Sodium-ion battery nickel-based precursor capable of being used for filling conductive material and positive electrode material

A sodium-ion battery and cathode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of inability to realize industrialized production, output potential attenuation, different synthesis methods, etc., and achieve good battery cycle performance, maintain stability, and prepare. simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

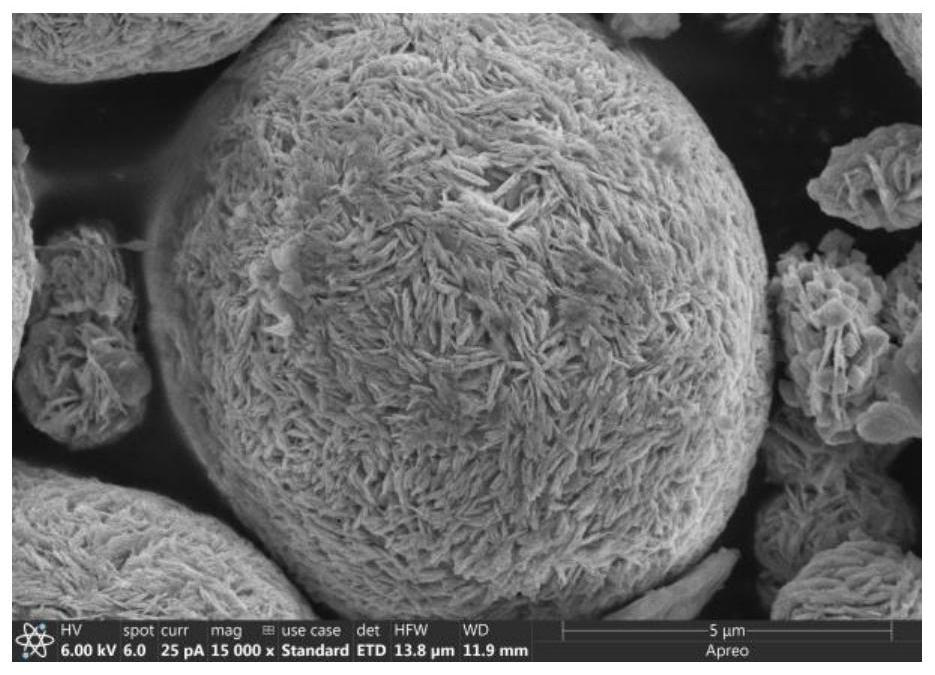

[0031] The chemical formula of the nickel-based ternary positive electrode material of the sodium ion battery that can be used to fill the conductive material in this embodiment is NaNi 0.8 Cr 0.1 Mo 0.1 o 2 & Ppy.

[0032] This embodiment can be used for the preparation method of the nickel-based ternary cathode material of the sodium-ion battery filled with conductive materials, comprising the following steps:

[0033] (1) Add nickel sulfate, chromium sulfate, and molybdenum sulfate into deionized water in a molar ratio of 0.8:0.1:0.1, stir evenly, and prepare a 4mol / L mixed salt solution; simultaneously prepare 6mol / L precipitant NaOH solution and 8mol / L / L complexing agent NH 3 ·H 2 O solution

[0034] (2) the mixed salt solution that step (1) obtains and precipitating agent and complexing agent and add in the reactor jointly, carry out co-precipitation reaction, and constantly stir, the stirring speed of control nucleation period is 300rpm, the pH of reaction soluti...

Embodiment 2

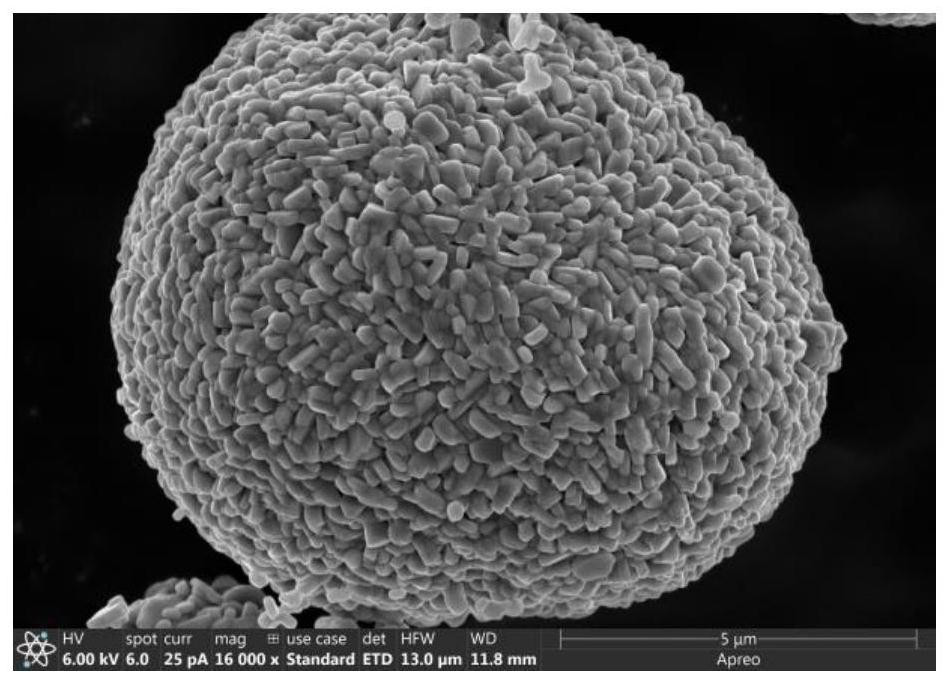

[0040] The chemical formula of the nickel-based ternary positive electrode material of the sodium ion battery that can be used to fill the conductive material in this embodiment is NaNi 0.7 Nb 0.1 Mo 0.2 o 2 &PAn.

[0041] This embodiment can be used for the preparation method of the nickel-based ternary cathode material of the sodium-ion battery filled with conductive materials, comprising the following steps:

[0042] (1) Add nickel sulfate, niobium sulfate, and molybdenum sulfate into deionized water in a molar ratio of 0.7:0.1:0.2, stir evenly, and prepare a 6mol / L mixed salt solution; at the same time, prepare 4mol / L precipitant NaOH solution and 6mol / L complexing agent NH 3 ·H 2 O solution

[0043] (2) the mixed salt solution that step (1) obtains and precipitating agent and complexing agent and add in reactor jointly, carry out co-precipitation reaction, and constantly stir, and the stirring speed of control nucleation period is 350rpm, and the pH of reaction sol...

Embodiment 3

[0048] The present embodiment can be used for the chemical formula of the nickel-based ternary positive electrode material of the sodium-ion battery filled with conductive material is Na 0.67 Ni 0.6 Nb 0.2 Mo 0.2 o 2 & Ppy.

[0049] This embodiment can be used for the preparation method of the nickel-based ternary cathode material of the sodium-ion battery filled with conductive materials, comprising the following steps:

[0050] (1) Add nickel sulfate, niobium sulfate, and molybdenum sulfate into deionized water at a molar ratio of 0.6:0.2:0.2, stir evenly, and prepare a 6mol / L mixed salt solution; prepare 6mol / L precipitant NaOH solution and 8mol / L complexing agent NH 3 ·H 2 O solution

[0051] (2) the mixed salt solution that step (1) obtains and precipitating agent and complexing agent and add in reactor jointly, carry out co-precipitation reaction, and constantly stir, and the stirring speed of control nucleation period is 350rpm, and the pH of reaction solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com