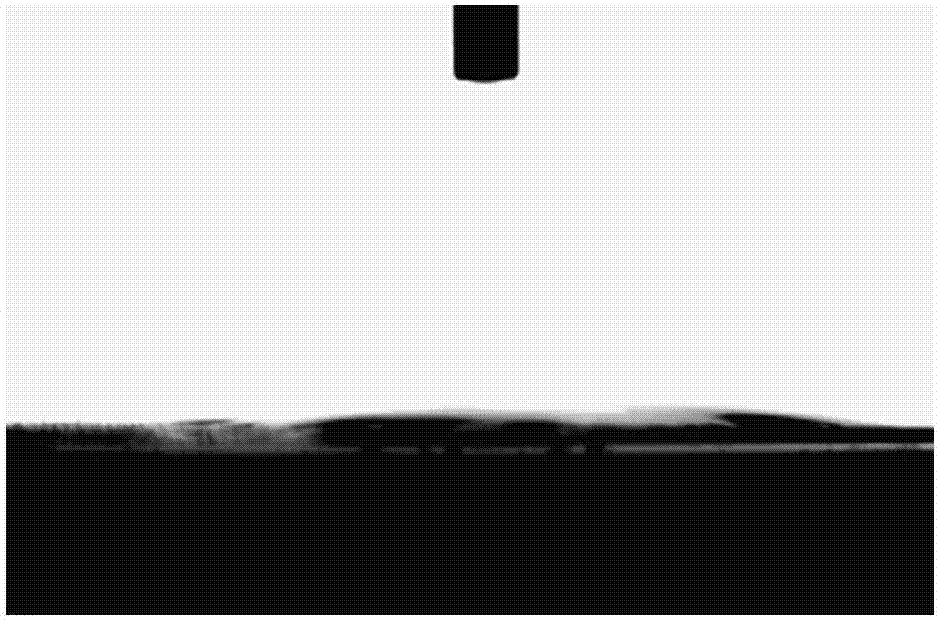

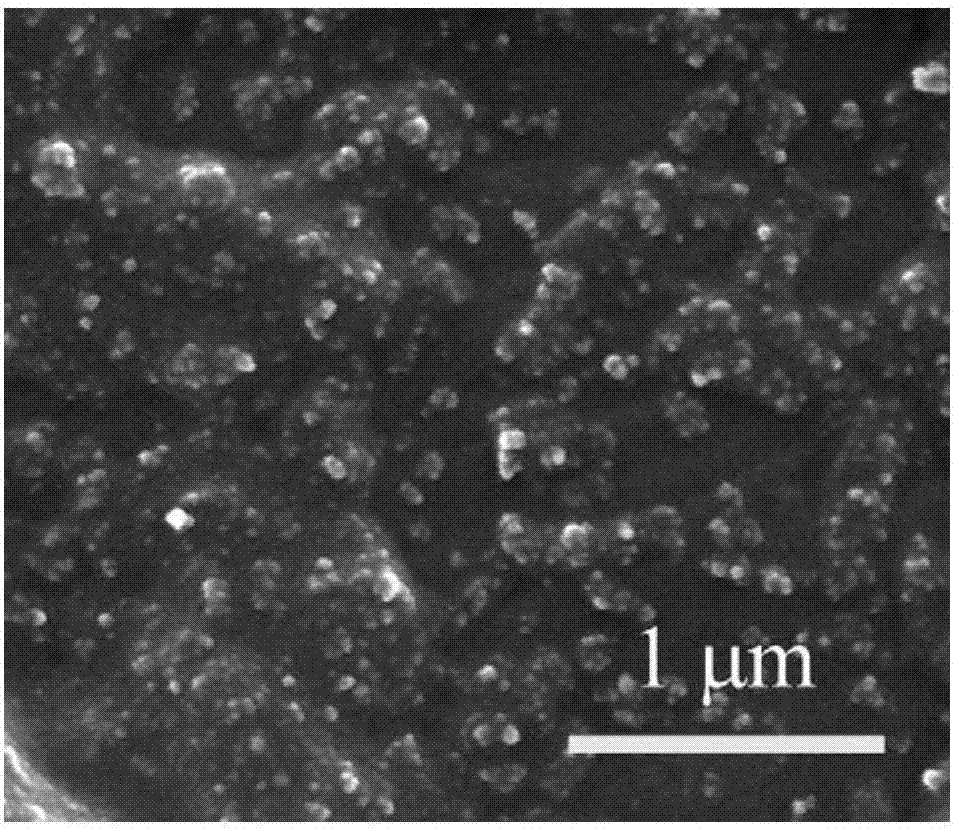

Super-lyophilic coating resistant to mechanical damages and preparation method thereof

A technology of coating and mechanical friction, applied in the direction of coating, pigmented coating, paper coating, etc., can solve the problem of poor wear resistance of super-lyophilic coating, achieve strong ultrasonic damage resistance, good affinity, Excellent effect of lyophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Prepare a low concentration low molecular weight polymer solution for the first layer

[0070] Add 0 to 2 times the amount of inorganic nanoparticles to polyacrylic acid, chitosan quaternary ammonium salt, polyethylene glycol, polyacrylamide, ethyl hydroxyethyl cellulose, and carbomer with a molecular weight of 100 to 100,000 g / mol, and use The solvent is formulated to produce a low concentration low molecular weight polymer solution for the first layer.

[0071]

Embodiment 2

[0073] Preparation of a low concentration high molecular weight polymer solution for the second layer

[0074] Add 0 to 2 times the amount of inorganic nanoparticles to polyacrylic acid, chitosan quaternary ammonium salt, polyethylene glycol, polyacrylamide, ethyl hydroxyethyl cellulose, and carbomer with a molecular weight of 100,000 to 2,000,000 g / mol, and use The solvent was formulated to produce a low concentration high molecular weight polymer solution for the second layer.

[0075]

Embodiment 3

[0077] Preparation of a high concentration high molecular weight polymer solution for the preparation of the third layer

[0078] Add 0 to 2 times the amount of inorganic nanoparticles to polyacrylic acid, chitosan quaternary ammonium salt, polyethylene glycol, polyacrylamide, ethyl hydroxyethyl cellulose, and carbomer with a molecular weight of 100,000 to 2,000,000 g / mol, and use The solvent is formulated to prepare a high concentration high molecular weight polymer solution for the third layer.

[0079]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com