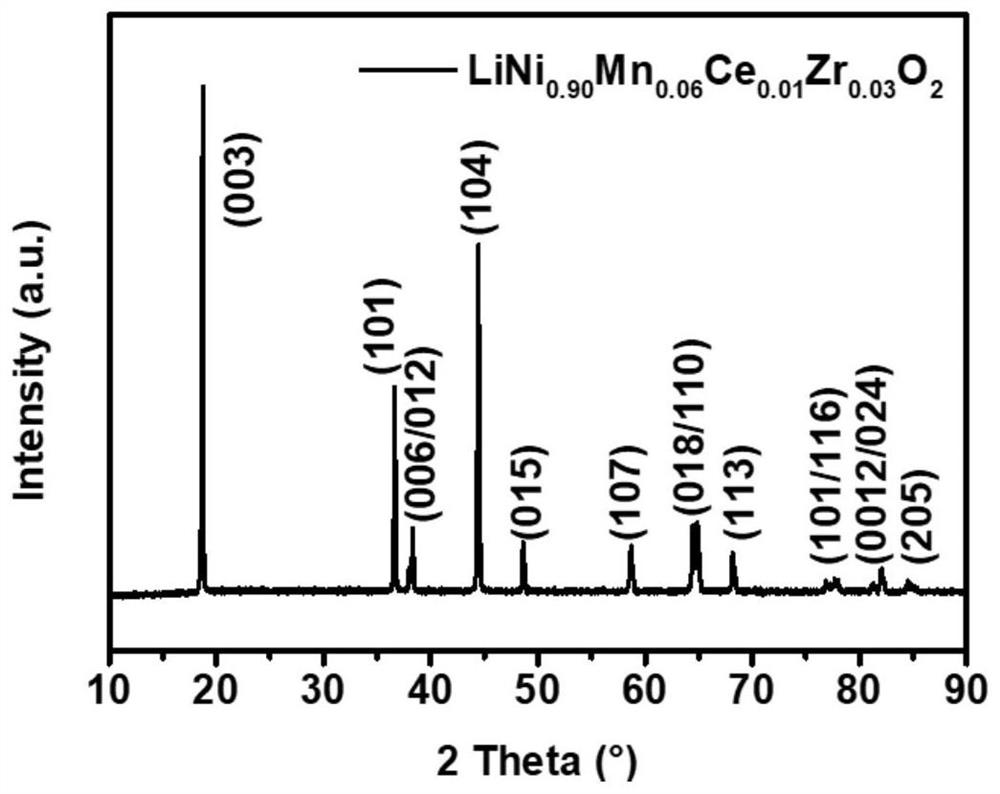

[0030] The chemical formula of the layered quaternary cobalt-free single crystal cathode material in this embodiment is LiNi 0.90 Mn 0.06Ce 0.01 Zr 0.03 O 2 .

[0031] The preparation method of the layered quaternary cobalt-free single crystal positive electrode material of the present embodiment includes the following steps:

[0032] (1) Nickel sulfate, manganese sulfate are added in deionized water in a molar ratio of 0.93:0.07, stirred uniformly, and mixed with a mixed salt solution A of 4mol / L; Nickel sulfate, manganese sulfate, cerium sulfate, zirconium sulfate are added in a molar ratio of 0.88 : 0.06: 0.02: 0.04 Add in deionized water, stir well, and prepare 4mol / L mixed salt solution B;

[0033] (2) the mixed salt solution A obtained in step (1), and the precipitant NaOH solution of 6mol / L and the complexing agent NH of 8mol / L 3 ·H 2 The O solution was added to the reaction kettle together to carry out co-precipitation reaction, and the temperature of the reacti...

Embodiment 2

[0040] The chemical formula of the layered quaternary cobalt-free single crystal cathode material in this embodiment is LiNi 0.83 Mn 0.10 Ce 0.03 Zr 0.04 O 2 .

[0041] The preparation method of the layered quaternary cobalt-free single crystal positive electrode material of the present embodiment includes the following steps:

[0042] (1) Nickel sulfate and manganese sulfate were added to deionized water in a molar ratio of 0.9:0.1, stirred uniformly, and mixed with a mixed salt solution A of 6 mol / L; Nickel sulfate, manganese sulfate, cerium sulfate, and zirconium sulfate were added in a molar ratio of 0.8 :0.09:0.05:0.06 Add in deionized water, stir well, and prepare 6mol / L mixed salt solution B;

[0043] (2) the mixed salt solution A obtained in step (1), and the precipitant NaOH solution of 6mol / L and the complexing agent NH of 8mol / L 3 ·H 2 The O solution was added into the reaction kettle together to carry out co-precipitation reaction, and the temperature of the...

Embodiment 3

[0048] The chemical formula of the layered quaternary cobalt-free single crystal cathode material in this embodiment is LiNi 0.65 Mn 0.20 Ce 0.06 Zr 0.09 O 2 .

[0049] The preparation method of the layered quaternary cobalt-free single crystal positive electrode material of the present embodiment includes the following steps:

[0050] (1) Nickel sulfate and manganese sulfate are added to deionized water in a molar ratio of 0.75:0.25, stirred uniformly, and mixed with a mixed salt solution A of 6 mol / L; Nickel sulfate, manganese sulfate, cerium sulfate, and zirconium sulfate are added in a molar ratio of 0.6 : 0.15: 0.1: 0.15 Add in deionized water, stir well, and prepare 6mol / L mixed salt solution B;

[0051] (2) the mixed salt solution A obtained in step (1), and the precipitant NaOH solution of 6mol / L and the complexing agent NH of 8mol / L 3 ·H 2 The O solution was added into the reaction kettle together to carry out co-precipitation reaction, and the temperature of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com