Polyionic liquid-coated bacterial cellulose diaphragm and preparation method thereof

A bacterial cellulose membrane and polyionic liquid technology, applied in the field of electrochemistry, can solve the problems of reducing electrolyte adsorption, complex equipment, poor heat resistance, etc., achieve improved cycle stability and safety, and simple preparation method , The effect of reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

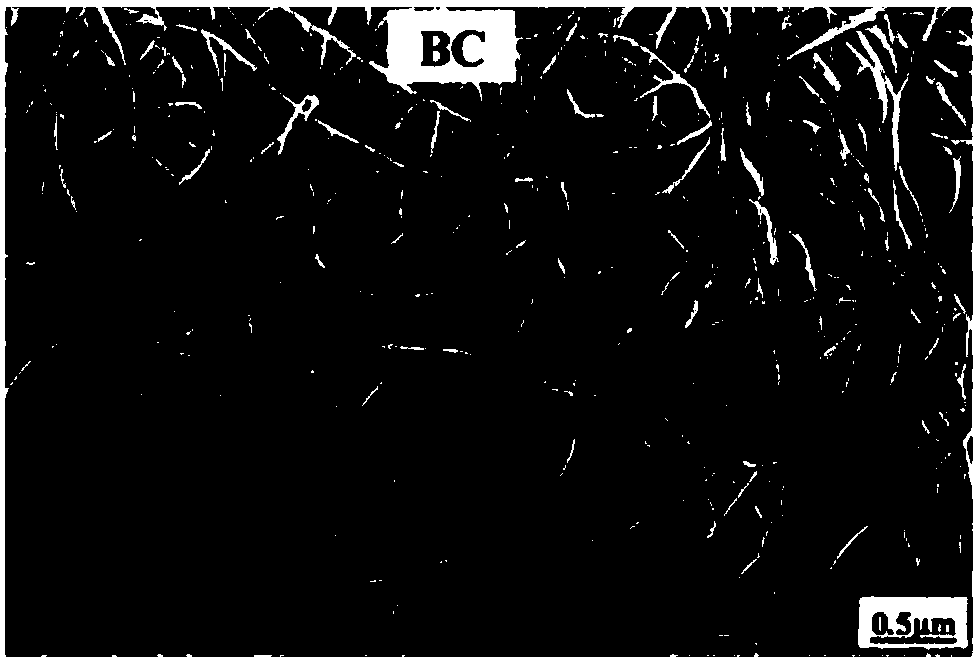

Image

Examples

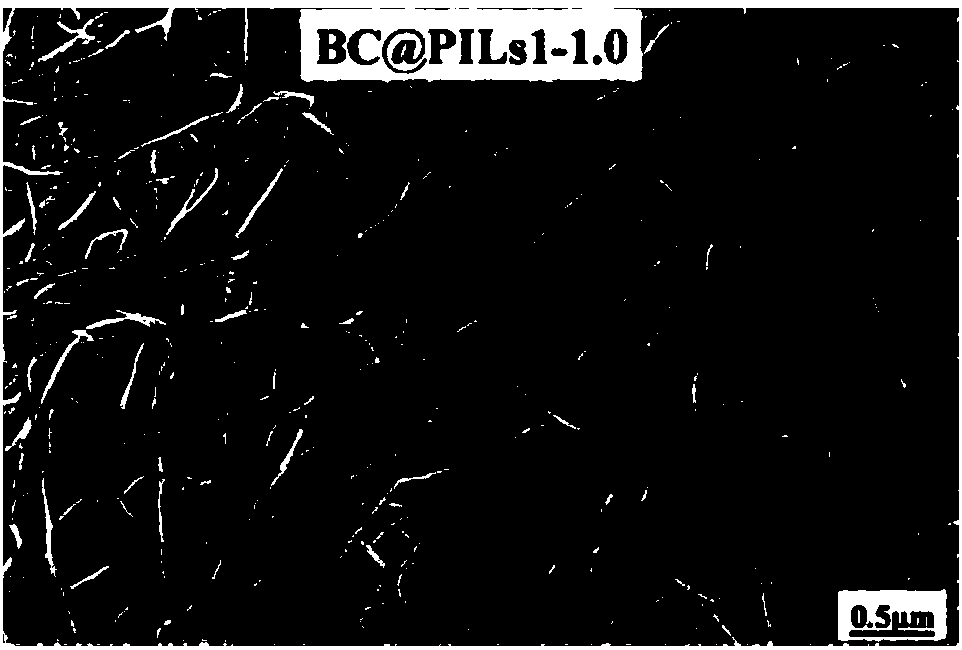

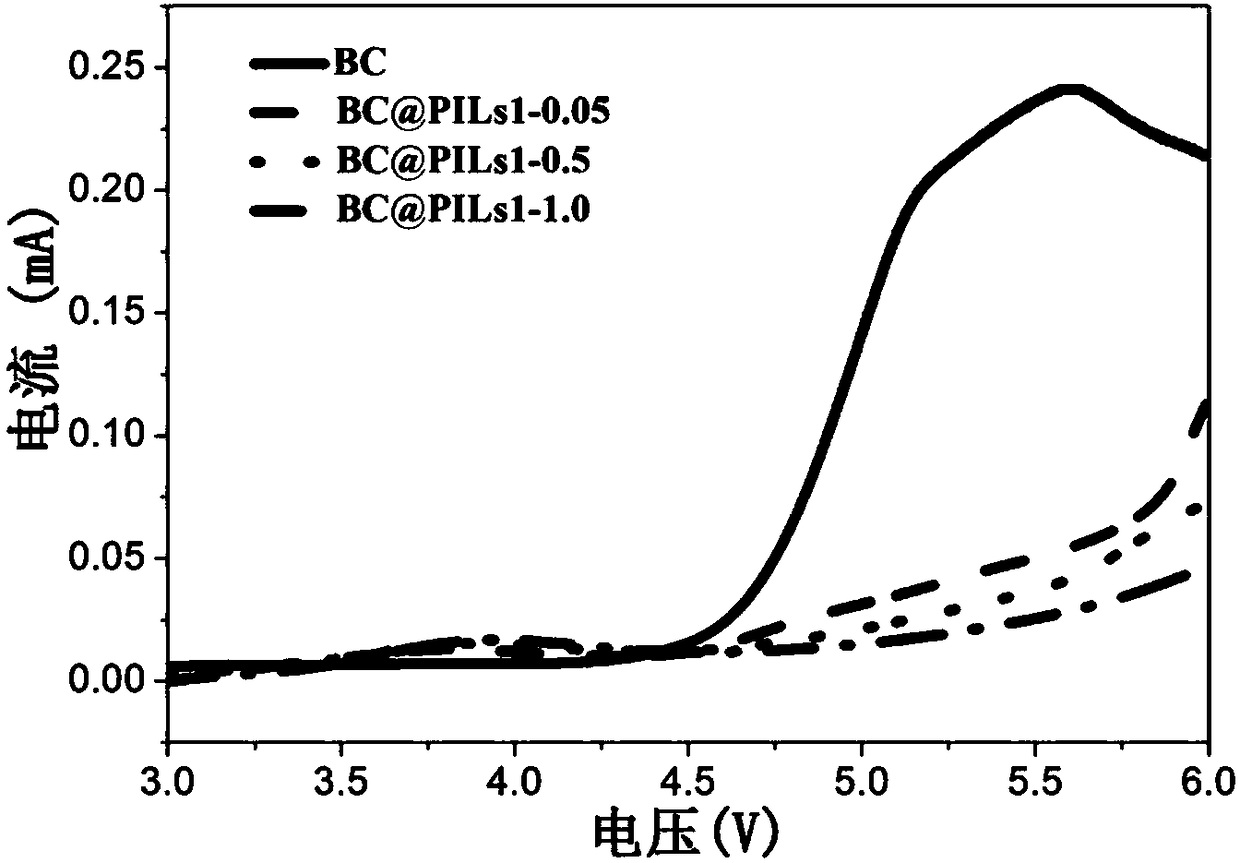

Embodiment 1

[0049]Prepare 100mL concentration of 1.0% polydiene dimethyl ammonium chloride aqueous solution (polyionic liquid aqueous solution), put 4g bacterial cellulose film (wet film) in this solution and soak for 24 hours, stir slowly (favorable to polydiene dimethyl ammonium chloride solution). Dimethyl ammonium chloride diffuses into the bacterial cellulose membrane), take it out, wash the surface slightly with deionized water, and then soak it in 50mL of acetone (precipitating agent) for 12 hours to make polydiene dimethyl ammonium chloride Precipitate completely and coat on the surface of nanofibers, then place 50mL concentration and then soak in 0.5% bistrifluoromethanesulfonimide lithium ethanol solution for 24 hours, stir slowly (favorable to bistrifluoromethanesulfonylimide ion and Chloride ions were exchanged), and finally the wet film was thinned at 60°C with a hot press, and dried at 80°C for 24 hours to obtain a polyionic liquid-coated bacterial cellulose film, which was d...

Embodiment 2

[0061] Prepare 50mL of 0.05% poly[3-ethyl-1-vinylimidazolium bromide] aqueous solution, put 2g of bacterial cellulose film (wet film) in the solution and soak for 12 hours, stir slowly, take it out and dry it slightly Clean the surface with deionized water, then soak in 30mL ethanol for 24 hours, so that poly[3-ethyl-1-vinylimidazolium bromide] is completely precipitated and coated on the surface of nanofibers, and then placed in 40mL with a concentration of 1.0% Soak in the lithium trifluoromethanesulfonate ethanol solution for 12 hours, stir slowly, and finally use a hot press to thin the wet film at 70°C, and dry it at 60°C for 24 hours to obtain the polyionic liquid-coated bacterial cellulose membrane , denoted as BC@PILs2-0.05 film, its morphology is shown in Figure 5 .

[0062] The main chemical components of BC@PILs2-0.05 membrane are bacterial cellulose and imidazolium salt polyionic liquid.

[0063] For the ionic conductivity of BC@PILs2 membrane see Figure 6 . ...

Embodiment 3

[0066] Prepare 200mL concentration of 2.0% poly[1-(4-benzyl)-3-n-butylimidazolium tetrafluoroborate] aqueous solution, put 8g bacterial cellulose wet film in the solution and soak for 48 hours, stir slowly After taking it out, wash the surface slightly with deionized water, and then soak it in 100mL methanol for 24 hours, so that poly[1-(4-benzyl)-3-n-butylimidazolium tetrafluoroborate] is completely precipitated and coated on The surface of the nanofibers was then soaked in 100 mL of 5.0% tris(trifluoromethylsulfonyl)methyllithium ethanol solution for 24 hours, stirred slowly, and finally the wet film was pressed thin at 60°C by a hot press. and dried at 70°C for 24 hours to obtain a polyionic liquid-coated bacterial cellulose membrane, which is denoted as BC@PILs3-2.0 membrane, and its morphology is shown in Figure 7 .

[0067] The main chemical components of BC@PILs3-2.0 membrane are bacterial cellulose and imidazolium salt polyionic liquid.

[0068] For the ionic conduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| electrochemical stability window | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com