Ceramic diaphragm with dopamine-containing composite binder and application of ceramic diaphragm with dopamine-containing composite binder in lithium ion battery

A technology of ceramic diaphragm and adhesive, which is applied in the direction of battery pack components, circuits, electrical components, etc., and can solve the problems of infiltration of ceramic powder and diaphragm matrix.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

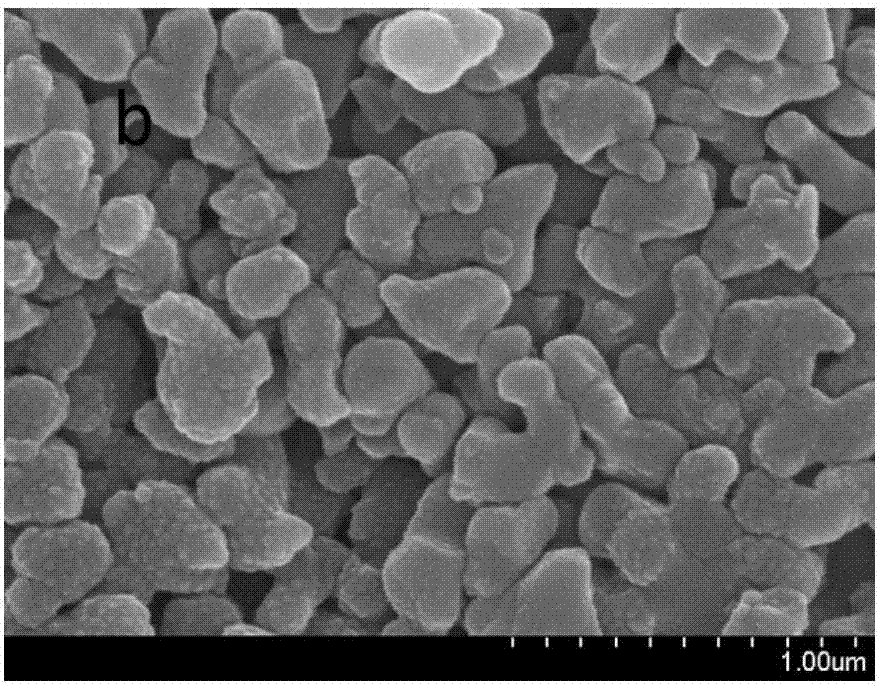

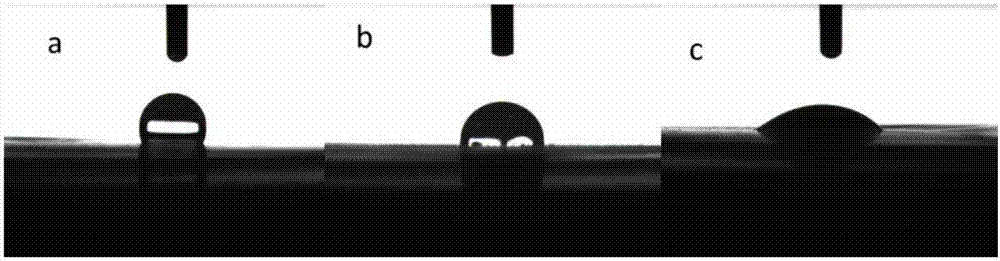

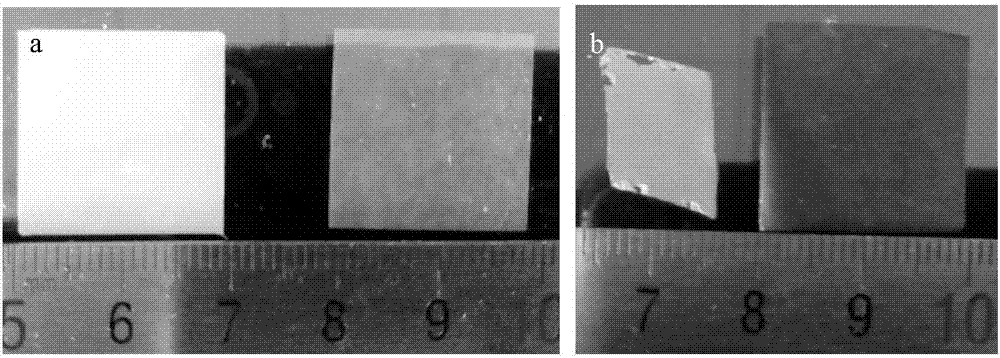

[0045] Mix 1g of aluminum oxide nanoparticles, sodium carboxymethyl cellulose (CMC) and styrene-butadiene rubber (SBR) in a mass ratio of 95:2:3, put in deionized water and ethanol (1:2, v:v ) mixed solution 10ml, stirred the obtained ceramic slurry overnight, ultrasonically dispersed the mixed slurry for 20min, adjusted the pH to 8.5, added 0.75g of dopamine, mixed evenly, and applied the obtained slurry to membrane coating. The ceramic diaphragm is made of ordinary polyethylene (PE) diaphragm as the diaphragm base material. The resulting slurry is uniformly coated on one or both sides of a common polyethylene (PE) separator. Aged at 25°C for 8 hours, washed with a solvent to remove impurities, and dried to remove the solvent to obtain a modified ceramic diaphragm.

Embodiment 2

[0052] Put 1 g of mixed powder of silica nanoparticles, gelatin and polyvinyl alcohol (PVA) in a mass ratio of 90:4:6, put 10 ml of mixed solution of deionized water and ethanol (1:3, v:v), and mix the obtained Stir the ceramic slurry overnight, ultrasonically disperse the mixed slurry for 20 minutes, adjust the pH to 8.0, add 0.4 g of dopamine, mix well, and apply the obtained slurry to membrane coating. The ceramic diaphragm is made of ordinary polypropylene (PP) diaphragm as the diaphragm base material. The resulting slurry is uniformly coated on one or both sides of a common polyethylene (PE) separator. Aged at 35°C for 10h, washed with a solvent to remove impurities, dried to remove the solvent, and obtained a modified ceramic diaphragm

Embodiment 3

[0054] Put titanium dioxide nanoparticles and polyacrylate terpolymer latex (LA132, LA133) in a mass ratio of 85:6:9 mixed powder 1g into a mixed solution of deionized water and ethanol (2:1, v:v) 15ml, stir the obtained ceramic slurry overnight, ultrasonically disperse the mixed slurry for 20min, adjust the pH to 9.0, add 0.2g dopamine, mix well, and apply the obtained slurry to membrane coating. The ceramic diaphragm is made of polyamide (PI) diaphragm as the diaphragm base material. The resulting slurry is uniformly coated on one or both sides of a common polyethylene (PE) separator. Aged at 50°C for 24 hours, washed with a solvent to remove impurities, dried to remove the solvent, and obtained a modified ceramic diaphragm

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com