Sodium ion positive electrode material with ternary layered structure, and preparation method for sodium ion positive electrode material

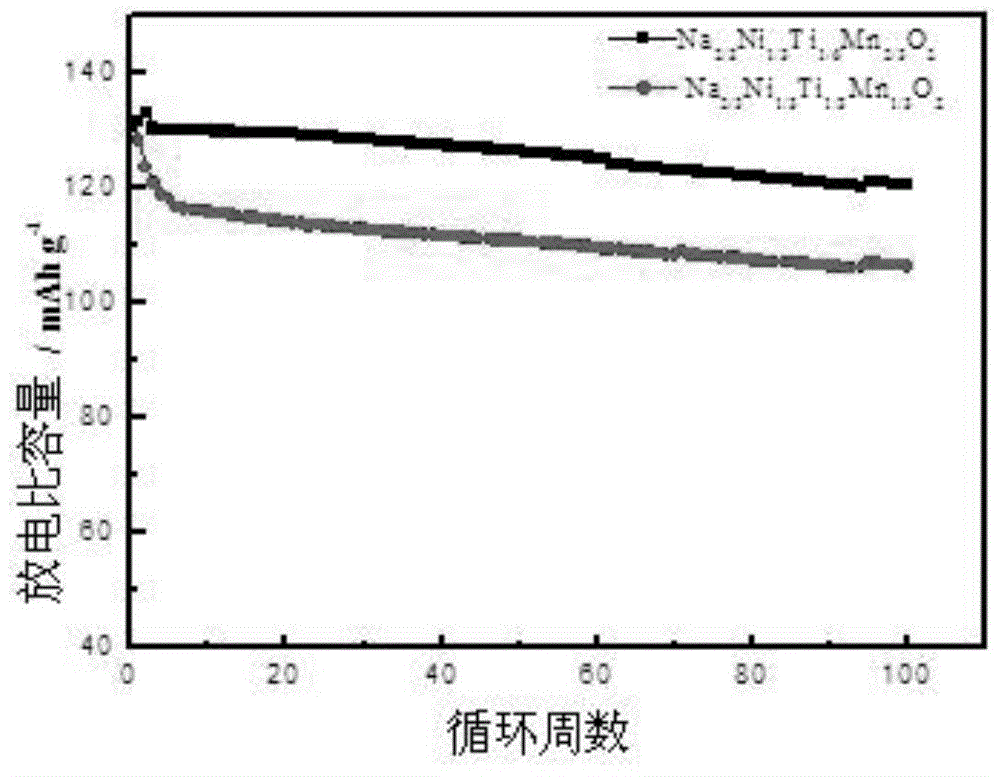

A positive electrode material and a ternary layered technology, applied in the field of sodium ion positive electrode materials and their preparation, can solve the problem of low cycle capacity of sodium ion positive electrode materials, and achieve the effects of high battery cycle performance, convenient operation and simple steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Another invention of the present invention also provides a kind of preparation method as above-mentioned sodium ion cathode material, comprises the following steps:

[0030] 1) The molar ratio of sodium atom, nickel atom, titanium atom and manganese atom is 2 / 3: 1 / 3: X: 2 / 3-X, mix sodium source, nickel source, titanium source and manganese source, and perform ball milling to obtain Mixtures where 0<X<2 / 3;

[0031] 2) Calcining the mixture to obtain the sodium ion cathode material.

[0032] The method is easy to operate and is suitable for mass production in industrial production. According to this method, the sodium ion cathode material with the above structure can be prepared. Other parameters not detailed in the method can be operated according to other parameters commonly used in the art to prepare a sodium ion positive electrode material with a ternary layered structure.

[0033] Preferably, the method also includes grinding the obtained sodium ion positive elect...

Embodiment 1

[0043] Weigh the sodium-containing compound as anhydrous sodium carbonate (Na 2 CO 3 ), nickel source is nickel oxide (NiO), titanium source is anatase titanium dioxide (TiO 2 ) and manganese source as manganese dioxide (MnO 2 ), so that the molar ratio of sodium atoms, nickel atoms, titanium atoms and manganese atoms is 4:2:1:3, then put the weighed raw materials in the ball mill jar, and then weigh a certain amount of zirconium balls and put them into Among them, without adding any dispersant, the mass ratio of the ball milling medium to the raw material is 1:3. After dry mixing, ball milling is carried out. During mechanical mixing, the speed of the ball mill is 600r / min, and the duration is 12 hours to form a mixture; next, the mixture prepared above is placed in a high temperature resistant crucible, and then the crucible is sent into the muffle furnace In the process, calcining at 900°C for 12 hours in an air atmosphere, the heating and cooling rate is 2°C / min. After ...

Embodiment 2

[0045] Weigh the sodium-containing compound as anhydrous sodium carbonate (Na 2 CO 3 ), nickel source is nickel oxide (NiO), titanium source is rutile titanium dioxide (TiO 2 ) and manganese source as manganese dioxide (MnO 2 ), the molar ratio of sodium atom, nickel atom, titanium atom and manganese atom is changed to 2:1:1:1, then the raw materials weighed are all placed in the ball mill jar, the ball mill medium, raw material and organic dispersant After mixing according to the mass ratio of 3:1:1, the rotation speed of the ball mill during mechanical mixing is 600r / min, and the duration is 12 hours to form a mixture; the formed mixture is dried in a blast drying oven, and the addition of organic solvent, the drying time is 12 hours, and the temperature is 70°C. Next, place the dried mixture in a high-temperature-resistant crucible, then put the crucible into a muffle furnace, and calcine it at 950°C for 10 hours in an air atmosphere, with a heating and cooling rate of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com