Composite nanofiber lithium battery diaphragm and preparation method thereof

A technology of composite nanofibers and lithium battery separators, applied in battery pack parts, separators/films/diaphragms/spacers, circuits, etc. To solve problems such as poor mechanical properties, to achieve the effects of excellent mechanical properties, improved electrochemical properties, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

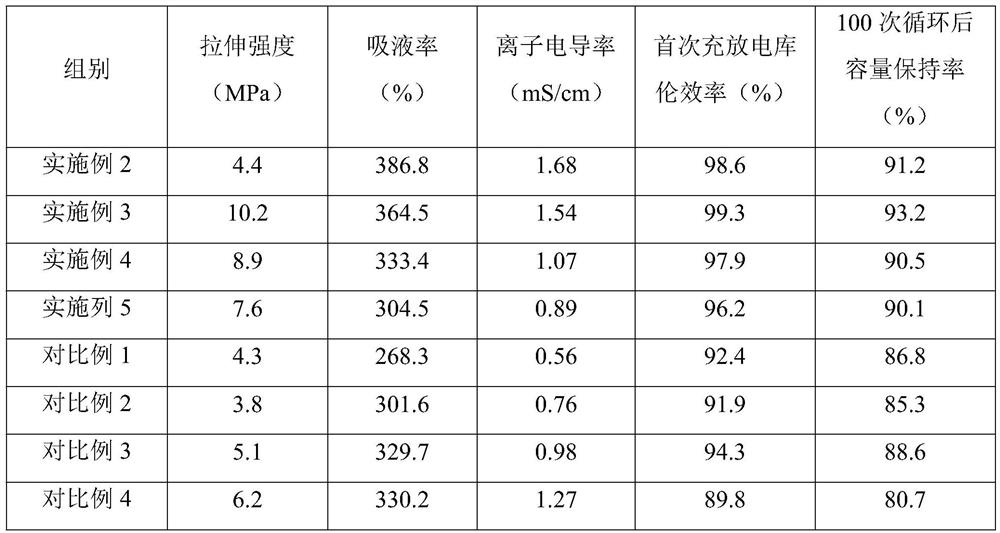

Examples

Embodiment 1

[0028] Preparation of PAA spinning solution:

[0029] Synthesize polyimide acid (PAA) spinning solution with pyromellitic dianhydride (PMDA) and 4,4-diaminodiphenyl ether (ODA) as raw materials: first dry PMDA and ODA, then dissolve ODA In N,N-dimethylacetamide (DMAC) and 1-methyl-2-pyrrolidone (NMP) volume ratio is 4: 6 mixed solvent, add PMDA while stirring, preparation mass concentration is 30-36wt% PAA spinning solution, standby; wherein, the molar ratio of PMDA to ODA is 1:1.

[0030] Preparation of PAN spinning solution:

[0031] Adding the dried polyacrylonitrile (PAN) powder into N,N-dimethylformamide (DMF) to prepare a PAN spinning solution with a mass fraction of 15-25% for later use.

[0032] TiOSO 4 Solution preparation: TiOSO 4 2H 2 O powder was dissolved in deionized water to prepare 0.5-2mol / L TiOSO 4 solution, set aside.

Embodiment 2

[0034] A composite nanofiber lithium battery separator, which has a coaxial three-layer composite structure, from outside to inside: the outer layer is TiO 2 Nano layer, the middle layer is a polyacrylonitrile (PAN) pre-oxidized fiber layer, and the core layer is a polyimide (PI) fiber layer; the thickness of the diaphragm is 20 μm; its preparation method specifically includes the following steps:

[0035] (1) Preparation of PAN@PAA nanofibrous membrane with coaxial double-layer structure

[0036] Using the PAA spinning solution with a mass concentration of 30wt% as the core material and the PAN spinning solution with a mass concentration of 20wt% as the shell material, a coaxial double-layer structure PAN@PAA nanofiber membrane was prepared by coaxial electrospinning technology; The coaxial electrospinning process parameters are as follows: the voltage is 18kV, the receiving distance is 20cm, the flow rate of PAA spinning solution is 0.1mL / h, and the flow rate of PAN spinning...

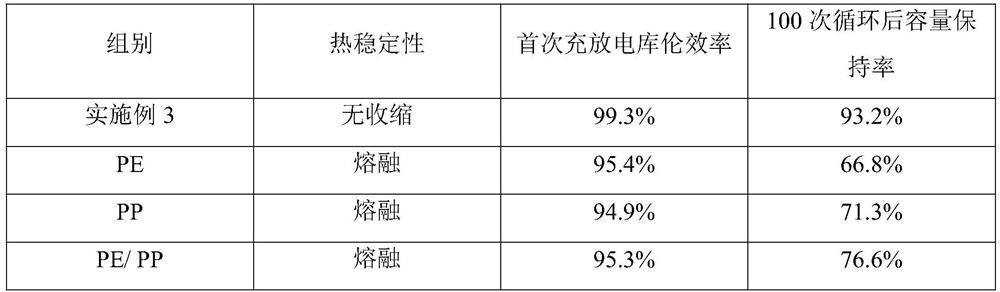

Embodiment 3

[0042] A composite nanofiber lithium battery separator, which has a coaxial three-layer composite structure, from outside to inside: the outer layer is TiO 2 Nano layer, the middle layer is a polyacrylonitrile (PAN) pre-oxidized fiber layer, and the core layer is a polyimide (PI) fiber layer; the thickness of the diaphragm is 50 μm; its preparation method specifically includes the following steps:

[0043] (1) Preparation of PAN@PAA nanofibrous membrane with coaxial double-layer structure

[0044] Using the PAA spinning solution with a mass concentration of 36wt% as the core material and the PAN spinning solution with a mass concentration of 18wt% as the shell material, a coaxial double-layer structure PAN@PAA nanofiber membrane was prepared by coaxial electrospinning technology; The coaxial electrospinning process parameters are as follows: the voltage is 18kV, the receiving distance is 20cm, the flow rate of PAA spinning solution is 0.2mL / h, and the flow rate of PAN spinning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com